Documente Academic

Documente Profesional

Documente Cultură

Sample Procedure Flow

Încărcat de

vyly1723Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sample Procedure Flow

Încărcat de

vyly1723Drepturi de autor:

Formate disponibile

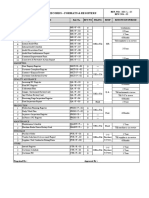

SYSTEM PROCEDURE DOC NO: QA-BPF-01

RECEIPT INSPECTION PAGE: 1 OF 3

REVISION RECORD SHEET

REV. DESCRIPTION OF AMMENDMENT DATE OF REASON FOR

NO. AMMENDMENT AMMENDMENT

00 Stated as per QS 9000: 1998 requirement 16.08.1999 QS9000:1998

updation

01 Responsibilities in column 3 re-defined & 25.10.1999 Observations during

changed to AM-QA. Preparation, Review Pre Assessment

& approval, Issuance & functional audit

deleted. Control plan for receipt/final

inspection added. Frequency of dock

audit changed. Separate register(QA-R-

11) used for dock audit

02 Responsibility of Layout Inspection 25.07.01 Observation during

changed to Exec. Tool Room from Exec Audit

QA. And register TLR-R-07 replaces QA-

R-08 for the same.

03 • Clause 4.1, resp. changed to Exec. 18.11.03 QS 9000 System

QS ipo AM-QA Review & Updation

• Clause 4.2& 4.3 merged.

• Clause 4.5, responsibility changed to

Executive store in place of Sr.

manager QA.

• Clause 4.8, provision added for

temporary process parameter

deviation to fulfill the requirement of

product.

• Clause 4.11, generation of inspection

standard added with responsibility

• Performance testing / initial testing

added

• Layout inspection re-defined

04 • Procedure changed from Simple Text 15.05.2004 System review due

to Flow Chart to switching to

• Title changed from Inspection & ISO/TS 16949

Testing to Receipt Inspection, only

• No. changed from QA-P-01 to QA-

BPF-01

• New Header & Footer added

DISTRIBUTED TO :

S.NO. DESIGNATION SIGNATURE OF THE RECEIVER

1. ASST. MANAGER (QA)

2. MANAGER (PRODUCTION)

3. MANAGER (PURCHASE)

4. MANAGER (ENGG.)

Prep. By: Reviewed & Appd. by: Issued by: REV. NO: 04

HOD-QA CEO / MR Exec-MIS DATE : 15.05.04

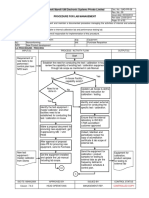

SYSTEM PROCEDURE DOC NO: QA-BPF-01

RECEIPT INSPECTION PAGE: 2 OF 3

1.0 Purpose:

To establish and maintain a system for inspection and testing in order to verify that the specified

requirements for the product are met

2.0 Scope :

All incoming goods including goods for job work.

3.0 Responsibility :

Asstt. Manager (QA)

4.0 Definition :

---

5.0 Description:

S. Input Process / Activity Resp. & Control Doc. / Output

No Interaction Check Point

5.1 MRR (STR-F- Store I/C Material Identification ---

03) MRR receipt from store QA-Exec tag (QA-F-01)

RGP (STR-F-10) Supplier Test

certificate /

Insp. Report

Reject & return

MRR to store

5.2 Check A.S.L. Pur-Exec Approved supplier Verification

Not OK QA-Exec List (PUR-D-01) of

& All related

doc. approved

supplier

OK

5.3 Tagged QA-Exec Quality Plan Incoming

material Store I/C (QA-Q-XXX) Inspection

Sampling Plan Report

Not OK Random (QA-D-04) (QA-F-02)

sample Calibrated

selection & instrument

Inspection

OK

5.4 Inspected QA-Exec Identification / Inspected

Material Tear off accepted / rejected QA-HOD Inspection Tag material

portion as applicable Store I/C (QA-F-01) Approved

MRR by

QA

5.5 -- QA-Exec Vendor history card Entry in

Update supplier history (QA-F-05) vendor

card history

card

Prep. By: Reviewed & Appd. by: Issued by: REV. NO: 04

HOD-QA CEO / MR Exec-MIS DATE : 15.05.04

SYSTEM PROCEDURE DOC NO: QA-BPF-01

RECEIPT INSPECTION PAGE: 3 OF 3

PERFORMANCE INDICATORS:

Efficiency: Line rejections trend

Effectiveness: Incoming %age Acceptance

6.0 Records:

6.1 QA-F-01 Identification Tag

6.2 QA-F-02 Incoming Inspection Report

6.3 QA-F-05 Vendor History Card

6.4 STR-F-03 Material Receipt cum Inspection Report

6.5 STR-F-10 Returnable Gate Pass / Receipt Report / Insp. Report – Job Work only

7.0 References:

7.1 QA-Q-XXX Relevant Quality Plans

7.2 QA-W-01 Work Instruction for Incoming Inspection

7.3 QA-D-04 Single Sampling Plan

7.4 PUR-D-01 Approved Supplier List

7.4 QA-D-05 List of Major / Minor Defects

Prep. By: Reviewed & Appd. by: Issued by: REV. NO: 04

HOD-QA CEO / MR Exec-MIS DATE : 15.05.04

S-ar putea să vă placă și

- Procedure For Material Requirement Planning & PurchasingDocument1 paginăProcedure For Material Requirement Planning & PurchasingHarkesh KumarÎncă nu există evaluări

- Estimating Process Section 11: Quality Assurance ManualDocument4 paginiEstimating Process Section 11: Quality Assurance ManualNgonidzashe ZvarevasheÎncă nu există evaluări

- Induction Training Text Format - StaffDocument5 paginiInduction Training Text Format - StaffJohnÎncă nu există evaluări

- SFT 0090 Control PlanDocument24 paginiSFT 0090 Control PlanspdhimanÎncă nu există evaluări

- Customer Complaint Handling Procedure Flow DiagramDocument1 paginăCustomer Complaint Handling Procedure Flow Diagramamit gajbhiyeÎncă nu există evaluări

- Objectives (2019 20)Document2 paginiObjectives (2019 20)Sekar KrishÎncă nu există evaluări

- 1 Internal & Product AuditDocument3 pagini1 Internal & Product AuditPrafull BhamareÎncă nu există evaluări

- GSQM TRW PDFDocument48 paginiGSQM TRW PDFJuan José Viñas Méndez50% (2)

- Describe and Compare Below The Changes Requested To Current Product Features/requirementsDocument1 paginăDescribe and Compare Below The Changes Requested To Current Product Features/requirementsdrustagiÎncă nu există evaluări

- List of Records - Formats & RegistersDocument1 paginăList of Records - Formats & RegistersSuraj KadamÎncă nu există evaluări

- PM - 7.04 Purchase ProcessDocument5 paginiPM - 7.04 Purchase ProcessMangBedjoÎncă nu există evaluări

- Control of Monitoring and Measuring EquipmentDocument3 paginiControl of Monitoring and Measuring EquipmentLinda Setya WatiÎncă nu există evaluări

- Capacity Planning (SOP-CAP-CAPP-021) Version 1.6Document11 paginiCapacity Planning (SOP-CAP-CAPP-021) Version 1.6ranga.ramanÎncă nu există evaluări

- ASP-NPD-04 (Process of Product Safety)Document5 paginiASP-NPD-04 (Process of Product Safety)akash.vd.1603Încă nu există evaluări

- Manufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)Document5 paginiManufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)khmorteza100% (1)

- Safety FMEADocument4 paginiSafety FMEAnormalÎncă nu există evaluări

- 0706 Product Change Request FormDocument2 pagini0706 Product Change Request FormulyssesÎncă nu există evaluări

- CSR Map ToolDocument51 paginiCSR Map ToolSarah JohnsonÎncă nu există evaluări

- Vda Fmea TemplateDocument54 paginiVda Fmea Templatehmp90Încă nu există evaluări

- Management Review Agenda and Minutes: M: Name Title Here Name Title HereDocument5 paginiManagement Review Agenda and Minutes: M: Name Title Here Name Title HereTrivesh SharmaÎncă nu există evaluări

- Building An Effective Supplier Control Program:: A Review of Key Program Elements & Their ImplementationDocument37 paginiBuilding An Effective Supplier Control Program:: A Review of Key Program Elements & Their Implementationmulyana-Încă nu există evaluări

- PFEMA Attachment B Rev 16fe15Document1 paginăPFEMA Attachment B Rev 16fe15Saulo TrejoÎncă nu există evaluări

- Name of Employee: Performance Evaluation FormDocument5 paginiName of Employee: Performance Evaluation FormShemu PlcÎncă nu există evaluări

- Safety: A) Machine Safety SystemDocument5 paginiSafety: A) Machine Safety SystemSagar DaundÎncă nu există evaluări

- Centurion Power Cables (P) LTD.: Control of DocumentDocument4 paginiCenturion Power Cables (P) LTD.: Control of DocumenttriveshÎncă nu există evaluări

- Balance Sheet: Current AssetsDocument32 paginiBalance Sheet: Current AssetsGiri ReddyÎncă nu există evaluări

- Anicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateDocument9 paginiAnicon Flowcontrols LLP Procedure: Procedure Name Department Responsibility Clause NO Target DateAnicon Flowcontols llpÎncă nu există evaluări

- Part Inspection Standard (May 2013)Document9 paginiPart Inspection Standard (May 2013)san moedano100% (1)

- 85-04, The BW Preventive Action Register.: Purpose and ScopeDocument2 pagini85-04, The BW Preventive Action Register.: Purpose and Scopedanaka007Încă nu există evaluări

- Product Development ProcedureDocument2 paginiProduct Development ProcedureLuke BilisÎncă nu există evaluări

- Supplier Quality Manual: Zetor Tractors A.S. Trnkova 111 628 00 BRNODocument42 paginiSupplier Quality Manual: Zetor Tractors A.S. Trnkova 111 628 00 BRNOumtÎncă nu există evaluări

- SAP Sales & Distribution in ActionDocument5 paginiSAP Sales & Distribution in Actionboss100% (1)

- Al PSW FormatDocument2 paginiAl PSW Formatabhayjha1988Încă nu există evaluări

- Global Supplier Quality Manual-Second EditionDocument43 paginiGlobal Supplier Quality Manual-Second EditionSuhas ChinchanikarÎncă nu există evaluări

- APQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareDocument2 paginiAPQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareselvamÎncă nu există evaluări

- Sanctioned Party List Screening in SapDocument13 paginiSanctioned Party List Screening in SapajaysapsdÎncă nu există evaluări

- Hardrock Attachments Pvt. LTD.: Preventive Maintenance ChecklistDocument1 paginăHardrock Attachments Pvt. LTD.: Preventive Maintenance ChecklistSandeep KumarÎncă nu există evaluări

- Sr. No. Metric Goal Data Source Base Line: TallbrosDocument3 paginiSr. No. Metric Goal Data Source Base Line: TallbrosVikas KashyapÎncă nu există evaluări

- CS-P03-HR Recruitment TrainingDocument5 paginiCS-P03-HR Recruitment TrainingIdrus IsmailÎncă nu există evaluări

- 8D ReportDocument2 pagini8D Reportgatofelix1980100% (1)

- QAD Procedure - Lab Management P1Document1 paginăQAD Procedure - Lab Management P1sumanÎncă nu există evaluări

- HR-2-001, Issue 01, Procedure For Training & DevelopmentDocument2 paginiHR-2-001, Issue 01, Procedure For Training & Developmentsajid waqasÎncă nu există evaluări

- Phased Ps Wwith P Pap Tracking FormDocument3 paginiPhased Ps Wwith P Pap Tracking FormKurt FinkÎncă nu există evaluări

- Form - Scar LogDocument18 paginiForm - Scar LogHarie BongkyÎncă nu există evaluări

- HDT First Article Inspection Policy 01Document7 paginiHDT First Article Inspection Policy 01Srinivasan VenkatÎncă nu există evaluări

- CS P09 Project ManagementDocument4 paginiCS P09 Project ManagementIdrus IsmailÎncă nu există evaluări

- Tablas FmeaDocument4 paginiTablas FmeaPalmer Dionicio100% (1)

- Control of Monitoring & Measuring DevicesDocument10 paginiControl of Monitoring & Measuring DevicesRamesh mudunuriÎncă nu există evaluări

- QP Nonconforming Product Sample 2014Document2 paginiQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Example of Using Pear FormDocument2 paginiExample of Using Pear Formjohnoo7Încă nu există evaluări

- Shree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramDocument2 paginiShree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramS. R. OvhalÎncă nu există evaluări

- Appendix 11 Design FMEA ChecklistDocument16 paginiAppendix 11 Design FMEA ChecklistDearRed FrankÎncă nu există evaluări

- CS P11 PurchasingDocument4 paginiCS P11 PurchasingIdrus IsmailÎncă nu există evaluări

- Supply Packaging Approve FormDocument1 paginăSupply Packaging Approve Formcong daÎncă nu există evaluări

- Action Plan For Red & Yellow Resp TGT Date Implemented / Proof Available Under Progress Not Implemented / Proof Not AvailableDocument39 paginiAction Plan For Red & Yellow Resp TGT Date Implemented / Proof Available Under Progress Not Implemented / Proof Not AvailableSanjay KumarÎncă nu există evaluări

- GM 1927 14 Maintenance ChecklistDocument7 paginiGM 1927 14 Maintenance ChecklistMostafa Abd ElalemÎncă nu există evaluări

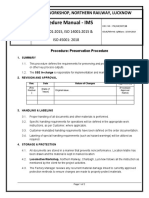

- Procedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowDocument2 paginiProcedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowMarjorie Dulay DumolÎncă nu există evaluări

- PUR-PM-06 Initial Flow Control For PCS SupplierDocument4 paginiPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarÎncă nu există evaluări

- Monthly Quality Report-FormatDocument16 paginiMonthly Quality Report-Formatchandra123456789Încă nu există evaluări

- Value Of Work Done A Complete Guide - 2020 EditionDe la EverandValue Of Work Done A Complete Guide - 2020 EditionÎncă nu există evaluări

- Fee Structure MalaysianDocument1 paginăFee Structure Malaysianvyly1723Încă nu există evaluări

- Preparation For ISO 45001 OH&S Management SystemsDocument19 paginiPreparation For ISO 45001 OH&S Management Systemsvyly1723Încă nu există evaluări

- Ims 15 18149 Manual Sample PDFDocument13 paginiIms 15 18149 Manual Sample PDFvyly1723Încă nu există evaluări

- KpiDocument10 paginiKpivyly1723Încă nu există evaluări

- PRINCE2 Foundation and Practitioner Exam Practice TestDocument21 paginiPRINCE2 Foundation and Practitioner Exam Practice Testvyly172389% (9)

- CAS090503QAQCPlan PDFDocument20 paginiCAS090503QAQCPlan PDFvyly1723Încă nu există evaluări

- Cis7 2014 Qlassic v2 PDFDocument66 paginiCis7 2014 Qlassic v2 PDFvyly1723100% (10)

- Road To WealthDocument216 paginiRoad To WealthandonalineÎncă nu există evaluări

- Cis7 2014 Qlassic v2 PDFDocument66 paginiCis7 2014 Qlassic v2 PDFvyly1723100% (10)

- GBI CertificationDocument32 paginiGBI Certificationvyly1723100% (1)

- How To Integrate EIA in EMSDocument14 paginiHow To Integrate EIA in EMSvyly1723Încă nu există evaluări

- Cosmic Laws - Part 1: PrefaceDocument26 paginiCosmic Laws - Part 1: Prefacevyly1723100% (1)

- Young Consumer Online ShoppingDocument20 paginiYoung Consumer Online Shoppingvyly1723Încă nu există evaluări

- Division 22 - Plumbing Section 22 11 16 - Domestic Water PipingDocument9 paginiDivision 22 - Plumbing Section 22 11 16 - Domestic Water PipingAlexander MasongsongÎncă nu există evaluări

- Bobbin Deisgn PDFDocument100 paginiBobbin Deisgn PDFPaul JosephÎncă nu există evaluări

- Mil PRF 83261CDocument7 paginiMil PRF 83261CbouzerzourÎncă nu există evaluări

- Iooc Idhc BPD Ins Pro 007 R4Document8 paginiIooc Idhc BPD Ins Pro 007 R4Fatholla SalehiÎncă nu există evaluări

- FM 7605 PDFDocument18 paginiFM 7605 PDFFahmi GbÎncă nu există evaluări

- BgasDocument8 paginiBgassudhakar rajendranÎncă nu există evaluări

- PQT Updates Egypt AUG 2018Document41 paginiPQT Updates Egypt AUG 2018KaRiM NassarÎncă nu există evaluări

- CH 6 Quality ManagementDocument44 paginiCH 6 Quality ManagementYaredÎncă nu există evaluări

- Katragadda Siva Sai Ram: Professional SummaryDocument2 paginiKatragadda Siva Sai Ram: Professional Summarysivaramk6866Încă nu există evaluări

- Fire Safety PolicyDocument22 paginiFire Safety PolicyMohamed GerezaÎncă nu există evaluări

- Lift Caps: General RequirementsDocument2 paginiLift Caps: General Requirementsislam atif100% (1)

- SPA Training Module Handout Continuous Sampling 6JUN2019Document46 paginiSPA Training Module Handout Continuous Sampling 6JUN2019Geovanni calderonÎncă nu există evaluări

- Inspection Test Plan: 1 QA/QC Document Submission & ApprovalDocument1 paginăInspection Test Plan: 1 QA/QC Document Submission & Approvalmohd as shahiddin jafri100% (2)

- BottricksDocument27 paginiBottricksshiv aroraÎncă nu există evaluări

- 16.sec.1600 (Steel Reinforcement)Document4 pagini16.sec.1600 (Steel Reinforcement)aalignup arc & const. pvt ltdÎncă nu există evaluări

- 4630 Maintenance Control (2) - Unlocked PDFDocument45 pagini4630 Maintenance Control (2) - Unlocked PDFkayau APCÎncă nu există evaluări

- Process ControlDocument5 paginiProcess ControlTuan Anh100% (1)

- 7.insulation SeminarDocument55 pagini7.insulation SeminarvgÎncă nu există evaluări

- Morbi Bridge CollapseDocument8 paginiMorbi Bridge CollapseAryan ChaubalÎncă nu există evaluări

- Production Planning & ControlDocument32 paginiProduction Planning & Controlrajaram vermaÎncă nu există evaluări

- Mil HDBK 728 - 1 End GeralDocument46 paginiMil HDBK 728 - 1 End GeralMarcosCardozoÎncă nu există evaluări

- NRF-049-PEMEX-2006 Inspección de Bienes y Servicios - Es.enDocument35 paginiNRF-049-PEMEX-2006 Inspección de Bienes y Servicios - Es.enDavid van TongerenÎncă nu există evaluări

- ST 7887 2019 INIT en EU Tempest AccreditationDocument30 paginiST 7887 2019 INIT en EU Tempest AccreditationRodica ParaschivaÎncă nu există evaluări

- MSTS Mark's API 510 STUDY GUIDE.Document30 paginiMSTS Mark's API 510 STUDY GUIDE.Hares SlalÎncă nu există evaluări

- 17-QA-QC ManualDocument34 pagini17-QA-QC ManualAbdul Gaffar100% (3)

- BS en 10021-2006 (2007)Document20 paginiBS en 10021-2006 (2007)Martijn Groot100% (1)

- Form QP 07-2 Supplier Evaluation Questionnaire - REV 0Document3 paginiForm QP 07-2 Supplier Evaluation Questionnaire - REV 0Charles Bill Eldredge100% (1)

- SAP Quality ManagementDocument5 paginiSAP Quality ManagementRoha AsimÎncă nu există evaluări

- An Overview of The Pipeline Defect Assessment Manual (Pdam)Document13 paginiAn Overview of The Pipeline Defect Assessment Manual (Pdam)Jorge Altamirano100% (1)

- Certificado de Calibracion Medidor de GasesDocument1 paginăCertificado de Calibracion Medidor de Gasesjames linresÎncă nu există evaluări