Documente Academic

Documente Profesional

Documente Cultură

303 PDF

Încărcat de

Frena1Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

303 PDF

Încărcat de

Frena1Drepturi de autor:

Formate disponibile

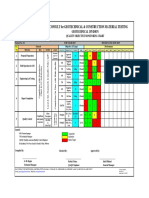

DISCRETE WIRING DISCRETE WIRING

DEADBUGS DEADBUGS (cont.)

DEADBUGS

The term Deadbugs is an industry nickname

for the discrete components added and wired

into a printed wiring assembly (PWA) to

facilitate active circuit modifications, rather

than redesign and manufacture a new board.

The nickname comes from their general

appearance on the board: upside down, with

their termination leads (legs) up in the air like ACCEPTABLE UNACCEPTABLE

a dead bug. PIGGYBACKING / STACKING TO ICs IMPROPER LEAD DRESS

AXIAL / RADIAL / SMT COMPONENTS Dead-bugged components shall be mounted and

While their use is an accepted practice, the IC piggybacking is acceptable when space and/or dressed in a manner that prevents shorting of the

customer must grant approval prior to their use noise requirements prohibit more traditional leads to the component case (pictured) or to

and installation. placement methods. Component leads / jumper other conductors.

wires shall meet minimum bend requirements. Best Workmanship Practice

Best Workmanship Practice

PREFERRED PREFERRED UNACCEPTABLE UNACCEPTABLE

AXIAL-LEADED COMPONENT GLASS-BODIED COMPONENT IMPROPER MOUNTING ORIENTATION IMPROPER MOUNTING

Component is properly mounted. Lead bends are Component is covered with a transparent resilient Components shall be mounted with the leads in SMT COMPONENTS MOUNTED ON LEADS

within limits. Terminations are properly wrapped. sleeving, and properly mounted. Lead bends are an orientation that ensures the terminations meet Chip and MELF devices shall not be directly

The solder joints meet all minimum requirements. within limits. Terminations are properly wrapped. minimum electrical spacing requirements. As mounted on component leads of integrated circuit

Jumper wires have appropriate stress relief. The solder joints meet all minimum requirements. pictured, the component terminals are resting on (chip) packages.

Best Workmanship Practice Jumper wires have appropriate stress relief. exposed circuitry and vias. Best Workmanship Practice

Best Workmanship Practice Best Workmanship Practice

PREFERRED PREFERRED UNACCEPTABLE UNACCEPTABLE

DUAL-INLINE PACKAGE (DIP) RADIAL-LEADED COMPONENT IMPROPER SOLDER TERMINATION IMPROPER STAKING

Component is properly mounted and terminated. Component is properly mounted and terminated. LEADED DEVICES The component shall be secured with an

Jumper wires are properly terminated, with Lead bends are within limits. Terminations are Jumper wires shall be lap soldered to the device adhesive material, per engineering

appropriate stress relief. The solder joints meet properly wrapped. The solder joints meet all leads. Wrapped terminations place stress on the documentation.

all minimum requirements. minimum requirements. Jumper wires have component lead, and may violate minimum lead-to-

lead electrical spacing requirements. Best Workmanship Practice

Best Workmanship Practice

appropriate stress relief.

Best Workmanship Practice Best Workmanship Practice

NASA WORKMANSHIP STANDARDS NASA WORKMANSHIP STANDARDS

Released: Revision: Revision Date: Released: Revision: Revision Date:

05.31.2002 05.31.2002

Book: Section: Page: Book: Section: Page:

3 3.03 1 3 3.03 3

DISCRETE WIRING DISCRETE WIRING

DEADBUGS (cont.) DEADBUGS (cont.)

UNACCEPTABLE UNACCEPTABLE PREFERRED PREFERRED

IMPROPER TERMINATION WRAP PIGGY-BACK / STACKING SURFACE MOUNT TECHNOLOGY SURFACE MOUNT TECHNOLOGY

CYLINDRICAL / MELF COMPONENTS CHIP / MELF / METALLIZED TERMINALS GULL-WING / J-LEAD / LEADED DEVICES

Jumper wires shall be wrapped at least 180 to

270 around the component lead prior to The piggy-backing / stacking of cylindrical / glass- Component is properly mounted and terminated. Component is properly mounted and terminated.

soldering, and shall not be located closer than bodied / MELF components is not recommended. Jumper wires are properly terminated, with Jumper wires are properly terminated, with

one (1) lead diameter to end of the component Best Workmanship Practice appropriate stress relief. The solder joints meet appropriate stress relief. The solder joints meet

lead. all minimum requirements. all minimum requirements.

Best Workmanship Practice Best Workmanship Practice Best Workmanship Practice

UNACCEPTABLE PREFERRED ACCEPTABLE

TOMBSTONED TERMINATION TO-CAN COMPONENT AXIAL COMPONENT PIGGYBACK

Deadbugged components shall be mounted parallel Component is properly mounted and terminated. Axial components may be piggybacked to axial

to and in contact with the base laminate, or base Lead bends are within limits. Terminations are components in a vertical or horizontal orientation,

component (if applicable). Tombstoning places properly wrapped. The solder joints meet all but shall be staked. Terminations shall meet

unacceptable stress on the component/solder pad minimum requirements. Jumper wires have minimum lead seal spacing, lead bend, wrap, and

termination. appropriate stress relief. solder fillet requirements.

Best Workmanship Practice Best Workmanship Practice Best Workmanship Practice

ACCEPTABLE ACCEPTABLE

CHIP / MELF / METALLIZED TERMINALS PIGGYBACKING / STACKING

ALTERNATE MOUNT SMT (3-5 SIDE) CHIP COMPONENTS

Chip component mounting to a single pad is The components are in vertical alignment, with no

acceptable, provided the component is properly overhang. The terminations exhibit fully wetted

staked to prevent stress to the solder joints or the solder fillets and the stack does not exceed two

component body. (2) components high.

Best Workmanship Practice Best Workmanship Practice

NASA WORKMANSHIP STANDARDS NASA WORKMANSHIP STANDARDS

Released: Revision: Revision Date: Released: Revision: Revision Date:

05.31.2002 05.31.2002

Book: Section: Page: Book: Section: Page:

3 3.03 4 3 3.03 2

S-ar putea să vă placă și

- Adapter DDR MemoryDocument15 paginiAdapter DDR MemoryFrena1Încă nu există evaluări

- 14841C HC908LJ LK24 TSMC2 QualDocument14 pagini14841C HC908LJ LK24 TSMC2 QualFrena1Încă nu există evaluări

- Computers Vs Humans 1Document7 paginiComputers Vs Humans 1Frena1Încă nu există evaluări

- PIC12F629/675 Data Sheet: 8-Pin FLASH-Based 8-Bit CMOS MicrocontrollersDocument132 paginiPIC12F629/675 Data Sheet: 8-Pin FLASH-Based 8-Bit CMOS MicrocontrollersDavid MartinezÎncă nu există evaluări

- TV RepairDocument2 paginiTV RepairFrena1Încă nu există evaluări

- 303Document2 pagini303Frena1Încă nu există evaluări

- Please, Like and Share. ElectronicsDocument1 paginăPlease, Like and Share. ElectronicsFrena1Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Product Catalog: Crystal-Vision Packaging SystemsDocument48 paginiProduct Catalog: Crystal-Vision Packaging SystemsWalterÎncă nu există evaluări

- Optimizing green sand casting process parameters using Taguchi's methodDocument6 paginiOptimizing green sand casting process parameters using Taguchi's methodpsprajkotÎncă nu există evaluări

- Bessemer Process 2Document3 paginiBessemer Process 2ShahzadAkhterÎncă nu există evaluări

- Jit PDFDocument28 paginiJit PDFRona S. Pepino - AguirreÎncă nu există evaluări

- PMBOK Chapter 7 - QualityDocument30 paginiPMBOK Chapter 7 - QualitylatehoursÎncă nu există evaluări

- Differentiation Between Strand Pellet Is Ing & Die Phase Pellet Is IngDocument22 paginiDifferentiation Between Strand Pellet Is Ing & Die Phase Pellet Is IngJohn Mathew100% (1)

- Vestamid NRG 2101Document2 paginiVestamid NRG 2101Leonardo MonroyÎncă nu există evaluări

- Caricom Regional Standard: Specification For CementDocument21 paginiCaricom Regional Standard: Specification For CementHamed HamidpourÎncă nu există evaluări

- Analysis of Short Run Cost of ProductionDocument12 paginiAnalysis of Short Run Cost of ProductionPrince KumarÎncă nu există evaluări

- Process Costing: Measuring, Monitoring, and Motivating PerformanceDocument50 paginiProcess Costing: Measuring, Monitoring, and Motivating PerformancearunprasadvrÎncă nu există evaluări

- NordDocument4 paginiNordanshatÎncă nu există evaluări

- Myford ML7 Lubrication ChartDocument6 paginiMyford ML7 Lubrication Chartjimxxx100% (3)

- E020 Series Sealed Snap-acting Momentary Pushbutton SwitchesDocument9 paginiE020 Series Sealed Snap-acting Momentary Pushbutton SwitchesabcÎncă nu există evaluări

- c2g Pump BrochureDocument8 paginic2g Pump Brochuretyutyu0% (1)

- Grant Prideco USA OCTG Tubular ProductsDocument2 paginiGrant Prideco USA OCTG Tubular ProductsMas Bagaz NoviantoÎncă nu există evaluări

- Master List of DrawingsDocument117 paginiMaster List of DrawingsBenudhar Sahoo100% (1)

- Receiving Inspections Power Point 10-22-16Document52 paginiReceiving Inspections Power Point 10-22-16Darby MorganÎncă nu există evaluări

- Carbon Dioxide Enhanced Oil Recovery Injection Operations TechnologiesDocument8 paginiCarbon Dioxide Enhanced Oil Recovery Injection Operations TechnologiesSaeid RajabiÎncă nu există evaluări

- Project On Logistics Management: Name: Suresh Marimuthu Roll No.: 520964937 LC Code: 3078Document147 paginiProject On Logistics Management: Name: Suresh Marimuthu Roll No.: 520964937 LC Code: 3078awaisjinnahÎncă nu există evaluări

- 00-Quality Objective Monitoring Chart Fof Geotech Div-2Document1 pagină00-Quality Objective Monitoring Chart Fof Geotech Div-2Adly Al-SaafinÎncă nu există evaluări

- Mini ProjectDocument23 paginiMini ProjectbpschbkÎncă nu există evaluări

- Evidence 4 PRODUCT DISTRIBUTIONDocument2 paginiEvidence 4 PRODUCT DISTRIBUTIONYAMILE HIGUITAÎncă nu există evaluări

- Inventory MGT Zuari Cement 2010Document65 paginiInventory MGT Zuari Cement 2010Ghule VinayakÎncă nu există evaluări

- Deep Hole Drlling On Maching Centres BOTEKDocument2 paginiDeep Hole Drlling On Maching Centres BOTEKmapalptsÎncă nu există evaluări

- Assigenment QuestionsDocument4 paginiAssigenment Questionsphase_shekhar21Încă nu există evaluări

- Warehouse AssignmentDocument14 paginiWarehouse AssignmentCosmas Teo100% (2)

- Production of FerroalloysDocument39 paginiProduction of Ferroalloysozgelke100% (3)

- Microeconomics Test 2Document26 paginiMicroeconomics Test 2a24dk100% (4)

- UZ Petroleum Engineering Catalytic CrackingDocument9 paginiUZ Petroleum Engineering Catalytic CrackingSaMiHRÎncă nu există evaluări

- Barlow Formula - Tube Burst PressureDocument2 paginiBarlow Formula - Tube Burst Pressureshinojbaby4148Încă nu există evaluări