Documente Academic

Documente Profesional

Documente Cultură

9 - Implementation and Study of BLDC Motor Drive System

Încărcat de

Trung TrựcTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

9 - Implementation and Study of BLDC Motor Drive System

Încărcat de

Trung TrựcDrepturi de autor:

Formate disponibile

[Sutar, 5(5): May, 2016] ISSN: 2277-9655

Impact Factor: 3.785

IJESRT

INTERNATIONAL JOURNAL OF ENGINEERING SCIENCES & RESEARCH

TECHNOLOGY

IMPLEMENTATION AND STUDY OF BLDC MOTOR DRIVE SYSTEM

Amol R. Sutar*, G. G. Bhide, J. J. Mane

Electronics Department, Electrical Department. FAMT Ratnagiri. India

DOI: 10.5281/zenodo.50975

ABSTRACT

The BLDC motor is an electronically commutated dc motor becoming very popular in many applications. There are

various speed control methods used for BLDC motor. The performance of BLDC motor drives can be improved

using sensored control techniques over sensorless technology. This paper presents Brushless Direct Current motor

drive system and its sensored speed control technique with PWM. Advantages and limitations of sensorless

techniques are reviewed and then, sensored speed control technique is introduced with their advantages,

performance analysis, practical implementation and applications. Torque and speed behavior during clockwise and

anticlockwise motion, use of hall sensors to detect rotor position, speed control technique using PWM method are

discussed in detail. Detailed hardware design its implementation and experimental results covered. This paper also

covers performance analysis of BLDC motor using experimental results.

KEYWORDS: back-EMF; sensored control; rotor position; Hall-effect sensors; PIC microcontroller, PWM.

INTRODUCTION

Brushless Direct Current (BLDC) motors are nowadays becoming popular in many applications such as Automotive,

Aerospace, Medical, Industrial automation Equipment and Instrumentation due to its advantageous features over

brushed dc motors and induction motors. BLDC motors have many advantages [1] [2] such as better speed versus

torque characteristics, High dynamic response, high efficiency, long operating life, noiseless operation and higher

speed ranges etc. BLDC motors do not use brushes for commutation; instead, they are electronically commutated

like stepper motor. In addition, the ratio of torque delivered to the size of the motor is higher, making it useful in

applications where size and weight are main constraint.

The BLDC motor drive voltage can be commutated by sensing the back EMF voltage on an un-driven motor

terminal during one of the drive phases. Like brushed dc motor and induction motors, BLDC motor generates back

emf during run condition. In off state of motor back emf across three phases is zero and increases with the speed of

motor. The advantage of sensor less control is only the elimination of the Hall position sensors but there are several

disadvantages [1] [2] of sensor less control:

1. The motor speed should be always greater than zero speed so as to generate sufficient back EMF to be sensed.

2. Sudden changes to the motor load and speed can result in loss of the spped control.

3. The BEMF voltage can be measured only when the motor speed is within a certain limited range of the ideal

commutation rate for the applied voltage.

4. Commutation at rates faster than the ideal rate will result in a discontinuous motor response.

5. Sensor less program code of microcontroller for BLDC motor is more complex than sensored control method.

http: // www.ijesrt.com International Journal of Engineering Sciences & Research Technology

[57]

[Sutar, 5(5): May, 2016] ISSN: 2277-9655

Impact Factor: 3.785

In addition BLDC motor speed control by sensing back emf needs extra voltage sensing and conditioning circuit to

be interfaced with microcontroller. But in applications where the motor speed requirement is higher, load conditions

remains same and low cost is a primary concern then sensorless control may be the better choice for the application.

To avoid above mentioned disadvantages BLDC motor is usually controlled using position sensors called Hall

Effect sensors which comes with BLDC motor itself. BLDC motors have three Hall sensors fixed into the stator on

the non-driving end of the motor. Whenever the rotor magnetic poles pass near the Hall sensors, they give a high or

low signal, indicating the N or S pole is passing near the sensors. Based on the combination of these three Hall

sensor signals, the exact sequence of commutation can be determined. To rotate the BLDC motor, the stator

windings should be energized in a sequence. It is important to know the rotor position in order to understand which

winding is to be energized following the energizing sequence. Based on the physical position of the Hall sensors,

there are two versions of output. The Hall sensors may be at 60 or 120 phase shift to each other. The motor

manufacturer defines the commutation sequence, which should be followed when controlling the motor. In this

paper, proposed the sensored speed control method and its implementation using PIC microcontroller for BLDC

motors.

BLDC MOTOR

BLDC motor consists of permanent magnetic rotor and stator windings. Depending on stator winding BLDC motor

may be single phase or three phase. Figure 1 shows internal structure of three phase BLDC motor and star connected

three phase stator winding[1]. The numbers one to six on stator winding represents the commutation sequence. Each

commutation sequence has one of the windings energized to positive power, the second winding is negative and the

third is in a non-energized condition. Torque is produced because of the interaction between the magnetic field

generated by the stator coils and the permanent magnets. Ideally, the peak torque occurs when these two fields are at

90 to each other and falls off as the fields move together. In order to keep the motor running, the magnetic field

produced by the windings should shift position, as the rotor moves to catch up with the stator field.

Fig.1 BLDC motor structure and stator winding

Commutation Sequence

Fig. 2 shows an example of phase voltage with respect to Hall sensor signals. As shown in these waveforms after

every 60 electrical degrees of rotation, one of the Hall sensors changes the state. In one electrical cycle, the phase

voltage and current switching occurs six times, each after every 60 electrical degrees. In BLDC motor, one electrical

cycle may not correspond to a complete mechanical revolution of the rotor. The number of electrical cycles to be

repeated to complete a mechanical rotation depends on number of the rotor pole pairs. For each rotor pole pair, one

electrical cycle is completed. So, the number of electrical cycles per rotations is equal to the number of rotor pole

pairs. For example in four poles BLDC motor four electrical cycles has to be completed for a mechanical revolution.

http: // www.ijesrt.com International Journal of Engineering Sciences & Research Technology

[58]

[Sutar, 5(5): May, 2016] ISSN: 2277-9655

Impact Factor: 3.785

The commutation sequence numbered one to six at top of waveforms and respective hall sensor signals are shown in

the fig.2.

The commutation sequence is generated based on the hall sensor output (rotor position) and required phase voltage.

For continuous rotation phase sequence numbered 1 to 6 should be followed to energize respective phases based on

hall sensor output.

Fig. 2 phase voltage and sensor output waveforms.

For example consider phase sequence number 1, the hall sensors logic output is 101 i.e HC=1, HB = 0, HA = 1

where the MSB bit is sensor HC and the LSB bit is sensor HA. The north pole of permanent magnet rotor points to

the sensor code that is output at that rotor position. To move the rotor from 101 position in forward direction phase

A should be positive energized, phase B should be negative energized and phase C is kept floating. The magnetic

field produced due to current flowing in phase A and B of stator winding is 90 0 out of phase to that of rotor poles

magnetic field. Due to this peak torque produced which drag the rotor to align with magnetic field of stator winding

where hall sensors output code is 100 as illustrated in fig.1.

Table 1 and Table 2 shows the six step sequence in which the power switches of three phase inverter should be

switched on and off based on the Hall sensor inputs HA, HB and HC. Table 1 shows hall sensor output code and

respective PWM codes for clockwise rotation of the motor and Table 2 is for counter clockwise motor rotation. This

is an example of Hall sensor signals having a 60 degree phase shift with respect to each other. Resultant hex code

can be used where driver output is in phase with input while inverted hex code (last column) can be used where

driver output is complementary.

Table 1. PWM sequence for rotating motor in clockwise direction.

No. Hall Sensor Active PWM HEX Inverted

HC HB HA PWMC PWMC PWMB PWMB PWMA PWMA Code HEX

Code

1 0 0 1 1 0 0 0 0 1 0x21 0xde

2 0 1 0 0 0 0 1 1 0 0x06 0xf9

3 0 1 1 1 0 0 1 0 0 0x24 0xdb

4 1 0 0 0 1 1 0 0 0 0x18 0xe7

5 1 0 1 0 0 1 0 0 1 0x09 0xf6

6 1 1 0 0 1 0 0 1 0 0x12 0xed

http: // www.ijesrt.com International Journal of Engineering Sciences & Research Technology

[59]

[Sutar, 5(5): May, 2016] ISSN: 2277-9655

Impact Factor: 3.785

Table 2. PWM sequence for rotating motor in counter-clockwise direction.

No. Hall Sensor Active PWM Inverted

HC HB HA PWMC PWMC PWMB PWMB PWMA PWMA HEX HEX

Code Code

1 0 0 1 0 1 0 0 1 0 0x12 0xed

2 0 1 0 0 0 1 0 0 1 0x09 0xf6

3 0 1 1 0 1 1 0 0 0 0x18 0xe7

4 1 0 0 1 0 0 1 0 0 0x24 0xdb

5 1 0 1 0 0 0 1 1 0 0x06 0xf9

6 1 1 0 1 0 0 0 0 1 0x21 0xde

BLDC MOTOR DRIVE SYSTEM:

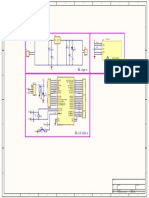

Typical three phase BLDC motor drive system is similar to three phase induction motor drive system as shown in

fig. 3. DC voltage source may be a battery, fuel-cell stack, diode rectifier and capacitor. DC source gives 5V, 12V

and 24V output for operation of controller, driver and the main inverter circuit respectively. Three phase inverter

circuit consists of six switches connected in three legs. PIC Microcontroller 18f452 has High Performance RISC

architecture, with in built four 16 bit timers, eight channel-10 bit configurable analog to digital controller, 10 bit

PWM generator, capture/compare module and many other advanced features. These advanced features make it

useful in all types of control system applications. Microcontroller is used to generate PWM pulses to control on/off

time of switching devices in a proper sequence based on hall sensor feedback signal. Driver circuit is used to

amplify PWM signal and to provide isolation between microcontroller and inverter circuit. A display device such as

LCD display is used to display speed and duty ratio of PWM signals and provides interaction between user and the

system.

Fig.3. BLDC Motor Control System block diagram.

LEDs are also used to indicate status such as ON/OFF, forward direction, reverse direction etc. Here PIC

microcontroller 18f452 used to generate PWM pulses at PORTD using its internal TIMER0. The potentiometer,

connected to one of the analog-to-digital converter channel in PIC microcontroller, is used to set reference speed.

Based on this reference input voltage, the PWM duty cycle is calculated. PWM output of PIC microcontroller is

applied to the respective gate terminals of inverter switches through gate drive circuit. The hall sensor feedback

signal is applied to the PORTE of microcontroller to sense the rotor position.

http: // www.ijesrt.com International Journal of Engineering Sciences & Research Technology

[60]

[Sutar, 5(5): May, 2016] ISSN: 2277-9655

Impact Factor: 3.785

Q1 D1 Q5 D5 Q3 D3

PWMA PWMB PWMC

A

Vs B

C

Q4 D4 Q2 D2 Q6 D6

PWMA' PWMB' PWMC'

Fig. 4. Three phase Inverter Bridge

The three phase inverter to drive the BLDC motor is shown in the Fig. 4. Q1 to Q6 are the power switches

controlled by the PIC18F452 micro-controller. Based on the motor voltage and current ratings, these switches can be

MOSFETs, or IGBTs, or simple bipolar transistors. The BLDC motor is connected at the output terminals A, B, C.

If the signals marked by PWMx are switched ON or OFF according to the sequence, the motor will run at the rated

speed, provided DC bus voltage is equal to the motor rated voltage, plus any losses across the switches.

SPEED CONTROL USING PWM

PWM method is very advantageous in motor control applications. The speed of the motor can be varied smoothly

from zero to rated speed, the starting current of motor as well as torque can be kept within limit these, also, if the

DC bus voltage is much higher than the motor rated voltage, the motor can be controlled by limiting the percentage

of PWM duty cycle corresponding to that of the motor rated voltage. The Pulse Width Modulated (PWM) signals

should have much higher frequency than the motor frequency. When the duty cycle of PWM is varied within the

sequences, the average voltage supplied to the stator reduces, thus reducing the speed. ADC module and TIMER0 of

PIC microcontroller is used for PWM signal generation. ADC module generates 10bit data with respect to analog

voltage at channel 0. This analog voltage corresponds to reference speed. ADC module is configured as left justified

so that the content of eight bit ADRSEL can be used for duty cycle adjustment as it is, without need of modification.

Here TIMER0 is configured in eight bit mode, so it can vary PWM duty ratio and speed in 256 levels which is

sufficient at higher PWM frequency to vary the speed smoothly. In eight bit mode timer rolls over after count = 255

and set its flag. Suppose PWM frequency is set to 10KHz. To obtain a PWM frequency of 10 kHz timer must be

running at 256 times that rate, or 2.56MHz. Assuming minimum prescaler value of timer is 1:2. It needs an input

frequency of 5.12MHz. The input to Timer is FOSC/4. This requires a crystal frequency (FOSC) of 20.48 MHz. That

is an odd frequency, and 20 MHz is close enough, so we can use 20 MHz resulting in a PWM frequency of around

9.77 kHz. If prescalar is bypassed reduces required crystal frequency to half i.e. 10MHz and 11.0592MHz is close

enough, resulting in a PWM frequency around 10.8kHz. At 11.0592 MHz clock rate, control latency may be caused

by the loop time, but it spreads evenly in all ON and OFF time and not so much significant. For low-cost, low-

resolution speed requirements, the Hall signals can be used to measure the speed feed-back. A timer other than

Timer0 from the PIC18F452 can be used to count between two Hall transitions. With this count, the actual speed of

the motor can be calculated.

I. Proteus Simulation

The simulation is performed using Proteus software to observe hall sensor signals and PWM signals. Use of Proteus

software reduces programming time greatly.

http: // www.ijesrt.com International Journal of Engineering Sciences & Research Technology

[61]

[Sutar, 5(5): May, 2016] ISSN: 2277-9655

Impact Factor: 3.785

Fig. 5.Hall sensor signals(Scale:2V/div) Fig. 6. PWM output signals. (Scale:2V/div)

The reference hall sensor signals are 1200 phase shifted from each other. So those signals can be generated using

three phase supply module, Op-amp comparator and diode combination. The generated signals are equivalent to the

Hall sensor signals as shown in fig. 5. These signals are applied to the PORTE of microcontroller. The

microcontroller is programmed to generate six PWM switching signals based on these hall sensor signals. The PWM

output signals PWMA, PWMB, PWMC corresponding to the reference hall sensor signals are shown in the fig.6.

PWM signals of lower switches are not shown in this figure, but are similar to upper switches and occur when

respective hall sensor signal switches to low level.

HARDWAE RESULTS

The hardware setup is shown the fig.7. The PWM signals generated by microcontroller as illustrated in fig.6 are

used to control the speed of BLDC motor. BLDC motor specifications are shown table 3.

Table 3. BLDC Motor Specifications

Sr. No Parameter Value

1 Rated voltage 24V

2 Rated current 1.8A

3 Rated speed 3000rpm

4 Rated power 37W

5 Impedance R= 0.632, L = 0.3mH

6 Number of poles 4

7 Frequency 50hz

Test is carried out in open loop with manual control. By varying pot resistance the analog voltage at channel 0 get

varied. ADC module converts this analog voltage in to equivalent 10 bit digital data. The range of output of ADC is

limited 0 to 255, by connecting a resistance in series with pot. Hardware results are taken for both full load and no

load. At no load motor runs at full speed more than rated one with very small current 0.19A. When load is

connected, the motor current increases with increase in load. Motor speed is found to vary smoothly from zero to

rated speed with increase in PWM duty cycle. The motor hall sensor signals are obtained as shown in the fig.8.

http: // www.ijesrt.com International Journal of Engineering Sciences & Research Technology

[62]

[Sutar, 5(5): May, 2016] ISSN: 2277-9655

Impact Factor: 3.785

Fig.7. Hardware setup

Fig.8. Motor Hall sensor signals. (Scale:5V/div) Fig.9. PWM output signals. (Scale:5V/div)

The PWM signals corresponding to the upper switches in inverter (fig.4) are shown in the fig.9. The hall sensor

signals and PWM signals are similar to the one observed in Proteus simulation. The driver circuit inverts these

PWM signals, which are then applied to MOSFET gate. Thus 0 levels in PWM signal indicates ON state of

MOSFET and 1 level indicates OFF state. The output voltage of inverter is found trapezoidal in nature as shown in

the fig.10. The output voltages of three phase inverter are 1200 phase shifted from each other. BLDC motor can be

also controlled by sensing back emf of the motor.

Fig.10. Motor input voltage. (Scale:20V/div)

http: // www.ijesrt.com International Journal of Engineering Sciences & Research Technology

[63]

[Sutar, 5(5): May, 2016] ISSN: 2277-9655

Impact Factor: 3.785

The output voltage of inverter is found trapezoidal in nature as shown in the fig.10. The output voltages of three

phase inverter are 1200 phase shifted from each other. BLDC motor can be also controlled by sensing back emf of

the motor.

CONCLUSION

BLDC motors have several advantages over brushed DC motors and induction motors. It provides highly efficient

and noiseless operation. With these advantages, BLDC motors can be used in all applications wherever brushed dc

motor and induction motor used. The sensored PWM control scheme proposed for BLDC motor to vary the speed of

motor worked well as expected. It provides wide speed control range with high torque. Test results are verified for

both CW to CCW direction. The significant advantages of the proposed work are: simple hardware circuit,

reliability of the control algorithm, excellent speed control with and without load conditions. The sensored control

algorithm is very simple to implement using PIC microcontroller. The designed and implemented prototype model

may be implemented even for higher rated motors.

REFERENCES

[1] P. Yedamale, Microchip Technology Inc., Brushless DC (BLDC) motor fundamentals, 2003, AN885.

[2] Ward Brown, Microchip Technology Inc., Brushless DC Motor Control Made Easy, 2002, AN857

[3] V. U, S. Pola, and K. P. Vittal, Simulation of four quadrant operation & speed control of BLDC motor on

MATLAB/SIMULINK, in Proc.IEEE Region 10 Conference, 2008, pp. 16.

[4] C.-W. Hung, C. T. Lin, C. W. Liu, and J.-Y. Yen, A variable-sampling controller for brushless DC motor

drives with low-resolution position sensors, IEEE Trans. Ind. Electronics, vol. 54, no. 5, pp. 28462852, Oct.

2007.

[5] Microchip, PIC18F4520 Data Sheet, High Performance PIC Microcontrollers

[6] Nesimi Ertugrul, Paul P. Acarnley, Indirect Rotor Position Sensing in Real Time for Brushless Permanent

Magnet Motor Drives, IEEE Transaction on Power Electronics, Vol. 13, No. 4, pp. 608-616, July 1998

[7] Fernando Rodriguez, Ali Emadi, A Novel Digital Control Technique for Brushless DC Motor Drives, IEEE

Transaction on Industrial Electronics, Vol. 54, No., 5, pp. 2365-2373, Oct. 2007

[8] Anand Sathyan, Nikola Milivojevic, Young-Joo Lee, Mahesh Krishnamurthy, Ali Emadi, An FPGA-Based

Novel Digital PWM Control Scheme for BLDC Motor Drives, IEEE Transaction on Industrial Electronics,

Vol. 56, No., 8, pp. 3040-3049, August 2009

http: // www.ijesrt.com International Journal of Engineering Sciences & Research Technology

[64]

S-ar putea să vă placă și

- Expanding Rural Cellular Networks With Virtual Coverage: Kurtis Heimerl Joshua Blumenstock Kashif AliDocument87 paginiExpanding Rural Cellular Networks With Virtual Coverage: Kurtis Heimerl Joshua Blumenstock Kashif AliTrung TrựcÎncă nu există evaluări

- Global Positioning System - GPS CDocument46 paginiGlobal Positioning System - GPS CTrung TrựcÎncă nu există evaluări

- SdsdsdsdsdsdsdsDocument1 paginăSdsdsdsdsdsdsdsTrung TrựcÎncă nu există evaluări

- FGFGDocument1 paginăFGFGTrung TrựcÎncă nu există evaluări

- BTS Base Transciever Station Structure IDocument79 paginiBTS Base Transciever Station Structure ITrung TrựcÎncă nu există evaluări

- Chinh Sua 1Document1 paginăChinh Sua 1Trung TrựcÎncă nu există evaluări

- Composite DrawingDocument1 paginăComposite DrawingTrung TrựcÎncă nu există evaluări

- Grammar Notes B.editEDDocument9 paginiGrammar Notes B.editEDTrung TrựcÎncă nu există evaluări

- Celltowerantennas 141213082821 Conversion Gate01Document32 paginiCelltowerantennas 141213082821 Conversion Gate01goodoo27Încă nu există evaluări

- CompositionsDocument2 paginiCompositionsTrung TrựcÎncă nu există evaluări

- Be late = đi trễ (không dùng "go to late" nha em) Imagine = tưởng tượng Should have = Đáng lẽ đã Document1 pagină Be late = đi trễ (không dùng "go to late" nha em) Imagine = tưởng tượng Should have = Đáng lẽ đã Trung TrựcÎncă nu există evaluări

- BLDC Motor Control ANfpgaDocument8 paginiBLDC Motor Control ANfpgasraamu2k55068100% (1)

- CompositionsDocument2 paginiCompositionsTrung TrựcÎncă nu există evaluări

- Temperature ControllersDocument43 paginiTemperature Controllersthulinh12a1100% (1)

- User Manual For Speed Control of BLDC Motor Using DspicDocument12 paginiUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcÎncă nu există evaluări

- Role DongDocument2 paginiRole DongTrung TrựcÎncă nu există evaluări

- Presentation - PDF (Bt Bộ Đề Thi)Document28 paginiPresentation - PDF (Bt Bộ Đề Thi)Trung TrựcÎncă nu există evaluări

- Moteur Brushless ProDocument42 paginiMoteur Brushless ProSaad EssahliÎncă nu există evaluări

- DC Motor Speed Control With PIC16F877A and CCS PIC C CompilerDocument3 paginiDC Motor Speed Control With PIC16F877A and CCS PIC C CompilerTrung TrựcÎncă nu există evaluări

- Lap Trinh PLC DK He Thong ATSDocument49 paginiLap Trinh PLC DK He Thong ATSTrung TrựcÎncă nu există evaluări

- Variable Speed BLDC Motor Drive Using PIC MicrocontrollerDocument6 paginiVariable Speed BLDC Motor Drive Using PIC MicrocontrollerTrung TrựcÎncă nu există evaluări

- New Text DocumentDocument1 paginăNew Text DocumentTrung TrựcÎncă nu există evaluări

- Moteur Brushless ProDocument42 paginiMoteur Brushless ProSaad EssahliÎncă nu există evaluări

- Khối nguồn Khối hiển thị: 7805 LCD16x2ADocument1 paginăKhối nguồn Khối hiển thị: 7805 LCD16x2ATrung Trực100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Technical Service Guide: "Customcool "Document22 paginiTechnical Service Guide: "Customcool "Alicia Gabriela GutierrezÎncă nu există evaluări

- Sky Star 2 PciDocument2 paginiSky Star 2 PciSor Dela FlorÎncă nu există evaluări

- Maintenance Contract TemplateDocument7 paginiMaintenance Contract Templateabigail_tito123Încă nu există evaluări

- Toc 2Document87 paginiToc 2Zefrin ParkerÎncă nu există evaluări

- India Structured Cabling Edition 2world Market For Cabling 2017r2016 (Sample)Document5 paginiIndia Structured Cabling Edition 2world Market For Cabling 2017r2016 (Sample)federicosanchezÎncă nu există evaluări

- Verification of Dual Port RAM Using System Verilog and UVM: A ReviewDocument6 paginiVerification of Dual Port RAM Using System Verilog and UVM: A ReviewIJRASETPublicationsÎncă nu există evaluări

- Mac OS X CPU SchedulingDocument21 paginiMac OS X CPU Schedulingyeyow :v0% (2)

- JP 1030, JP 1230 PartsDocument291 paginiJP 1030, JP 1230 PartsCaroline DanielÎncă nu există evaluări

- Vyzex Pocket Pod PreferencesDocument11 paginiVyzex Pocket Pod PreferencesDaz MasonÎncă nu există evaluări

- Oda ExamDocument8 paginiOda ExamArif Mohammed Rangrezz100% (1)

- PQ ProductcatalogusDocument72 paginiPQ ProductcatalogusJohn FreackÎncă nu există evaluări

- Descargar Gratis Libro Side by Side Third EditionDocument21 paginiDescargar Gratis Libro Side by Side Third EditionMelissa Santos Canales17% (6)

- RAID Level 0 - Striping: AdvantagesDocument19 paginiRAID Level 0 - Striping: AdvantagesoakkarÎncă nu există evaluări

- Ajit Azure BookDocument59 paginiAjit Azure BookKakoli SenÎncă nu există evaluări

- STC TCL Lib Installation GuideDocument4 paginiSTC TCL Lib Installation GuideVenkatÎncă nu există evaluări

- Bdx33B Bdx33C Bdx34B Bdx34C: Complementary Silicon Power Darlington TransistorsDocument5 paginiBdx33B Bdx33C Bdx34B Bdx34C: Complementary Silicon Power Darlington TransistorsJavier BendekÎncă nu există evaluări

- T40 E41 M46 G NPB Ver.c PDFDocument51 paginiT40 E41 M46 G NPB Ver.c PDFEduardo AramburuÎncă nu există evaluări

- Variables and TypesDocument8 paginiVariables and TypesmefiestoÎncă nu există evaluări

- AWAP608HDocument2 paginiAWAP608HomerbinhussainÎncă nu există evaluări

- D T R E P L Y: Designtree Service Consultants Pvt. Ltd. Page 1 of 11Document11 paginiD T R E P L Y: Designtree Service Consultants Pvt. Ltd. Page 1 of 11waz ahmedÎncă nu există evaluări

- Bms Computer Karang Asem Timur: List Harga LaptopDocument1 paginăBms Computer Karang Asem Timur: List Harga LaptopBMS COMPUTERÎncă nu există evaluări

- Research Papers On Analog Integrated CircuitsDocument4 paginiResearch Papers On Analog Integrated Circuitsafmcmuugo100% (1)

- Lab Report FpgaDocument34 paginiLab Report FpgaMuhammad Furqan JavedÎncă nu există evaluări

- ST Micro M25P16 Serial FlashDocument40 paginiST Micro M25P16 Serial FlashAziz Maqtri100% (1)

- Geotechnical Core Drilling Tools Catalogue - NewDocument130 paginiGeotechnical Core Drilling Tools Catalogue - NewAdmir100% (1)

- MiCOM P44XDocument8 paginiMiCOM P44XMahesh YadaÎncă nu există evaluări

- Experiment On Basic Configuration of Cisco SwitchDocument3 paginiExperiment On Basic Configuration of Cisco SwitchCassandra ShafferÎncă nu există evaluări

- Mirici-155: Miniature Gigabit Ethernet Over Stm-1/Oc-3 ConverterDocument1 paginăMirici-155: Miniature Gigabit Ethernet Over Stm-1/Oc-3 Converterrafaelmartins2010Încă nu există evaluări

- Take Assessment1 15Document6 paginiTake Assessment1 15Rick CobbÎncă nu există evaluări

- NanoDiag PDFDocument8 paginiNanoDiag PDFQuarmina HesseÎncă nu există evaluări