Documente Academic

Documente Profesional

Documente Cultură

5060 Piping and Valves

Încărcat de

nmosilvaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

5060 Piping and Valves

Încărcat de

nmosilvaDrepturi de autor:

Formate disponibile

Additional Technical Requirements

Piping and Valve Specification Greater Ekofisk Field

ADDITIONAL REQUIREMENTS TO

THE NORSOK STANDARDS:

L-001 Piping and Valves

Disclaimer:

"The ConocoPhillips Norway specifications attached to this homepage are an unofficial and

uncontrolled version and are set forth for information purposes only. Contractors who have

contracts with ConocoPhillips Norway are advised that they must comply with the binding,

controlled version of the specifications set forth in their contracts with ConocoPhillips Norway,

and that they are responsible for ensuring proper compliance by their subcontractors with such

controlled version of the specifications".

For information please contact the following:

T.G.Tangeland tor.g.tangeland@conocophillips.com (TAG Piping)

S.T. Mohagen sverre.t.mohagen@conocophillips.com (TAG Material & Corrosion)

J.E. Stene jan.e.stene@conocophillips.com (TAG Valves)

H. Monsen henning.monsen@conocophillips.com (Leader Inspection Planning)

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

5060 0 20.02.2003 Dept.Director, Maint.

Page 1 of 9

Additional Technical Requirements

Piping and Valve Specification Greater Ekofisk Field

1 INTRODUCTION .....................................................................................................................3

1.1 Objective and Scope ..........................................................................................................................3

1.2 Responsibility and Ownership..........................................................................................................3

1.3 Approval.............................................................................................................................................3

1.4 Distribution ........................................................................................................................................3

1.5 Filing ...................................................................................................................................................3

1.6 Registration ........................................................................................................................................4

1.7 Definitions/Abbreviations .................................................................................................................4

1.7.1 Definitions................................................................................................................................................. 4

1.7.2 Abbreviations ............................................................................................................................................ 4

1.8 Normative References .......................................................................................................................5

1.8.1 Regulations................................................................................................................................................ 5

1.8.2 NORSOK Standards.................................................................................................................................. 5

1.8.3 ConocoPhillips References........................................................................................................................ 6

1.8.4 Standards ................................................................................................................................................... 6

1.9 Non-Conformances............................................................................................................................7

2 TECHNICAL REQUIREMENTS............................................................................................7

2.1 General ...............................................................................................................................................7

2.1.1 Introduction ............................................................................................................................................... 7

2.2 NORSOK L-001: Piping and Valves................................................................................................8

2.2.1 Piping Specifications................................................................................................................................ 8

2.2.2 Vendor Package Design ............................................................................................................................ 8

Annex 1

Piping and Valve Specification Greater Ekofisk Field ................................................................9

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

5060 0 20.02.2003 Dept.Director, Maint.

Page 2 of 9

Additional Technical Requirements

Piping and Valve Specification Greater Ekofisk Field

1 INTRODUCTION

1.1 Objective and Scope

This document identifies the additional technical requirements for topside piping systems

for:

new installations and

modification projects on existing facilities

in the Greater Ekofisk field.

This TCD2 document 5060 is based upon NORSOK L-001 and the EKO II document

KE-P-T-001.

This TCD2 document 5060 replaces NORSOK L-001 for all COPNOs installations,

except for ELDE where the original Eldfisk EWI (Aker Offshore Partner) Pipe Class

Sheets in document B875-AE-P-000014 still shall be used. The Aker document is partly

based upon NORSOK L-CR-001 Revision 1.

This document shall be read in conjunction with the regulations and supporting

documents, especially TCD2 4583, listed under section 1.8 Normative References.

1.2 Responsibility and Ownership

Leader Inspection Planning is the owner of this document and is

responsible for updating or withdrawal of the document as dictated by

organisational or operational changes.

1.3 Approval

The procedure is approved by the Department Director, Maintenance.

1.4 Distribution

This document is distributed electronically only.

1.5 Filing

The Record Copy (RC) is filed by Department for Information Logistics.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

5060 0 20.02.2003 Dept.Director, Maint.

Page 3 of 9

Additional Technical Requirements

Piping and Valve Specification Greater Ekofisk Field

1.6 Registration

The document is registered by its document number in COPNOs document

administration system, which is administrated by the Department for Information

Logistics.

1.7 Definitions/Abbreviations

1.7.1 Definitions

Interface engineering: Engineering required for tie-in of new / modified equipment

to old existing equipment or tie-ins between new equipment

installed by different Contractors.

Conform with: Follow the intent

Contractor: Provider of one or more of the following services directly to

Company: Engineering (E), Procurement (P), Construction,

Installation (I) and Commissioning.

Company: ConocoPhillips (COPNO)

Comply with: Fully adhere to

Sub-Contractor: Provider of services directly to Contractor(s)

Supplier Organisation or person that provides a product, for example;

producer, distributor, retailer or vendor of a product, or

provider of a service or information. A supplier can be

internal or external to the organisation. And in a contractual

situation a supplier is sometimes called sub-contractor.

TAG Technical responsible engineer in COPNO

1.7.2 Abbreviations

API American Petroleum Institute

COPNO ConocoPhillips Norge

Cu-Ni Copper-Nickel

CS Carbon-manganese steel

DFI Design, fabrication and installation

EDS Element Data Sheets

EKO II Ekofisk redevelopment with 2/4X and 2/4J

EKO I Greater Ekofisk Area installations built before EKO II

GRP Glass-fibre Reinforced Plastics

MDS Material data sheet

MDT Minimum design temperature

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

5060 0 20.02.2003 Dept.Director, Maint.

Page 4 of 9

Additional Technical Requirements

Piping and Valve Specification Greater Ekofisk Field

MF Mechanical Flowsheet, now termed P&ID

MSS Manufacturers Standardisation Society of the Valve and Fitting

Industry

NB Nominal Bore

NDE Non-Destructive Examination

NDT Non-Destructive Testing

NFPA National Fire Protection Association

NPD Norwegian Petroleum Directorate

NPT National (American) Standard Pipe Tread

NORSOK Norsk Sokkels Konkurranseposisjon

NSDP North Sea Design Premises (COPNO)

PCS Pipe Class Sheet

PED Pressure Equipment Directive

P&ID Process and Instrument Diagram

RF Raised face

RTJ Ring type joint

SS Stainless steel

TAG Technical responsible engineer in COPNO

UKOOA UK Offshore Operators Association

VDS Valve Data Sheet

1.8 Normative References

1.8.1 Regulations

Norwegian Petroleum Directorate:

- regulations

- guidelines.

Pressure Equipment Directive (97/23/EC)

1.8.2 NORSOK Standards

L-001 Piping and Valves

L-002 Piping Design, Layout and Stress Analysis

L-CR-003 Piping Details

L-CR-004 Piping Fabrication, Installation, Flushing and Pressure Testing

M-001 Material Selection

M-710 Qualification of non-metallic sealing materials and manufacturers

M-CR-621 GRP Piping Materials

M-501 Surface Preparation and Protective Coating

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

5060 0 20.02.2003 Dept.Director, Maint.

Page 5 of 9

Additional Technical Requirements

Piping and Valve Specification Greater Ekofisk Field

M-630 Material Data Sheets Piping

M-650 Qualification of Manufacturers of Special Materials

R-001 Mechanical Equipment

P-001 Process Design

H-CR-002 Piping and Plumbing

1.8.3 ConocoPhillips References

4314 Documents for Operation

4293 Surface Preparation and Protective Coating

4368 Material Data Sheets Piping

4472 Qualification of Manufacturers of Special Materials

4583 Piping Design Requirements for New Installations and Modification

to Exiting Facilities

4621 Material, Fabrication and Surface Treatment Requirements for

Procurement Packages

4650 Material Selection

4980 Welding and Inspection of Piping

B875-AE-P-00014 Piping Specifications for the Water Injection Project and

Modification Projects. Eldfisk (1)

(1) 2/7E project specification.

1.8.4 Standards

ASME B16.11 Forged fittings, socket-welding and threaded

ASME B16.48 Steel line blanks

ASME B16.5 Pipe Flanges and Flanged fittings

ASME B1.20.1 Pipe treads. General purpose (inch)

ASME B 31.3 Process piping

API 570 Piping Inspection Code. Inspection, Repair, Alteration, and Rerating

of In-Service Piping Systems

EN 13480 Metallic industrial piping

EN 764 Pressure Equipment

EN 1591 Flanges and their joints Design rules for gasketed circular flange

connections

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

5060 0 20.02.2003 Dept.Director, Maint.

Page 6 of 9

Additional Technical Requirements

Piping and Valve Specification Greater Ekofisk Field

ISO 15649 Petroleum and natural gas industries piping

BS 7159 Design and Construction of Glass Reinforced Plastics Piping

Systems for Individual Plants or Sites

DIN V 2505 Flanged Joint Calculation

1.9 Non-Conformances

This document contains both requirements and recommendations. Deviations from

requirements contained in this document shall be addressed to the position responsible

for this document, according to document no. 4920 Control of Non-Conformity.

Reporting according to procedure no. 4920 is not required for deviations from

recommendations. However, significant deviations shall be reported to the position

responsible for this document.

2 TECHNICAL REQUIREMENTS

2.1 General

Design of new installations and modifications to the existing facilities shall comply with

NPD regulations and guidelines which are relevant

Pressure Equipment Directive (97/23/EC)

and conform to:

ASME B31.3

API 570

this document.

If other designs/solutions are selected by the Designer, Manufacturer and

Fabricator/Erector (Contractor) than described in the referenced documents, the

selected designs/solutions shall be equal or better seen from a life cycle cost and

technical point of view. In case of doubt contact the relevant COPNO TAG engineer and

recommendation in writing will be given by COPNO, which is the sole judge. See

Section 1.9.

In case of conflicting requirements see TCD2 3759 Section 1.11.

2.1.1 Introduction

Original piping system designs on COPNO operated platforms have been to various sets

of specifications (e.g. Brown & Root, Worley, Kvaerner, Tecnomare etc.). In 1987 the

North Sea Design Premises (NSDP), section 12 Topside Piping Design was

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

5060 0 20.02.2003 Dept.Director, Maint.

Page 7 of 9

Additional Technical Requirements

Piping and Valve Specification Greater Ekofisk Field

introduced, and new platforms and modifications to exiting facilities and systems have

since 1987 been designed in accordance to the specifications given in the NSDP.

In 1994, NSDP was withdrawn as an official design requirement and was to the extent

possible replaced by the EKO II project and NORSOK specifications.

For 2/4X, 2/4J and the existing piping systems modified during the EKO II project, KE-P-

T-001 Piping and Valve Material Specification was applied.

For 2/7E and the existing piping systems modified during the Eldfisk EWI, B875-AE-P-

00014 Piping Specifications for the Water Injection Project and Modification Projects

was applied. This document contains basically plain NORSOK PCS (rev.1) but some

project specific PCSs were developed to cover the voids in NORSOK and some P-

PCSs were used.

In order to avoid a vast amount of project specifications a COPNO Piping and Valve

Specification Greater Ekofisk Field (TCD2 5060) was developed in 2002, based on

the EKO II and NORSOK specifications. Some of the unique P-specifications were also

included in TCD2 5060 for maintenance and modification use.

The TCD2 5060 Piping and Valve specification shall be used on all existing and new

COPNO installations. The only exception is 2/7E, which shall continue to use the original

project specification B875-AE-P-00014 for all modification work. However, the latest

revision of the referenced piping and valve specifications (PCS) in B875-AE-P-00014

shall be used (NORSOK and COPNO P-specifications in document TCD2 5060).

2.2 NORSOK L-001: Piping and Valves

This document TCD2 5060 Piping and Valve Specification Greater Ekofisk Field

replaces NORSOK L-001 for all existing and new COPNO installations except 2/7E,

which shall continue to use: B875-AE-P-00014 Piping Specifications for the Water

Injection Project and Modification Projects.

See Section 2.1.1 above.

2.2.1 Piping Specifications

Several COPNO P-specifications have been replaced by modified EKO II PCS. Some

P-specifications need to be retained due to special design features and/or materials in

use (e.g. CuNi). A cross-reference index for accepted specifications is given in Annex A

in TCD2 4583.

2.2.2 Vendor Package Design

For piping systems in vendor packages (equipment skids, etc.) the Piping Class Sheets

(PCS) in this document shall be used. See TCD2 4621 for additional requirements.

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

5060 0 20.02.2003 Dept.Director, Maint.

Page 8 of 9

Additional Technical Requirements

Piping and Valve Specification Greater Ekofisk Field

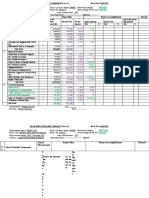

Annex 1

Piping and Valve Specification Greater Ekofisk Field

SECTION 1: GENERAL

SECTION 2: SERVICE CODE

SECTION 3: PIPING CLASS SHEET

SECTION 4: ELEMENT DATA SHEET

SECTION 5: VALVE SELECTION MANUAL

SECTION 6: VALVE DATA SHEET

SECTION 7: VALVE SPECIFICATION

SECTION 8: MATERIAL DATA SHEET

DOCUMENT NO.: REVISION NO.: REVISION DATE: APPROVED:

5060 0 20.02.2003 Dept.Director, Maint.

Page 9 of 9

S-ar putea să vă placă și

- Caliper Presentation Pig LauncherDocument34 paginiCaliper Presentation Pig LauncherMix VichaitanapatÎncă nu există evaluări

- BS en Iso 6553-2017Document14 paginiBS en Iso 6553-2017GT-LUCAS BARCIÎncă nu există evaluări

- NT 109.15 PDFDocument29 paginiNT 109.15 PDFBrahim BahriÎncă nu există evaluări

- NorsokDocument133 paginiNorsokNuzuliana EnuzÎncă nu există evaluări

- Sa 980 P 11409 Ultrasonic Flowmeter Rev t02Document3 paginiSa 980 P 11409 Ultrasonic Flowmeter Rev t02altipatlarÎncă nu există evaluări

- Technical Recommendations For Choke Valve SpecificationsDocument7 paginiTechnical Recommendations For Choke Valve SpecificationsajaysapruÎncă nu există evaluări

- Norsok L-002 Piping System Layout, Design and StructuralDocument36 paginiNorsok L-002 Piping System Layout, Design and Structuralkhaireddin50% (2)

- Mokveld Brochure Angle Choke ValveDocument16 paginiMokveld Brochure Angle Choke ValvekglorstadÎncă nu există evaluări

- Technical Requisition FMSDocument33 paginiTechnical Requisition FMSgiribabuÎncă nu există evaluări

- PD Iso-Tr 15377-2023 - (2023-11-29 - 10-16-03 Am)Document38 paginiPD Iso-Tr 15377-2023 - (2023-11-29 - 10-16-03 Am)Luís SilvaÎncă nu există evaluări

- IMIOrton MV SeriesDocument4 paginiIMIOrton MV SeriesFelipe Gamboa GálvezÎncă nu există evaluări

- Calculate Flow Rate From Differential PressureDocument27 paginiCalculate Flow Rate From Differential PressureThang Hoang Anh100% (1)

- PFS WedgeDocument26 paginiPFS WedgeMontheardÎncă nu există evaluări

- Norsok U-001 Rev 3 2002Document15 paginiNorsok U-001 Rev 3 2002lutfirashid87Încă nu există evaluări

- 5 Foam PigsDocument13 pagini5 Foam PigsLuis R MartínezÎncă nu există evaluări

- Monobore Sub SeaDocument9 paginiMonobore Sub Seacamilo777Încă nu există evaluări

- Elastopipe A Flexible Piping SystemDocument2 paginiElastopipe A Flexible Piping SystemRuano StumpfÎncă nu există evaluări

- Brazil StatutoryDocument2 paginiBrazil Statutorydaus nasÎncă nu există evaluări

- NORSOKDocument38 paginiNORSOKAnonymous YSA8CZ0Tz5Încă nu există evaluări

- SOFEC CALM BUOY FINAL 3page RedDocument3 paginiSOFEC CALM BUOY FINAL 3page RedJ. Jorge TorresÎncă nu există evaluări

- Catalogue 2019Document450 paginiCatalogue 2019AntonÎncă nu există evaluări

- NORSOK Standard U-001r2Document10 paginiNORSOK Standard U-001r2Eileen WongÎncă nu există evaluări

- Bornemann MultiphaseDocument24 paginiBornemann MultiphaseReza Ghanavati100% (1)

- Canalta DBB Product Manual - LOW RESDocument12 paginiCanalta DBB Product Manual - LOW RESFer VFÎncă nu există evaluări

- Shaft Alignment - Vibration Analysis - OutlineDocument4 paginiShaft Alignment - Vibration Analysis - OutlineElias RizkÎncă nu există evaluări

- Versa ValveDocument24 paginiVersa ValvetalangocdayÎncă nu există evaluări

- Norsok H 003Document22 paginiNorsok H 003Kunal KapoorÎncă nu există evaluări

- Z 015 2004Document54 paginiZ 015 2004mreavy7399Încă nu există evaluări

- HippsDocument31 paginiHippsAjaykumar TiwariÎncă nu există evaluări

- DNV Os-E201 - 2012-12Document1 paginăDNV Os-E201 - 2012-12Muthu KumarÎncă nu există evaluări

- Norsok L-004-CR Ror OgDocument29 paginiNorsok L-004-CR Ror OgWissam Jarmak100% (2)

- Norsok Z-004 CAD SymbolsDocument162 paginiNorsok Z-004 CAD Symbolssebastinsk100% (5)

- Norsok Standard ListsDocument3 paginiNorsok Standard Listsdondo1004100% (3)

- Integrity Testing of Water Filtration Membrane Systems: Standard Practice ForDocument14 paginiIntegrity Testing of Water Filtration Membrane Systems: Standard Practice ForOh No PotatoÎncă nu există evaluări

- Total Pms Scope of Work: Days Start Date End DateDocument6 paginiTotal Pms Scope of Work: Days Start Date End DateElhamy M. SobhyÎncă nu există evaluări

- Tuv Nel - Evaluation of Roxar MPFM2600 Multiphase Flowmeter PDFDocument23 paginiTuv Nel - Evaluation of Roxar MPFM2600 Multiphase Flowmeter PDFReza GhanavatiÎncă nu există evaluări

- DBB Datasheet WHRP PDFDocument48 paginiDBB Datasheet WHRP PDFRajendraÎncă nu există evaluări

- Seat Leakage Article Valve WorldDocument2 paginiSeat Leakage Article Valve WorldjshadwanÎncă nu există evaluări

- USB - Ole Gjerstad - SUT - Manifolds and Connections May 2014Document76 paginiUSB - Ole Gjerstad - SUT - Manifolds and Connections May 2014solicoco100% (1)

- V8 Import Spreadsheet Rev 11Document5.363 paginiV8 Import Spreadsheet Rev 11Raymond de WeeverÎncă nu există evaluări

- Norsok T 003Document22 paginiNorsok T 003erstendrainÎncă nu există evaluări

- Project Standards and Specifications Pig Catcher Package Rev01Document9 paginiProject Standards and Specifications Pig Catcher Package Rev01hiyeonÎncă nu există evaluări

- Iso 91 2017Document22 paginiIso 91 2017anitagissellatapiaÎncă nu există evaluări

- Comparison OCIMF 2009 and OCIMF 1991Document14 paginiComparison OCIMF 2009 and OCIMF 1991Rashidi Yaakob100% (1)

- Norsok L-CR-003Document41 paginiNorsok L-CR-003asoka.pwÎncă nu există evaluări

- Preq - Al Jaber Engineering - Wiltz - TemboDocument292 paginiPreq - Al Jaber Engineering - Wiltz - Tembo721917114 47Încă nu există evaluări

- Pipeline Field Joint CoatingDocument38 paginiPipeline Field Joint CoatingObinna Francis Mgbojikwe100% (2)

- Q2118121 01 El Bod 00001Document11 paginiQ2118121 01 El Bod 00001haitam terribleÎncă nu există evaluări

- Data Network and Digital Microwave Radio Installation Operation, and Maintenance ManualDocument217 paginiData Network and Digital Microwave Radio Installation Operation, and Maintenance Manualselamet riantoÎncă nu există evaluări

- Statoil TR0042 Version 4Document14 paginiStatoil TR0042 Version 4BlainÎncă nu există evaluări

- C 84514 BK KK0 PRO GN 00 0014 Subsea Pre Commissioning Procedure - Rev.0BDocument65 paginiC 84514 BK KK0 PRO GN 00 0014 Subsea Pre Commissioning Procedure - Rev.0BFAR_A_DAY100% (3)

- Petroleum Development Oman L.L.C.: (AMENDMENTS/SUPPLEMENTS TO ISO 15590-2: 2003)Document19 paginiPetroleum Development Oman L.L.C.: (AMENDMENTS/SUPPLEMENTS TO ISO 15590-2: 2003)Sapana MallaÎncă nu există evaluări

- Specification For Instrument Cables PDFDocument39 paginiSpecification For Instrument Cables PDFNishanthÎncă nu există evaluări

- 12-MGDP-T-1037-0 (Spec For Fiber Optic Cable)Document32 pagini12-MGDP-T-1037-0 (Spec For Fiber Optic Cable)cherif yahyaouiÎncă nu există evaluări

- Sow No.e03th012021000.07 - Epc For Osbl Rev.2Document15 paginiSow No.e03th012021000.07 - Epc For Osbl Rev.2watanapomgÎncă nu există evaluări

- MQ SP P 5028 PDFDocument10 paginiMQ SP P 5028 PDFjaseelÎncă nu există evaluări

- MDR Manufacturers Data Report InfoDocument13 paginiMDR Manufacturers Data Report InfoSaut Maruli Tua Samosir100% (4)

- SP-1208 - Sep 2005 PIPELINE - CONSTRUCTION - SPECIFICATION - (PCS-01) - SP-1208Document125 paginiSP-1208 - Sep 2005 PIPELINE - CONSTRUCTION - SPECIFICATION - (PCS-01) - SP-1208Vignesh Naidu69% (13)

- Inspection and Shipping Minimum Requirements For Contractor/VendorDocument17 paginiInspection and Shipping Minimum Requirements For Contractor/Vendortomas budrysÎncă nu există evaluări

- KJO 3412 v3 (Aprvd) - Engineering Procedure For Certification PDFDocument21 paginiKJO 3412 v3 (Aprvd) - Engineering Procedure For Certification PDFmunirÎncă nu există evaluări

- Jovanovic - Comparison Between The New European Risk-Based Inspection (RBI) Standard EN16991 2018Document65 paginiJovanovic - Comparison Between The New European Risk-Based Inspection (RBI) Standard EN16991 2018nmosilvaÎncă nu există evaluări

- Criticality Analysis For Assets Priority Setting of Abadan Oil Refinery Using AHP and DelphiDocument7 paginiCriticality Analysis For Assets Priority Setting of Abadan Oil Refinery Using AHP and DelphinmosilvaÎncă nu există evaluări

- D2Z Angled Armrest Wedges Key InformationDocument4 paginiD2Z Angled Armrest Wedges Key InformationnmosilvaÎncă nu există evaluări

- Ageing of Hazardous InstallationsDocument34 paginiAgeing of Hazardous InstallationsnmosilvaÎncă nu există evaluări

- Iaea Safety Standards and Other Publications For Ageing Maanagement and Long Term Operation of Nuclear Power PlantsDocument12 paginiIaea Safety Standards and Other Publications For Ageing Maanagement and Long Term Operation of Nuclear Power PlantsnmosilvaÎncă nu există evaluări

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 paginăGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaÎncă nu există evaluări

- Csni r2002 26Document32 paginiCsni r2002 26nmosilvaÎncă nu există evaluări

- Triathlon Strength Training GuideDocument5 paginiTriathlon Strength Training Guidenmosilva100% (1)

- The All-New Speed Concept: The Fastest Bike Just Got FasterDocument40 paginiThe All-New Speed Concept: The Fastest Bike Just Got FasternmosilvaÎncă nu există evaluări

- Garlock Gasketing GYLON Standard Style 3501-E 2.0mm DIN EN13555 Datasheet Rev.3 KU25318 en EU LRDocument3 paginiGarlock Gasketing GYLON Standard Style 3501-E 2.0mm DIN EN13555 Datasheet Rev.3 KU25318 en EU LRnmosilvaÎncă nu există evaluări

- Trek-Seed PconceptDocument36 paginiTrek-Seed PconceptnmosilvaÎncă nu există evaluări

- TK18 Madone Whitepaper en-GBDocument30 paginiTK18 Madone Whitepaper en-GBnmosilvaÎncă nu există evaluări

- Characterization of Gaskets Flange ConnectionsDocument18 paginiCharacterization of Gaskets Flange ConnectionsnmosilvaÎncă nu există evaluări

- Ppcon Additional Technical RequirementsDocument13 paginiPpcon Additional Technical RequirementsnmosilvaÎncă nu există evaluări

- Strength BiasDocument11 paginiStrength BiasnmosilvaÎncă nu există evaluări

- Official Crossfit Warm-Up Warm Up DDocument1 paginăOfficial Crossfit Warm-Up Warm Up DnmosilvaÎncă nu există evaluări

- Journal: Scaling: How Less Can Be MoreDocument8 paginiJournal: Scaling: How Less Can Be MorenmosilvaÎncă nu există evaluări

- 4621 Rev 01Document11 pagini4621 Rev 01nmosilvaÎncă nu există evaluări

- PressureReliefValves SpecsDocument11 paginiPressureReliefValves SpecsnmosilvaÎncă nu există evaluări

- NHT-P51-00032 04MDocument937 paginiNHT-P51-00032 04MnmosilvaÎncă nu există evaluări

- Angus Thermospray NozzleDocument1 paginăAngus Thermospray NozzlenmosilvaÎncă nu există evaluări

- Api 1120Document17 paginiApi 1120nmosilva100% (2)

- Data Performance 2Document148 paginiData Performance 2Ibnu Abdillah MuhammadÎncă nu există evaluări

- Astm A712 PDFDocument3 paginiAstm A712 PDFCristian OtivoÎncă nu există evaluări

- Umur Ekonomis Mesin RevDocument3 paginiUmur Ekonomis Mesin Revrazali akhmadÎncă nu există evaluări

- Technology For Teaching and Learning 2 OBE SyllabusDocument9 paginiTechnology For Teaching and Learning 2 OBE Syllabusjesreel canalÎncă nu există evaluări

- Cooling Tower (Genius)Document7 paginiCooling Tower (Genius)JeghiÎncă nu există evaluări

- Quarterly Progress Report FormatDocument7 paginiQuarterly Progress Report FormatDegnesh AssefaÎncă nu există evaluări

- RCM Design and ImplementationDocument34 paginiRCM Design and ImplementationRozi YudaÎncă nu există evaluări

- Power of AttorneyDocument10 paginiPower of AttorneyRocketLawyer82% (17)

- RB Boiler Product SpecsDocument4 paginiRB Boiler Product Specsachmad_silmiÎncă nu există evaluări

- 1 BSC Iriigation Engineering 2018 19 Std1Document70 pagini1 BSC Iriigation Engineering 2018 19 Std1Kwasi BempongÎncă nu există evaluări

- Full Bridge Phase Shift ConverterDocument21 paginiFull Bridge Phase Shift ConverterMukul ChoudhuryÎncă nu există evaluări

- MSU-Iligan Institute of TechnologyDocument5 paginiMSU-Iligan Institute of TechnologyYuvi Rociandel LUARDOÎncă nu există evaluări

- Equine Anesthesia Course NotesDocument15 paginiEquine Anesthesia Course NotesSam Bot100% (1)

- Phenotype and GenotypeDocument7 paginiPhenotype and GenotypeIrish Claire Molina TragicoÎncă nu există evaluări

- Keygene Strengthens Its Patent Portfolio On Keypoint Mutation BreedingDocument1 paginăKeygene Strengthens Its Patent Portfolio On Keypoint Mutation Breedingapi-99034713Încă nu există evaluări

- ME-317 Internal Combustion Engines - TurbochargingDocument21 paginiME-317 Internal Combustion Engines - TurbochargingHamzaJavedÎncă nu există evaluări

- 348 - Ct-Tol Toluene TdsDocument1 pagină348 - Ct-Tol Toluene Tdsonejako12Încă nu există evaluări

- Pentacam Four Maps RefractiveDocument4 paginiPentacam Four Maps RefractiveSoma AlshokriÎncă nu există evaluări

- Leadership PresentationDocument10 paginiLeadership Presentationapi-404415990Încă nu există evaluări

- Multilevel Full Mock Test 5: Telegramdagi KanalDocument20 paginiMultilevel Full Mock Test 5: Telegramdagi KanalShaxzod AxmadjonovÎncă nu există evaluări

- Dam Lecture 14 - Design Criteria Earth DamsDocument4 paginiDam Lecture 14 - Design Criteria Earth DamsCarolineMwitaMoseregaÎncă nu există evaluări

- Human Rights Law - Yasin vs. Hon. Judge Sharia CourtDocument7 paginiHuman Rights Law - Yasin vs. Hon. Judge Sharia CourtElixirLanganlanganÎncă nu există evaluări

- Project PlanDocument55 paginiProject PlanAlfredo SbÎncă nu există evaluări

- For Hand Grip Strength: NormsDocument7 paginiFor Hand Grip Strength: NormsPraneethaÎncă nu există evaluări

- Faculty Based Bank Written PDFDocument85 paginiFaculty Based Bank Written PDFTamim HossainÎncă nu există evaluări

- Perioperative Care For CABG PatientsDocument32 paginiPerioperative Care For CABG PatientsAya EyadÎncă nu există evaluări

- Installation Manual (DH84309201) - 07Document24 paginiInstallation Manual (DH84309201) - 07mquaiottiÎncă nu există evaluări

- Wa0016Document3 paginiWa0016Vinay DahiyaÎncă nu există evaluări

- Biology 2 Chapter 4Document61 paginiBiology 2 Chapter 4Malas Nak TaipÎncă nu există evaluări

- BS7-Touch Screen PanelDocument96 paginiBS7-Touch Screen PanelEduardo Diaz Pichardo100% (1)