Documente Academic

Documente Profesional

Documente Cultură

Celanex 3316

Încărcat de

klausoshoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Celanex 3316

Încărcat de

klausoshoDrepturi de autor:

Formate disponibile

CELANEX 3316 | PBT | Glass Reinforced

Description

Celanex 3316 is a non-exuding flame retarded (UL and CSA approved V-0 at 1/32 inch and 5V at 1/16 inch), 30% fiberglass

reinforced polybutylene terephthalate which has an excellent balance of mechanical properties and processability. It is well

suited for electrical connector applications where its UL approved 50% regrind use capability allows maximum use of

purchased product.

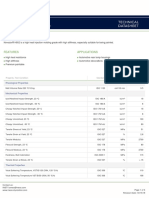

Physical properties Value Unit Test Standard

Density 1660 kg/m ISO 1183

Melt volume rate (MVR) 7 cm/10min ISO 1133

MVR test temperature 250 C ISO 1133

MVR test load 2.16 kg ISO 1133

Mold shrinkage - parallel 0.3-0.5 % ISO 294-4

Water absorption (23C-sat) 0.4 % ISO 62

Humidity absorption (23C/50%RH) 0.2 % ISO 62

Mechanical properties Value Unit Test Standard

Tensile modulus (1mm/min) 10700 MPa ISO 527-2/1A

Tensile stress at break (5mm/min) 135 MPa ISO 527-2/1A

Tensile strain at break (5mm/min) 2.5 % ISO 527-2/1A

Flexural modulus (23C) 10300 MPa ISO 178

Flexural strength (23C) 200 MPa ISO 178

Charpy impact strength @ 23C 42 kJ/m ISO 179/1eU

Charpy impact strength @ -30C 42 kJ/m ISO 179/1eU

Charpy notched impact strength @ 23C 8.5 kJ/m ISO 179/1eA

Charpy notched impact strength @ -30C 8.5 kJ/m ISO 179/1eA

Notched impact strength (Izod) @ 23C 7.7 kJ/m ISO 180/1A

Rockwell hardness 89 M-Scale ISO 2039-2

Thermal properties Value Unit Test Standard

Melting temperature (10C/min) 225 C ISO 11357-1,-2,-3

DTUL @ 1.8 MPa 208 C ISO 75-1/-2

DTUL @ 0.45 MPa 220 C ISO 75-1/-2

DTUL @ 8.0 MPa 165 C ISO 75-1/-2

Vicat softening temperature B50 (50C/h 50N) 225 C ISO 306

Coeff.of linear therm. expansion (parallel) 0.25 E-4/C ISO 11359-2

Coeff.of linear therm. expansion (normal) 0.77 E-4/C ISO 11359-2

Limiting oxygen index (LOI) 30 % ISO 4589

Flammability at thickness h V-0 class UL94

thickness tested (h) 0.38 mm UL94

Flammability 5V at thickness h 5VA class UL94

thickness tested (5V) 1.5 mm UL94

Electrical properties Value Unit Test Standard

Relative permittivity - 100 Hz 4 - IEC 60250

Relative permittivity - 1 MHz 3.6 - IEC 60250

Dissipation factor - 100 Hz 33 E-4 IEC 60250

Dissipation factor - 1 MHz 145 E-4 IEC 60250

Volume resistivity 1E13 Ohm*m IEC 60093

Surface resistivity 1E15 Ohm IEC 60093

Printed: 12. January 2007 Page: 1

Ticona - A business of Celanese

CELANEX 3316 | PBT | Glass Reinforced

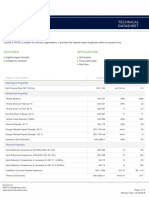

Electrical properties Value Unit Test Standard

Electric strength 34 kV/mm IEC 60243-1

Comparative tracking index CTI 225 - IEC 60112

Test specimen production Value Unit Test Standard

Processing conditions acc. ISO 7792-2 - Internal

Injection molding melt temperature 260 C ISO 294

Injection molding mold temperature 82 C ISO 294

Injection molding flow front velocity 300 mm/s ISO 294

Injection molding hold pressure 48 MPa ISO 294

Viscosity-shear rate Shearstress-shear rate

Printed: 12. January 2007 Page: 2

Ticona - A business of Celanese

CELANEX 3316 | PBT | Glass Reinforced

Stress-strain Secant modulus-strain

Typical injection moulding processing conditions

Maximum residual moisture content: 0.0200%

Processing Temperatures:

Cavity Melt Hot Runner Die 4 3 2 1 Feeding Hopper

min (C) 65 235 250 240 240 235 235 230 230 20

max (C) 96 255 260 255 255 250 250 240 240 50

Processing Pressures:

No info

Injection speed: medium - fast

Printed: 12. January 2007 Page: 3

Ticona - A business of Celanese

CELANEX 3316 | PBT | Glass Reinforced

Screw speed:

Screw diameter (mm) 25 40 55

Screw speed (rpm) 90 75 60

Pre-drying conditions:

To avoid hydrolytic degradation during processing, CELANEX resins have to be dried to a moisture level equal to or less than

0.02%. Drying should be done in a dehumidifying hopper dryer capable of dewpoints <-40F (-40C) at 250F (121C) for 4

hours.

For subsequent storage of the material in the dryer until processed (<= 60 h) it is necessary to lower the temperature to 100

C.

Drying time: 4 h

Drying temperature: 120 - 130 C

Special information:

Heating the hopper may be advantageous.

In case of reinforced materials:

For moulded parts with high demands to the surface quality: Tw = 110 C (230 F)

Injection Molding

Rear Temperature 450-470(230-240) deg F (deg C)

Center Temperature 460-480(235-250) deg F (deg C)

Front Temperature 470-490(240-255) deg F (deg C)

Nozzle Temperature 480-490(250-255) deg F (deg C)

Melt Temperature 460-490(235-255) deg F (deg C)

Mold Temperature 150-200(65-93) deg F (deg C)

Back Pressure 0-50 psi

Screw Speed Medium

Injection Speed Fast

Injection speed, injection pressure and holding pressure have to be optimized to the individual article geometry. To avoid

material degradation during processing low back pressure and minimum screw speed have to be used. Overheating of the

material has to be avoided, in particular for flame retardant grades. Up to 50% clean and dry regrind may be used for the 16

series flame retardant grades.

Contact Information

Americas Europe

Ticona Ticona GmbH

Product Information Service Information Service

8040 Dixie Highway Tel.: +49 (0) 180-5842662 (Germany)*

Florence, KY 41042 +49 (0) 69-30516299 (Europe)

USA Fax: +49 (0) 180-2021202 (Germany & Europe)**

Tel.: +1-800-833-4882 email: infoservice@ticona.de

Tel.: +1-859-372-3244 Internet: www.ticona.com

email: prodinfo@ticona.com

Ticona on the web: www.ticona.com *starting 01.01.2007 0,14/minute + local landline rates

**0,06/Call + local landline rates

Customer Service

Printed: 12. January 2007 Page: 4

Ticona - A business of Celanese

CELANEX 3316 | PBT | Glass Reinforced

Tel.: +1-800-526-4960

Tel.: +1-859-372-3214

Fax: +1-859-372-3125

General Disclaimer

NOTICE TO USERS: Values shown are based on testing of laboratory test specimens and represent data that fall within the standard range

of properties for natural material. These values alone do not represent a sufficient basis for any part design and are not intended for use in

establishing maximum, minimum, or ranges of values for specification purposes. Colorants or other additives may cause significant variations

in data values.

Properties of molded parts can be influenced by a wide variety of factors including, but not limited to, material selection, additives, part

design, processing conditions and environmental exposure. Any determination of the suitability of a particular material and part design for any

use contemplated by the users and the manner of such use is the sole responsibility of the users, who must assure themselves that the

material as subsequently processed meets the needs of their particular product or use.

To the best of our knowledge, the information contained in this publication is accurate; however, we do not assume any liability whatsoever for

the accuracy and completeness of such information. The information contained in this publication should not be construed as a promise or

guarantee of specific properties of our products. It is the sole responsibility of the users to investigate whether any existing patents are

infringed by the use of the materials mentioned in this publication.

Moreover, there is a need to reduce human exposure to many materials to the lowest practical limits in view of possible adverse effects. To

the extent that any hazards may have been mentioned in this publication, we neither suggest nor guarantee that such hazards are the only

ones that exist. We recommend that persons intending to rely on any recommendation or to use any equipment, processing technique or

material mentioned in this publication should satisfy themselves that they can meet all applicable safety and health standards.

We strongly recommend that users seek and adhere to the manufacturers current instructions for handling each material they use, and

entrust the handling of such material to adequately trained personnel only. Please call the telephone numbers listed (+49 (0) 69 30516299 for

Europe and +1 859-372-3244 for the Americas) for additional technical information. Call Customer Services for the appropriate Materials

Safety Data Sheets (MSDS) before attempting to process our products.

The products mentioned herein are not intended for use in medical or dental implants.

Copyright 2007, Ticona, all rights reserved. (Pub. 02-Jan-2007)

Printed: 12. January 2007 Page: 5

Ticona - A business of Celanese

S-ar putea să vă placă și

- Celanex 3300-2 PBTDocument3 paginiCelanex 3300-2 PBTDiegoTierradentroÎncă nu există evaluări

- R42000249GKF - Celanex 2003 - PBT - TDSDocument4 paginiR42000249GKF - Celanex 2003 - PBT - TDSCarlos AgianiÎncă nu există evaluări

- Makrolon® 2805Document8 paginiMakrolon® 2805Dridi BadredineÎncă nu există evaluări

- Bayer Makrolon 2407Document3 paginiBayer Makrolon 2407DiegoTierradentro100% (1)

- CELANEX® 2000-K-EnDocument3 paginiCELANEX® 2000-K-EnCarlos AgianiÎncă nu există evaluări

- TDS MakrolonET3113Document3 paginiTDS MakrolonET3113It WittayaÎncă nu există evaluări

- PocanB3235000000 GF30 1Document5 paginiPocanB3235000000 GF30 1rihabÎncă nu există evaluări

- TerluranGP 22Document5 paginiTerluranGP 22Chu ChuÎncă nu există evaluări

- Asa Ineos Styrolution Europe GMBH: Luran® S 776seDocument6 paginiAsa Ineos Styrolution Europe GMBH: Luran® S 776sebobÎncă nu există evaluări

- ABS - Novodur P2HGVDocument2 paginiABS - Novodur P2HGVarmandoÎncă nu există evaluări

- 2024 03 06 TDS Elastollan1185ADocument4 pagini2024 03 06 TDS Elastollan1185AChaker AbdellatifÎncă nu există evaluări

- HOSTAFORM® C 9021 TF-enDocument4 paginiHOSTAFORM® C 9021 TF-enshahin_723Încă nu există evaluări

- Riteflex 640aDocument3 paginiRiteflex 640aazaleaemersonÎncă nu există evaluări

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 paginiNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrÎncă nu există evaluări

- 76 StyrolutionPS454NDocument5 pagini76 StyrolutionPS454N59074Încă nu există evaluări

- Campus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHDocument2 paginiCampus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHAngererÎncă nu există evaluări

- Terluran GP35Document5 paginiTerluran GP35cristinamss33Încă nu există evaluări

- HOSTAFORM® C 27021 - POM - Unfilled: DescriptionDocument5 paginiHOSTAFORM® C 27021 - POM - Unfilled: Descriptionrahul vermaÎncă nu există evaluări

- Luran S757 GDocument5 paginiLuran S757 GPeter EvansÎncă nu există evaluări

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 paginiNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezÎncă nu există evaluări

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 paginiLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobÎncă nu există evaluări

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 paginiLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaÎncă nu există evaluări

- CELCONM90Document5 paginiCELCONM90DiegoTierradentroÎncă nu există evaluări

- CELCON® M90-EnDocument8 paginiCELCON® M90-EnJosue OrtizÎncă nu există evaluări

- Emerge™ Pc/Abs 7740: Technical InformationDocument3 paginiEmerge™ Pc/Abs 7740: Technical InformationbobÎncă nu există evaluări

- Product Texts: P:Partial BreakDocument8 paginiProduct Texts: P:Partial BreakDridi BadredineÎncă nu există evaluări

- TDS PC - LEXAN+141R - enDocument2 paginiTDS PC - LEXAN+141R - enSơn Nguyễn ĐắcÎncă nu există evaluări

- Elix ABS E401: Technical InformationDocument3 paginiElix ABS E401: Technical InformationDiegoTierradentroÎncă nu există evaluări

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 paginiCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinÎncă nu există evaluări

- CAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 TiconaDocument2 paginiCAMPUS® Datasheet: CELANEX LW2333R - PBT - (GB+GF) 50 TiconaAngererÎncă nu există evaluări

- Technyl Safe C 116FC NCDocument3 paginiTechnyl Safe C 116FC NCkls.thorodinsonÎncă nu există evaluări

- Luran 368 RDocument5 paginiLuran 368 RmucahitkaraballÎncă nu există evaluări

- CELANEX® 1600a-EnDocument4 paginiCELANEX® 1600a-EnleftpowtaÎncă nu există evaluări

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Document3 paginiStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoÎncă nu există evaluări

- Makrolon Solid Flame Retardant Polycarbonate Sheet: Your BenefitsDocument2 paginiMakrolon Solid Flame Retardant Polycarbonate Sheet: Your BenefitsAbdelmajid HmÎncă nu există evaluări

- ABS Terlux 2802 TR - Fiche Technique enDocument2 paginiABS Terlux 2802 TR - Fiche Technique endamien_roule5728Încă nu există evaluări

- Elix ABS M220: Technical InformationDocument3 paginiElix ABS M220: Technical InformationDiegoTierradentroÎncă nu există evaluări

- Elix ABS P2M-AT: Technical InformationDocument3 paginiElix ABS P2M-AT: Technical InformationDiegoTierradentroÎncă nu există evaluări

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 paginiCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererÎncă nu există evaluări

- Novodur P2H-ATDocument3 paginiNovodur P2H-ATavinashchauhan2695Încă nu există evaluări

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pagini(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluÎncă nu există evaluări

- Luran HH-120: Please SelectDocument3 paginiLuran HH-120: Please SelectDavid Costi da RosaÎncă nu există evaluări

- SABIC® PPcompound - H1030 - Global - Technical - Data - SheetDocument2 paginiSABIC® PPcompound - H1030 - Global - Technical - Data - SheetRobertoÎncă nu există evaluări

- Ultradur B2520Document2 paginiUltradur B2520Phung LucÎncă nu există evaluări

- Dupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinDocument6 paginiDupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinomarÎncă nu există evaluări

- Ultramid: Product Information ®Document2 paginiUltramid: Product Information ®muthuÎncă nu există evaluări

- StyrolutionTDS400700190196 PDFDocument3 paginiStyrolutionTDS400700190196 PDFMirella FaresÎncă nu există evaluări

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 paginiLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezÎncă nu există evaluări

- Policarbonato Teijin Panlite Ad-5503Document1 paginăPolicarbonato Teijin Panlite Ad-5503marioÎncă nu există evaluări

- Bayblend T85 XF ISO enDocument3 paginiBayblend T85 XF ISO enryanÎncă nu există evaluări

- PBT - Lanxess Pocan B3235 000000Document3 paginiPBT - Lanxess Pocan B3235 000000armandoÎncă nu există evaluări

- Torelina® A490MA50: Toray Resin CompanyDocument2 paginiTorelina® A490MA50: Toray Resin CompanyChunYenHuangÎncă nu există evaluări

- Pe-Uhmw Technical Data SheetDocument1 paginăPe-Uhmw Technical Data SheetPrashant MalikÎncă nu există evaluări

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 paginiStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoÎncă nu există evaluări

- LANXESS Durethan A30SFN31 000000 ISO ENDocument3 paginiLANXESS Durethan A30SFN31 000000 ISO ENNguyen Dinh VinhÎncă nu există evaluări

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 paginiTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobÎncă nu există evaluări

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Document3 paginiBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoÎncă nu există evaluări

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 paginiUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoÎncă nu există evaluări

- Kynar Flex® 2800-20 ResinDocument5 paginiKynar Flex® 2800-20 ResinmohammedÎncă nu există evaluări

- Tutorial - 2 - Structural Static Simulation Using Altair SimLabDocument19 paginiTutorial - 2 - Structural Static Simulation Using Altair SimLabklausoshoÎncă nu există evaluări

- !learning Digital PhotographyDocument55 pagini!learning Digital PhotographyklausoshoÎncă nu există evaluări

- Tutorial - 1 - Heat Transfer Simulation Using Altair SimLabDocument17 paginiTutorial - 1 - Heat Transfer Simulation Using Altair SimLabklausoshoÎncă nu există evaluări

- 2019 DYNAmore Seminarbrochure e PDFDocument64 pagini2019 DYNAmore Seminarbrochure e PDFklausoshoÎncă nu există evaluări

- FE Simulation of Ultrasonic Vibrations in TurningDocument11 paginiFE Simulation of Ultrasonic Vibrations in TurningklausoshoÎncă nu există evaluări

- Speos Light Modeling v15.1Document251 paginiSpeos Light Modeling v15.1klausoshoÎncă nu există evaluări

- 2019 DYNAmore Seminarbrochure e PDFDocument64 pagini2019 DYNAmore Seminarbrochure e PDFklausoshoÎncă nu există evaluări

- 2018 DYNAmore Seminar Brochure EDocument64 pagini2018 DYNAmore Seminar Brochure EklausoshoÎncă nu există evaluări

- Rivets Web5116 PDFDocument61 paginiRivets Web5116 PDFklausoshoÎncă nu există evaluări

- True Stress-Strain ME 207 - Chapter 3 - P3Document13 paginiTrue Stress-Strain ME 207 - Chapter 3 - P3klausoshoÎncă nu există evaluări

- Schaums 2500 Problemas Resueltos de Mecanica de Fluidos e HidrulicaDocument807 paginiSchaums 2500 Problemas Resueltos de Mecanica de Fluidos e HidrulicaJ Andres Gonzalez83% (23)

- Friction Stir WeldingDocument17 paginiFriction Stir WeldingklausoshoÎncă nu există evaluări

- Finite Element Aanalysis - David W. NicholsonDocument271 paginiFinite Element Aanalysis - David W. NicholsonkeyvenÎncă nu există evaluări

- ESBEmixing DanfossDocument4 paginiESBEmixing Danfosse-ComfortUSAÎncă nu există evaluări

- Enabling Fingerprint Authentication in Embedded Systems For Wireless ApplicationsDocument11 paginiEnabling Fingerprint Authentication in Embedded Systems For Wireless Applicationspatilrahul100% (2)

- StrippersDocument6 paginiStrippersDiliniÎncă nu există evaluări

- CASANOVA + HERNANDEZ + "SON" Engineering & ConstructionDocument68 paginiCASANOVA + HERNANDEZ + "SON" Engineering & ConstructionMica Mico100% (1)

- ETAG006 2finDocument66 paginiETAG006 2finSerban RaduÎncă nu există evaluări

- TM9-2350-311-20-1 - M109a2 & M109a3Document914 paginiTM9-2350-311-20-1 - M109a2 & M109a3Вадим ЗахарченкоÎncă nu există evaluări

- S60MC-C8 2Document385 paginiS60MC-C8 2Silvia GeorgianaÎncă nu există evaluări

- Aspire Manual PumpDocument19 paginiAspire Manual Pumpsouhaib alviÎncă nu există evaluări

- Guidance For Carrying Out Rig ChecksDocument2 paginiGuidance For Carrying Out Rig Checksargon39Încă nu există evaluări

- Whirlpool Awo D 43105Document28 paginiWhirlpool Awo D 43105Ioana PetrescuÎncă nu există evaluări

- Vit System PDFDocument6 paginiVit System PDFArun S100% (1)

- Pressure Sewerage Drawing IndexDocument1 paginăPressure Sewerage Drawing IndexAndrew FerrierÎncă nu există evaluări

- Folder-Small L & B-EnGDocument16 paginiFolder-Small L & B-EnGRodrigo GonçalvesÎncă nu există evaluări

- Gothong Southern Logistics Company Profile (2017)Document15 paginiGothong Southern Logistics Company Profile (2017)lj_inosaÎncă nu există evaluări

- BPA Market ReportsDocument16 paginiBPA Market Reportsrazamehdi3Încă nu există evaluări

- Whirlpool JT 359 Alu PDFDocument6 paginiWhirlpool JT 359 Alu PDFGustavo Valdez100% (2)

- Tso PitotDocument8 paginiTso PitotElkin CuevasÎncă nu există evaluări

- 938H Partes PDFDocument1.181 pagini938H Partes PDFCarlosirabedra100% (2)

- 9ackermann PDFDocument28 pagini9ackermann PDFravi474Încă nu există evaluări

- Sephco WA Series Workshop and Portable Load Banks OptionsDocument2 paginiSephco WA Series Workshop and Portable Load Banks OptionsFELIXDEJÎncă nu există evaluări

- Part - A: Bangladesh Marine Academy, ChittagongDocument2 paginiPart - A: Bangladesh Marine Academy, ChittagongXahid HasanÎncă nu există evaluări

- 04ref203 054 en Faro Laser Scanner Focus BrochureDocument11 pagini04ref203 054 en Faro Laser Scanner Focus BrochureSabino LaraÎncă nu există evaluări

- Parts Manual Allied W8L PDFDocument328 paginiParts Manual Allied W8L PDFkertajaya ekarya86% (7)

- The B-52 Competition of 1946 and Dark Horses From Douglas, 1947-1950Document7 paginiThe B-52 Competition of 1946 and Dark Horses From Douglas, 1947-1950Jared Zichek100% (15)

- Fosroc Supercast PVC Waterstops: Technical Data SheetDocument4 paginiFosroc Supercast PVC Waterstops: Technical Data Sheetarvin jay santarinÎncă nu există evaluări

- Blasting HazardsDocument107 paginiBlasting Hazardspatel lakulesh100% (2)

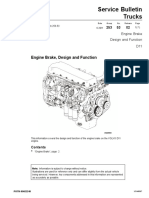

- Engine Brake, Design and Function Volvo D11Document7 paginiEngine Brake, Design and Function Volvo D11Hamilton Miranda0% (1)

- Chaboche NLK Hardening Model Calibration MethodologyDocument10 paginiChaboche NLK Hardening Model Calibration MethodologynicolasÎncă nu există evaluări

- HT Catalog PDFDocument372 paginiHT Catalog PDFLuis De JesúsÎncă nu există evaluări

- Immersion V FitbitDocument29 paginiImmersion V FitbitJonah ComstockÎncă nu există evaluări