Documente Academic

Documente Profesional

Documente Cultură

Boom Lift SWP

Încărcat de

Sayed AbbasDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Boom Lift SWP

Încărcat de

Sayed AbbasDrepturi de autor:

Formate disponibile

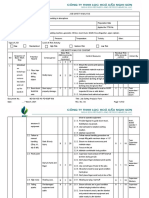

SAFE WORK PROCEDURES

BOOM LIFT

SPECIAL INSTRUCTIONS:

1. Persons should not operate a boom lift unless they have been instructed in the precautions to be observed and the safe use of the machine.

2. A Certificate of Competency for Boom type elevating work platform (class WP) is required to operate machines with boom length greater than 11 metres.

3. Carry out safety checks as listed in manufacturers instructions before use of machine, or check log book for inspections on hired-in equipment.

Task sequence Identified hazards in task Key processes to be followed Precautions / PPE required

1. Pre-start checks Loss of power Ensure that battery is fully charged before using an electric-powered boom Do not use if battery power is low.

lift for any working at heights. Recharge battery before use.

Check liquid levels (fuel, oil, coolant, hydraulic oil, etc) before operation. Top up liquids if levels are low.

Loss of control Check all controls for correct operation before commencing use. Check top and bottom controls.

Risk of falls Check all movements before commencing should be smooth and steady. Do not use if movements jerky.

Accidental movement Check operation of brakes, stops, outriggers, etc to ensure that unit remains Do not use if brakes or stops do

steady when boom is extended. not prevent all movement of unit.

Ensure that guard fence and gate/s is secure and closes securely. Check operation of gate latch.

Ensure that suitable safety harnesses are available and that anchor points in Safety harness must be worn by

platform are in sound condition. persons in platform at all times.

2. Safety Harnesses and Failure of components All fall arrest harnesses must comply with Australian Standard AS 1891.1 Faulty or out-of-date equipment

Fall Arrest Devices Industrial fall-arrest systems and devices Safety belts and harnesses. must not be used.

Incorrect use and fitting All persons required to use a safety harness must receive instruction and Harnesses must be fitted

training in their use before they are allowed to use the harness. correctly for safety in use.

Suspension trauma Suitable equipment to rescue a person in the event of a fall must be available Other persons on site must be

within a short period to minimise risk of suspension trauma. instructed in rescue procedures.

3. Travel Instability Check path that machine will be traversing to ensure adequate clearance and Remove obstacles and cover

that surface will not cause machine to become unstable when travelling. voids, drains, etc.

Ensure that boom is retracted and lowered for travelling. Check for clearance for boom.

Reduce speed when turning corners, on rough surfaces or where visibility is Always travel at safe speed.

restricted (eg, blind corners, etc). Corner at slow speed only.

Boom should be lowered before moving unit even for short distances. Do not travel with boom raised.

Keep body fully within confines of cage when traversing. Ensure that gates on cage closed.

4. Security of worksite Collision Use barricades, traffic cones and signs, etc, to prevent collision of other Use signs barricades, cones, etc, to

plant or vehicles working in vicinity with boom lift. protect work area.

Isolate and tag out travelling overhead cranes in area where boom lift used. Prevent movement of cranes.

Falling objects Prevent access of persons into vicinity of machine when boom is raised. Prevent unauthorised entry.

Unauthorised use Store machine in secure area, lower fully, and remove key on completion. Prevent unauthorised use.

SWP465 Version 2.0 ASSA Pty Ltd www.assaohs.com.au Page 1 of 2

SAFE WORK PROCEDURES

BOOM LIFT

Task sequence Identified hazards in task Key processes to be followed Precautions / PPE required

5. Electrical hazards Electric shock Inspect work area to identify location of overhead electrical installations. Keep safe distance from electric

Keep safe distance from electricity wires unless specifically authorised to catenary wires at all times.

access or carry out electrical work. Observe safe clearance distances. Ensure at least .5m clearance of

Ensure that electric wires are de-energised or insulated with matting and tools or equipment from LV wires.

identified with tiger tails before work commences.

Post competent observer when operating in vicinity of live electric wires.

6. Working at heights Instability Ensure that unit is on level surface (or is levelled with outriggers if working Ensure that unit is parked on a

on uneven surfaces) before raising boom. stable, firm surface before raising.

Persons falling Persons in EWP bucket must wear appropriate safety harness which will Parachute type harness only to

prevent them falling to ground or on to any part of the machine. be worn belts must not be used.

Do not over-reach out beyond confines of cage when working at heights. Do not open gates when elevated.

Do not rock unit when platform is raised. Avoid sudden or jerky movement.

Ensure that gates on platform guard rails are closed and locked in place. Do not sit, stand or climb on

Overloading of platform Ensure that total load in bucket of EWP (including personnel tools and platform guard rails.

equipment, and materials) does not exceed the safe working load of the unit. Never exceed the safe working

Do not use boom lift as a crane to lift materials loads must be carried load of the EWP.

within confines of platform cage.

Do not tie boom or platform to adjacent structures. Do not place loads outside

Falling objects Use lanyards, etc, to prevent tools and materials falling during use. perimeter of platform,

7. Maintenance of electric Fire/explosion risk Avoid shorting of terminals when inspecting or maintaining battery packs. Remove rings, watches, etc before

boom lifts Use approved battery charger set to correct voltage to charge batteries. working on batteries.

Instability of machine Do not replace batteries with batteries that weigh less than those originally Ensure that total weight of battery

fitted to machine (used a counterweight, and critical to machine stability). pack is at least approved minimum

Harmful contact or exposure Avoid spilling or contacting battery acid neutralise spills and flush area. Wear eye and hand protection.

Battery pack must remain in upright position at all times. Avoid tipping or dropping battery.

Do not expose batteries or charger to water or rain. Recharge in protected area only.

PRECAUTIONS: Maintenance of

The following precautions are to be observed when battery packs in

operating or working in the vicinity of elevating work electric boom lifts

platforms and boom lifts.

SWP465 Version 2.0 ASSA Pty Ltd www.assaohs.com.au Page 2 of 2

S-ar putea să vă placă și

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 paginiJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- 003 SWMS - ExcavationDocument11 pagini003 SWMS - Excavationsasi kumar50% (2)

- Working at Height Is One of The Hazardous OccupationsDocument6 paginiWorking at Height Is One of The Hazardous OccupationsHemaÎncă nu există evaluări

- Operating A Telescoping Aerial Boom LiftDocument1 paginăOperating A Telescoping Aerial Boom LiftTFattahÎncă nu există evaluări

- Manual Handling RubbishDocument1 paginăManual Handling RubbishScribder0% (1)

- Supplier Evaluation and Approval - Disapproval PGP2001ADocument6 paginiSupplier Evaluation and Approval - Disapproval PGP2001ASayed AbbasÎncă nu există evaluări

- Metal Chop Saw SopDocument2 paginiMetal Chop Saw SopkylealamangoÎncă nu există evaluări

- Scaffolding SafetyDocument20 paginiScaffolding SafetyKate Ann Baja IIÎncă nu există evaluări

- Scaffold CampaignDocument9 paginiScaffold CampaignAdel SukerÎncă nu există evaluări

- Jsa Tank CleaningDocument5 paginiJsa Tank CleaningASLAM MULANIÎncă nu există evaluări

- Basic Safety Instructions For All Employees Visiting or Working in The Construction of The HgpepDocument42 paginiBasic Safety Instructions For All Employees Visiting or Working in The Construction of The Hgpepmalik jahanÎncă nu există evaluări

- Working at Height Training ModuleDocument41 paginiWorking at Height Training ModuleYudha kurniawanÎncă nu există evaluări

- Risk Assessment - Lifting OperationsDocument3 paginiRisk Assessment - Lifting Operationsdnmule100% (2)

- 0 JsaDocument54 pagini0 JsaRavi AmarlapudiÎncă nu există evaluări

- Fencing, Installation and Repair.: Activity DescriptionDocument6 paginiFencing, Installation and Repair.: Activity DescriptionVictorÎncă nu există evaluări

- Scaffold Plan TOIPL PDFDocument11 paginiScaffold Plan TOIPL PDFDinesh Kanukollu100% (1)

- Job Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureDocument2 paginiJob Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureM Waqas HabibÎncă nu există evaluări

- Jsa No-01 Container UnloadingDocument4 paginiJsa No-01 Container Unloadingsumith s100% (1)

- Working at Height Day 2Document46 paginiWorking at Height Day 2OsamaAlaasam67% (3)

- Scissor Lift Pre-Use Inspection Checklist 2Document1 paginăScissor Lift Pre-Use Inspection Checklist 2Harun SaniÎncă nu există evaluări

- Working at Height Risk Assessment Mar 21Document2 paginiWorking at Height Risk Assessment Mar 21tariq1987Încă nu există evaluări

- A320FAM EFCS Troubleshooting Tips 2018Document88 paginiA320FAM EFCS Troubleshooting Tips 2018EssamÎncă nu există evaluări

- Welding Oxy A4Document2 paginiWelding Oxy A4LoveÎncă nu există evaluări

- RA Tower 0004 Dec 2011Document8 paginiRA Tower 0004 Dec 2011grandeÎncă nu există evaluări

- Jsa SKDocument10 paginiJsa SKTri SubaktiÎncă nu există evaluări

- Construction Safety: Page 1 of 4Document4 paginiConstruction Safety: Page 1 of 4ryan.aniceteÎncă nu există evaluări

- JSA #28 - Use of Hand ToolsDocument1 paginăJSA #28 - Use of Hand ToolsSubham SohalÎncă nu există evaluări

- Cegard3D Operation Manual en 100713Document56 paginiCegard3D Operation Manual en 100713bahaÎncă nu există evaluări

- Akk Jha Installation of Diesel TankDocument3 paginiAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Job Safety Analysis: S.No Activities Hazard Risk Control MeasuresDocument2 paginiJob Safety Analysis: S.No Activities Hazard Risk Control Measureskhaja asifuddinÎncă nu există evaluări

- Working at Heights: Dr.P.MuralidharDocument48 paginiWorking at Heights: Dr.P.MuralidharRituraj SinghÎncă nu există evaluări

- Monthly Ladder Inspection ChecklistDocument1 paginăMonthly Ladder Inspection ChecklistshahidÎncă nu există evaluări

- Safety Inspections Workbook PDF enDocument36 paginiSafety Inspections Workbook PDF enSayed Abbas100% (1)

- HIRAC - Work - at - Height - Template PDFDocument8 paginiHIRAC - Work - at - Height - Template PDFRohma Desi ThirtasariÎncă nu există evaluări

- Storage of Hazardous Chemicals in Warehouses and Drum StoresDocument4 paginiStorage of Hazardous Chemicals in Warehouses and Drum Storessjmpak100% (1)

- Road Haulage Company: Example Risk Assessment For ADocument3 paginiRoad Haulage Company: Example Risk Assessment For ASayed Abbas100% (1)

- Forklift RADocument5 paginiForklift RAFachri HidayatÎncă nu există evaluări

- Technical Policy Board Guidelines For Marine Lifting OperationsDocument42 paginiTechnical Policy Board Guidelines For Marine Lifting Operationscostantin2100% (1)

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 paginiGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- Factories (Building Operations and Works of Engineering Construction) RegulationsDocument60 paginiFactories (Building Operations and Works of Engineering Construction) RegulationsJeffrey Ng25% (4)

- Jsa For The Installation of I EamDocument5 paginiJsa For The Installation of I EamMohammed MinhajÎncă nu există evaluări

- Jsa Ground Grid MocksvilleDocument2 paginiJsa Ground Grid MocksvilleChristopher NewbyÎncă nu există evaluări

- RiggingDocument2 paginiRiggingpruncu.alianmÎncă nu există evaluări

- PPE Notice PolicyDocument1 paginăPPE Notice PolicyLenaj EbronÎncă nu există evaluări

- Fan InstallationDocument2 paginiFan InstallationKrishna PatilÎncă nu există evaluări

- Safety Management SystemsDocument125 paginiSafety Management Systemsridgell100% (2)

- Rigging JSA SafetyDocument5 paginiRigging JSA SafetyaQiLGunawanÎncă nu există evaluări

- Lift Plan - Method Statement - Risk Assessment - SafetyCultureDocument21 paginiLift Plan - Method Statement - Risk Assessment - SafetyCulturebalachander100% (1)

- MODEL 632: Product Information SheetDocument4 paginiMODEL 632: Product Information SheetHenrique NogueiraÎncă nu există evaluări

- FB10RL (F) /13RL (F) /15RL (F) /18RL (F) - FB10RW/13RW/15RW-: Electric Reach TruckDocument169 paginiFB10RL (F) /13RL (F) /15RL (F) /18RL (F) - FB10RW/13RW/15RW-: Electric Reach TruckSami Kuşcu100% (1)

- Manual Bluelight Bl6-UDocument238 paginiManual Bluelight Bl6-UYok Mulyono100% (2)

- Safe Unloading of Cut and BentDocument16 paginiSafe Unloading of Cut and BentAbhinav SinhaÎncă nu există evaluări

- 024 - Mobile Scaffold Inspection ChecklistDocument1 pagină024 - Mobile Scaffold Inspection ChecklistFaiez AripiÎncă nu există evaluări

- 660MW Air Cooled CondenserDocument26 pagini660MW Air Cooled CondenserRaj_Jai030% (1)

- 9103796-105CN - Techn Descr SC 45Document139 pagini9103796-105CN - Techn Descr SC 45happyÎncă nu există evaluări

- Subject: Work at Height: Unit: Maihar Cement WorksDocument3 paginiSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- Ac Motor Controller: B60Z (B230) B80Z (B233) B60Z (A262) B80Z (A257)Document116 paginiAc Motor Controller: B60Z (B230) B80Z (B233) B60Z (A262) B80Z (A257)Christian Bedoya100% (3)

- HL740 9SDocument528 paginiHL740 9SAnonymous yjK3peI786% (7)

- MB Concrete Tall Buildings Feb18 PDFDocument20 paginiMB Concrete Tall Buildings Feb18 PDFAlparslan GureÎncă nu există evaluări

- Grhorq Antiguas 393Document1.163 paginiGrhorq Antiguas 393lilyricardoseaman100% (1)

- JSA #19 - Heavy Lifting in Hazardous AreaDocument1 paginăJSA #19 - Heavy Lifting in Hazardous AreaMock ProjectÎncă nu există evaluări

- Abus Cranes CatalogDocument28 paginiAbus Cranes CatalogGeorge JabbourÎncă nu există evaluări

- Hot Works: Risk Assesment Form For Rolling ShutterDocument1 paginăHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30Încă nu există evaluări

- Instructions For Using The Risk Assessment FormDocument9 paginiInstructions For Using The Risk Assessment FormMalik Khuram ShazadÎncă nu există evaluări

- Work at HeightDocument11 paginiWork at HeightEhsanÎncă nu există evaluări

- Jsa Ducting Rev 00Document1 paginăJsa Ducting Rev 00SRR HSE Department, Sandvik Project,Încă nu există evaluări

- JHA M&F ToiletDocument3 paginiJHA M&F ToiletBala Subra ManiamÎncă nu există evaluări

- Topic For TBMDocument19 paginiTopic For TBMdauxomÎncă nu există evaluări

- HSF-PR-0063 Work at HeightDocument32 paginiHSF-PR-0063 Work at HeightChris Bonnington0% (1)

- JSA - Crane Setuppdf PDFDocument12 paginiJSA - Crane Setuppdf PDFChoko ChokriÎncă nu există evaluări

- MSDS - Asada Threading Oiil Red - ENDocument7 paginiMSDS - Asada Threading Oiil Red - ENnghiaÎncă nu există evaluări

- Building De-Dusting JSADocument3 paginiBuilding De-Dusting JSAJayesh J PillaiÎncă nu există evaluări

- 2.1 Precautions For Tower Crane Dismantle: Chapter II DismantlingDocument6 pagini2.1 Precautions For Tower Crane Dismantle: Chapter II DismantlingYoutube SaleemÎncă nu există evaluări

- A002 C NightclubDocument6 paginiA002 C NightclubBlas de LezoÎncă nu există evaluări

- JSO Cable Drum (02 Sept.'07)Document2 paginiJSO Cable Drum (02 Sept.'07)Francis Enriquez TanÎncă nu există evaluări

- JSA For New EmployeesDocument20 paginiJSA For New EmployeesNilayÎncă nu există evaluări

- Safe System Of Work A Complete Guide - 2020 EditionDe la EverandSafe System Of Work A Complete Guide - 2020 EditionÎncă nu există evaluări

- SD - 727Document4 paginiSD - 727Sayed AbbasÎncă nu există evaluări

- Sheet: Using Portable Generators SafelyDocument2 paginiSheet: Using Portable Generators SafelybsiofncÎncă nu există evaluări

- Effect of Angle of Lift On A Sling'S Rated Capacity: WarningDocument1 paginăEffect of Angle of Lift On A Sling'S Rated Capacity: WarningSayed AbbasÎncă nu există evaluări

- SD - 727Document4 paginiSD - 727Sayed AbbasÎncă nu există evaluări

- TM - PS 01 Quality PolicyDocument1 paginăTM - PS 01 Quality PolicySayed AbbasÎncă nu există evaluări

- Building An Effective Health and Safety Management SystemDocument52 paginiBuilding An Effective Health and Safety Management SystemSayed Abbas100% (1)

- 01 Construction Hazards QCDocument1 pagină01 Construction Hazards QCduku5440Încă nu există evaluări

- 010-Scaffold Erection Checklist PDFDocument1 pagină010-Scaffold Erection Checklist PDFSayed AbbasÎncă nu există evaluări

- Spot Inspection Report: HSESM, 97/02Document3 paginiSpot Inspection Report: HSESM, 97/02Sayed AbbasÎncă nu există evaluări

- Probing Questions (Exploring Evidence) :: Six Questioning Friends (5WH)Document3 paginiProbing Questions (Exploring Evidence) :: Six Questioning Friends (5WH)Sayed AbbasÎncă nu există evaluări

- Worker Safety Series - Warehousing PDFDocument15 paginiWorker Safety Series - Warehousing PDFAndi WahyudinÎncă nu există evaluări

- UMC SystemScaffoldingDocument3 paginiUMC SystemScaffoldingSayed AbbasÎncă nu există evaluări

- Whsms ManualDocument22 paginiWhsms ManualSayed AbbasÎncă nu există evaluări

- Equipment Register - Pat Testing Original CertificateDocument3 paginiEquipment Register - Pat Testing Original CertificateSayed AbbasÎncă nu există evaluări

- Fes Hazad FallDocument3 paginiFes Hazad FallSayed AbbasÎncă nu există evaluări

- Tuv Rheinland Iso 9001 Faq enDocument4 paginiTuv Rheinland Iso 9001 Faq enSayed AbbasÎncă nu există evaluări

- Spot Inspection Report: HSESM, 97/02Document3 paginiSpot Inspection Report: HSESM, 97/02Sayed AbbasÎncă nu există evaluări

- WEEE Insight GuideDocument4 paginiWEEE Insight GuideSayed AbbasÎncă nu există evaluări

- Investigation ReportDocument3 paginiInvestigation ReportAnn Dolor DeseoÎncă nu există evaluări

- Checklist For Office EnvironmentsDocument3 paginiChecklist For Office EnvironmentsSayed AbbasÎncă nu există evaluări

- Investigation ReportDocument3 paginiInvestigation ReportAnn Dolor DeseoÎncă nu există evaluări

- Construction - Environmental Checklist Project:: Not Appl Description AirDocument2 paginiConstruction - Environmental Checklist Project:: Not Appl Description AirSayed AbbasÎncă nu există evaluări

- Fall Protection Work Plan Short Version EngDocument1 paginăFall Protection Work Plan Short Version EngSayed AbbasÎncă nu există evaluări

- FORMULAS For CALCULATING RATES PDFDocument4 paginiFORMULAS For CALCULATING RATES PDFĐào Hùng0% (1)

- Architects DetailsDocument73 paginiArchitects DetailsAshish A.Încă nu există evaluări

- 89 Gas and Oilfield Safety Inspection ChecklistDocument14 pagini89 Gas and Oilfield Safety Inspection Checklistdilip matalÎncă nu există evaluări

- Manual E-Learning HWS01Document8 paginiManual E-Learning HWS01Marshall SanchezÎncă nu există evaluări

- West Bengal Fire RulesDocument33 paginiWest Bengal Fire RulesPratik ChakrabartiÎncă nu există evaluări

- 007 Legends WalkthroughDocument14 pagini007 Legends WalkthroughpaulphoenicksÎncă nu există evaluări

- Easy Move: Tailor-Made Solutions For Private and Public PremisesDocument12 paginiEasy Move: Tailor-Made Solutions For Private and Public PremisesAlex NgÎncă nu există evaluări

- Leaflet ACTIA MULLER Vehicle TestingDocument44 paginiLeaflet ACTIA MULLER Vehicle Testingnicolas_perrierÎncă nu există evaluări

- BienDocument25 paginiBienAlfredo VSÎncă nu există evaluări

- Wa0004Document5 paginiWa0004Jms QuinteroÎncă nu există evaluări

- Hubli Bye LawsDocument17 paginiHubli Bye LawsAbhishek DalabanjanÎncă nu există evaluări

- Architectural Design For Crime Prevention Oscar Newman PDFDocument233 paginiArchitectural Design For Crime Prevention Oscar Newman PDFAngel VeraÎncă nu există evaluări

- GLPM Mi 02 10991790enDocument56 paginiGLPM Mi 02 10991790enDiego Fernandes do NascimentoÎncă nu există evaluări

- Schindler 3300: Distinctive Design. Cost-Effective Solution. Green Technology Made EasyDocument20 paginiSchindler 3300: Distinctive Design. Cost-Effective Solution. Green Technology Made EasyHakim BgÎncă nu există evaluări

- JLG 1350SJP Operation Safety ManualDocument134 paginiJLG 1350SJP Operation Safety ManualMatthew Neuberger100% (1)

- HP Steam Drum-Hrsg IiDocument6 paginiHP Steam Drum-Hrsg IiDeepak SharmaÎncă nu există evaluări

- Installation Manual & Technical Information Automatic Laser Control Control Box Model CB26 Model CB24+Document33 paginiInstallation Manual & Technical Information Automatic Laser Control Control Box Model CB26 Model CB24+magzigio100% (1)