Documente Academic

Documente Profesional

Documente Cultură

CAJ1317

Încărcat de

Luis AlbertoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CAJ1317

Încărcat de

Luis AlbertoDrepturi de autor:

Formate disponibile

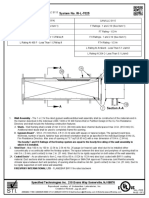

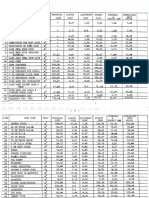

System No.

C-AJ-1317

Through Penetrations

March 28, 2012

ANSI/UL1479 (ASTM E814) CAN/ULC S115

F Rating 2 Hr F Rating 2 Hr

T Rating 0 Hr FT Rating 0 Hr

L Rating At Ambient Less Than 1 CFM/sq ft FH Rating 2 Hr

L Rating At 400 F 2 CFM/sq ft FTH Rating 0 Hr

L Rating At Ambient Less Than 1 CFM/sq ft

L Rating At 400 F 2 CFM/sq ft

Metallic Pipes

1. Floor or Wall Assembly Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3)

concrete. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 10-1/2 in. (267 mm).

1000 Series

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2. Through Penetrants One metallic pipe or tubing to be installed either concentrically or eccentrically within the firestop system. The

annular space between tube and periphery of opening shall be min 0 in. (point contact) to max 1-7/8 in. (48 mm). Penetrants to be rigidly

supported on both sides of floor or wall assembly. The following types and sizes of metallic pipes or tubing may be used:

A. Steel Pipe Nom 8 in. (203 mm) diam (or smaller) Schedule 10 (or heavier) steel pipe.

B. Iron Pipe Nom 8 in. (201 mm) diam (or smaller) cast or ductile iron pipe.

C. Conduit Nom 6 in. (152 mm) diam (or smaller) steel conduit, or nom 4 in.(102 mm) diam (or smaller) steel electrical metallic tubing.

D. Copper Tubing Nom 4 in. (102 mm) diam (or smaller) Type M (or heavier) copper tube.

E. Copper Pipe Nom 4 in. (102 mm) diam (or smaller) Regular (or heavier) copper pipe.

3. Firestop System The details of the firestop system shall be as follows:

A. Packing Material Min 2 in. (51 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into opening as a

permanent form. Packing material to be recessed from top surface of floor or from both surfaces of wall as required to accommodate the

required thickness of fill material.

A1. Forming Material* As an alternate to the packing material in Item 3, nom 4 in. (102 mm) wide strips of min 1/2 in (13 mm) thick

Concrete

compressible mat to be stacked to a thickness greater than the width of the annular space and compression-fitted, edge-first, to fill the

annular space to a min 4 in. (102 mm) depth. As an option, the strips of min 1/2 in. (13mm) thick compressible mat may be folded in half,

lengthwise, and stacked to a thickness greater than the width of the annular space and compression-fitted, edge-first, to fill the annular

space to a min 2 in. (51 mm) depth. Top of forming material to be recessed from top surface of floor or from both surfaces of wall as

necessary to accommodate the required thickness of caulk fill material.

3M COMPANY

3M FIRE PROTECTION PRODUCTS Fire Barrier Packing Material

B. Fill Void or Cavity Materials* Caulk Min 1/4 in. (6 mm) thickness of fill material applied within the annulus, flush with top surface

of floor or with both surfaces of wall. Min 1/2 in. (13 mm) diam bead of caulk applied to the penetrant/concrete interface at the point

contact location on the top surface of floor or both surfaces of wall.

3M COMPANY

3M FIRE PROTECTION PRODUCTS FD-150+ Caulk

*Bearing the UL Classification Mark

CAJ

Reprinted from the Online Certifications Directory with permission from UL

2013 UL LLC

3M Fire Protection Products

www.3M.com/firestop 1-800-328-1687 Through Penetrations Applicators and Specifiers Guide

C-AJ-1317 1 of 1

S-ar putea să vă placă și

- Reinforced Concrete Flat RoofDocument3 paginiReinforced Concrete Flat RoofDiana Zuhairi40% (5)

- Principle of Architectural Design: Organization of Form & SpaceDocument27 paginiPrinciple of Architectural Design: Organization of Form & SpaceFais IbrahimÎncă nu există evaluări

- Ar. I.M. PIEDocument32 paginiAr. I.M. PIEHardutt PurohitÎncă nu există evaluări

- CAJ1066 Multiples MTDocument1 paginăCAJ1066 Multiples MTEdwin G Garcia ChÎncă nu există evaluări

- WL1167Document1 paginăWL1167Juvenal GutierrezÎncă nu există evaluări

- HW-D-0038 - 1 of 1: 3M Fire Protection ProductsDocument1 paginăHW-D-0038 - 1 of 1: 3M Fire Protection Productskirollos HabibÎncă nu există evaluări

- C Aj 1609Document2 paginiC Aj 1609vhin84Încă nu există evaluări

- Ul Fs On Max Rectangular Duct Block WallDocument2 paginiUl Fs On Max Rectangular Duct Block WallhossamÎncă nu există evaluări

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 paginiSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlÎncă nu există evaluări

- WL7223Document1 paginăWL7223Juvenal GutierrezÎncă nu există evaluări

- System No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRDocument2 paginiSystem No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRArulÎncă nu există evaluări

- Max 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyDocument2 paginiMax 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyvikaspisalÎncă nu există evaluări

- System WJ 2256Document1 paginăSystem WJ 2256Manoj SamÎncă nu există evaluări

- System No. C-AJ-8175: F Rating - 2 HR T Rating - 0 HRDocument2 paginiSystem No. C-AJ-8175: F Rating - 2 HR T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaÎncă nu există evaluări

- C-AJ-2834 - Through-Penetration Firestop Systems - UL Product IqDocument3 paginiC-AJ-2834 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitÎncă nu există evaluări

- Firestopping System Applications AND Standard Application - Ul ListedDocument5 paginiFirestopping System Applications AND Standard Application - Ul ListedAry TubagusÎncă nu există evaluări

- HWD0134Document2 paginiHWD0134Edwin Jalanoca LlaulliÎncă nu există evaluări

- UntitledDocument2 paginiUntitledandy_ramblaÎncă nu există evaluări

- Approval Document ASSET DOC LOC 523Document1 paginăApproval Document ASSET DOC LOC 523aÎncă nu există evaluări

- C Aj 2586 PDFDocument1 paginăC Aj 2586 PDFEmanuel PastlÎncă nu există evaluări

- CAJ6002 BlindobarrasDocument1 paginăCAJ6002 BlindobarrasEdwin G Garcia ChÎncă nu există evaluări

- Ul HWD 0209Document2 paginiUl HWD 0209jlledwinestebanÎncă nu există evaluări

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 paginiXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamÎncă nu există evaluări

- W L 1176Document1 paginăW L 1176shama093Încă nu există evaluări

- System PDF Files - 1. UL and cUL Systems - fc2320Document1 paginăSystem PDF Files - 1. UL and cUL Systems - fc2320Emanuel PastlÎncă nu există evaluări

- C-AJ-2813 - Through-Penetration Firestop Systems - UL Product IqDocument3 paginiC-AJ-2813 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitÎncă nu există evaluări

- System No. HW-D-0441Document1 paginăSystem No. HW-D-0441kirollos HabibÎncă nu există evaluări

- WWD0021Document1 paginăWWD0021AidilÎncă nu există evaluări

- W L 1054Document2 paginiW L 1054shama093Încă nu există evaluări

- Fire Stop Design 673Document4 paginiFire Stop Design 673raviÎncă nu există evaluări

- HW-D-1010 - 1 of 1: 3M Fire Protection ProductsDocument1 paginăHW-D-1010 - 1 of 1: 3M Fire Protection Productskirollos HabibÎncă nu există evaluări

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 paginiFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoÎncă nu există evaluări

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 paginiSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlÎncă nu există evaluări

- Welded Wire Lath: Standard Specification ForDocument2 paginiWelded Wire Lath: Standard Specification ForአንዋርጀማልÎncă nu există evaluări

- Approval Document ASSET DOC LOC 99Document1 paginăApproval Document ASSET DOC LOC 99Amir IqbalÎncă nu există evaluări

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 paginiÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoÎncă nu există evaluări

- System No. W-J-5116: F Rating - 2 HR T Rating - 1 HRDocument2 paginiSystem No. W-J-5116: F Rating - 2 HR T Rating - 1 HRArulÎncă nu există evaluări

- Product Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966Document1 paginăProduct Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966shama093Încă nu există evaluări

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersDocument2 paginiDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimÎncă nu există evaluări

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 paginiSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlÎncă nu există evaluări

- System No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRDocument2 paginiSystem No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaÎncă nu există evaluări

- Bandeja - Concreto - W-J-4031Document2 paginiBandeja - Concreto - W-J-4031cesar walter salazar garciaÎncă nu există evaluări

- Hilti Firestop Submittal - Balamand UniversityDocument32 paginiHilti Firestop Submittal - Balamand UniversitybasbousrÎncă nu există evaluări

- Firestop Application Handbook (Macau) - Part-8 PDFDocument30 paginiFirestop Application Handbook (Macau) - Part-8 PDFSharoon S raoÎncă nu există evaluări

- System No. W-L-2199Document2 paginiSystem No. W-L-2199DatÎncă nu există evaluări

- FC-2000 1.5 Hour Curtain Fire DampersDocument6 paginiFC-2000 1.5 Hour Curtain Fire DampersnuqÎncă nu există evaluări

- Firestop: System SelectionDocument28 paginiFirestop: System SelectionSai KotaÎncă nu există evaluări

- System No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Document2 paginiSystem No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Lea Rebeca Tuesta Gonzales ZuñigaÎncă nu există evaluări

- Detailed Specification PE Casing Jacket With Standard UIP System 1) GeneralDocument3 paginiDetailed Specification PE Casing Jacket With Standard UIP System 1) GeneralMina MagdyÎncă nu există evaluări

- Design No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263Document3 paginiDesign No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263EngTamerÎncă nu există evaluări

- W L 1297Document1 paginăW L 1297shama093Încă nu există evaluări

- FM Design 628 (FB-4003)Document2 paginiFM Design 628 (FB-4003)raviÎncă nu există evaluări

- System No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRDocument2 paginiSystem No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRArulÎncă nu există evaluări

- CEJ114PDocument2 paginiCEJ114PGauri Calderon TrujilloÎncă nu există evaluări

- CAJ1353Document1 paginăCAJ1353Anonymous PCsoNCt0mFÎncă nu există evaluări

- System PDF Files - 1. UL and cUL Systems - Caj8113 - DLDocument4 paginiSystem PDF Files - 1. UL and cUL Systems - Caj8113 - DLEmanuel PastlÎncă nu există evaluări

- YORK-AHUDocument11 paginiYORK-AHUTienNguyenÎncă nu există evaluări

- w-j-2094 - PVC CPVC, ABS 2 Hr.Document2 paginiw-j-2094 - PVC CPVC, ABS 2 Hr.DatÎncă nu există evaluări

- Proofex Torchseal 3P and 4P UAEDocument2 paginiProofex Torchseal 3P and 4P UAEhbangash2022Încă nu există evaluări

- SuperLite LL-XL 120Document2 paginiSuperLite LL-XL 120Marija MilenkovicÎncă nu există evaluări

- Approval Document ASSET DOC LOC 716Document2 paginiApproval Document ASSET DOC LOC 716fazil yoosufÎncă nu există evaluări

- Atco - Hoja Tecnica PDFDocument2 paginiAtco - Hoja Tecnica PDFAlison ThompsonÎncă nu există evaluări

- Roman Architecture InnovationsDocument36 paginiRoman Architecture InnovationsNykha AlentonÎncă nu există evaluări

- Absolute Architects - Singh House PDFDocument18 paginiAbsolute Architects - Singh House PDFbharathvarmaÎncă nu există evaluări

- GANTT CHART ExcelDocument1 paginăGANTT CHART ExcelAlexÎncă nu există evaluări

- Pier (Architecture)Document2 paginiPier (Architecture)Haider ShahÎncă nu există evaluări

- Standard Output RatesDocument48 paginiStandard Output RatesRobel TesfazgiÎncă nu există evaluări

- Typical Deck EdgeDocument1 paginăTypical Deck EdgeShane AndersonÎncă nu există evaluări

- Project in Detail: Residence For The Shetty'sDocument6 paginiProject in Detail: Residence For The Shetty'ssakthivisalakshiÎncă nu există evaluări

- RS-1-1066223674 3.7.23Document12 paginiRS-1-1066223674 3.7.23CARMEN DILLARDÎncă nu există evaluări

- Lecture 9 - Renaissance Art PDFDocument26 paginiLecture 9 - Renaissance Art PDFBrian DimalantaÎncă nu există evaluări

- Types of StairsDocument6 paginiTypes of StairsTanyaÎncă nu există evaluări

- 2.1 Greek and Roman ArchitectureDocument141 pagini2.1 Greek and Roman ArchitectureWenna Dale PasquinÎncă nu există evaluări

- Claudine Arendt's Lecture Following The Van Hove Prize Award CeremonyDocument2 paginiClaudine Arendt's Lecture Following The Van Hove Prize Award CeremonyconstatbpuÎncă nu există evaluări

- Guideto Permits 110119Document16 paginiGuideto Permits 110119Ayyub AbduraufovÎncă nu există evaluări

- Eeu BoqDocument12 paginiEeu BoqSisay chaneÎncă nu există evaluări

- Matera 27: Bedrooms Bathrooms GarageDocument4 paginiMatera 27: Bedrooms Bathrooms GarageindyanexpressÎncă nu există evaluări

- Dead Loads, Live Loads and Load CombinationsDocument9 paginiDead Loads, Live Loads and Load Combinationspaineno100% (5)

- Appendix 5 RC Pier DesignDocument11 paginiAppendix 5 RC Pier DesignebsiÎncă nu există evaluări

- Wall Bracing Handout PDFDocument45 paginiWall Bracing Handout PDFalbertÎncă nu există evaluări

- Material Unit Unit Price Concrete: FormworksDocument3 paginiMaterial Unit Unit Price Concrete: FormworksLester MuscaÎncă nu există evaluări

- Drop Down List: Sensitivity: LNT Construction Internal UseDocument14 paginiDrop Down List: Sensitivity: LNT Construction Internal UseGnana Sekar BÎncă nu există evaluări

- CH 02 - Intro To HVAC SystemsDocument38 paginiCH 02 - Intro To HVAC SystemsKamaruz DanialÎncă nu există evaluări

- Adolf LoosDocument23 paginiAdolf LoosJACKULIN DAFNEEÎncă nu există evaluări

- General PresentationDocument53 paginiGeneral PresentationKARIM GARAHÎncă nu există evaluări

- Chapter 7-1 FoundationDocument15 paginiChapter 7-1 FoundationMikias TewachewÎncă nu există evaluări

- Evanmar O. Pinoliad BSCE-5B July 13, 2020 Bridge Engineering - Assignment #3 Engr. Marvin O. Madera Design of Abutment On Spread FootingDocument10 paginiEvanmar O. Pinoliad BSCE-5B July 13, 2020 Bridge Engineering - Assignment #3 Engr. Marvin O. Madera Design of Abutment On Spread FootingBUGTOK TVÎncă nu există evaluări

- PDF Q1 Mod 1 EIM GRADE 12 NewDocument10 paginiPDF Q1 Mod 1 EIM GRADE 12 NewCloud DullasÎncă nu există evaluări

- Porch Stairs Section Detail Lintel Beam Section Detail: H (H Depth of Beam)Document1 paginăPorch Stairs Section Detail Lintel Beam Section Detail: H (H Depth of Beam)Lourdjeth AlvaradoÎncă nu există evaluări