Documente Academic

Documente Profesional

Documente Cultură

Seu 0100c

Încărcat de

RasoolKhadibiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Seu 0100c

Încărcat de

RasoolKhadibiDrepturi de autor:

Formate disponibile

HN 402/462/522

SUBJECT: Auxiliary Spring Shim Design

LIT NO: SEU-0100

DATE: June 2006 REVISION: C

IMPORTANT NOTICE

Effective November 3, 2000 an improved auxiliary spring assembly with a new shim design

was introduced for production for the HN 402/462/522.

The new design:

Addresses the importance of matching ride quality and stability for vocational

applications. Ride quality is subject to many influences in heavy-duty applications. They

include, but are not limited to: body equipment, rear suspension, cab suspension,

terrain, chassis/frame specifications, tires/wheels, front suspension, and wheelbase.

Is completely interchangeable with the auxiliary spring system used in new

HN402/462/522 suspension systems manufactured between August 1998 and

November 2000. Contact Hendrickson Tech Services regarding vehicles equipped with

an HN suspension system manufactured prior to August 1998.

Offers adjustability for a greater level of ride performance and handling.

Production vehicles are to be equipped with the standard production auxiliary spring assem-

bly, (see Figure 2), using a three (3) spacer shim system. A small percentage of select vehi-

cles will require a shim system other than the standard production assembly.

An adjustment matrix on the back of this publication will assist in determining the correct

amount of shims that your vehicle may need. The unladen tandem axle weight with the body

installed is the primary determining factor for a match to your vehicle and application.

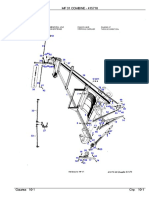

Figure 1 Figure 2

Prior Production New Production

Auxiliary Spring Assembly Auxiliary Spring Assembly

Three " shims

offer adjustability

GUIDELINES The following guidelines are essential in maximizing your suspension performance.

View the matrix below and check if your vehicle falls under one of the following applications

and is within the unladen tandem axle weight ranges (with all equipment/truck bodies

installed).

1. If so, these applications require optimum ride quality and a very high level of loaded

stability. Install or remove shims in order to reach the recommended number of total

shims per saddle as stated below.

2. Applications where stability is more important than ride quality, install additional shims

onto each saddle to reach the recommended shims (maximum of 5) per saddle.

For additional questions, contact Hendrickson Tech Services at 630.910.2800.

INSTALLATION The following instructions are recommended for removal and installation of the shim spacer(s)

after determining the proper shims required as per the guidelines listed in this bulletin.

UNLADEN TANDEM WEIGHT WITH BODY/EQUIPMENT INSTALLED*

APPLICATION 10,00018,000 lbs. 18,00123,000 lbs. 23,00128,000 lbs.

Dump Truck 2 Shims 2 Shims

Refuse Front Load Dump 5 Shims 5 Shims

Refuse Front Load Eject

Refuse Rear Load Eject 2 Shims No Shims

Refuse Side Loader

STD3 Shims

Refuse Side Loader Dump

5 Shims 5 Shims

Refuse Recycler Dump

Refuse Recycler Eject 2 Shims No Shims

Transit Mixer STD- 3 Shims STD- 3 Shims

Crane Carrier 5 Shims 5 Shims

IMPORTANT: Each side of the HN suspension must have an equal number of shims in place.

Shim Kit Available: Number 58960-001

* Matrix based on extensive field testing under varying conditions.

Disassembly Figure 3

1. Chock wheels.

2. Loosen the nuts that attach the

auxiliary spring assembly to the

saddle.

3. Remove or install additional

shims as per guidelines.

Assembly

1. Re-assemble fasteners and

tighten locknuts to

75-105 foot pounds torque.

2. Remove the wheel chocks.

www.hendrickson-intl.com

Truck Suspension Systems 630.910.2800

800 South Frontage Road Fax 630.910.2899

Woodridge, IL 60517-4904 USA

Information contained in this literature was accurate at the time of publication. Product changes may have been made after the copyright date that are not reflected.

SEU-0100 Rev C 06-06 2006 Hendrickson USA, L.L.C. (U.S. Rights) Hendrickson International Corporation (Rights Outside U.S.) All Rights Reserved Printed in United States of America

S-ar putea să vă placă și

- Atlas Copco Portable Air Compressors: XA (T, V) S 375 JD6 T3Document2 paginiAtlas Copco Portable Air Compressors: XA (T, V) S 375 JD6 T3RasoolKhadibiÎncă nu există evaluări

- 3040359Document1 pagină3040359RasoolKhadibiÎncă nu există evaluări

- Fuel Injection Systems Diesel Fuel InjecDocument39 paginiFuel Injection Systems Diesel Fuel InjecRasoolKhadibiÎncă nu există evaluări

- 3 C 6896Document2 pagini3 C 6896RasoolKhadibiÎncă nu există evaluări

- XL As11437bm en UsDocument20 paginiXL As11437bm en UsRasoolKhadibiÎncă nu există evaluări

- 4769663Document24 pagini4769663RasoolKhadibiÎncă nu există evaluări

- 150 CadDocument154 pagini150 CadRafael Quevedo Mogollon100% (4)

- Daewoo Excavators Spec 89bb26Document6 paginiDaewoo Excavators Spec 89bb26RasoolKhadibiÎncă nu există evaluări

- Baldwin Fuel Filters PDFDocument20 paginiBaldwin Fuel Filters PDFheartofdixieÎncă nu există evaluări

- Transmission Glycol TestDocument1 paginăTransmission Glycol TestRasoolKhadibiÎncă nu există evaluări

- Transmission Glycol TestDocument2 paginiTransmission Glycol TestRasoolKhadibiÎncă nu există evaluări

- 23717945Document36 pagini23717945RasoolKhadibiÎncă nu există evaluări

- Cylinder Liners and Pistons, Replace (All) PDFDocument14 paginiCylinder Liners and Pistons, Replace (All) PDFEsam PhlipeÎncă nu există evaluări

- Fluid Analysis Services: Call 131 228Document1 paginăFluid Analysis Services: Call 131 228RasoolKhadibiÎncă nu există evaluări

- Variable Vane Pumps PV7Document32 paginiVariable Vane Pumps PV7RasoolKhadibi100% (1)

- Torque ConverterDocument6 paginiTorque ConverterRasoolKhadibiÎncă nu există evaluări

- EthanethiolDocument3 paginiEthanethiolRasoolKhadibiÎncă nu există evaluări

- Mercaptans in Crude Oil: Larry Kremer & Weldon Cappel Baker HughesDocument11 paginiMercaptans in Crude Oil: Larry Kremer & Weldon Cappel Baker HughesRasoolKhadibiÎncă nu există evaluări

- M EthanethiolDocument4 paginiM EthanethiolRasoolKhadibiÎncă nu există evaluări

- New Holland AgricultureDocument14 paginiNew Holland AgricultureRasoolKhadibiÎncă nu există evaluări

- Wheel Tractor ScraperDocument2 paginiWheel Tractor ScraperRasoolKhadibi0% (1)

- Paver (Vehicle)Document3 paginiPaver (Vehicle)RasoolKhadibiÎncă nu există evaluări

- Caterpillar D6Document3 paginiCaterpillar D6RasoolKhadibi100% (1)

- Caterpillar D11Document3 paginiCaterpillar D11RasoolKhadibiÎncă nu există evaluări

- Claas Kgaa MBHDocument3 paginiClaas Kgaa MBHRasoolKhadibiÎncă nu există evaluări

- Caterpillar D9Document4 paginiCaterpillar D9RasoolKhadibiÎncă nu există evaluări

- DYNA4 Car ProfessionalDocument4 paginiDYNA4 Car ProfessionalRasoolKhadibiÎncă nu există evaluări

- Caterpillar 797Document7 paginiCaterpillar 797RasoolKhadibiÎncă nu există evaluări

- Komatsu D575ADocument4 paginiKomatsu D575ARasoolKhadibiÎncă nu există evaluări

- TerexDocument5 paginiTerexRasoolKhadibiÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 2021 Audi q8 78209Document332 pagini2021 Audi q8 78209Charlotte EmeryÎncă nu există evaluări

- Tablero Aveo 1.6LTS. 2Document1 paginăTablero Aveo 1.6LTS. 2Ricardo Reyes HernándezÎncă nu există evaluări

- AOC Catalog Insignia Sports Tourer Central Market English PDFDocument15 paginiAOC Catalog Insignia Sports Tourer Central Market English PDFGreen_Beret_8Încă nu există evaluări

- 09 Perf PartsDocument61 pagini09 Perf Parts武知沢菩Încă nu există evaluări

- Bajaj Auto OCRDocument29 paginiBajaj Auto OCRMurtaza ChoolawalaÎncă nu există evaluări

- CV. Duta Perkasa - Tentang KamiDocument3 paginiCV. Duta Perkasa - Tentang KamiAneka Teknik SolusindoÎncă nu există evaluări

- ETL SQUIX2 en PDFDocument12 paginiETL SQUIX2 en PDFAnonymous EDWe9ZÎncă nu există evaluări

- Specifications 7 Series 730i 730li PDFDocument2 paginiSpecifications 7 Series 730i 730li PDFKhawaja Arslan AhmedÎncă nu există evaluări

- 8398Document1 pagină8398Sujith Raj SÎncă nu există evaluări

- Volvo XC70 (08-) - 2009 VOLVO V70 (08-), XC70 (08-) & S80 (07-) WIRING DIAGRAMDocument35 paginiVolvo XC70 (08-) - 2009 VOLVO V70 (08-), XC70 (08-) & S80 (07-) WIRING DIAGRAMsen til100% (2)

- MHT-X 790Document5 paginiMHT-X 790JpbÎncă nu există evaluări

- mf31 1 160810203506 PDFDocument200 paginimf31 1 160810203506 PDFagrodostavaÎncă nu există evaluări

- L - (MG) - FRM - 111 - R1 Vehicle Daily ChecklistDocument1 paginăL - (MG) - FRM - 111 - R1 Vehicle Daily ChecklistEdhz Bilog100% (1)

- Aston Martin Driver Issue 1 March 2022Document100 paginiAston Martin Driver Issue 1 March 2022aldoiugianiÎncă nu există evaluări

- Suspension Fturur (Video Tutorial) SolidWorks - YouTubeDocument2 paginiSuspension Fturur (Video Tutorial) SolidWorks - YouTubekuldip singhÎncă nu există evaluări

- Daily Inspection Report Non-FillableDocument2 paginiDaily Inspection Report Non-FillableTommyÎncă nu există evaluări

- My22 Giant Wheelsystem Instruction Manual: For Giant Wheel Service Center Only 2021. JuneDocument36 paginiMy22 Giant Wheelsystem Instruction Manual: For Giant Wheel Service Center Only 2021. JuneBenÎncă nu există evaluări

- Truck GMC 1500 3500 Service ManualDocument477 paginiTruck GMC 1500 3500 Service ManualDiego Hernan Piñeiro100% (1)

- Chevrolet Traverse Awd Workshop Manual (V6-3.6L (2011) )Document1.947 paginiChevrolet Traverse Awd Workshop Manual (V6-3.6L (2011) )Ty SmithÎncă nu există evaluări

- Premobilisation Bus InspectionDocument1 paginăPremobilisation Bus InspectionArjun SatheesanÎncă nu există evaluări

- HondaDocument20 paginiHondaVivek DhandeÎncă nu există evaluări

- AP39JD2560: Vehicle Detailed DescriptionDocument1 paginăAP39JD2560: Vehicle Detailed Descriptionsrinu nikitaÎncă nu există evaluări

- FCA Trucks NHTSADocument8 paginiFCA Trucks NHTSABTÎncă nu există evaluări

- MyFerrari - Ferrari 296 GTB - 6jorj90Document11 paginiMyFerrari - Ferrari 296 GTB - 6jorj906370Încă nu există evaluări

- Bucket Control Lever - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsDocument3 paginiBucket Control Lever - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsashraf elsayedÎncă nu există evaluări

- Trojan Trailer ComponentsDocument44 paginiTrojan Trailer ComponentsMarty DelimaÎncă nu există evaluări

- Baja Virtuals PPT Team ABADHA CRCEDocument14 paginiBaja Virtuals PPT Team ABADHA CRCESahil WaguzariÎncă nu există evaluări

- Your Bentley Continental GT Speed: PresentingDocument9 paginiYour Bentley Continental GT Speed: PresentingMARTIN EDUARDO LOPEZ DURANÎncă nu există evaluări

- Dimension Specification: Hyundai Heavy IndustriesDocument6 paginiDimension Specification: Hyundai Heavy IndustriesАлександр ОлейникÎncă nu există evaluări

- ApplBro LogHandl 21A1003717Document16 paginiApplBro LogHandl 21A1003717Bilal VURALÎncă nu există evaluări