Documente Academic

Documente Profesional

Documente Cultură

Bolt Thread and Head Fillet Stress

Încărcat de

Bishwajyoti DuttaMajumdarDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bolt Thread and Head Fillet Stress

Încărcat de

Bishwajyoti DuttaMajumdarDrepturi de autor:

Formate disponibile

Bolt Thread and Head Fillet Stress

Terry F. Lehnhoff

Department of Mechanical

Concentration Factors

and Aerospace Engineering

Linear finite element analysis (FEA) was performed to determine stress concentration

and Engineering Mechanics,

factors for the threads and the bolt head fillet in a bolted connection. The FEA models

106C Mechanical Engineering Building,

consisted of axisymmetric representations of a bolt and two circular steel plates each 20

1870 Miner Circle,

mm in thickness. The bolts studied were 8, 12, 16, 20, and 24-mm-dia grade 10.9 metric

University of Missouri, Rolla,

bolts with the standard M thread profile. The threads were modeled at both the minimum

Rolla, MO 65409-0050

and maximum allowable depths. The fillet between the bolt shank and bolt head connec-

e-mail: lehnhoff@umr.edu

tion was modeled at its minimum radius. Each bolt was loaded to its proof strength. A

comparison is made to stress concentration factors typically used in bolted connection

design. Stress concentration factors in the head fillet were 3.18, 3.23, 3.63, 3.58, and 3.90

Bradley A. Bunyard for the 8, 12, 16, 20, and 24-mm bolts, respectively. Thread stress concentration factors

Applications Engineering,

were highest in the first engaged thread and decreased in each successive thread moving

Ferguson Company,

toward the end of the bolt. Stress concentration factors for the shallow thread models

St. Louis, MO

ranged from 1.17 to 4.33, 0.87 to 4.32, 0.83 to 4.67, 0.87 to 4.77, and 0.82 to 4.82 for the

e-mail: bbunyard@ferguson-co.com

8, 12, 16, 20, and 24-mm bolts, respectively. Likewise, stress concentration factors for the

deep thread models ranged from 1.18 to 4.80, 0.88 to 4.80, 0.78 to 5.12, 0.83 to 5.17, and

0.82 to 5.22 for the 8, 12, 16, 20, and 24-mm bolts, respectively.

S0094-99300001402-5

Introduction thread roots were approximately square and ranged in size from

0.023 mm for the 8-mm bolt to 0.057 mm for the 24-mm bolt. In

It is becoming increasingly important to accurately predict the

the head fillet area the element size ranged from 0.061 mm for the

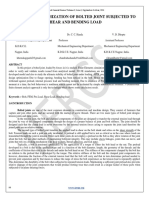

behavior of bolted joints such as the one pictured in Fig. 1. This

8-mm bolt to 0.083 mm for the 24-mm bolt.

paper is focused particularly on the stress concentrations that de-

Friction was included between all surfaces that came into con-

velop at the root of the loaded threads and the fillet beneath the

tact. For all contacting surfaces other than the threads a coefficient

head of the bolt when the bolts are loaded statically with uniaxial

external loads. Linear finite element methods were used to deter-

mine these stress concentrations.

There were ten models studied. The models included bolted

connections where two 20-mm-thick circular steel plates were

bolted together by a single bolt. The bolt diameters used were 8,

12, 16, 20, and 24 mm. Two models were made for each bolt

diameter. The first model used the maximum allowable thread

depth based on tolerances for the M thread profile. The second

model used the minimum allowable thread depth. The head fillet

was modeled at its minimum radius. Dimension definition for the

thread profiles can be seen in Figs. 2 and 3. Actual dimensions are

shown in Table 1. Information concerning thread form and dimen-

sions was obtained from Oberg et al. 1 and Avallone and

Baumeister 2.

The loads that were used in the bolted connection were ob-

tained from research conducted by the authors 3 concerning bolt

and member stiffnesses. However, virtually any loads would have Fig. 1 Typical bolted joint

worked for the research reported here due to its linear nature.

The Finite Element Model

The FEA models consisted of parabolic axisymmetric solid el-

ements. A schematic of the bolted joint models is shown in Fig. 4.

Gap elements were used to separate the threads in the bolt/nut

region and in the areas of contact between the bolt, nut and mem-

bers. With the exception of the engaged bolt threads and the head

fillet areas, element sizes were determined by research conducted

by Lehnhoff and Wistehuff 4,5. Element size for the engaged

threads and the head fillet areas were determined by obtaining

several solutions for the model with the element size being re-

duced each time. Elements at the location of the high stress in the

Contributed by the Pressure Vessels and Piping Division for publication in the

JOURNAL OF PRESSURE VESSEL TECHNOLOGY. Manuscript received by the PVP

Division, August 11, 1999; revised manuscript received March 7, 2000. Associate

Technical Editor: Y. W. Kwon. Fig. 2 Thread dimensions for deep thread models

180 Vol. 122, MAY 2000 Copyright 2000 by ASME Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 11/29/2015 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Fig. 3 Thread dimensions for shallow thread models Fig. 4 Schematic of axisymmetric model

of friction of 0.80 was used. A coefficient of friction of 0.15 was The geometric experimental stress concentration factors are

used for the threads. Grade 10.9 bolts were used with a proof based on fatigue stress concentration factor data presented by both

strength, S p , equal to 830 MPa. The grade 10.9 bolts were used Shigley and Mischke 6 and Norton 7. The values given by both

only to facilitate comparison to fatigue stress concentration factors sources give the reduced fatigue stress concentration factor (K f )

reported by Shigley and Mischke 6. No residual stresses were based on the type of thread rolled or cut and bolt material. Be-

included in the modeling of the threads. The modulus of elasticity, cause residual stresses were not modeled, results were compared

E, used for all components of the bolted joint models was 206, to values given for cut threads. Since the experimental values are

780 MPa. The value used for Poisons ratio, , was 0.30. Standard the fatigue stress concentration factors, it was necessary to use the

bolt clearances of 1 mm were used for the 24, 20, 16, and 12-mm following relation to obtain the geometric experimental stress con-

bolts and of 0.5 mm was used for the 8-mm bolt. Bolt lengths centration value (K t ):

were determined by taking the shortest standard length bolt that K f 1

would allow two to three threads to protrude beyond the nut. K t 1 (4)

q

Analysis Procedure for comparison to the results of this research. The notch sensitiv-

ity factor, q, depends on the material strength Grade 10.9 and

Each of the ten finite element models were solved using the was approximated from graphical data found in Shigley and Mis-

loading and material properties, as described in the foregoing. chke 6. The values used in calculations for this paper are shown

After the solution was obtained, the highest value of von Mises in Table 1.

stress was recorded for each of the engaged bolt threads and the

head fillet. This stress value was then divided by the nominal

stress. The value for nominal stress used in the calculation of the

stress concentration factors for the threads, was calculated by the Discussion of Results

following relation: There were five bolt threads in contact with nut threads regular

t b

Ab

At

(1)

hexagonal nuts for the 8-mm bolt models. Figure 5 shows the

plotted data for the 8-mm bolt shallow thread model. Starting with

the first thread engaged with the nut, the stress concentration fac-

where tors for each thread were 4.33, 2.88, 1.97, 1.43, and 1.17. Using

the method outlined in the foregoing and the average fatigue

Fb strength reduction factor, K f , as reported by Shigley and Mischke

b (2)

Ab 6 the value of K t is 4.46. Comparing, it is seen that the FEA

results range from 97 to 26 percent of the reported value. Results

and for the 8-mm deep thread model are shown in Fig. 6. Again,

F b kb

k b k mPF i (3)

starting with the first engaged thread the stress concentration fac-

tors were 4.80, 2.97, 2.03, 1.47, and 1.18. Comparing the FEA

results to Shigley and Mischkes 6 experimental value the stress

The applied bolt stress, b , was used for the nominal stress in concentration factors ranged from 108 percent to 26 percent of the

calculating the head fillet stress concentration factors. reported value.

Table 1 Bolt model parameters

Journal of Pressure Vessel Technology MAY 2000, Vol. 122 181

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 11/29/2015 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Fig. 5 Stress concentration factor by thread 8-mm bolt shal- Fig. 8 Stress concentration factor by thread 12-mm bolt deep

low threads threads

Fig. 6 Stress concentration factor by thread 8-mm bolt deep Fig. 9 Stress concentration factor by thread 16-mm bolt shal-

threads low threads

Fig. 7 Stress concentration factor by thread 12-mm bolt shal- Fig. 10 Stress concentration factor by thread 16-mm bolt

low threads deep threads

For the 12-mm bolt models, there were six bolt threads in con- nut threads. Results for the shallow thread and deep thread models

tact with nut threads. Results for the shallow thread model are are shown in Figs. 9 and 10, respectively. For the shallow thread

shown in Fig. 7. The stress concentration factor for the engaged model the stress concentration factors were 4.67, 3.26, 2.25, 1.63,

bolt threads were 4.32, 3.04, 2.06, 1.44, 1.04, and 0.87. The value 1.20, 0.93, and 0.83. The value of K t calculated from Shigley and

of K t calculated from Shigley and Mischkes 6 data is 4.42. The Mischke 6 is 4.37. The FEA results ranged from 107 to 19

FEA results range from 98 percent to 20 percent of this value. percent of this value. The deep thread model had stress concen-

Figure 8 shows the results from the deep thread model of the tration factors of 5.12, 3.30, 2.28, 1.65, 1.23, 0.96, and 0.83. For a

12-mm bolt. Stress concentration factors for this model were 4.80, range of 117 to 19 percent of the experimental value.

3.12, 2.12, 1.48, 1.08, and 0.88. Comparing to the value obtained The 20-mm bolt models had seven bolt threads in contact with

from Shigley and Miscke 6, the FEA results ranged from 109 to nut threads. Results for the shallow thread and deep thread models

20 percent of the experimental value. are shown in Figs. 11 and 12, respectively. Stress concentration

The 16-mm bolt models had seven threads in contact with the factors for the shallow thread model ranged from 4.77 to 0.87 or

182 Vol. 122, MAY 2000 Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 11/29/2015 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Fig. 11 Stress concentration factor by thread 20-mm bolt Fig. 14 Stress concentration factor by thread 24-mm bolt

shallow threads deep threads

Fig. 12 Stress concentration factor by thread 20-mm bolt Fig. 15 Stress concentration factor for bolt head fillet all bolt

deep threads diameters

Fig. 13 Stress concentration factor by thread 24-mm bolt

shallow threads

111 percent to 20 percent of the experimental value. For the deep Fig. 16 Example of stress contour plot at head fillet

thread model the stress concentration factors ranged from 5.17 to

0.86 or 121 to 20 percent of the experimental value.

Seven threads were in contact in the models for the 24 mm bolt. thread models. That is, the stress concentration factors for the 8

Figures 13 and 14 show the results for the shallow thread and and 12-mm bolts are approximately equal and then increase for

deep thread models, respectively. Stress concentration factors each increase in bolt diameter. For the deep thread models the

ranged from 4.82 to 0.82 or 113 percent to 19 percent of the stress concentration factor increases 6.67 percent between the 12

experimental value, while the stress concentration factors for the and 16-mm bolts, 0.97 percent between the 16-mm and 20-mm

deep thread model ranged from 5.22 to 0.82 or 123 to 19 percent bolts, and 0.97 percent between the 20 and 24-mm bolts. Like-

of the experimental value. wise, the stress concentration factors in the shallow thread models

The same pattern is seen when comparing stress concentration increase 8.10 percent between the 12 and 16-mm bolts, 2.14 per-

factors in the first engaged thread for both the shallow and deep cent between the 16 and 20-mm bolts, and 1.05 percent between

Journal of Pressure Vessel Technology MAY 2000, Vol. 122 183

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 11/29/2015 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Mises stress in the thread root and head fillet regions. The highest

stress occurred below the deepest point of the thread, while the

largest stress in the head fillet region occurred near the center of

the fillet arc length.

Conclusions

It should be noted that, the modeling of the bolted joint as done

in this research does not fully simulate the geometry as well as the

nonlinear response that occurs in bolted joints. Therefore, the re-

sults reported here cannot be quantitatively precise. However, it is

believed that they can provide important insight into the behavior

of bolted connections. The largest discrepancy from reality is the

fact that the model solutions were obtained using a linear material

model. It is generally accepted that local yielding occurs in both

the thread roots and the head fillet. However, it is significant to

observe that the stress concentration factors in both the head fillet

and the threads deviate more from the experimental values, for the

larger bolts. This can be important in the construction of any large

equipment and especially large pressure vessels. A review of the

discussion of the various experimental studies referenced in

Fig. 17 Example of stress contour plot at first engaged thread Pilkey 8 shows considerable variation between researchers but

there is no indication of why these results might deviate more

from our results for the larger diameter bolts. Perhaps it is too

the 20 and 24-mm bolts. When comparing the shallow thread to much to expect to be able to extrapolate the experimental values

the deep thread, it is seen that there is an increase of 10.9 percent given by Shigley.

for the 8-mm bolts, 11.1 percent for the 12-mm bolts, 9.6 percent The results of this research are summarized in Table 2 and

for the 16-mm bolts, 8.4 percent for the 20-mm bolts, and 8.3 should be applicable to many bolted joint design problems where

percent for the 24-mm bolts. the joints can be assumed to behave in an axisymmetric fashion.

Head fillet stress concentration factor results are shown in Fig.

15. The values are 3.18, 3.23, 3.63, 3.58, and 3.90 for the 8, 12,

16, 20, and 24-mm bolts. These values correspond to 126, 131,

Nomenclature

147, 147, 160 percent of the average values reported by Shigley A b cross-sectional area in unthreaded portion of bolt mm2

and Mishcke 6. A t cross-sectional area of bolt in threaded portion of bolt

The stress concentration factor in the head fillet does not show mm2

a consistent increase as the bolt diameter increases. The stress E modulus of elasticity N/m2

concentration factor increases by 1.6 percent between the 8 and EP external load edge pressure N/m2

12-mm bolts, increases 12.4 percent between the 12 and 16-mm F b force in bolt N

bolts, decreases 1.4 percent between the 16 and 20-mm bolts, and F i preload in bolt N

increases 8.9 percent between the 20 and 24-mm bolts. This in- H height of fundamental triangle mm

consistent pattern can be explained by looking at the difference in k b bolt stiffness N/m

the amount of load that each bolt can carry as well as the head k m member stiffness N/m

fillet radius of the bolts. There is an increase in load-carrying K f fatigue stress concentration factor

capacity of 125 percent between the 8 and 12-mm bolts, 78 per- K t stress concentration factor

cent between the 12 and 16-mm bolts, 56 percent between the 16 L bolt grip length mm

and 20-mm bolts, and 44 percent between the 20 and 24-mm P external load N

bolts. The head fillet radius increases by 50 percent between the 8 p thread pitch mm

and 12-mm bolts, stays the same between the 12 and 16-mm bolts, q notch sensitivity factor

increases by 33 percent between the 16 mm and 20 mm bolts, and r a inside radius of applied external load mm

stays the same between the 20 and 24-mm bolts. It is noted that r b outside radius of applied external load mm

the two large increases in stress concentration factor occur where r min minimum radius of bolt thread fillet

there is an increase in load and no change in head fillet radius. The S p proof strength of bolts N/m2

small changes in stress concentration factor occurred when both T d2 tolerance on pitch diameter of external thread mm

the load and the head fillet radius increased. t1 thickness of top member mm

Figures 16 and 17 show examples of contour plots of the von t2 thickness of bottom member mm

Table 2 Theoretical geometric stress concentration factors

184 Vol. 122, MAY 2000 Transactions of the ASME

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 11/29/2015 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Poisons ratio Stiffness of Bolted Joints, ASME, Anaheim, CA, Recent Advances in Solids

b nominal stress applied to nominal diameter of bolt and Structures, PVP-Vol. 381, pp. 141146.

4 Lehnhoff, T. F., and Wistehuff, W. E., 1994, Nonlinear Effects on the Stiff-

N/m2

ness of Bolted Joints, ASME Pressure Vessels and Piping Conference, Min-

t nominal stress in threaded portion of bolt N/m2 neapolis, MN.

5 Lehnhoff, T. F., and Wistehuff, W. E., 1996, Nonlinear Effects on the Stiff-

References ness of Bolted Joints, ASME J. Pressure Vessel Technol., 118, pp. 4853.

6 Shigley, J. E., and Mischke, C. R., 1989, Mechanical Engineering Design,

1 Oberg, E., Jones, F. D., Holbrook, H. L., and Ryffel, H. H., 1996, Machinerys

Handbook, Industrial Press, 25th Edition. McGraw-Hill, 5th Edition.

2 Avallone, A. A., and Baumeister, III, T., 1996, Marks Standard Handbook for 7 Norton, R. L., 1996, Machine Design an Integrated Approach, Prentice-Hall.

Mechanical Engineers, McGraw-Hill, 10th Edition. 8 Pilkey, Walter D., 1997, Petersons Stress Concentration Factors, Wiley, 2nd

3 Lehnhoff, T. F., and Bunyard, B. A., 1998, Effects of Bolt Threads on the Edition.

Journal of Pressure Vessel Technology MAY 2000, Vol. 122 185

Downloaded From: http://pressurevesseltech.asmedigitalcollection.asme.org/ on 11/29/2015 Terms of Use: http://www.asme.org/about-asme/terms-of-use

S-ar putea să vă placă și

- Domex Welding PDFDocument16 paginiDomex Welding PDFAgourame Abderrahmane100% (1)

- AA V6 I2 Modeling Threaded Bolted Joints in ANSYS Workbench PDFDocument3 paginiAA V6 I2 Modeling Threaded Bolted Joints in ANSYS Workbench PDFdanaosajoÎncă nu există evaluări

- Engineering - Bulletin - Calculating Thread StrengthDocument2 paginiEngineering - Bulletin - Calculating Thread StrengthrobigedÎncă nu există evaluări

- Fastener Tightening PDFDocument3 paginiFastener Tightening PDFAbdullah AnsariÎncă nu există evaluări

- Analysis of Stress Concentration Factor in Bolted Joint Using Finite Element MethodDocument9 paginiAnalysis of Stress Concentration Factor in Bolted Joint Using Finite Element Methodvj2011100% (1)

- ISO Metric Screw Thread StandardsDocument4 paginiISO Metric Screw Thread StandardsskluxÎncă nu există evaluări

- GuidanceNotes EN131 Version2Document10 paginiGuidanceNotes EN131 Version2Javier Quintero SaavedraÎncă nu există evaluări

- Bolted Joint Analysis - MechaniCalcDocument22 paginiBolted Joint Analysis - MechaniCalcHasan BoxkiÎncă nu există evaluări

- Structural Properties of Bolted JointsDocument5 paginiStructural Properties of Bolted JointsL095244Încă nu există evaluări

- Codes For Vessels/Heat ExchangersDocument23 paginiCodes For Vessels/Heat Exchangersegy pureÎncă nu există evaluări

- Preload in Bolted JointsDocument88 paginiPreload in Bolted JointsZulfiqar Ali100% (1)

- Hinge DesignDocument2 paginiHinge Designpare222Încă nu există evaluări

- Calculation of Retaining RingsDocument7 paginiCalculation of Retaining RingsDobrica PetrovicÎncă nu există evaluări

- En 12944Document11 paginiEn 12944scribd99190100% (1)

- Ultimate Strength of Fillet Welded Connections Loaded in PlaneDocument13 paginiUltimate Strength of Fillet Welded Connections Loaded in PlanePatrick PolujanÎncă nu există evaluări

- Minimum Thread Engagement With Respect To Material StrengthDocument10 paginiMinimum Thread Engagement With Respect To Material StrengthDarío CostasÎncă nu există evaluări

- Rohi Product CatalogeDocument39 paginiRohi Product CatalogefinojÎncă nu există evaluări

- VDI2230 Review Design GuidelineDocument15 paginiVDI2230 Review Design GuidelinebreeeeezzzzzeÎncă nu există evaluări

- 06 Eurocodes Steel Workshop WALDDocument136 pagini06 Eurocodes Steel Workshop WALDFrancisco RojasÎncă nu există evaluări

- Iso 2768 EnglishDocument3 paginiIso 2768 EnglishfethiaktuncÎncă nu există evaluări

- UNC UNF BSW BSF Screw Thread ChartDocument4 paginiUNC UNF BSW BSF Screw Thread ChartDave Slope100% (1)

- Safety Factor of Statically Loaded Weld JointDocument2 paginiSafety Factor of Statically Loaded Weld JointMoonzeÎncă nu există evaluări

- Technical Reference Guide For Fastening BoltsDocument62 paginiTechnical Reference Guide For Fastening BoltssydengineerÎncă nu există evaluări

- 5 Strength AnalysisDocument63 pagini5 Strength Analysisdan20000Încă nu există evaluări

- A Calculation of Piston Rod Strength - Bennet, M.CDocument12 paginiA Calculation of Piston Rod Strength - Bennet, M.CLeandro FabrisÎncă nu există evaluări

- BARNES Associated Spring Raymond 2010Document260 paginiBARNES Associated Spring Raymond 2010Francois LaroucheÎncă nu există evaluări

- Case DepthDocument2 paginiCase DepthSumeet SainiÎncă nu există evaluări

- Astm A516Document11 paginiAstm A516Kokoh Aji LesmanaÎncă nu există evaluări

- Neral Notes On Engineering Hardware - FastenersDocument45 paginiNeral Notes On Engineering Hardware - Fastenersbrotaccristian100% (1)

- Design of fillet weld as per BS EN 1993 1 8 CL 4.5.3Document2 paginiDesign of fillet weld as per BS EN 1993 1 8 CL 4.5.3Giri DharanÎncă nu există evaluări

- Metric Bolt StrengthDocument18 paginiMetric Bolt StrengthSachin ShindeÎncă nu există evaluări

- Metric DIN 434 Square Taper Washers Technical Specifications and StandardsDocument4 paginiMetric DIN 434 Square Taper Washers Technical Specifications and StandardsRodrigoÎncă nu există evaluări

- Zinc/Aluminum Corrosion Protective Coatings For FastenersDocument3 paginiZinc/Aluminum Corrosion Protective Coatings For FastenersDarwin DarmawanÎncă nu există evaluări

- WeldDocument3 paginiWeldSenthil SubramanianÎncă nu există evaluări

- Worm and Worm Wheel NomenclatureDocument1 paginăWorm and Worm Wheel NomenclaturemuhdqasimÎncă nu există evaluări

- Bursting Pressure of Mild Steel Cylindrical VesselsDocument4 paginiBursting Pressure of Mild Steel Cylindrical VesselsAris FauziÎncă nu există evaluări

- Root and Face Bend TestsDocument3 paginiRoot and Face Bend TestsErlinawati Bintu SupiyoÎncă nu există evaluări

- ISO 10243.die SpringsDocument12 paginiISO 10243.die SpringsКонстантин Косарев100% (1)

- Tolerances FitsDocument25 paginiTolerances FitsAnonymous E2oSW7Încă nu există evaluări

- MDESIGN Bolt, VDI 2230 (Coupling - Bolt - CalDocument6 paginiMDESIGN Bolt, VDI 2230 (Coupling - Bolt - CalSridhar Tholasingam100% (1)

- Torsion Bolt-Report PDFDocument147 paginiTorsion Bolt-Report PDFTuanQuachÎncă nu există evaluări

- AD 2000-Merkblatt B 13 English Vom 07-2012Document44 paginiAD 2000-Merkblatt B 13 English Vom 07-2012GÖKHAN İNCİRLİÎncă nu există evaluări

- Fatigue Analysis of Ball JointDocument21 paginiFatigue Analysis of Ball JointAmbalam NandhuÎncă nu există evaluări

- SIE1010 Lesson 5.2 - Dimensioning and Tolerancing (Part 2)Document56 paginiSIE1010 Lesson 5.2 - Dimensioning and Tolerancing (Part 2)lightsoul91Încă nu există evaluări

- Membrane BendingDocument12 paginiMembrane BendingAnonymous tGFxtqNÎncă nu există evaluări

- Din 76-1Document5 paginiDin 76-1mesa142Încă nu există evaluări

- Proper Bolt Axial Tightening ForceDocument1 paginăProper Bolt Axial Tightening ForcePrabhu SelvaRajÎncă nu există evaluări

- Analyzing Taper Fits For ManufacturingDocument7 paginiAnalyzing Taper Fits For Manufacturingsalgado_24Încă nu există evaluări

- Shear Strength of High-Strength BoltsDocument61 paginiShear Strength of High-Strength Boltsloox600Încă nu există evaluări

- ASME Y14.1-2005, Drawing Sheet Size and FormatDocument5 paginiASME Y14.1-2005, Drawing Sheet Size and FormatpalaniÎncă nu există evaluări

- Pressure Vessel Plates, Alloy Steel, Quenched and Tempered 7, 8, and 9 % NickelDocument4 paginiPressure Vessel Plates, Alloy Steel, Quenched and Tempered 7, 8, and 9 % Nickelalucard375100% (1)

- Spring DesignDocument49 paginiSpring DesignbennyfergusonÎncă nu există evaluări

- Bolts TheoryDocument30 paginiBolts TheoryIbrahim Mesfin100% (1)

- Shear Lag in Tension Member Welded ConnectionsDocument10 paginiShear Lag in Tension Member Welded ConnectionsRamesh PrabhakarÎncă nu există evaluări

- Thread Root RadiusDocument6 paginiThread Root RadiusVasile CojocaruÎncă nu există evaluări

- Shigley's Mechanical Engineering Design - Chapter 8 - Part 1Document71 paginiShigley's Mechanical Engineering Design - Chapter 8 - Part 1RM ShahbabÎncă nu există evaluări

- McDowell, 2000, Modeling and Experiments in PlasticityDocument17 paginiMcDowell, 2000, Modeling and Experiments in PlasticityBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Zhang Et Al., 2006, Shock Induced Decomposition and Sensitivity of Energetic Materials by reaxFF Molecular DynamicsDocument4 paginiZhang Et Al., 2006, Shock Induced Decomposition and Sensitivity of Energetic Materials by reaxFF Molecular DynamicsBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Wagner, Holian, Massively Parallel Molecular Dynamics Simulations of Two-Dimensional Materials at High Strain RatesDocument6 paginiWagner, Holian, Massively Parallel Molecular Dynamics Simulations of Two-Dimensional Materials at High Strain RatesBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Polymethylmethacrylate Manganin Gauge and VISAR Histories in Shock-StressedDocument9 paginiPolymethylmethacrylate Manganin Gauge and VISAR Histories in Shock-StressedBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Study On A Zerilli-Armstrong and An Artificial Neural Network Model For 4Cr5Mosiv1 Quenched Steel at High Strain RateDocument4 paginiStudy On A Zerilli-Armstrong and An Artificial Neural Network Model For 4Cr5Mosiv1 Quenched Steel at High Strain RateBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Bringa Et Al., 2006, Shock Deformation of Face-Centred-Cubic Metals On Subnanosecond TimescalesDocument5 paginiBringa Et Al., 2006, Shock Deformation of Face-Centred-Cubic Metals On Subnanosecond TimescalesBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Germann, Holian, 2002, Molecular Dynamics Simulations of Detonation in Defective Explosive CrystalsDocument9 paginiGermann, Holian, 2002, Molecular Dynamics Simulations of Detonation in Defective Explosive CrystalsBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Mechanics of Materials: Mingxin Huang, Pedro E.J. Rivera-Díaz-del-Castillo, Olivier Bouaziz, Sybrand Van Der ZwaagDocument7 paginiMechanics of Materials: Mingxin Huang, Pedro E.J. Rivera-Díaz-del-Castillo, Olivier Bouaziz, Sybrand Van Der ZwaagBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Study On A Zerilli-Armstrong and An Artificial Neural Network Model For 4Cr5Mosiv1 Quenched Steel at High Strain RateDocument4 paginiStudy On A Zerilli-Armstrong and An Artificial Neural Network Model For 4Cr5Mosiv1 Quenched Steel at High Strain RateBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Estimating Maximum Pressures and Dissociation of Nitrous Oxide Induced by THPP Based InitiatorsDocument10 paginiEstimating Maximum Pressures and Dissociation of Nitrous Oxide Induced by THPP Based InitiatorsBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Modeling The Energy Release Characteristics of THPP Based InitiatorsDocument13 paginiModeling The Energy Release Characteristics of THPP Based InitiatorsBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Change of Shear Modulus and Yield Stress With Pressure and TemperatureDocument6 paginiChange of Shear Modulus and Yield Stress With Pressure and TemperatureBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Pyroshock Prediction of Ridge-Cut Explosive BoltsDocument15 paginiPyroshock Prediction of Ridge-Cut Explosive BoltsBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Polymethylmethacrylate Manganin Gauge and VISAR Histories in Shock-StressedDocument9 paginiPolymethylmethacrylate Manganin Gauge and VISAR Histories in Shock-StressedBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Estimating Maximum Pressures and Dissociation of Nitrous Oxide Induced by THPP Based InitiatorsDocument10 paginiEstimating Maximum Pressures and Dissociation of Nitrous Oxide Induced by THPP Based InitiatorsBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Order of FunctioningDocument8 paginiOrder of FunctioningBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Mechanics of Materials: Mingxin Huang, Pedro E.J. Rivera-Díaz-del-Castillo, Olivier Bouaziz, Sybrand Van Der ZwaagDocument7 paginiMechanics of Materials: Mingxin Huang, Pedro E.J. Rivera-Díaz-del-Castillo, Olivier Bouaziz, Sybrand Van Der ZwaagBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Change of Shear Modulus and Yield Stress With Pressure and TemperatureDocument6 paginiChange of Shear Modulus and Yield Stress With Pressure and TemperatureBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Berne Cker 1967Document10 paginiBerne Cker 1967Bishwajyoti DuttaMajumdarÎncă nu există evaluări

- Verma 2016Document5 paginiVerma 2016Bishwajyoti DuttaMajumdarÎncă nu există evaluări

- The Use of Two Nuts To Prevent Self Loosening PDFDocument2 paginiThe Use of Two Nuts To Prevent Self Loosening PDFBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Modeling The Energy Release Characteristics of THPP Based InitiatorsDocument13 paginiModeling The Energy Release Characteristics of THPP Based InitiatorsBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Design and Optimization of Bolted Joint Subjected ToDocument10 paginiDesign and Optimization of Bolted Joint Subjected ToBishwajyoti DuttaMajumdarÎncă nu există evaluări

- How Can I Implement A Prestressing Effect On Springs in Explicit DynamicsDocument1 paginăHow Can I Implement A Prestressing Effect On Springs in Explicit DynamicsBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Electronic Safe and ArmDocument7 paginiElectronic Safe and ArmBishwajyoti DuttaMajumdarÎncă nu există evaluări

- Post-Fire Short Circuit PhenomenaDocument9 paginiPost-Fire Short Circuit PhenomenaBishwajyoti DuttaMajumdarÎncă nu există evaluări

- ?@ Abcd@ ?CE FCGH at IB: Ij - PM JRH N Rsil QN Uy N L Z N RL L N Z N I IlDocument8 pagini?@ Abcd@ ?CE FCGH at IB: Ij - PM JRH N Rsil QN Uy N L Z N RL L N Z N I IlBishwajyoti DuttaMajumdarÎncă nu există evaluări

- ModalMass PDFDocument36 paginiModalMass PDFKhuất Trần ThanhÎncă nu există evaluări

- Ecss e ST 32c Rev 1Document134 paginiEcss e ST 32c Rev 1Bishwajyoti DuttaMajumdarÎncă nu există evaluări

- Abcdef Ghijkl Mnopq Rstuv Wxyz Alphabet Backpack Book Bookcase CalculatorDocument4 paginiAbcdef Ghijkl Mnopq Rstuv Wxyz Alphabet Backpack Book Bookcase Calculatornutka88Încă nu există evaluări

- Organizational BehaviorDocument15 paginiOrganizational Behaviorjuvy anne PobleteÎncă nu există evaluări

- Lewatit VP OC 1600 LDocument3 paginiLewatit VP OC 1600 Lphucuong2410Încă nu există evaluări

- Write EssayDocument141 paginiWrite Essayamsyous100% (1)

- No. of Periods UNIT - 1: Antenna FundamentalsDocument8 paginiNo. of Periods UNIT - 1: Antenna Fundamentalsbotla yogiÎncă nu există evaluări

- Enclosure No. 6.7: Parental ConsentDocument3 paginiEnclosure No. 6.7: Parental ConsentRhea CarinoÎncă nu există evaluări

- TPS6 LecturePowerPoint 11.1 DT 043018Document62 paginiTPS6 LecturePowerPoint 11.1 DT 043018Isabelle TorresÎncă nu există evaluări

- Federal Decree Law No. 47 of 2022Document56 paginiFederal Decree Law No. 47 of 2022samÎncă nu există evaluări

- Crema Coffee Garage - Understanding Caffeine Content of Popular Brewing Methods Within The Australian Coffee Consumer MarketDocument33 paginiCrema Coffee Garage - Understanding Caffeine Content of Popular Brewing Methods Within The Australian Coffee Consumer MarketTDLemonNhÎncă nu există evaluări

- Research On Water Distribution NetworkDocument9 paginiResearch On Water Distribution NetworkVikas PathakÎncă nu există evaluări

- Site Handover and Completion FormDocument3 paginiSite Handover and Completion FormBaye SeyoumÎncă nu există evaluări

- PistonDocument247 paginiPistonmeyyiti01Încă nu există evaluări

- The German Tradition of Psychology in Literature and Thought 1700-1840 PDFDocument316 paginiThe German Tradition of Psychology in Literature and Thought 1700-1840 PDFerhan savasÎncă nu există evaluări

- Wi-Fi Planning and Design Questionnaire 2.0Document12 paginiWi-Fi Planning and Design Questionnaire 2.0Free Space67% (3)

- Quraani Nabatat K Khwas o Afadiat Tib e Jadeed K Nuqta e Nazar Se Fayaz Ahmed PH.D 2010Document542 paginiQuraani Nabatat K Khwas o Afadiat Tib e Jadeed K Nuqta e Nazar Se Fayaz Ahmed PH.D 2010Muhammad Ahmed Tarazi100% (1)

- Malunggay cooking oil substituteDocument5 paginiMalunggay cooking oil substitutebaba112Încă nu există evaluări

- File Download ActionDocument45 paginiFile Download Actionecarter9492Încă nu există evaluări

- SQL QuestionsDocument297 paginiSQL Questionskeysp75% (4)

- DGS PBDocument103 paginiDGS PBibraheemÎncă nu există evaluări

- The New York Times OppenheimerDocument3 paginiThe New York Times Oppenheimer徐大头Încă nu există evaluări

- Metamorphic differentiation explainedDocument2 paginiMetamorphic differentiation explainedDanis Khan100% (1)

- Sociology Viva NotesDocument4 paginiSociology Viva NotesTaniaÎncă nu există evaluări

- Jene Sys 2016 ApplicationformDocument4 paginiJene Sys 2016 ApplicationformReva WiratamaÎncă nu există evaluări

- Ear Discharge (Otorrhoea) FinalDocument24 paginiEar Discharge (Otorrhoea) Finaljaya ruban100% (1)

- Helical Axes of Skeletal Knee Joint Motion During RunningDocument8 paginiHelical Axes of Skeletal Knee Joint Motion During RunningWilliam VenegasÎncă nu există evaluări

- Sample of Med CertDocument1 paginăSample of Med CertRegineDagumanFuellasÎncă nu există evaluări

- Interventional Radiology & AngiographyDocument45 paginiInterventional Radiology & AngiographyRyBone95Încă nu există evaluări

- Fracture Mechanics HandbookDocument27 paginiFracture Mechanics Handbooksathya86online0% (1)

- Business Ethics and Social ResponsibilityDocument16 paginiBusiness Ethics and Social Responsibilitytitan abcdÎncă nu există evaluări

- Data & InformationDocument48 paginiData & InformationDave DearingÎncă nu există evaluări