Documente Academic

Documente Profesional

Documente Cultură

Friction Factor (Power Screw)

Încărcat de

AndiniPermanaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Friction Factor (Power Screw)

Încărcat de

AndiniPermanaDrepturi de autor:

Formate disponibile

Page 3 of 8

Untreated Steel 0,12 - 0,18 0,10 - 0,17

Phosphated Steel 0,12 - 0,18 0,10 - 0,17

Cadmium Plated Steel 0,09 - 0,14 0,08 -0,23

Galvanised steel 0,14 - 0,23 0,12 - 0,2

Degreased steel 0,19 - 0,25

Female Thread -Nut or Tapped Hole in steel(Galvanised)

Male screw Friction Coeffient (Dry) Friction Coefficient(Lub.)

Untreated Steel 0,14 - 0,2 0,12 - 0,18

Phosphated Steel 0,14 - 0,2 0,12 - 0,18

Cadmium Plated Steel 0,1 - 0,16 0,09 - 0,15

Galvanised steel 0,14 - 0,25 0,12 - 0,2

Degreased steel 0,19 - 0,25

Coefficient of Friction Nut/Bolt Face against Clamped surface

Clamped Surface = Steel

Bolt/Nut Mat'l Friction Coeffient (Dry) Friction Coefficient(Lub.)

Untreated Steel 0,10 - 0,18 0,08 - 0.15

Phosphated Steel 0,10 - 0,18 0,08 - 0,15

Galvanised steel 0,10 - 0,2 0,09 - 0,18

Clamped Surface -Galvanised Steel

Bolt/Nut Mat'l Friction Coefficient (Dry) Friction Coefficient (lub)

Untreated Steel 0,10 - 0,18 0,08 - 0,15

Phosphated Steel 0,10 - 0,18 0,08 - 0,15

Galvanised steel 0,16 - 0,22 0,09 - 0,18

Coefficient of friction between surfaces clamped by bolts /screws.

These values allow calculation of the shear force necessary to cause slip between surfaces when clamped by bolts.

Contact Surfaces slip coefficient

Steel On Steel- No treatment 0,15- 0,25

Steel On Cast Iron- No treatment 0,18 - 0,3

Steel On Steel- Machined (Degreased) 0,12- 0,18

Steel On Cast Iron- Machined (Degreased) 0,15 - 0,25

Grit -Sandblasted surfaces 0,48 - 0,55

Friction Factors for Power Screws

The following factors are typical friction factors for power screw torque and efficiency calculations..

1) Screw Thread Friction values (s)

(Friction factors apply mainly for screw thread friction (s) - can be applied to collar friction(c)

Nut Material

Screw Material

Steel Brass Bronze Cast Iron

Steel(Dry) 0,15-0,25 0,15-0,23 0,15-0,19 0,15-0,25

Steel (Lubricated) 0,11-0,17 0,10-0,16 0,10-0,15 0,11-0,17

Bronze (Lubricated) 0,08-0,12 0,04-0,06 - 0,06-0,09

2) Thrust collar Friction values (c)

Surface Combinations Moving Starting

Soft Steel on Cast Iron 0,12 0,17

Hard Steel on Cast Iron 0,09 0,15

Soft Steel on Bronze 0,08 0,10

Hard Steel on Bronze 0,06 0,08

Press Fit Mechanical Joints

In mechanical engineering rotary motion can be transferred by mechanical connections between a shaft and hub using only a tight fit. Methods of achieving this

type of connection include the engineered interference fit, the taper lock bush and hydraulic fit bush. These keyless shaft/hub connections all transfer torque by

friction.

The coefficient of friction used for designing these types of connections is dependent on the interface pressure, materials, surface condition, surface coatings etc.

The coefficient of friction is also dependent on the method of installation. A different value result if the shaft is forced into the hub (force fit) compared to the value

if the assemble is completed by heating the hub or freezing the shaft prior to assembly (shrink fit)...

Various values of relevant coefficients of friction are provided below;

Steel Hub , Steel Shaft unlubricated - force fit ...C. of Friction = 0,07 to 0,16

Steel Hub , Steel Shaft greased - force fit ...C. of Friction = 0,05 to 0,12

Steel Hub , Steel Shaft unlubricated - Shrink fit ...C. of Friction = 0,15 to 0,25

Steel Hub , Steel Shaft greased - Shrink fit ...C. of Friction = 0,08 to 0,16

The manufacturers of the proprietary keyless hub/shaft systems indicate that their products are based on a coefficient of friction of 0,12 for lightly oiled connections

and 0,15 for dry assemblies. These companies can provide surface coating fluids containing particles to increase the coefficient of friction i.e. coefficient of

friction to 0,25 to 0,3. (ref links 1 below)

The American Gear Manufactures Association (AGMA) recommends a value of between 0,12-0,15 for hydraulically expanded hubs and 0,15-0,20 for shrink or

press fit hubs.

05/08/2015

S-ar putea să vă placă și

- Abd El Rahman Et - AlDocument11 paginiAbd El Rahman Et - AlAndiniPermanaÎncă nu există evaluări

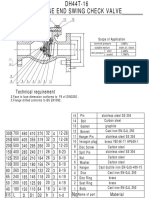

- Flanged End Swing Check Valves DIN3202 F6Document2 paginiFlanged End Swing Check Valves DIN3202 F6AndiniPermanaÎncă nu există evaluări

- FM Approvals Certification MarksDocument3 paginiFM Approvals Certification MarksAndiniPermanaÎncă nu există evaluări

- Tabel Toleransi: UNTUK POROS (Table 5.4, Ref. To NSK) Diameter (MM) TOLERANSI (0.001mm) Over Incl. MIN MAXDocument1 paginăTabel Toleransi: UNTUK POROS (Table 5.4, Ref. To NSK) Diameter (MM) TOLERANSI (0.001mm) Over Incl. MIN MAXAndiniPermanaÎncă nu există evaluări

- Effect of Pass Schedule On Cross-Sectional Shapes of Circular Seamless Pipes Reshaped Into Square Shapes by Hot Roll Sizing MillDocument6 paginiEffect of Pass Schedule On Cross-Sectional Shapes of Circular Seamless Pipes Reshaped Into Square Shapes by Hot Roll Sizing MillAndiniPermanaÎncă nu există evaluări

- Common Etchants PDFDocument2 paginiCommon Etchants PDFAndiniPermanaÎncă nu există evaluări

- Permit To Work PolicyDocument5 paginiPermit To Work PolicyAndiniPermanaÎncă nu există evaluări

- Uddeholm C Si MN CR Mo V W Ni Co P S: Vidar SupremeDocument1 paginăUddeholm C Si MN CR Mo V W Ni Co P S: Vidar SupremeAndiniPermanaÎncă nu există evaluări

- Hari Tanggal N K 19000 0 589000 1 11400 939000 2 26600 3 41800 5 79800 Income (/hari) 6 95000 7 117800 Save (/hari) 133000Document2 paginiHari Tanggal N K 19000 0 589000 1 11400 939000 2 26600 3 41800 5 79800 Income (/hari) 6 95000 7 117800 Save (/hari) 133000AndiniPermanaÎncă nu există evaluări

- CCT Vanadis 60Document1 paginăCCT Vanadis 60AndiniPermanaÎncă nu există evaluări

- Uddeholm C Si MN CR Mo V W Ni Co P S: ToughtemDocument1 paginăUddeholm C Si MN CR Mo V W Ni Co P S: ToughtemAndiniPermanaÎncă nu există evaluări

- CCT Vanadis 23Document1 paginăCCT Vanadis 23AndiniPermanaÎncă nu există evaluări

- CCT Vanadis 60 PDFDocument1 paginăCCT Vanadis 60 PDFAndiniPermanaÎncă nu există evaluări

- Uddeholm C Si MN CR Mo V W Ni Co P S: Vanadis 4Document1 paginăUddeholm C Si MN CR Mo V W Ni Co P S: Vanadis 4AndiniPermanaÎncă nu există evaluări

- Uddeholm C Si MN CR Mo V W Ni Co P S: GraneDocument1 paginăUddeholm C Si MN CR Mo V W Ni Co P S: GraneAndiniPermanaÎncă nu există evaluări

- Uddeholm C Si MN CR Mo V W Ni Co P S: Impax SupremeDocument1 paginăUddeholm C Si MN CR Mo V W Ni Co P S: Impax SupremeAndiniPermanaÎncă nu există evaluări

- Uddeholm C Si MN CR Mo V W Ni Co P S: Orvar SupremeDocument1 paginăUddeholm C Si MN CR Mo V W Ni Co P S: Orvar SupremeAndiniPermanaÎncă nu există evaluări

- CCT Orvar Supreme PDFDocument1 paginăCCT Orvar Supreme PDFAndiniPermanaÎncă nu există evaluări

- Uddeholm C Si MN CR Mo V W Ni Co P S: CompaxDocument1 paginăUddeholm C Si MN CR Mo V W Ni Co P S: CompaxAndiniPermanaÎncă nu există evaluări

- Uddeholm C Si MN CR Mo V W Ni Co P S: ElmaxDocument1 paginăUddeholm C Si MN CR Mo V W Ni Co P S: ElmaxAndiniPermanaÎncă nu există evaluări

- CCT Chipper VikingDocument1 paginăCCT Chipper VikingAndiniPermanaÎncă nu există evaluări

- Uddeholm C Si MN CR Mo V W Ni Co P S: DievarDocument1 paginăUddeholm C Si MN CR Mo V W Ni Co P S: DievarAndiniPermanaÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 9cbse-ATOMS AND MOLECULES-NOTES-JAN 2023 - UpdatedDocument4 pagini9cbse-ATOMS AND MOLECULES-NOTES-JAN 2023 - UpdatedTamers artÎncă nu există evaluări

- Durometer Types & Specifications: Type Model No. Force Indenter Description ApplicationsDocument2 paginiDurometer Types & Specifications: Type Model No. Force Indenter Description ApplicationsDarwin_Sidney100% (1)

- PagesDocument1 paginăPagesEnedis Pimentel0% (1)

- Coordination CompoundDocument76 paginiCoordination Compoundashok pradhanÎncă nu există evaluări

- Laboratory Worksheet: Pre-Lab QuestionsDocument2 paginiLaboratory Worksheet: Pre-Lab QuestionsKelee DeWittÎncă nu există evaluări

- Zero Door SealsDocument120 paginiZero Door SealsChen Yaohui VictorÎncă nu există evaluări

- B1e 004 PDFDocument40 paginiB1e 004 PDFNguyễn Xuân ĐiệpÎncă nu există evaluări

- Factors Affecting Enzyme ActionDocument18 paginiFactors Affecting Enzyme Actionanon_458882066Încă nu există evaluări

- Biosensors PDFDocument338 paginiBiosensors PDFHarry Yucra100% (2)

- Effects of Zinc and Linoleic Acid Supplementation On The Skin and Coat Quality of Dogs Receiving A Complete and Balanced Diet (PagesDocument8 paginiEffects of Zinc and Linoleic Acid Supplementation On The Skin and Coat Quality of Dogs Receiving A Complete and Balanced Diet (PagesjenÎncă nu există evaluări

- Chemical Raw Material PDFDocument4 paginiChemical Raw Material PDFA MahmoodÎncă nu există evaluări

- Tallentex Class 10 # 2022-23Document20 paginiTallentex Class 10 # 2022-23Sreeja SujithÎncă nu există evaluări

- Ster RadDocument4 paginiSter RadKlos BettoÎncă nu există evaluări

- Done By: Neha Jain Priya Upadhyay Saanchi AroraDocument13 paginiDone By: Neha Jain Priya Upadhyay Saanchi AroraPriya UpadhyayÎncă nu există evaluări

- K02 Mechanical Seal Leak - RCA DocumentDocument8 paginiK02 Mechanical Seal Leak - RCA DocumentMidha NeerÎncă nu există evaluări

- STP Montelukast Sa.Document6 paginiSTP Montelukast Sa.ShagorShagor100% (1)

- Homework Chapter 22 Solutions PDFDocument16 paginiHomework Chapter 22 Solutions PDFbidinÎncă nu există evaluări

- Safety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIDocument10 paginiSafety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIazerÎncă nu există evaluări

- Eco Hopper GBDocument8 paginiEco Hopper GBArmand SpiderHerpÎncă nu există evaluări

- Astm D3302-D3302M-12Document8 paginiAstm D3302-D3302M-12Sendy Arfian SaputraÎncă nu există evaluări

- Pvi PDFDocument3 paginiPvi PDFBharat ChatrathÎncă nu există evaluări

- Eucalyptus CamadulensisDocument12 paginiEucalyptus Camadulensismagdy edreesÎncă nu există evaluări

- Lamitex CE Tube Metric DataDocument1 paginăLamitex CE Tube Metric Dataabdulloh_99Încă nu există evaluări

- MSDS Dhmo PDFDocument5 paginiMSDS Dhmo PDFEric SchonÎncă nu există evaluări

- Periodic Table 01-InvertDocument17 paginiPeriodic Table 01-InvertSaurabh BhaiÎncă nu există evaluări

- Sunscreen-1Document14 paginiSunscreen-1faikaÎncă nu există evaluări

- AC178 InterimCriteriaforInspectionandVerificationofConcreteandReinforcedandUnreinforcedMasonryusingFRPDocument7 paginiAC178 InterimCriteriaforInspectionandVerificationofConcreteandReinforcedandUnreinforcedMasonryusingFRPBayram AygunÎncă nu există evaluări

- Systemic FluoridesDocument58 paginiSystemic FluoridesShalakha BhardwajÎncă nu există evaluări

- Cempol SBR: Bonding AdmixtureDocument2 paginiCempol SBR: Bonding AdmixtureJagdishÎncă nu există evaluări

- 20 eDocument57 pagini20 eakanksha vermaÎncă nu există evaluări