Documente Academic

Documente Profesional

Documente Cultură

Device Net Resistencia Terminal

Încărcat de

Anonymous MKALEeDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Device Net Resistencia Terminal

Încărcat de

Anonymous MKALEeDrepturi de autor:

Formate disponibile

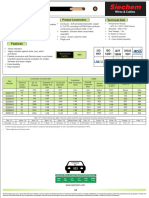

recision Mil-Qualifi

Precision ed

Mil-Qualified

etal Metal

Glaze Resistor

Glaze Resistor

RN Series

Precision Mil-Qualified

Spiraled or laser

helixed to

resistance value,

1/8 watt to 1/2 watt High temperature tolerance

Series Metal

10 ohms toGlaze

1M ohms Resistor soldered termination-lead

assembly

0.5% to 1% tolerance

watt to 1/2 watt

Digital marking per

ohms to 1M ohms

MIL-R-10509 25 ppm/C to 100 MIL-R-10509

Spiraled or laser

helixed to

resistance value, Tough molded jacket

tolerance

% to 1% tolerance

RN Series

High temperature

soldered termination-lead

Metal Glaze thick film

assembly

element fired at 1000C to

-R-10509 25

1/8ppm/C

watt to 1/2to 100

watt solid ceramic core

Digital marking per

MIL-R-10509

10 ohms to 1M ohms Tin-lead electroplated copper leads

Tough molded jacket

0.1% to 1% tolerance

ctrical Data

Metal Glaze thick film

element fired at 1000C to

MIL-R-10509 25 ppm/C to 100 solid ceramic core

Tin-lead electroplated copper leads

Resistance

L Type

Electrical

Marking

Data

Tolerance T.C. Power Rating

Range

Nominal Max Voltage

(%) (ppm/C) (watts) Resistance Size Rating

MIL Type Marking

Tolerance T.C. Power Rating (ohms)Nominal

Range

Max Voltage

(%) (ppm/C) (watts) Size Rating

(ohms)

0C* Stamp 1 50 1/20 @ 125C 10 to 100K 1/8W 200

RN50C* Stamp 1 50 1/20 @ 125C 10 to 100K 1/8W 200

5D Stamp

RN55D Stamp 1 1 100100 1/8 @70C

1/8 @ 70C 10 to10 to

301K 301K1/4W 1/4W200 200

5C RN55C

RN55E

5E

RN60D Stamp 1 100 1/4 @ 70C 10 to 1M 1/2W 300

0D Stamp

RN60C 1 100 1/4 @ 70C 10 to 1M 1/2W 300

0C RN60E

* Conformally coated construction on all 1/8 nominal sizes.

0E

Environmental Data

mally coated construction on all 1/8 nominal sizes.

MIL-R-10509 Test RN55 Max.

vironmental Data Test Conditions Limits Allowed

RN55 (D) RN55 (C) T0-55

%R (3)

T2-55

Temperature Coefficient (ppm/C) MIL-R-10509 50

+200/-500 Test 100 RN55

50 Max.

ConditionsLow Temperature Operation Limits Allowed

0.50% 0.25% 0.10% 0.10%(3)

%R

Temperature Cycling RN55 (D)

0.50% RN55

0.25% (C) 0.10% T0-55 0.10% T2-55

perature Coefficient

Moisture (ppm/C)

Resistance +200/-500

1.50% 50

0.50% 0.50% 100 0.50% 50

Short Time Overload 0.50% 0.25% 0.10% 0.10%

Temperature Operation 0.50% 0.25% 0.10% 0.10%

Load Life (70C-1/2W, 125C-1/100W) 1000 hours 1.00% 0.50% 0.30% 0.20%

perature Cycling

Terminal Strength 0.50%

0.20% 0.25%

0.20% 0.05% 0.10%0.05% 0.10%

Effect of Soldering 0.50% 0.10% 0.10%

sture Resistance 1.50% 0.50% 0.50%0.10% 0.50%

Shock 0.50% 0.25% 0.05% 0.05%

rt Time Overload 0.50% 0.25% 0.10% 0.10%

Vibration 0.50% 0.25% 0.05% 0.05%

d Life (70C-1/2W, 125C-1/100W)

High Temperature 1000 hours

Exposure (150C No Load) 1.00%

N/A 0.50%

N/A 0.50% 0.30%0.50% 0.20%

2X Rated Power for 10,000 hours @ 70C N/A N/A 0.50% 0.50%

minal Strength 0.20% 0.20% 0.05% 0.05%

Temperature Rise @ 1/4W Power Load - - See Temperature Rise Chart

ct of Soldering

Dielectric Strength

0.50%

0.50%

0.10%

0.25% 0.05%

0.10%0.05% 0.10%

ck General Note 0.50% 0.25% 0.05% 0.05%

IRC reserves the right to make changes in product specification without notice or liability.

General

All information Note

is subject to IRCs own data and is considered accurate at time of going to print.

ation TT

Wireelectronics

and Film reserves the right toDivision

Technologies make changes in product

4222 South specification

Staples Street without

Corpus Christi

0.50%

Texas notice or liability.

78411 USA

0.25% 0.05% A subsidiary of

TT electronics plc 0.05%

Telephone:

All 361 992 7900

information Facsimile:

is subject to TT 361electronics

992 3377 Website:

own www.irctt.com

data and is considered accurate at time of going to print. RN Series Issue March 2009 Sheet 1 of 2

www.bitechnologies.com www.irctt.com www.welwyn-tt.com

h Temperature Exposure (150C No Load) N/A N/A 0.50% 0.50%

TT electronics plc

Rated Power for 10,000 hours @ 70C N/A N/A 0.50% 10.13

0.50%

Precision Mil-Qualified

Precision Mil-Qualified

Metal Glaze Resistor

Metal Glaze Resistor

RN Series

Physical Data

LL BL

LD

BD

Dimensions (Inches and (mm))

Nominal Body Length Body Diameter Lead Length Lead Diameter

Clean Lead

Size BL BD LL LD

0.150 0.020 0.066 0.008 1.00 0.125 0.016 0.002 0.225

1/8 watt

(3.8 0.5) (1.7 0.2) (25.4 3.2) (0.41 0.05) (5.7)

0.250 0.015 0.090 0.008 1.50 0.125 0.025 0.002 0.310

1/4 watt

(6.4 0.4) (2.3 0.2) (38.1 3.2) (0.64 0.05) (7.9)

0.390 0.010 0.140 0.008 1.50 0.125 0.025 0.002 0.450

1/2 watt

(9.9 0.3) (3.6 0.2) (38.1 3.2) (0.64 0.05) (11.4)

MIL Spec. Power Derating Chart Ordering Data

Sample Part No. RN 55 D 1002 F

100

% Of MIL Spec. Rated Power

RN55C, 60C MIL Style

80 RL = Fixed Film Resistor

& 50C, RN55E, High stability

60E

60 Power Rating

50 = 1/20 watt

RN55D, 60D 55 = 1/10 watt

40 60 = 1/8 watt

T.C. Characteristics

20 D = 100ppm/C

C = 50ppm/C

E = 25ppm/C

0

0 125 150 165 175 Resistance

First three digits represent significant figures;

fourth digit is number of zeros.

Ambient Temperature (C)

Tolerance

F = 1%, D = 0.5%

Wire and Film Technologies Division 4222 South Staples Street Corpus Christi Texas 78411 USA

Telephone: 361 992 7900 Facsimile: 361 992 3377 Website: www.irctt.com RN Series Issue March 2009 Sheet 2 of 2

General Note

TT electronics reserves the right to make changes in product specification without notice or liability.

All information is subject to TT electronics own data and is considered accurate at time of going to print.

www.bitechnologies.com www.irctt.com www.welwyn-tt.com

TT electronics plc

10.13

S-ar putea să vă placă și

- Di Cap Data Sheet 022818Document2 paginiDi Cap Data Sheet 022818威爾WÎncă nu există evaluări

- Avx FilmDocument20 paginiAvx FilmVilnis PetersonsÎncă nu există evaluări

- RB Ate EngDocument6 paginiRB Ate EngFathi FathiÎncă nu există evaluări

- RCA-HP E3: Vishay DraloricDocument10 paginiRCA-HP E3: Vishay DraloricMohendra PatiÎncă nu există evaluări

- RK CableDocument1 paginăRK CableKristaÎncă nu există evaluări

- US CrimpposterDocument1 paginăUS CrimpposterGábor SulyokÎncă nu există evaluări

- SXL CableDocument1 paginăSXL CableVijay KarthikeyanÎncă nu există evaluări

- FLRYWK CablesDocument1 paginăFLRYWK CablesKristaÎncă nu există evaluări

- Type TE Series: Key FeaturesDocument3 paginiType TE Series: Key FeaturesMohammed Mosaad LyricsÎncă nu există evaluări

- To-5 Relays Established Reliability Military DPDT: Series 412Document9 paginiTo-5 Relays Established Reliability Military DPDT: Series 412Afzal ImamÎncă nu există evaluări

- Auto 125 CableDocument1 paginăAuto 125 CableKristaÎncă nu există evaluări

- Float Guided Switch Catalogue RadixDocument2 paginiFloat Guided Switch Catalogue RadixArjun BharambeÎncă nu există evaluări

- FLR4Y CablesDocument1 paginăFLR4Y CablesVijay KarthikeyanÎncă nu există evaluări

- Metal Foil Low Resistance Chip Resistors: KRL 1220E - C - R010 - F - T1Document3 paginiMetal Foil Low Resistance Chip Resistors: KRL 1220E - C - R010 - F - T1Adrian SalazarÎncă nu există evaluări

- Description: Commercial Level Y XDocument2 paginiDescription: Commercial Level Y Xjonatas priscoÎncă nu există evaluări

- Tourline PDFDocument9 paginiTourline PDF2022A Micha Michela FitrianaÎncă nu există evaluări

- SGX CableDocument1 paginăSGX CableVijay KarthikeyanÎncă nu există evaluări

- SGX CableDocument1 paginăSGX CableKristaÎncă nu există evaluări

- R2 CableDocument1 paginăR2 CableKristaÎncă nu există evaluări

- Item 18 Esk107m035ae3aaDocument1 paginăItem 18 Esk107m035ae3aadifa20061168Încă nu există evaluări

- Y-Cy-Jz / Y-Cy-Oz: EMC-preferred Type, With Inner SheathDocument2 paginiY-Cy-Jz / Y-Cy-Oz: EMC-preferred Type, With Inner SheathMARIA EUGENIAÎncă nu există evaluări

- FLR2X11Y CablesDocument1 paginăFLR2X11Y CablesVijay KarthikeyanÎncă nu există evaluări

- FLR2X11Y CablesDocument1 paginăFLR2X11Y CablesKristaÎncă nu există evaluări

- Low Resistance Chip Resistors: RL 1220 S - 1R0 - FDocument2 paginiLow Resistance Chip Resistors: RL 1220 S - 1R0 - FCarlos DominguezÎncă nu există evaluări

- Lf2 Series: Failsafe Fusible Wirewound ResistorsDocument1 paginăLf2 Series: Failsafe Fusible Wirewound ResistorsStuxnetÎncă nu există evaluări

- CABT CablesDocument1 paginăCABT CablesKristaÎncă nu există evaluări

- Sub-D Feedthroughs: Three Versions For Different Technical RequirementsDocument2 paginiSub-D Feedthroughs: Three Versions For Different Technical RequirementsDeaÎncă nu există evaluări

- Data Sheet Sylomer SR 850 ENDocument4 paginiData Sheet Sylomer SR 850 ENlpczyfansÎncă nu există evaluări

- Bourns CRM0805 DatasheetDocument5 paginiBourns CRM0805 DatasheetbarisÎncă nu există evaluări

- C I I G Product CatalogueDocument24 paginiC I I G Product CatalogueAbcd EfgÎncă nu există evaluări

- Transformers: Spec Tech Industrial 203 Vest Ave. Valley Park, MO 63088 Phone: 888 SPECTECHDocument12 paginiTransformers: Spec Tech Industrial 203 Vest Ave. Valley Park, MO 63088 Phone: 888 SPECTECHEngineerOmarÎncă nu există evaluări

- Eng DS 1773218 eDocument2 paginiEng DS 1773218 eZorbanfrÎncă nu există evaluări

- FL91Y-FL11Y CablesDocument1 paginăFL91Y-FL11Y CablesKristaÎncă nu există evaluări

- Samtec Connector - MaleDocument1 paginăSamtec Connector - MaleMRousstiaÎncă nu există evaluări

- Data Sheet Sylomer SR 42 ENDocument4 paginiData Sheet Sylomer SR 42 ENlpczyfansÎncă nu există evaluări

- Cu ZN 10Document1 paginăCu ZN 10Sara RiddleÎncă nu există evaluări

- Automig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Document1 paginăAutomig 100S-G / Tigfil 100S-G: AWS A/SFA 5.28Jagannath SahuÎncă nu există evaluări

- RHRB & RHSB: Material SpecificationsDocument1 paginăRHRB & RHSB: Material SpecificationsHKC EQUIPEMENTSÎncă nu există evaluări

- ENG DS 1-1773735-5 Harness 1116Document5 paginiENG DS 1-1773735-5 Harness 1116OguzhanÎncă nu există evaluări

- We20 Ihd00 Le DatasheetDocument4 paginiWe20 Ihd00 Le Datasheetabdul qadirÎncă nu există evaluări

- AW Tech Datasheet Inconel X 750Document2 paginiAW Tech Datasheet Inconel X 750stevemwilliamsÎncă nu există evaluări

- pdp122 UazhDocument2 paginipdp122 UazhzakjarekÎncă nu există evaluări

- QP ReactorsDocument17 paginiQP ReactorssaravanakumarpalaniÎncă nu există evaluări

- Te Connectivity - Crimp Quality GuidelinesDocument1 paginăTe Connectivity - Crimp Quality GuidelinesGustavo RamirezÎncă nu există evaluări

- FLALRY CablesDocument1 paginăFLALRY CablesKristaÎncă nu există evaluări

- FLALRY CablesDocument1 paginăFLALRY CablesVijay KarthikeyanÎncă nu există evaluări

- Aluminum Electrolytic CapacitorsDocument271 paginiAluminum Electrolytic CapacitorsButchÎncă nu există evaluări

- Dms3106a22-14p CPDocument14 paginiDms3106a22-14p CPnishank srivastavaÎncă nu există evaluări

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 paginiDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezÎncă nu există evaluări

- WH/WN Series: Miniature Molded WirewoundDocument2 paginiWH/WN Series: Miniature Molded WirewoundVebry AndrianÎncă nu există evaluări

- Patrol Light RH-LDocument1 paginăPatrol Light RH-Ldrawing yamahaÎncă nu există evaluări

- Bondstrand Series 2400 Fiberglass Pipe and FittingsDocument6 paginiBondstrand Series 2400 Fiberglass Pipe and FittingsIsmailÎncă nu există evaluări

- ABC Self Support SANS 1418Document1 paginăABC Self Support SANS 1418Awelani MandavhaÎncă nu există evaluări

- Data MP35N Rev-2Document2 paginiData MP35N Rev-2Nishant MehtaÎncă nu există evaluări

- Acl l4tDocument5 paginiAcl l4tMichał KoziarÎncă nu există evaluări

- Surface Mount - 200W SMF SeriesDocument6 paginiSurface Mount - 200W SMF Seriesm3y54mÎncă nu există evaluări

- Item 19 Esk107m050ag3aaDocument1 paginăItem 19 Esk107m050ag3aadifa20061168Încă nu există evaluări

- N Catalog Partition01 En-1140338Document3 paginiN Catalog Partition01 En-1140338hajarÎncă nu există evaluări

- CCBT CablesDocument1 paginăCCBT CablesVijay KarthikeyanÎncă nu există evaluări

- 182tc Thru 256tc And-213uc Thru 256ucDocument3 pagini182tc Thru 256tc And-213uc Thru 256ucAnonymous MKALEeÎncă nu există evaluări

- In-Sight Track & Trace: User ManualDocument80 paginiIn-Sight Track & Trace: User ManualAnonymous MKALEeÎncă nu există evaluări

- Heavy Duty Inverter/Charger 1000 Watt Weatherproof: Owner's GuideDocument48 paginiHeavy Duty Inverter/Charger 1000 Watt Weatherproof: Owner's GuideAnonymous MKALEeÎncă nu există evaluări

- Data Sheet Epig2k PDFDocument1 paginăData Sheet Epig2k PDFAnonymous MKALEeÎncă nu există evaluări

- IP1012 AL Inverter/Charger With Ignition Protection: Owner's GuideDocument52 paginiIP1012 AL Inverter/Charger With Ignition Protection: Owner's GuideAnonymous MKALEeÎncă nu există evaluări

- Vacon OPT D2 ManualDocument5 paginiVacon OPT D2 ManualAnonymous MKALEeÎncă nu există evaluări

- UnidriveDocument208 paginiUnidrivecdepedro.s5704Încă nu există evaluări

- SteamTurbineGenerator Datasheet 500MWDocument8 paginiSteamTurbineGenerator Datasheet 500MWParantap RahaÎncă nu există evaluări

- Sandvik 533: Technical Specification 533-Revision 2 1/9Document9 paginiSandvik 533: Technical Specification 533-Revision 2 1/9ricardoÎncă nu există evaluări

- Charge Air System of Alco LocosDocument44 paginiCharge Air System of Alco LocosmajjisatÎncă nu există evaluări

- Company ProfileDocument189 paginiCompany ProfileplanningÎncă nu există evaluări

- ML023030334 Risk ManagementDocument157 paginiML023030334 Risk ManagementMutahirrasoolÎncă nu există evaluări

- AntennaDocument78 paginiAntennaSandeep Balhara33% (3)

- 1.1.1.2 The Four-Stroke-Cycle Spark-Ignition (Petrol) EngineDocument1 pagină1.1.1.2 The Four-Stroke-Cycle Spark-Ignition (Petrol) EngineFuad AnwarÎncă nu există evaluări

- Research and Development: Applied Research IN Renewable Energy SystemsDocument22 paginiResearch and Development: Applied Research IN Renewable Energy SystemsBilaljafraniÎncă nu există evaluări

- KP-00+++-MQ758-V0010-Rev 0-MS For CB Installation Works PDFDocument27 paginiKP-00+++-MQ758-V0010-Rev 0-MS For CB Installation Works PDFUtku Can Kılıç100% (1)

- Activities On AC Motors in 2007Document22 paginiActivities On AC Motors in 2007CarlosÎncă nu există evaluări

- Catalogo Apollo Detectores de HumoDocument176 paginiCatalogo Apollo Detectores de HumoJohn EspinozaÎncă nu există evaluări

- 1 TransformerDocument3 pagini1 TransformerSyed Noman AhmedÎncă nu există evaluări

- 6120-A - Electric Motors Rated Up To 150KWDocument7 pagini6120-A - Electric Motors Rated Up To 150KWharmlesdragonÎncă nu există evaluări

- Installation and Operation Manual - enDocument2 paginiInstallation and Operation Manual - enArt RaÎncă nu există evaluări

- 1 Introduction and Mathematical ConceptsDocument13 pagini1 Introduction and Mathematical ConceptsKim CastilloÎncă nu există evaluări

- Lyceum of The Philippines University Cavite: Iredalei (Crassotrea: Ostreidae) ) As An Exhaust Filter For Selected PublicDocument42 paginiLyceum of The Philippines University Cavite: Iredalei (Crassotrea: Ostreidae) ) As An Exhaust Filter For Selected PublicCj Lucero50% (2)

- Chapter 16 Design of Pumping StationsDocument20 paginiChapter 16 Design of Pumping Stationsvipul gargÎncă nu există evaluări

- 8500 BHP AHTS Seabulk BetsyDocument2 pagini8500 BHP AHTS Seabulk BetsyRahul SunilÎncă nu există evaluări

- Roto-Glide: Heavy-Duty Bearing Grease For Electric MotorsDocument1 paginăRoto-Glide: Heavy-Duty Bearing Grease For Electric MotorsJoao Botas50% (2)

- HUAWEI BTS3900E Hardware Structure and Principle-090519-IsSUE1.0-BDocument78 paginiHUAWEI BTS3900E Hardware Structure and Principle-090519-IsSUE1.0-BJaime Ambaco Matsena100% (1)

- EXPERIMENT 7 Organic Chem LabDocument5 paginiEXPERIMENT 7 Organic Chem LabRenz Roger Esteves BuendichoÎncă nu există evaluări

- Ci Ride Leader - Guide To Cycling On The Road PDFDocument10 paginiCi Ride Leader - Guide To Cycling On The Road PDFΑυτός είμαι εγώÎncă nu există evaluări

- 20CMHDocument41 pagini20CMHMuhammad Safri Adi ZamilÎncă nu există evaluări

- MIM WinGD X52DF-S2-0Document259 paginiMIM WinGD X52DF-S2-0Κώστας ΧατζηδάκηςÎncă nu există evaluări

- Sample Project Report Format of 2020 Passout.Document84 paginiSample Project Report Format of 2020 Passout.Prem sharmaÎncă nu există evaluări

- Automation Direct - An Industry Guide To Control System EngineeringDocument93 paginiAutomation Direct - An Industry Guide To Control System EngineeringCesar CamachoÎncă nu există evaluări

- Thermodynamic Analysis of Zinc Ferrite ZnFe2O4 Formation InsideDocument16 paginiThermodynamic Analysis of Zinc Ferrite ZnFe2O4 Formation InsideFatemeh RezaeiÎncă nu există evaluări

- Mechanizing Philippine Agriculture For Food SufficiencyDocument21 paginiMechanizing Philippine Agriculture For Food SufficiencyViverly Joy De GuzmanÎncă nu există evaluări

- Load Dispatch Centre: By-Siddharth KumarDocument16 paginiLoad Dispatch Centre: By-Siddharth KumarSIDDHARTHÎncă nu există evaluări