Documente Academic

Documente Profesional

Documente Cultură

Soft Foot

Încărcat de

Javier GutierrezTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Soft Foot

Încărcat de

Javier GutierrezDrepturi de autor:

Formate disponibile

Soft foot; what are you look at correcting?

Motor anchor bolt holes & feet area.

1 4

Jack

3 2

When checking for soft foot we normally loosen one foots anchor bolt at a time. A four-

footed motor works like a chair that will wobble whereas a three-legged stool has no rock

or soft foot. Hence, some machine are three-footed.

On our model; lets loosen anchor bolt #1 is there deflection? No! Move to foot #3.

Deflection? Yes! None at foot #2; OK. We have a relative simple correction problem. Or

is it?

Our 3-4 (blue line) diagonal is the soft diagonal. The 1-2 (green line) is the hard diagonal.

Since #3 was soft, will #4 be equally as soft? Maybe if textbook perfect. Our standard

tolerance is 2 mils (0.002). We like zero will settle for 2 mils.

Lets say we had 8 mils soft foot at #3. Since bolts 1 & 2 were tight the unit wont

respond in a linear fashion but some fraction thereof. With bolts 1 & 2 remaining tight

loosen #4 did the dial indicator show deflection and did #3 decrease in the amount of

soft foot? You may want to shim under both feet. Was #4 under 2 mils? If #4 was under 2

mils you can opt to shim #3 only. If so, you can tighten #s 2 & 4 and loosen #1. This

gives the greatest amount of machine flexibility at foot #3 and keeps the machine

basically at its present location (your particular machine may not allow this practice and

it may not be practical). Providing you have machine dimensions that give flexibility you

can jack at or near the foot to make the adjustment. As youve already seen, just because

you had 8 mils deflection doesnt mean that an 8 mil shim will make the final correction.

We can check soft foot as long as mass doesnt overcome stiffness. If mass overcomes

stiffness all four feet down on their respective pads and adding ~20 mils shimming to

one foot doesnt create a soft foot on an adjacent foot.

S-ar putea să vă placă și

- Structural Health MonitoringDe la EverandStructural Health MonitoringDaniel BalageasÎncă nu există evaluări

- Soft Foot - What It Is and How To Minimize ItDocument6 paginiSoft Foot - What It Is and How To Minimize ItilyasÎncă nu există evaluări

- Soft FootingDocument4 paginiSoft FootingSantoshÎncă nu există evaluări

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionDe la EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionÎncă nu există evaluări

- Checking Bearing AlignmentDocument4 paginiChecking Bearing AlignmentTheerayootÎncă nu există evaluări

- ISO 10816 6 1995 en PreviewDocument5 paginiISO 10816 6 1995 en Previewblacx_rzkyÎncă nu există evaluări

- Plant Maintenance A Complete Guide - 2020 EditionDe la EverandPlant Maintenance A Complete Guide - 2020 EditionÎncă nu există evaluări

- Fan VibrationDocument6 paginiFan VibrationRavi Deshmukh100% (2)

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreDe la EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreÎncă nu există evaluări

- P178Document9 paginiP178keepmoshingÎncă nu există evaluări

- Soft Foot CorrectionDocument1 paginăSoft Foot CorrectionJaime Berry100% (2)

- ISO10816 ChartsDocument14 paginiISO10816 ChartsMeiliana Cendra AsihÎncă nu există evaluări

- Dynamic Analysis Using FEADocument19 paginiDynamic Analysis Using FEANallathambiÎncă nu există evaluări

- Soft Foot Diagnosis & The Soft Foot WizardDocument25 paginiSoft Foot Diagnosis & The Soft Foot WizardDiego Alejandro100% (1)

- SWCC Training Center Al-Jubail Mechanical Maintenance Course Machinery Alignment Advanced CourseDocument2 paginiSWCC Training Center Al-Jubail Mechanical Maintenance Course Machinery Alignment Advanced CoursevinothenergyÎncă nu există evaluări

- Hydrodynamic BearingsDocument14 paginiHydrodynamic BearingsShobhit MishraÎncă nu există evaluări

- BearingDocument41 paginiBearingM.IBRAHEEMÎncă nu există evaluări

- Jaw Coupling Installation GuideDocument7 paginiJaw Coupling Installation GuideGnana Subramanian ArumugamÎncă nu există evaluări

- Field Application Note: Reverse Dial Indicator Alignment RdiaDocument7 paginiField Application Note: Reverse Dial Indicator Alignment RdiaYasir BhattiÎncă nu există evaluări

- CL - 08 Sleeve Bearing InspectionDocument1 paginăCL - 08 Sleeve Bearing Inspectionmsaqibraza93Încă nu există evaluări

- Stresses in Beams AdvancedDocument10 paginiStresses in Beams Advanceddeathes0% (1)

- Cam DesignDocument74 paginiCam DesignMuhammad Maarij Farooq0% (1)

- Alignment Shaft Thermal GrowthDocument6 paginiAlignment Shaft Thermal Growthmmcsw6624Încă nu există evaluări

- Engineers Guide To Shaft Alignment 1661215823Document192 paginiEngineers Guide To Shaft Alignment 1661215823Michael SanchezÎncă nu există evaluări

- Factor of Alignment-PDocument12 paginiFactor of Alignment-Pvinothenergy100% (1)

- Notes On BearingsDocument42 paginiNotes On BearingsPRAVEEN KUMAR SINGHÎncă nu există evaluări

- Reverse Dial AlignmentDocument7 paginiReverse Dial AlignmentPopescu CarmenÎncă nu există evaluări

- AllignmentDocument2 paginiAllignmentVishnu Vardhan . CÎncă nu există evaluări

- Couplings PDFDocument34 paginiCouplings PDFAhmed El-Shafei100% (1)

- Five Basic Errors in Shaft AlignmentDocument5 paginiFive Basic Errors in Shaft AlignmentiosalcidoÎncă nu există evaluări

- Rim Face V Bs Dial On MovableDocument1 paginăRim Face V Bs Dial On MovablereiÎncă nu există evaluări

- Chapter 7 Shaft AlignmentDocument29 paginiChapter 7 Shaft Alignmentعبدالحافظ زايدÎncă nu există evaluări

- Balancing Without PhaseDocument2 paginiBalancing Without PhasevahidyasharÎncă nu există evaluări

- Balance LineDocument0 paginiBalance Linewsjouri2510Încă nu există evaluări

- Alignment For Engineers - OGSDocument128 paginiAlignment For Engineers - OGSAhmed Abdelwahab100% (3)

- Condition Monitoring Comparison Guide April 2020 EditionDocument14 paginiCondition Monitoring Comparison Guide April 2020 Editionkikayi8209Încă nu există evaluări

- Plane Balancing of Rotors PresentationDocument29 paginiPlane Balancing of Rotors PresentationOleg1142Încă nu există evaluări

- Mscthesis Final Submit PDFDocument140 paginiMscthesis Final Submit PDFgeorgez111Încă nu există evaluări

- Soft Foot Checking ProcedureDocument2 paginiSoft Foot Checking ProcedureBv RaoÎncă nu există evaluări

- CEP VFD ManualDocument234 paginiCEP VFD ManualUsama ZubairÎncă nu există evaluări

- Couplings: Nizwa College of TechnologyDocument11 paginiCouplings: Nizwa College of TechnologySyed ShahidÎncă nu există evaluări

- Vibration Versus Bearing Life HandoutDocument11 paginiVibration Versus Bearing Life Handoutscribdtaker12345Încă nu există evaluări

- October 30, 2007 © SKF Group Slide 1Document23 paginiOctober 30, 2007 © SKF Group Slide 1AVÎncă nu există evaluări

- Encoders Catalog 2012Document28 paginiEncoders Catalog 2012sreelakshmisnr100% (1)

- Advanced Alignment Alberta ModuleDocument31 paginiAdvanced Alignment Alberta ModuleRick Conrad100% (3)

- Bearing Defect1Document14 paginiBearing Defect1Muthukumar100% (2)

- NATCOM Alignment TrainingDocument133 paginiNATCOM Alignment TrainingMohamed M. AfifiÎncă nu există evaluări

- Pressure Dam Bearings USEFULDocument16 paginiPressure Dam Bearings USEFULAmna Chaudary100% (1)

- Complete Rim and Face Using One DialDocument7 paginiComplete Rim and Face Using One DialAzani NoorÎncă nu există evaluări

- Rim and Face AlignmentDocument8 paginiRim and Face Alignmentnazir305Încă nu există evaluări

- WE 201 - Bearing Maintenance and TechnologyDocument2 paginiWE 201 - Bearing Maintenance and TechnologyBjorn FejerÎncă nu există evaluări

- Bhausaheb Vartak Polytechnic: A Presentation ON Bearing Prepared by Akash Panchal S.Y.P.T - 1429Document51 paginiBhausaheb Vartak Polytechnic: A Presentation ON Bearing Prepared by Akash Panchal S.Y.P.T - 1429PreethamBAsaravalliMohanÎncă nu există evaluări

- Manual AMARILLO Drive Pump Repair Man 250 350 v0215Document23 paginiManual AMARILLO Drive Pump Repair Man 250 350 v0215Widi PrasetyoÎncă nu există evaluări

- SKF SphericalDocument72 paginiSKF SphericalNath BoyapatiÎncă nu există evaluări

- Training Program On: Vibration Monitoring, Alignment and Balancing Triveni Reliability Services and Training AcademyDocument77 paginiTraining Program On: Vibration Monitoring, Alignment and Balancing Triveni Reliability Services and Training AcademyMithlesh SharmaÎncă nu există evaluări

- Unit 4 Balancing of Rotating MassesDocument46 paginiUnit 4 Balancing of Rotating MassesNAVEEN100% (1)

- A O G E I R - D S: Nalysis F Yroscopic Ffects N Otor ISC YstemsDocument48 paginiA O G E I R - D S: Nalysis F Yroscopic Ffects N Otor ISC YstemsTarun BhardwajÎncă nu există evaluări

- Vibxpert Manual English PDFDocument86 paginiVibxpert Manual English PDFRizki A-fÎncă nu există evaluări

- Approximate Vibration Levels enDocument2 paginiApproximate Vibration Levels enJavier GutierrezÎncă nu există evaluări

- Peak VueDocument1 paginăPeak VueJavier GutierrezÎncă nu există evaluări

- GM Motors &DELPHI Vibration STD PDFDocument66 paginiGM Motors &DELPHI Vibration STD PDFMachineryeng0% (1)

- Motor Bars All1Document158 paginiMotor Bars All1Javier GutierrezÎncă nu există evaluări

- ISO 10816 - Severidad en Vibracion PDFDocument2 paginiISO 10816 - Severidad en Vibracion PDFJuan Carlos Bonifacio BricenoÎncă nu există evaluări

- Lube Oil Pump B Vibration 270219Document7 paginiLube Oil Pump B Vibration 270219Javier GutierrezÎncă nu există evaluări

- Motor DatabaseDocument55 paginiMotor DatabaseJavier GutierrezÎncă nu există evaluări

- The HFD Value Can Be Obtained As FollowsDocument2 paginiThe HFD Value Can Be Obtained As FollowsJavier GutierrezÎncă nu există evaluări

- Vibration Diagnostic ChartDocument49 paginiVibration Diagnostic ChartAlex George100% (4)

- Gap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Document8 paginiGap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Javier Gutierrez100% (1)

- SeasonalDocument20 paginiSeasonalJavier GutierrezÎncă nu există evaluări

- Parameter ProfileDocument1 paginăParameter ProfileJavier GutierrezÎncă nu există evaluări

- SeasonalDocument20 paginiSeasonalJavier GutierrezÎncă nu există evaluări

- Copa 90mm Horno #5 Cemex-Nic-Hc5-089Document1 paginăCopa 90mm Horno #5 Cemex-Nic-Hc5-089Javier GutierrezÎncă nu există evaluări

- Horizontal Alignment FormsDocument6 paginiHorizontal Alignment FormsJavier GutierrezÎncă nu există evaluări

- Chaveta Piñon Transmision Principal - Horno #5 - CEMEX-NIC-HC5-090Document1 paginăChaveta Piñon Transmision Principal - Horno #5 - CEMEX-NIC-HC5-090Javier GutierrezÎncă nu există evaluări

- Gap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Document8 paginiGap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Javier Gutierrez100% (1)

- Control of Gearing Between Gear Ring and Pinion in Kiln - Through Leaden HeelsDocument3 paginiControl of Gearing Between Gear Ring and Pinion in Kiln - Through Leaden HeelsJavier GutierrezÎncă nu există evaluări

- 5S Audit FormDocument12 pagini5S Audit FormJavier GutierrezÎncă nu există evaluări

- RCM II Decision Diagram - v2Document2 paginiRCM II Decision Diagram - v2Javier Gutierrez100% (1)

- Alignement of The Main Transmission, Gear Ring and PinionDocument5 paginiAlignement of The Main Transmission, Gear Ring and PinionJavier GutierrezÎncă nu există evaluări

- Kiln Maintenance ManualDocument111 paginiKiln Maintenance ManualJavier Gutierrez100% (5)

- Gear Ring Radial AlignmentDocument2 paginiGear Ring Radial AlignmentJavier GutierrezÎncă nu există evaluări

- 5S Team Lead & Area ListDocument33 pagini5S Team Lead & Area ListJavier GutierrezÎncă nu există evaluări

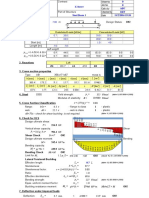

- Steel Beam BS 5950Document17 paginiSteel Beam BS 5950Javier GutierrezÎncă nu există evaluări

- Mangueras Succion de GasesDocument12 paginiMangueras Succion de GasesJavier GutierrezÎncă nu există evaluări

- 5S Implementation Audit: 5S To-Do Items Observed Condition Improvement ActionDocument2 pagini5S Implementation Audit: 5S To-Do Items Observed Condition Improvement ActionJavier GutierrezÎncă nu există evaluări

- 5S Audit Checklist - Supply StorageDocument16 pagini5S Audit Checklist - Supply StorageJavier GutierrezÎncă nu există evaluări

- MC1087 Welding BoothDocument2 paginiMC1087 Welding BoothJavier GutierrezÎncă nu există evaluări

- Contoh Label Sensus 2022Document313 paginiContoh Label Sensus 2022Ajenk SablackÎncă nu există evaluări

- Tensile Strength of Ferro Cement With Respect To Specific SurfaceDocument3 paginiTensile Strength of Ferro Cement With Respect To Specific SurfaceheminÎncă nu există evaluări

- Zoom g2 1nu Manual Do Utilizador PDFDocument56 paginiZoom g2 1nu Manual Do Utilizador PDFEliude Gonçalves FerreiraÎncă nu există evaluări

- Aspen Plus User ModelsDocument339 paginiAspen Plus User Modelskiny81100% (1)

- Gilbert Cell Design PDFDocument22 paginiGilbert Cell Design PDFvysÎncă nu există evaluări

- Teaching Mathematics Content Through Explicit TeachingDocument39 paginiTeaching Mathematics Content Through Explicit Teachingronna drio100% (1)

- Overview of MEMDocument5 paginiOverview of MEMTudor Costin100% (1)

- 【SIEMENS】Cios Spin-FlyerDocument8 pagini【SIEMENS】Cios Spin-FlyerAshleyÎncă nu există evaluări

- Spelling Grammar Punctuation: Teacher BookDocument8 paginiSpelling Grammar Punctuation: Teacher BookNeil MenezesÎncă nu există evaluări

- AE HM6L-72 Series 430W-450W: Half Large CellDocument2 paginiAE HM6L-72 Series 430W-450W: Half Large CellTaso GegiaÎncă nu există evaluări

- TOPIC: Movable and Immovable Property Under Section-3 of Transfer of Property ActDocument10 paginiTOPIC: Movable and Immovable Property Under Section-3 of Transfer of Property ActRishAbh DaidÎncă nu există evaluări

- AT ChapIDocument48 paginiAT ChapIvigneshwaranbeÎncă nu există evaluări

- Video Tutorial: Machine Learning 17CS73Document27 paginiVideo Tutorial: Machine Learning 17CS73Mohammed Danish100% (2)

- Puratattva No 41Document3 paginiPuratattva No 41ultimategoonÎncă nu există evaluări

- BC 672772 RBRS Service TraningDocument385 paginiBC 672772 RBRS Service TraningTeknik Makina100% (2)

- Gastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterDocument9 paginiGastone Petrini: Strutture e Costruzioni Autarchiche Di Legno in Italia e Colonie Caratteri e CriterPier Pasquale TrausiÎncă nu există evaluări

- Motive 27Tmx: Data SheetDocument2 paginiMotive 27Tmx: Data SheetUlisesGómezÎncă nu există evaluări

- Focal Length of Convex LensDocument5 paginiFocal Length of Convex LensHey AnuragÎncă nu există evaluări

- Test Report: Tested By-Checked byDocument12 paginiTest Report: Tested By-Checked byjamilÎncă nu există evaluări

- Rules and Fallacies For Categorical SyllogismsDocument5 paginiRules and Fallacies For Categorical SyllogismsFatima Ismael PortacioÎncă nu există evaluări

- Gr. 10 Persuasive EssayDocument22 paginiGr. 10 Persuasive EssayZephania JandayanÎncă nu există evaluări

- Bug Life Cycle in Software TestingDocument2 paginiBug Life Cycle in Software TestingDhirajÎncă nu există evaluări

- The Adoption of e Procurement in Tanzani PDFDocument5 paginiThe Adoption of e Procurement in Tanzani PDFDangyi GodSeesÎncă nu există evaluări

- Planning Theory Syllabus - 2016Document24 paginiPlanning Theory Syllabus - 2016LakshmiRaviChanduKolusuÎncă nu există evaluări

- Quemador BrahmaDocument4 paginiQuemador BrahmaClaudio VerdeÎncă nu există evaluări

- Ch.1 Essential Concepts: 1.1 What and How? What Is Heat Transfer?Document151 paginiCh.1 Essential Concepts: 1.1 What and How? What Is Heat Transfer?samuel KwonÎncă nu există evaluări

- GARCH (1,1) Models: Ruprecht-Karls-Universit at HeidelbergDocument42 paginiGARCH (1,1) Models: Ruprecht-Karls-Universit at HeidelbergRanjan KumarÎncă nu există evaluări

- Yz125 2005Document58 paginiYz125 2005Ignacio Sanchez100% (1)

- Hooke's LawDocument1 paginăHooke's LawAnan BarghouthyÎncă nu există evaluări

- Power-Miser 12 Water Heater ManualDocument32 paginiPower-Miser 12 Water Heater ManualClaudeVanDammÎncă nu există evaluări