Documente Academic

Documente Profesional

Documente Cultură

Caminhão Betoneira Avto Betonomechalka

Încărcat de

Jose Ventura0 evaluări0% au considerat acest document util (0 voturi)

18 vizualizări11 paginiCaminhão betoneira em madeira

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentCaminhão betoneira em madeira

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

18 vizualizări11 paginiCaminhão Betoneira Avto Betonomechalka

Încărcat de

Jose VenturaCaminhão betoneira em madeira

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 11

CEMENT TRUCK

fort Ui s General Instructions

Bc Start by cutting materials needed using the List of Materials on pages 86 and

87. Pay attention to the rough and finished size, and identify parts as they

are cut.

Please note: Different types of wood can be used for the various parts. It is

suggested, however, that hard wood be used since many of the parts would be

much too fragile if using soft wood. We have used a combination of Maple,

Pine, Oak and exotic woods such as Padauk (dark wood), Yellowheart (light

colour) and Mahogany (dark wood) to give the models a nice contrast!

Ea Parts F1 to F12 are already complete. Parts F13 to F26 and F36 will need a few

more steps. See the Parts Drawing section on pages 88 and 89 for more de-

tails.

Ea Parts F27 to F40 require removing the Full-Sized Patterns sheet found on

page 119 of the Appendix. Cut out the patterns, leaving approximately */s" al

around, and place on the proper piece of wood. Patterns can be secured to

the wood using either spray adhesive or rubber cement. If using the latter, cut

and sand the part first to finished size. If drilling is required, mark the hole by

inserting an awl or nail through the pattern into the wood. Remove the pattern

before drilling

Eo Follow the assembly drawings on pages 91 to 93 to complete your model.

Please note: In order for this model to move properly, it is recommended that

you apply a lubricant to wheel shafts and axle block holes. Lardis the cheapest

and safest option. tis non-toxic and found in most households.

folate

Detailed Drawings

ip SA -

see

1 eh

®

oT

Cement Truck

86

List of Materials

Part Description aty. | T Ww L Material *

FI Cabin Front 1 vet | ta" | ane Oak F

F2 Root 1 ve | aye" | 2m Oak F

FS Wheel Shafts 3 2h dia. 3%" |Maple Dowel] F

r4 Bumper Support 1 aut | oy | tit | Maple F

FS. Floor Boards 2 vw" |e" | 176" | Dark Wood | F

Fé Muffler - Top Pieces 2 vA dia. 2" |Maple Dowel] F

F7 Rear Bumper 1 ae | ae " Oak F

re | Headlights 2 ver | 9" 5" | Light Colour | F

F9 | Flashers & Brake Lights | 4 6 ve" | Dark Wood | F

F10 Mirrors 2 te" 1" | Dark Wood | F

Fit | Top Brace 1 ut | a" | 7m" Maple F

F12 | Container Support Dowel | 1 ve dia. 11° | Maple Dowel} F

Fi3 Main Frame 1 on’ | 2%" | 10%" | Maple F

F14 Hood 1 | im" | oat | ave Oak F

F15 | Axle Block - Front Wheels | 1 ” 1 | 2% | Maple F

F16 | Axle Block - Rear Wheels | 2 at fe " Maple F

FI7 Wheels | io | Maple F

F18 Fuel Tanks 2 9h" dia Maple Dowel | F

F19 | Muffler - Bottom Pieces | 2 ve" dia 214 [Maple Dowel | _F

F20 Top Frame 1 te a] 7 Maple F

List of Materials

Part Description ay. | T WwW a Material x

F21 Container - Section 1 1 15" 314" dia. Pine fF

F22 Container - Section 2 & 4 2 15)" 34" dia. Pine F

F23 | Container - Section 3 1 aM 3.2" dia. Oak F

F24 Container - Section 5 1 1%" 34" dia. Pine F

F25 | Container Support (top) 1 ue 3" dia Pine R

F26 | Container Support (bottom) | 1 au vw] 1m Pine F

F27 Outlet Plates 2 veh | aun ie Maple F

F28 Chute Plate 1 we | om | ia Oak F

F29 Cabin Back 1 var | 2am | 27m" Oak R

F30 Front Bumper 1 tp" ew] 4m Oak R

* | Fat Mirror Supports 2 ve | om | te Maple R

F32 Motor Cover 1 a" dia. Pine rE

F33 Cabin Sides ay | 2 | ew Oak R

F34 Fenders 2 sa" PF 27h" Oak R

F385 Front Grill 1 wr | aut | awe Maple R

F36 Container Support 1 aut | 15 | 196" Pine F

F37 Main Supports 2 we | 19 | aie Maple R

F38 Intake Tub 1 ” a | 2m Pine R

F39 Upper Chute Sides 2 16" ve! | 196" | Maple R

F40 Lower Chute Sides 2 th" veh | 17h" Oak R

87

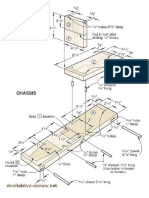

Cement Truck Parts Drawing

F13

Main Frame

Sand each side

to match angles

of front grill B29.

FAIS

Axle Blocks - Front Wheels

FI6

Axle Blocks - Rear Wheels

Dril=/0" dia.

FI9

Muffler- Bottom Piece

Fig

Fuel Tanks Drill" dia

"fe" deep

, Groove "hs" wide 2S)

(shs" deep >

auc

Ys" dia

aE

Parts Drawing Coated

194" dia—\ |

\P \

Es

mri Fat

Drive" dia. Container - Section 1

ve" deep

F22 F23 F24

Container - Section 2 & 4 Container - Section 3 Container - Section 5

S716" inside

aa

bee cia 294" dia.

F25 F26 F36

Container support (Top) Container Support Container Support

(bottom)

Rae

Drill 4" dia, The”

89

fe ate 6 Full-Sized Patterns: Set One

F27

Outlet Plates

(side view) F31

Mirror Supports

SZ

Motor 6 Cover

F28

Chute Plate

(side view)

—— ing

Cabin Back

F30

Front Bumper

F34

Fenders

F33

Cabin Sides

F36

Container Support

(side view)

F37

Main

‘Supports

es [ 4

nee ue Upper Chute Sides:

F40

Lower Chute Sides

{top view)

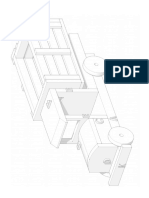

Assembly Drawings

MainFrame F13

Under)

Fis a

-F16 a =

6 -— 5

- —_ 27h

F15

Give axle blocks F15 and F16,

See next step for exact locaton, Where to glue axe blocks

Fs

29

} F33,

l 1 J

f f

Ft

Glue cabin sides F39 onto

cabin front F1 and back 29, Glue cabin assembly onto mainframe

=

Fe /

Y

Giue root F2 onto cabin assembly Glue hood F14 onto mainframe.

ot

lena tito

Assembly Drawings

Insert wheel shafts F3

through axle blocks (do not glue).

Before glueing fenders F34, sand surfaces as

shown in the next frame, Glue bumper support F4

Glue parts, as shown.

Glue parts, as shown.

92

Assembly Drawings

Glue parts, as shown,

Glue container support F36 onto frame F20.

Glue dowel F12 into support, not into container.

You may need to

sand a section of

parts 37 to match

Container contour.

Glue support assembly onto main frame

Container should turn freely.

Glue parts, as shown,

F38,

Glue intake tub F38.

Glue assembly onto frame.

Your model should now be complete.

93

S-ar putea să vă placă și

- Estrela de Natal Formato A3Document1 paginăEstrela de Natal Formato A3Jose VenturaÎncă nu există evaluări

- Depressao JayAdamsDocument4 paginiDepressao JayAdamsDaniel Gomes da SilvaÎncă nu există evaluări

- Dispositivo para Furar Rodinhas de MadeiraDocument6 paginiDispositivo para Furar Rodinhas de MadeiraJose VenturaÎncă nu există evaluări

- Projeto Lixadeira Com Motor EsmerilDocument11 paginiProjeto Lixadeira Com Motor EsmerilWellyngthon Ricardo DeFreitas100% (1)

- Afiação de FerramentasDocument1 paginăAfiação de FerramentasJose VenturaÎncă nu există evaluări

- D8T PDFDocument20 paginiD8T PDFjoaojuniortst100% (1)

- Caminhão Rural 2Document1 paginăCaminhão Rural 2Jose VenturaÎncă nu există evaluări

- O Controle Patrimonial Na Administração PúblicaDocument9 paginiO Controle Patrimonial Na Administração PúblicaJose VenturaÎncă nu există evaluări

- Caminhão Boiadeiro A3Document1 paginăCaminhão Boiadeiro A3Jose VenturaÎncă nu există evaluări

- Angulação de Goivas Torno de MadeiraDocument1 paginăAngulação de Goivas Torno de MadeiraJose VenturaÎncă nu există evaluări

- Ebook AlzheimerDocument19 paginiEbook AlzheimerJose VenturaÎncă nu există evaluări

- O Fator MelquisedequeDocument19 paginiO Fator MelquisedequeedsowevesÎncă nu există evaluări

- Caminhão Do Canal The Wood Toy BlokeDocument4 paginiCaminhão Do Canal The Wood Toy BlokeJose VenturaÎncă nu există evaluări

- Catalago TigreDocument7 paginiCatalago TigreCarlos Gomes AraujoÎncă nu există evaluări

- Abra Os Ouvidos Mensagem 5 Parece Mais Não É PDFDocument9 paginiAbra Os Ouvidos Mensagem 5 Parece Mais Não É PDFJose VenturaÎncă nu există evaluări

- A Maldição Do Discurso MotivacionalDocument4 paginiA Maldição Do Discurso MotivacionalJose VenturaÎncă nu există evaluări

- Caminhão Rural 1Document1 paginăCaminhão Rural 1Jose VenturaÎncă nu există evaluări

- Abra Os Ouvidos - Continue Firme - PR Jailson SantosDocument11 paginiAbra Os Ouvidos - Continue Firme - PR Jailson SantosJose VenturaÎncă nu există evaluări

- Estrutura e Tipos de SermãoDocument8 paginiEstrutura e Tipos de SermãoJose VenturaÎncă nu există evaluări

- A Paixão de Deus Por Sua Glória É EgoísmoDocument3 paginiA Paixão de Deus Por Sua Glória É EgoísmoJose VenturaÎncă nu există evaluări

- Abra Os Ouvidos (6) Porta Escancarada PR JailsonDocument10 paginiAbra Os Ouvidos (6) Porta Escancarada PR JailsonJose VenturaÎncă nu există evaluări

- Abra Os Ouvidos - 7Document12 paginiAbra Os Ouvidos - 7Jose VenturaÎncă nu există evaluări

- Abra Os Ouvidos Mensagem 5 Parece Mais Não É PDFDocument9 paginiAbra Os Ouvidos Mensagem 5 Parece Mais Não É PDFJose VenturaÎncă nu există evaluări

- Acesso Direto A DeusDocument1 paginăAcesso Direto A DeusJose VenturaÎncă nu există evaluări

- Dave Neta Jackson - Despachado para A ChinaDocument183 paginiDave Neta Jackson - Despachado para A ChinaStewart CaetanoÎncă nu există evaluări

- Cálculo de Tempo de AberturaDocument1 paginăCálculo de Tempo de AberturaJose VenturaÎncă nu există evaluări

- Como Manter A Igreja VivaDocument2 paginiComo Manter A Igreja VivaJose VenturaÎncă nu există evaluări

- 12 Passos para Um Culto AntropocentricoDocument1 pagină12 Passos para Um Culto AntropocentricoJose VenturaÎncă nu există evaluări

- Deus Escolheu Alguns Por Que Previu A Fé NelesDocument2 paginiDeus Escolheu Alguns Por Que Previu A Fé NelesJose VenturaÎncă nu există evaluări