Documente Academic

Documente Profesional

Documente Cultură

09 - Bolt PDF

Încărcat de

Shivam Shakti DubeyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

09 - Bolt PDF

Încărcat de

Shivam Shakti DubeyDrepturi de autor:

Formate disponibile

INSTALLATION GUIDE

S I N G L E E X PA N S I O N B O LT S ( F B N I I )

Drill the hole through the pre-drilled hole in the fixture DRILL HOLE &

into the concrete. This hole should be drilled perpendicular REMOVE DEBRIS

to the substrate surface and to the correct diameter and

depth. All dust and loose material should be removed from

the hole using a wire brush or blow pump.

Lightly tap the throughbolt through the fixture into the INSERT BOLT

hole with a hammer, until the fixing depth is reached.

Tighten to the recommended torque.

BEFORE I NS TA LL AT IO N

The following checks must be carried out prior to

installation of Single Expansion Bolts.

TIGHTEN BOLT

1. The appropriate length and diameter drill bit is used.

2. The correct edge distance and spacing are used in

accordance with the design requirements.

3. The anchor/fixing is the correct size.

4. The correct setting tools are used.

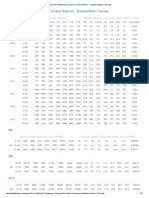

Single Expansion Bolts

FBNII FBNII FBNII FBNII FBNII FBNII FBNII FBNII

Bolt Reference

6/10 8/20 10/20 10/50 12/20 12/50 16/25 16/50

Thread Size M6 M8 M10 M10 M12 M12 M16 M16

Overall Length (mm) 55 81 96 126 116 146 145 170

Hole Dia. in Concrete (mm) 6 8 10 10 12 12 16 16

Hole Dia. in Fixture (mm) 6.5 9 11 11 13 13 17 17

Min. Embedment (mm) 30 40 50 50 65 65 80 80

Width Across Nut (mm) 10 13 17 17 19 19 24 24

Tightening Torque (Nm) 4 10 20 20 35 35 80 80

Max. Fixing Thickness (mm) 10 20 20 50 20 50 25 50

Note: For use in non-cracked concrete C20/25 to C50/60.

February 2012 Page 1 of 2

INSTALLATION GUIDE

H I G H P E R F O R M A N C E B O LT S ( FA Z I I )

Drill the hole through the pre-drilled hole in the fixture DRILL HOLE &

into the concrete. This hole should be drilled perpendicular REMOVE DEBRIS

to the substrate surface and to the correct diameter and

depth. All dust and loose material should be removed from

the hole using a wire brush or blow pump.

Insert the bolt through the component to be fixed and

into the concrete. Add any packing shims that maybe

required.

INSERT BOLT

Tighten to the recommended torque.

BEFORE I NS TA LL AT IO N

The following checks must be carried out prior to

installation of High Performance Bolts.

1. The appropriate length and diameter drill bit is used.

2. The correct edge distance and spacing are used in

accordance with the design requirements. TIGHTEN BOLT

3. The anchor/fixing is the correct size.

4. The correct setting tools are used.

High Performance Expansion Bolts

Bolt Reference FAZII FAZII FAZII FAZII FAZII FAZII FAZII FAZII

8/30 10/10 10/30 10/50 12/30 12/50 16/25 16/50

Thread Size M8 M10 M10 M10 M12 M12 M16 M16

Overall Length (mm) 95 95 115 135 130 150 148 173

Hole Dia in Concrete (mm) 8 10 10 10 12 12 16 16

Hole Dia in Fixture (mm) 9 11 11 11 13 13 17 17

Min. Embedment (mm) 45 60 60 60 70 70 85 85

Width Across Nut (mm) 13 17 17 17 19 19 24 24

Tightening Torque (Nm) 20 45 45 45 60 60 110 110

Max. Fixing Thickness (mm) 30 10 30 50 30 50 25 50

Note: For use in cracked and non-cracked concrete C20/25 to C50/60.

Ancon Building Products, 2012

The Construction applications and details provided in this guide are indicative only. In every case installation should be entrusted to Tel: 1300 304 320

appropriately qualified and experienced persons. Normal handling precautions should be taken to avoid physical injury. Ancon Building Email: info@ancon.com.au

Products cannot be held responsible for any injury as a result of using our products, unless such injury arises as a result of our negligence. Web: www.ancon.com.au

Page 2 of 2 February 2012

S-ar putea să vă placă și

- 09 - Bolt FixingsDocument2 pagini09 - Bolt FixingsbetsegaÎncă nu există evaluări

- TD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)Document5 paginiTD - 17-0005 - HIT-RE500-V3 - Annular Gap - Oversized Holes - Do 1,5xd (ETAG)phamducquangÎncă nu există evaluări

- 19 - Tds - Emaco r307Document5 pagini19 - Tds - Emaco r307aahtagoÎncă nu există evaluări

- Install Bolt GuideDocument2 paginiInstall Bolt GuideShanoor ASÎncă nu există evaluări

- Structural/non structural fixings in concreteDocument20 paginiStructural/non structural fixings in concreteabhishek yadavÎncă nu există evaluări

- Drop-In Anchor W-EDS (090401016)Document7 paginiDrop-In Anchor W-EDS (090401016)Alex DeschevogÎncă nu există evaluări

- Zinc Plated Shield Anchor Hex BoltDocument1 paginăZinc Plated Shield Anchor Hex BoltMarko KavaricÎncă nu există evaluări

- Rothoblaas - Ab7.technical Data Sheets - enDocument1 paginăRothoblaas - Ab7.technical Data Sheets - enAndrei GheorghicaÎncă nu există evaluări

- Telma F7 Installation On Meritor RS160-180-185 Axle TL103014Document6 paginiTelma F7 Installation On Meritor RS160-180-185 Axle TL103014Odim41Încă nu există evaluări

- Excalibur HSB 16mmDocument3 paginiExcalibur HSB 16mmlkokoÎncă nu există evaluări

- Mechanical Anchoring TruBoltDocument3 paginiMechanical Anchoring TruBoltwokeoooÎncă nu există evaluări

- MN EnglishDocument2 paginiMN EnglishMohamed Ahmed ElFekyÎncă nu există evaluări

- Stainless Steel Anchor TitleDocument3 paginiStainless Steel Anchor TitleأبومحمدالزياتÎncă nu există evaluări

- 6 4 CLCC 2018 Solid AbutmentsDocument48 pagini6 4 CLCC 2018 Solid AbutmentsAbdul Rahman SalehÎncă nu există evaluări

- Mechanical Anchoring TruBoltGäóDocument3 paginiMechanical Anchoring TruBoltGäóSame GeoÎncă nu există evaluări

- Mhda Hollow Ceiling AnchorDocument1 paginăMhda Hollow Ceiling AnchorMohammed AnwarÎncă nu există evaluări

- Project Anchor Bolt Capacity DesignDocument9 paginiProject Anchor Bolt Capacity Designrao_vinay8296Încă nu există evaluări

- Epomax-Anchor: Fast-Curing Anchoring Adhesive For Reinforcement RodsDocument2 paginiEpomax-Anchor: Fast-Curing Anchoring Adhesive For Reinforcement Rodschaval01Încă nu există evaluări

- Multifix All Mechanical Anchor - Design GuideDocument28 paginiMultifix All Mechanical Anchor - Design GuideConstantino L. Ramirez III0% (1)

- Mechanical Anchoring BoltDocument6 paginiMechanical Anchoring BoltMani MaranÎncă nu există evaluări

- 05 Repair of Concrete Super&Substructure by RecyDocument65 pagini05 Repair of Concrete Super&Substructure by RecyErika BanguilanÎncă nu există evaluări

- Henco TM 1.2.1 PDFDocument1 paginăHenco TM 1.2.1 PDFAnonymous O0T8aZZÎncă nu există evaluări

- Cushion-Mount Plus Plate Mounting Tapes With Easy Mount Adhesive High Plateside AdhesionDocument6 paginiCushion-Mount Plus Plate Mounting Tapes With Easy Mount Adhesive High Plateside AdhesionSerhan ÜnverÎncă nu există evaluări

- Rothoblaas - Abs Red - Technical Data Sheets - enDocument1 paginăRothoblaas - Abs Red - Technical Data Sheets - enAndrei GheorghicaÎncă nu există evaluări

- Product Data Sheet-Le-ZnDocument5 paginiProduct Data Sheet-Le-ZnDavid SeeÎncă nu există evaluări

- Heavy Duty Expansion Anchor Ce1: Codes and DimensionsDocument2 paginiHeavy Duty Expansion Anchor Ce1: Codes and DimensionsKenan AvdusinovicÎncă nu există evaluări

- DSI UK DYWI Drill Hollow Bar ENG PDFDocument16 paginiDSI UK DYWI Drill Hollow Bar ENG PDFFrans van der MerweÎncă nu există evaluări

- Cushion-Mount Plus Plate Mounting Tapes With Easy Mount AdhesiveDocument6 paginiCushion-Mount Plus Plate Mounting Tapes With Easy Mount AdhesiveSerhan ÜnverÎncă nu există evaluări

- Sleeve Anchor Data Sheet - For SubmittalDocument3 paginiSleeve Anchor Data Sheet - For SubmittalvtalexÎncă nu există evaluări

- Rate AnalysisDocument4 paginiRate AnalysisPradeep BillaÎncă nu există evaluări

- GroutecDocument82 paginiGroutecThompson LaiÎncă nu există evaluări

- Dyna BoltDocument5 paginiDyna BoltAnggana 'Anma' D'sleepyholicÎncă nu există evaluări

- RE100 100% CapacityDocument1 paginăRE100 100% CapacitySantosoÎncă nu există evaluări

- Trimo 2967 Trimo Assembly SNVDocument14 paginiTrimo 2967 Trimo Assembly SNVBogdan RuxandaÎncă nu există evaluări

- FoFoFuOne v1-1Document19 paginiFoFoFuOne v1-1Jose TeixeiraÎncă nu există evaluări

- Project Design CalculationsDocument8 paginiProject Design CalculationsmohamedhaniÎncă nu există evaluări

- Annex AllemandDocument13 paginiAnnex AllemandsobhiÎncă nu există evaluări

- Steel Stud Installation GuideDocument6 paginiSteel Stud Installation GuiderfadeÎncă nu există evaluări

- Undeground: Cable ProtectionDocument12 paginiUndeground: Cable ProtectionShahir IbrahimiÎncă nu există evaluări

- 3M L Series Datapage-March2017-V3Document5 pagini3M L Series Datapage-March2017-V3Serhan ÜnverÎncă nu există evaluări

- Fine Blanking Design GuideDocument33 paginiFine Blanking Design GuideVikram Borkhediya100% (5)

- DJJ3032 - Workshop Practice 3 (Lathe Machining)Document8 paginiDJJ3032 - Workshop Practice 3 (Lathe Machining)Afiq Fahmi100% (2)

- MNK EnglishDocument2 paginiMNK EnglishMohamed Ahmed ElFekyÎncă nu există evaluări

- HILTI-HIT RE100 Injection Adhesive With Rebar ApplicationDocument1 paginăHILTI-HIT RE100 Injection Adhesive With Rebar ApplicationSantosoÎncă nu există evaluări

- JCP Resin Data SheetDocument2 paginiJCP Resin Data SheetgijimmyyoÎncă nu există evaluări

- Datasheet TBUT000400 enDocument2 paginiDatasheet TBUT000400 enpetkoÎncă nu există evaluări

- P14 CX Hydr NippelsDocument11 paginiP14 CX Hydr NippelsasdfÎncă nu există evaluări

- CR Manual enDocument2 paginiCR Manual endenisÎncă nu există evaluări

- ETA 13-0730 MaxxFast PromaxDocument11 paginiETA 13-0730 MaxxFast PromaxXavierÎncă nu există evaluări

- Tremco FX 120 TdsDocument4 paginiTremco FX 120 TdsRajesh ThakurÎncă nu există evaluări

- 1332 Rawlplug en R Dca Wedge AnchorDocument4 pagini1332 Rawlplug en R Dca Wedge AnchorMustafa Darweesh SalehÎncă nu există evaluări

- Product Range - Pipes - : Load and Service Years Can Be Seen atDocument4 paginiProduct Range - Pipes - : Load and Service Years Can Be Seen atConstantin CilibiuÎncă nu există evaluări

- HVU Adhesive With RebarDocument7 paginiHVU Adhesive With RebarBogdanBÎncă nu există evaluări

- Wurth WIT-PE - 500Document26 paginiWurth WIT-PE - 500Igor DzuklevskiÎncă nu există evaluări

- Lokfix: Mix and Place Polyester Resin Anchoring GroutsDocument4 paginiLokfix: Mix and Place Polyester Resin Anchoring GroutsMuhamad HisyamÎncă nu există evaluări

- Mechanical - Anchoring - DynaBolt Plus PDFDocument6 paginiMechanical - Anchoring - DynaBolt Plus PDFAnonymous dSFbLxc9Încă nu există evaluări

- Todo Safety Break Away CouplingsDocument8 paginiTodo Safety Break Away CouplingsKamalÎncă nu există evaluări

- Design Manual Provides Safety Guidance for Timing Belt ApplicationsDocument141 paginiDesign Manual Provides Safety Guidance for Timing Belt ApplicationsVikram BorkhediyaÎncă nu există evaluări

- Belt, Chain and Gear DriveDocument45 paginiBelt, Chain and Gear DriveShivam Shakti DubeyÎncă nu există evaluări

- Bright Bar CorusDocument8 paginiBright Bar CorusShivam Shakti DubeyÎncă nu există evaluări

- INTERNET STANDARDSDocument18 paginiINTERNET STANDARDSDawn HaneyÎncă nu există evaluări

- Indeterminate Beams Deflection MethodDocument9 paginiIndeterminate Beams Deflection MethodShivam Shakti DubeyÎncă nu există evaluări

- Hilti - Anchor Fastening Technology ManualDocument0 paginiHilti - Anchor Fastening Technology ManualDavid Salomão Pinto Castanho BizarroÎncă nu există evaluări

- Bending, Shear and TorsionDocument7 paginiBending, Shear and TorsionBonaventure Mills-DadsonÎncă nu există evaluări

- Westermann Tables Materials Classification and PropertiesDocument86 paginiWestermann Tables Materials Classification and PropertiesDipak88% (17)

- MP SheetMetal PDFDocument48 paginiMP SheetMetal PDFShivam Shakti DubeyÎncă nu există evaluări

- CEED - 2016 Paper 2 PDFDocument23 paginiCEED - 2016 Paper 2 PDFShivam Shakti DubeyÎncă nu există evaluări

- CH 8 Slides M PDFDocument96 paginiCH 8 Slides M PDFAnkit NayakÎncă nu există evaluări

- CEED - 2016 Paper 1Document22 paginiCEED - 2016 Paper 1Shivam Shakti DubeyÎncă nu există evaluări

- Guidelines Wise PDFDocument6 paginiGuidelines Wise PDFShivam Shakti DubeyÎncă nu există evaluări

- Hydroliclift 150829145659 Lva1 App6892Document19 paginiHydroliclift 150829145659 Lva1 App6892Shivam Shakti DubeyÎncă nu există evaluări

- Lec 10Document34 paginiLec 10Shivam Shakti DubeyÎncă nu există evaluări

- Antilock Braking SystemDocument8 paginiAntilock Braking SystemShivam Shakti DubeyÎncă nu există evaluări

- Lec 3Document40 paginiLec 3Shivam Shakti DubeyÎncă nu există evaluări

- Lec 1Document41 paginiLec 1Shivam Shakti DubeyÎncă nu există evaluări

- SampleCalculationspipingB3132008 PDFDocument13 paginiSampleCalculationspipingB3132008 PDFsosatlantiqueÎncă nu există evaluări

- Lec 7Document36 paginiLec 7Shivam Shakti DubeyÎncă nu există evaluări

- Questions For InterviewDocument9 paginiQuestions For Interviewpragya_dubeyÎncă nu există evaluări

- Lec 5Document34 paginiLec 5Shivam Shakti DubeyÎncă nu există evaluări

- Lec 6Document29 paginiLec 6Shivam Shakti DubeyÎncă nu există evaluări

- ASME B31.11 Slurry Transportation Piping Systems CodeDocument2 paginiASME B31.11 Slurry Transportation Piping Systems CodeKevin McGrathÎncă nu există evaluări

- IIT Roorkee Lecture on Solid Mechanics Stress ComponentsDocument39 paginiIIT Roorkee Lecture on Solid Mechanics Stress ComponentsShivam Shakti DubeyÎncă nu există evaluări

- IIT Roorkee Lecture on Solid Mechanics Stress ComponentsDocument39 paginiIIT Roorkee Lecture on Solid Mechanics Stress ComponentsShivam Shakti DubeyÎncă nu există evaluări

- Questions For InterviewDocument9 paginiQuestions For Interviewpragya_dubeyÎncă nu există evaluări

- IIT Roorkee Prof Explains Strength of Materials FundamentalsDocument32 paginiIIT Roorkee Prof Explains Strength of Materials FundamentalsShivam Shakti DubeyÎncă nu există evaluări

- Unifai Screw INCHDocument21 paginiUnifai Screw INCHAnonymous RgGtg29Încă nu există evaluări

- Conexões DetroitDocument11 paginiConexões DetroitJosé CastroÎncă nu există evaluări

- Thread InspectionDocument3 paginiThread InspectionAbdullah AnsariÎncă nu există evaluări

- Fitter Sem3 TTDocument134 paginiFitter Sem3 TTPooja7 7Încă nu există evaluări

- Tabla de Viscosidad de LubricantesDocument52 paginiTabla de Viscosidad de LubricantesXavi X QunqiÎncă nu există evaluări

- LinkTechKing 2010 CatalogoDocument36 paginiLinkTechKing 2010 CatalogoKING COMERCIAL LTDAÎncă nu există evaluări

- Pre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsDocument3 paginiPre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsmukeshkumarjÎncă nu există evaluări

- Kyodo Pipe Producs SpecificationDocument3 paginiKyodo Pipe Producs SpecificationTengku MunzirÎncă nu există evaluări

- Iso 3506 2 1997Document11 paginiIso 3506 2 1997Arun SharmaÎncă nu există evaluări

- Whitepaper Bolted ConnectionsDocument18 paginiWhitepaper Bolted ConnectionsdanaosajoÎncă nu există evaluări

- Fortec Brochure 2015Document4 paginiFortec Brochure 2015Hanuman BuildersÎncă nu există evaluări

- Bollhoff Helicoil Plus Kits and Inserts CatalogueDocument49 paginiBollhoff Helicoil Plus Kits and Inserts CatalogueThor InternationalÎncă nu există evaluări

- Design of Machine Elements 2 6Document25 paginiDesign of Machine Elements 2 6sasikskÎncă nu există evaluări

- AA-036322-001 - Anchor Bolt DetailsDocument1 paginăAA-036322-001 - Anchor Bolt DetailsGaurav BedseÎncă nu există evaluări

- Guide to Standard Thread Dimensions, Tolerances and DesignationsDocument1 paginăGuide to Standard Thread Dimensions, Tolerances and DesignationstnchsgÎncă nu există evaluări

- Sa 325 PDFDocument12 paginiSa 325 PDFMo'men Abu-SmaihaÎncă nu există evaluări

- As1721 1985Document91 paginiAs1721 1985Ankur GoyalÎncă nu există evaluări

- ZMM C8C Cu325 Eng PDFDocument67 paginiZMM C8C Cu325 Eng PDFRolando Soledad75% (4)

- Hammelmann 2016Document68 paginiHammelmann 2016Cleaner MagazineÎncă nu există evaluări

- Series 31h Weights DimensionsDocument2 paginiSeries 31h Weights DimensionsGourav SharmaÎncă nu există evaluări

- TG4 19Document24 paginiTG4 19Arjun Soman100% (1)

- BPM CRS Operation Manual CompletoDocument49 paginiBPM CRS Operation Manual CompletoJose Mauricio SandovalÎncă nu există evaluări

- Festo Basic Catalog WebDocument274 paginiFesto Basic Catalog WebIlham Nugeraha SÎncă nu există evaluări

- Certificate of ComplianceDocument7 paginiCertificate of ComplianceNabilah HusnaÎncă nu există evaluări

- Pneufit C Composite - Pneufit M MetricDocument11 paginiPneufit C Composite - Pneufit M MetricSonthi MooljindaÎncă nu există evaluări

- W01 358 6996Document29 paginiW01 358 6996MROstop.comÎncă nu există evaluări

- UNIT-III Design of Fasteners and Welded Joints: Session - 1Document18 paginiUNIT-III Design of Fasteners and Welded Joints: Session - 1Narendra ChavdaÎncă nu există evaluări

- Better Handling For The Angle Grinder: InstructablesDocument7 paginiBetter Handling For The Angle Grinder: InstructablesprijadyÎncă nu există evaluări

- Astm A1014Document3 paginiAstm A1014Shunmugavel KarpagamÎncă nu există evaluări

- Neral Notes On Engineering Hardware - FastenersDocument45 paginiNeral Notes On Engineering Hardware - Fastenersbrotaccristian100% (1)