Documente Academic

Documente Profesional

Documente Cultură

Astm e 467 Rev A 2006 PDF

Încărcat de

JORGE ARTURO TORIBIO HUERTATitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Astm e 467 Rev A 2006 PDF

Încărcat de

JORGE ARTURO TORIBIO HUERTADrepturi de autor:

Formate disponibile

--````,`,,```,,`,`````,,`,,,,,,-`-`,,`,,`,`,,`---

Designation: F 467 06a

Standard Specification for

Nonferrous Nuts for General Use1

This standard is issued under the fixed designation F 467; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* E 54 Test Methods for Chemical Analysis of Special

1.1 This specification covers the requirements for commer- Brasses and Bronzes3

cial wrought nonferrous nuts 0.250 to 1.500 in. inclusive in E 55 Practice for Sampling Wrought Nonferrous Metals and

diameter in a number of alloys in common use and intended for Alloys for Determination of Chemical Composition

general service applications. E 62 Test Methods for Chemical Analysis of Copper and

1.2 Applicable bolts, cap screws, and studs for use with nuts Copper Alloys (Photometric Methods)

covered by this specification are covered by Specification E 75 Test Methods for Chemical Analysis of Copper-Nickel

F 468. and Copper-Nickel-Zinc Alloys

E 76 Test Methods for Chemical Analysis of Nickel-Copper

NOTE 1A complete metric companion to Specification F 467 has been Alloys3

developedF 467M; therefore no metric equivalents are presented in this

E 92 Test Method for Vickers Hardness of Metallic Mate-

specification.

rials

2. Referenced Documents E 101 Test Method for Spectrographic Analysis of Alumi-

2.1 ASTM Standards: 2 num and Aluminum Alloys by the Point-To-Plane Tech-

B 154 Test Method for Mercurous Nitrate Test for Copper nique3

Alloys E 120 Test Methods for Chemical Analysis of Titanium and

B 574 Specification for Low-Carbon Nickel-Chromium- Titanium Alloys3

Molybdenum, Low-Carbon Nickel-Molybdenum- E 165 Test Method for Liquid Penetrant Examination

Chromium-Tantalum, Low-Carbon Nickel-Chromium- E 227 Test Method for Optical Emission Spectrometric

Molybdenum-Copper, and Low-Carbon Nickel- Analysis of Aluminum and Aluminum Alloys by the

Chromium-Molybdenum-Tungsten Alloy Rod Point-to-Plane Technique3

D 3951 Practice for Commercial Packaging E 354 Test Methods for Chemical Analysis of High-

E 18 Test Methods for Rockwell Hardness and Rockwell Temperature, Electrical, Magnetic, and Other Similar Iron,

Superficial Hardness of Metallic Materials Nickel, and Cobalt Alloys

E 29 Practice for Using Significant Digits in Test Data to E 478 Test Methods for Chemical Analysis of Copper

Determine Conformance with Specifications Alloys

E 34 Test Methods for Chemical Analysis of Aluminum and E 1409 Test Method for Determination of Oxygen and

Aluminum-Base Alloys Nitrogen in Titanium and Titanium Alloys by the Inert Gas

E 38 Methods for Chemical Analysis of Nickel-Chromium Fusion Technique

and Nickel-Chromium-Iron Alloys3 F 468 Specification for Nonferrous Bolts, Hex Cap Screws,

E 53 Test Method for Determination of Copper in Unal- and Studs for General Use

loyed Copper by Gravimetry F 606 Test Methods for Determining the Mechanical Prop-

erties of Externally and Internally Threaded Fasteners,

Washers, and Rivets

1 F 1470 Guide for Fastener Sampling for Specified Mechani-

This specification is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.04 on Nonferrous cal Properties and Performance Inspection

Fasteners. 2.2 ASME Standards:4

Current edition approved Aug. 1, 2006. Published August 2006. Originally B 1.1 Unified Inch Screw Threads (UN and UNR Thread

approved in 1976. Last previous edition approved in 2006 as F 467 06.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Form)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standards Document Summary page on

4

the ASTM website. Available from Global Engineering Documents, 15 Inverness Way, East

3

Withdrawn. Englewood, CO 80112-5704, http://global.ihs.com.

*A Summary of Changes section appears at the end of this standard.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

No reproduction or networking permitted without license from IHS Not for Resale, 12/21/2006 15:06:55 MST

F 467 06a

B 18.2.2 Square and Hex Nuts 5.2 Manufacturers Analysis:

5.2.1 Except as provided in 5.2.2, when test reports are

3. Ordering Information

required on the inquiry or purchase order (3.1.8), the manu-

3.1 Orders for nuts under this specification shall include the facturer shall make individual analyses of randomly selected

following information: finished nuts from the product to be shipped and report the

3.1.1 Quantity (number of pieces of each item and size); results to the purchaser. Alternatively, if heat and lot identities

3.1.2 Name of item; have been maintained, the analysis of the raw material from

3.1.3 Size (diameter and threads per inch); which the nuts have been manufactured may be reported

3.1.4 Alloy number (Table 1); instead of product analysis.

3.1.5 Stress relieving, if required (4.2.3); 5.2.2 For aluminum nuts, instead of 5.2.1, the manufacturer

3.1.6 Shipment lot testing, as required (Section 9); may furnish a certificate of conformance certifying compliance

3.1.7 Source inspection, if required (Section 14); with the chemical composition specified in Table 1.

3.1.8 Certificate of compliance or test report, if required 5.3 Product Analysis:

(Section 16); 5.3.1 Product analyses may be made by the purchaser from

3.1.9 Additional requirements, if any, to be specified on finished products representing each lot. The chemical compo-

the purchase order (4.2.1, 7.2, 8.2, 12.1, and 13.1), sition thus determined shall conform to the requirements in

3.1.10 Supplementary requirements, if any; and Table 1.

3.1.11 ASTM designation (including year or published 5.3.2 In the event of disagreement, a referee chemical

date). analysis of samples from each lot shall be made in accordance

NOTE 2A typical ordering description is as follows: 10 000 pieces, with 12.1 and 13.1.

Hex Nut, 0.2509 -20, Alloy 270, Furnish Certificate of Compliance,

Supplementary Requirement S 1, ASTM Specification F 467-XX 6. Mechanical Properties

4. Materials and Manufacture 6.1 The nuts shall be tested in accordance with the mechani-

cal testing requirements for the applicable type and shall meet

4.1 Materials:

the mechanical requirements in Table 2 for the specified alloy.

4.1.1 The nuts shall be manufactured from material having

6.2 Where both proof load and hardness tests are performed,

a chemical composition conforming to the requirements in

the proof load test results shall take precedence for acceptance

Table 2 and capable of developing the required mechanical

purposes.

properties for the specified alloy in the finished fastener. See

Specification B 574 for nickel alloys.

7. Dimensions

4.1.2 The starting condition of the raw material shall be at

the discretion of the fastener manufacturer but shall be such 7.1 NutsUnless otherwise specified, the dimensions of

that the finished products conform to all the specified require- nuts shall be in accordance with the requirements of ASME

ments. B8.2.2.

4.2 Manufacture: 7.2 ThreadsUnless otherwise specified, the nuts shall

4.2.1 FormingUnless otherwise specified, the nuts shall have Class 6H threads in accordance with ASME B 1.1.

be hot pressed, cold formed, or machined from suitable

material at the option of the manufacturer. 8. Workmanship, Finish, and Appearance

4.2.2 ConditionExcept as provided in 4.2.3, the nuts shall 8.1 WorkmanshipNuts shall have a workmanlike finish

be furnished in the condition specified below: free of injurious burrs, seams, laps, irregular surfaces, and

Alloy Condition other imperfections affecting serviceability.

Copper (all alloys) As formed or stress relieved at manufacturers

8.2 FinishUnless otherwise specified, the nuts shall be

option furnished without any additive chemical or metallic finish.

Nickel alloys 400 and 405 As formed or stress relieved at manufacturers

option

Nickel alloy 500 Solution annealed and aged

9. Sampling

Aluminum alloys: 9.1 A lot, for the purposes of selecting test specimens, shall

2024-T4 Solution treated and naturally aged

6061-T6 Solution treated and artificially aged consist of not more than 100 000 pieces offered for inspection

6262-T9 Solution treated, artificially aged, and cold at one time having the following common characteristics:

worked 9.1.1 One type of item,

Titanium As formed

625 Annealed 9.1.2 Same alloy and temper, and

9.1.3 One nominal diameter and thread series.

4.2.3 Stress RelievingWhen required, stress relieving

shall be specified by the purchaser for all copper alloys and

10. Number of Tests and Retests

nickel alloys 400 and 405.

10.1 Normal TestingThe requirements of this specifica-

5. Chemical Composition tion shall be met in continuous mass production for stock (see

5.1 Chemical CompositionThe nuts shall conform to the Table 3). The manufacturer shall make sample inspections as

chemical composition specified in Table 1 for the specified specified below to ensure that the product conforms to the

alloy. specified requirements. When tests of individual shipments are

--````,`,,```,,`,`````,,`,,,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

No reproduction or networking permitted without license from IHS Not for Resale, 12/21/2006 15:06:55 MST

F 467 06a

required, Supplementary Requirement S 2 shall be specified. place of manufacture prior to shipment. The inspector repre-

senting the purchaser shall have controlled entry only to those

parts of the manufacturers operations that concern the manu-

Acceptance Criteria facture of the ordered product and only when and where work

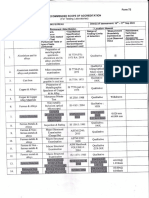

Number of Pieces in No. of Accept- Rejection on the contract of the purchaser is being performed. The

Lot Tests ance No. No.

50 and under 2 0 1

manufacturer shall afford the inspector all reasonable facilities

51 to 500 3 0 1 to satisfy him that the product is being furnished in accordance

501 to 35 000 5 0 1 with this specification. All inspections and tests shall be

35 001 to 100 000 8 0 1

conducted so as not to interfere unnecessarily with the opera-

10.2 Retests: tions of the manufacturer.

10.2.1 When tested in accordance with the required sam-

pling plan, a lot shall be subject to rejection if any of the test 15. Rejection and Rehearing

specimens fails to meet the applicable test requirements.

15.1 Unless otherwise specified, any rejection based on tests

10.2.2 If the failure of a test specimen is due to improper

specified herein and made by the purchaser shall be reported to

preparation of the specimen or to incorrect testing technique,

the manufacturer as soon as practical after receipt of the

the specimen shall be discarded and another specimen substi-

product by the purchaser.

tuted.

11. Significance of Numerical Limits 16. Certification and Test Reports

11.1 For purposes of determining compliance with the 16.1 Certificate of ComplianceWhen specified in the

specified limits for requirements of the properties listed in this contract or purchase order, the manufacturer shall furnish

specification, an observed value or calculated value shall be certification that the product was manufactured and tested in

rounded in accordance with Practice E 29. accordance with this specification and conforms to all specified

requirements.

12. Test Specimens 16.2 Test ReportsWhen Shipment Lot Testing in accor-

12.1 Chemical TestsWhen required, samples for chemical dance with Supplementary Requirement S2 is specified in the

analysis shall be taken in accordance with Practice E 55 by contract or purchase order, the manufacturer shall furnish a test

drilling, sawing, milling, turning, clipping, or such other report showing the results of the mechanical tests for each lot

methods capable of producing representative samples. shipped.

12.2 Mechanical Tests:

12.2.1 Nuts shall be tested in full section. 17. Product, Packaging and Package Marking

12.2.2 The hardness shall be determined on the top or

17.1 Individual NutsAll products shall be marked with a

bottom face of the nut.

symbol identifying the manufacturer. In addition, they shall be

13. Test Methods marked with the alloy/mechanical property marking specified

13.1 Chemical AnalysisWhen required, the chemical in Table 1. The marking shall be raised or depressed at the

composition shall be determined by any recognized commer- option of the manufacturer.

cial test method. In the event of disagreement, the following 17.2 Packaging:

test methods shall be used for referee purposes. 17.2.1 Unless otherwise specified, packaging shall be in

Alloy Test Method accordance with Practice D 3951.

Copper E 53, E 54, E 62, E 75, E 478 17.2.2 When special packaging requirements are required

Aluminum E 34, E 101, 8a E 227

Nickel E 38, E 76, E 354

by the purchaser, they shall be defined at the time of inquiry

Titanium E 120, E 1409 and order.

13.2 Mechanical: 17.3 Package MarkingEach shipping unit shall include

13.2.1 The proof load or proof stress tests shall be deter- or be plainly marked with the following:

mined in accordance with the appropriate methods of Test 17.3.1 ASTM designation,

Methods F 606. Loads to be determined using Table 2 and 17.3.2 Alloy number,

Table 4. 17.3.3 Alloy/mechanical property marking,

13.2.2 The hardness shall be determined in accordance with 17.3.4 Size,

Test Methods E 18 and E 92. For sizes 14 (0.250) to 716 17.3.5 Name and brand or trademark of the manufacturer,

(0.4375) in. one reading shall be taken. For sizes 12 (0.500) in. 17.3.6 Number of pieces,

and larger the hardness shall be the average of four readings 17.3.7 Country of origin, and

located 90 to one another.

17.3.8 Purchase order number.

14. Inspection

14.1 When specified on the inquiry or purchase order, the 18. Keywords

product shall be subject to inspection by the purchaser at the 18.1 general use; nonferrous; nuts

--````,`,,```,,`,`````,,`,,,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

No reproduction or networking permitted without license from IHS Not for Resale, 12/21/2006 15:06:55 MST

F 467 06a

SUPPLEMENTARY REQUIREMENTS

One or more of the following supplementary requirements shall be applied only when specified by

the purchaser in the inquiry, contract, or order. Supplementary requirements shall in no way negate any

requirement of the specification itself.

S1. Stress Corrosion Requirements, Copper Alloys S2.4 The manufacturer shall furnish a test report for each

S1.1 Copper alloy fasteners shall exhibit no evidence of lot in the shipment showing the actual results of the chemical

cracking after immersion for 30 min in an aqueous solution of analysis and mechanical property tests performed in accor-

mercurous nitrate when tested in accordance with Test Method dance with Supplementary Requirement S2.

B 154.

S1.1.1 WarningMercury is a definite health hazard and S3. Dye Penetrant Inspection

equipment for the detection and removal of mercury vapor S3.1 When dye penetrant inspection is specified on the

produced in volatilization is recommended. The use of rubber purchase order, the nuts shall be tested in accordance with

gloves in testing is advisable. Practice E 165 or other mutually acceptable procedures and

S2. Shipment Lot Testing shall conform to acceptance criteria as mutually agreed upon

between the purchaser and the manufacturer.

S2.1 When Supplementary Requirement S2 is specified on

the order (3.1.6), the manufacturer shall make sample tests on

S4. Heat Control (Alloys 400, 405, and 500 Only)

the individual lots for shipment to ensure that the product

conforms to the specified requirements. S4.1 When Supplementary Requirement S4 is specified on

S2.2 The manufacturer shall make an analysis of a ran- the inquiry or order, the manufacturer shall control the product

domly selected finished nut from each lot of product to be by heat analysis and identify the finished product in each

shipped. Heat or lot control shall be maintained. The analysis shipment by the actual heat number.

of the starting material from which the nuts have been S4.2 When Supplementary Requirement S4 is specified on

manufactured may be reported in place of the product analysis. the inquiry and order, Supplementary Requirement S2 shall be

S2.3 The manufacturer shall perform mechanical property considered automatically invoked with the addition that the

tests in accordance with this specification and Guide F 1470 on heat analysis shall be reported to the purchaser on the test

the individual lots for shipment. reports.

--````,`,,```,,`,`````,,`,,,,,,-`-`,,`,,`,`,,`---

SUMMARY OF CHANGES

Committee F16 has identified the location of selected changes to this standard since the last issue (F 467 06)

that may impact the use of this standard. (Approved Aug. 1, 2006.)

(1) Revised proof stress for Ni 686 in Table 2.

Committee F16 has identified the location of selected changes to this standard since the last issue (F 467 05) that may

impact the use of this standard. (Approved May 1, 2006.)

(1) Added new alloys UNS N06059 and UNS C26000 in Table (2) Added alloys Ni 59 and Cu 260 in Table 2.

1.

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

No reproduction or networking permitted without license from IHS Not for Resale, 12/21/2006 15:06:55 MST

Copyright ASTM International

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS

TABLE 1 Chemical Requirements

Composition, %

UNS Copper and Copper-Base Alloys

Designa- Man-

tion Alumi- Copper, Iron, Nickel, Phos- Zinc, Lead, Arsenic,

Alloy General Name ganese, Silicon Tin

Number num min max max phorus maxA max max

max

C11000 110 ETP copper 99.9

C26000 260 brass 68.571.5 0.05 balance 0.07

C27000 270 brass 63.068.5 0.07 balance 0.10

C46200 462 naval brass 62.065.0 0.10 balance 0.20 0.51.0

C46400 464 naval brass 59.062.0 0.10 balance 0.20 0.51.0

C51000 510 phosphor bronze balanceA 0.10 0.030.35 0.30 0.05 4.25.8

B

C61300 613 aluminum bronze 6.07.5 2.03.0 0.10 0.15C 0.015 0.10 0.05 0.01 0.200.50

5

D

C61400 614 aluminum bronze 6.08.0 88.0 1.53.5 1.0

C63000 630 aluminum bronze 9.011.0 78.0D 2.04.0 1.5 4.05.5 0.25 max 0.20 max

C64200 642 aluminum silicon bronze 6.37.6 88.65D 0.30 0.10 0.25 1.52.2E 0.50 0.05 0.20 max 0.15

C65100 651 silicon bronze 96.0D 0.8 0.7 0.82.0 1.5 0.05

C65500 655 silicon bronze 94.8D 0.8 1.5 0.6 2.83.8 1.5 0.05

F 467 06a

C66100 661 silicon bronze 94.0D 0.25 1.5 2.83.5 1.5 0.200.8

C67500 675 manganese bronze 0.25 max 57.060.0 0.82.0 0.050.5 balance 0.20 0.51.5

C71000 710 cupro-nickel 74.0D 0.60 1.00 19.023.0C 1.00 0.05

C71500 715 cupro-nickel 65.0D 0.400.7 1.00 29.033.0C 1.00 0.05

A

Not for Resale, 12/21/2006 15:06:55 MST

Elements shown as balance shall be arithmetically computed by deducting the sum of the other named elements from 100.

B

Copper plus specified elements = 99.8 min; copper plus silver = 88.591.5.

C

Cobalt is to be counted as nickel.

D

Minimum content of copper plus all other elements with specified limits shall be 99.5 %.

E

An alloy containing as high as 2.6 % silicon is acceptable provided the sum of all the elements other than copper, silicon, and iron does not exceed 0.30 %.

Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

--````,`,,```,,`,`````,,`,,,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS

TABLE 1 Continued

Nickel and Nickel-Base Alloys

UNS

Man- Phos-

Designa- Car- Sili- Co-

Al- General Alumi- Chro- Iron, ga- pho- Tita- Molyb- Sulfur, Vana- Tung-

tion bon, CopperA NickelA con, balt,

loy Name num mium max nese, rus, nium denum max dium sten

Num- max max max

max max

ber

N10001 335 Ni-Mo 0.05 1.0 max 4.06.0 1.0 balance 0.025 1.00 2.50 26.030.0 0.030 0.20.4

N10276 276 Ni-Mo-Cr 0.02 14.516.5 4.07.0 1.00 balance 0.040 0.08 2.50 15.017.0 0.030 0.35 max 3.04.5

B

N04400 400 Ni-Cu Class A 0.3 balance 2.5 2.0 63.070.0 0.5 0.024

B

6

N04405 405 Ni-Cu Class B 0.3 balance 2.5 2.0 63.070.0 0.5 0.0250.060

B

N05500 500 Ni-Cu-Al 2.303.15 0.25 balance 2.0 1.5 63.070.0 0.5 0.350.85 0.01

N06059 59 NiCr-Mo 0.10.4 0.010 22.024.0 0.5 max 1.5 0.5 balance 0.015 0.10 0.3 15.016.5 0.010 max

max max max max max max

N06625 625C Ni-Cr-Mo-Cb 0.40 0.010 20.023.0 5.0 0.50 58.0 min 0.015 0.50 0.40 max 1.00 8.010.0 0.015 3.24.2

F 467 06a

max max max max

N06686 686 Ni-Cr-Mo-W 0.010 19.023.0 5.0 0.75 balance 0.04 0.08 0.020.25 15.017.0 0.02 max 3.04.4

max max max max max

A

Elements shown as balance shall be arithmetically computed by deducting the sum of the other named elements from 100.

B

Not for Resale, 12/21/2006 15:06:55 MST

Cobalt is to be counted as nickel.

C

Alloy 625 material shall be refined using the electroslag remelting process (ESR), or the vacuum arc remelting process (VAR).

Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

--````,`,,```,,`,`````,,`,,,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS

TABLE 1 Continued

Composition, %

Aluminum-Base AlloysA

UNS Other Elements,

Desig- Manga- Tita- max

Al- General Alumi- Chro- Iron, Silicon, Zinc, Magne-

nation Copper nese, nium,

loy Name numA mium max max max sium

Num- max max

ber Each Total

7

A92024 2024 Aluminum balance 0.10 3.84.9 0.50 0.300.9 0.50 0.15B 0.25 1.21.8 0.05 0.15

--````,`,,```,,`,`````,,`,,,,,,-`-`,,`,,`,`,,`---

2024 max

A96061 6061 Aluminum balance 0.040.35 0.150.40 0.7 0.15 0.400.8 0.15 0.25 0.81.2 0.05 0.15

6061

C

A96262 6262 Aluminum balance 0.040.14 0.150.40 0.7 0.15 0.400.8 0.15 0.25 0.81.2

F 467 06a

6262

A

Analysis shall regularly be made only for the elements specified in this table. If, however, the presence of other elements is suspected or indicated in amounts greater than the specified limits, further analysis shall

be made to determine that these elements are not present in excess of the specified limits.

B

Titanium + zirconium 0.20 %, max.

C

Lead 0.40.7 %; bismuth 0.40.7 %.

Not for Resale, 12/21/2006 15:06:55 MST

Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

Copyright ASTM International

Provided by IHS under license with ASTM

No reproduction or networking permitted without license from IHS

TABLE 1 Continued

Titanium and Titanium-Base AlloysA

UNS ResidualsB

Car- Nitro- Oxy- Molyb- Zirco- Sili Ruthe-

Des- General Alumi- Iron, Tita- Hydro- Palla- Vana- Chro- Tin, to-

Alloy bon, gen, gen, denum, nium, con, nium, each,

ignation Name num, Al Fe nium, Ti gen, H dium, Pd dium, V mium, Cr Sn tal,

C N O Mo Zr Si Ru max

Number max

R50250 1 Titanium Gr 1 0.10 0.20 balance 0.0125 0.05 0.18 0.1 0.4

R50400 2 Titanium Gr 2 0.10 0.30 balance 0.0125 0.05 0.25 0.1 0.4

R50700 4 Titanium Gr 4 0.10 0.50 balance 0.0125 0.07 0.40 0.1 0.4

8

R56400 5 Titanium Gr 5 5.56.75 0.10 0.40 balance 0.0125 0.05 0.20 3.54.5 0.1 0.4

R56401 23 Titanium Ti-6Al-4V 5.56.5 0.08 0.25 balance 0.0125 0.05 0.13 3.54.5 0.1 0.4

ELI

R52400 7 Titanium Gr 7 0.10 0.30 balance 0.0125 0.05 0.25 0.120.25 0.1 0.4

R58640 19 Titanium Ti-38-6-44 3.04.0 0.05 0.30 balance 0.0200 0.03 0.12 0.10A 7.58.5 5.56.5 3.54.5 3.54.5 0.10C 0.15 0.4

F 467 06a

R55111 32 Titanium Ti-5-1-1-1 4.55.5 0.08 0.25 balance 0.0125 0.03 0.11 0.61.4 0.61.2 0.61.4 0.61.40.060.14 0.1 0.4

A

All reported values are maximums, unless a range is specified.

B

A residual is an element present in a metal or an alloy in small quantities inherent to the manufacturing process but not added intentionally. Residual elements need not be reported unless a report is specifically required

by the purchaser.

C

Not for Resale, 12/21/2006 15:06:55 MST

Ruthenium and Palladium, or both, may be added to Grade 19 for enhanced corrosion resistance as negotiated between purchaser and vendor. Chemical analysis is not required unless specifically negotiated.

Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

--````,`,,```,,`,`````,,`,,,,,,-`-`,,`,,`,`,,`---

F 467 06a

TABLE 2 Mechanical Property Requirements

Alloy Mechanical Hardness, Proof Stress,

Property Marking minA min, ksi

Cu 110 F 467A 65 HRF 30

Cu 260 F 467AB 55 HRF 60

Cu 270 F 467B 55 HRF 60

Cu 462 F 467C 65 HRB 50

Cu 464 F 467D 55 HRB 50

Cu 510 F 467E 60 HRB 60

Cu 613 F 467F 70 HRB 80

Cu 614 F 467G 70 HRB 75

Cu 630 F 467H 85 HRB 100

Cu 642 F 467J 75 HRB 75

Cu 651 F 467K 75 HRB 70

Cu 655 F 467L 60 HRB 50

Cu 661 F 467M 75 HRB 70

Cu 675 F 467N 60 HRB 55

Cu 710 F 467P 50 HRB 45

Cu 715 F 467R 60 HRB 55

Ni 59 Grade 1 F 467FN 21HRC 120

Ni 59 Grade 2 F 467GN 23HRC 135

Ni 59 Grade 3 F 467HN 25HRC 160

Ni 59 Grade 4 F 467JN 80HRB 100

Ni 335 F 467S 20 HRC 115

Ni 276 F 467T 20 HRC 110

Ni 400 F 467U 75 HRB 80

Ni 405 F 467V 60 HRB 70

Ni 500 F 467W 24 HRC 130

Ni 625 F 647AC 85 HRB-35 HRC 60

Ni 686 Grade 1 F 467BN 21 HRC 120

Ni 686 Grade 2 F 467CN 23 HRC 135

Ni 686 Grade 3 F 467DN 25 HRC 160

Ni 686 Grade 4 F 467EN 65 HRB-25HRC 100

Al 2024-T4B F 467X 70 HRB 55

Al 6061-T6 F 467Y 40 HRB 40

Al 6262-T9 F 467Z 60 HRB 52

Ti 1 F 467AT 140 HV 40

Ti 2 F 467BT 150 HV 55

Ti 4 F 467CT 200 HV 85

Ti 5 F 467DT 30 HRC 135

Ti 7 F 467ET 160 HV 55

Ti-19 F 467FT 24 HRC 120

Ti 23 F 467GT 25 HRC 125

Ti-5-1-1-1 F 467HT 24 HRC 105

A

For aluminum and titanium alloys hardness values are for information only.

B

Aluminum alloy 2024-T4 shall be supplied in naturally aged condition. This material is not recommended for nuts in sizes greater than 14 (0.250) in.

Copyright ASTM International

--````,`,,```,,`,`````,,`,,,,,,-`-`,,`,,`,`,,`---

9

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

No reproduction or networking permitted without license from IHS Not for Resale, 12/21/2006 15:06:55 MST

F 467 06a

TABLE 3 Mechanical Test Requirements for Nuts

Product Proof Stress, Tests Conducted Using Full-

ksi size Product

Hardness Proof Load

A

Jam, slotted, and castle nuts all ...

A

All other nuts up to 120 ...

A

over 120 ...

Tests in accordance with section 11.2.2 12.2.1

A

Mandatory tests.

TABLE 4 Tensile Stress Areas and Threads per Inch

Nominal Size, Coarse Threads-UNC Fine Threads-UNF 8 Thread Series-8UN

in.

Threads/in. Stress AreaA, Threads/in. Stress AreaA, Threads/in. Stress AreaA,

in2 in2 in2

--````,`,,```,,`,`````,,`,,,,,,-`-`,,`,,`,`,,`---

14 20 0.0318 28 0.0364 ... ...

5 16 18 0.0524 24 0.0580 ... ...

38 16 0.0775 24 0.0878 ... ...

7 16 14 0.1063 20 0.1187 ... ...

12 13 0.1419 20 0.1599 ... ...

9 16 12 0.1820 18 0.2030 ... ...

58 11 0.2260 18 0.2560 ... ...

34 10 0.3340 16 0.3730 ... ...

78 9 0.4620 14 0.5090 ... ...

1 8 0.6060 12 0.6630 ... ...

1 1 8 7 0.7630 12 0.8560 8 0.790

1 1 4 7 0.9690 12 1.0730 8 1.000

1 3 8 6 1.1550 12 1.3150 8 1.233

1 1 2 6 1.4050 12 1.5810 8 1.492

A

Tensile stress areas are computed using the following formula:

F

As 5 0.7854 D 2

0.9743

n G

where:

As = tensile stress area, in.2,

D = nominal size (basic major diameter), in., and

n = number of threads per inch.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International 10

Provided by IHS under license with ASTM Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=Mendez, Fernan

No reproduction or networking permitted without license from IHS Not for Resale, 12/21/2006 15:06:55 MST

S-ar putea să vă placă și

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39De la EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Evaluare: 5 din 5 stele5/5 (1)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363De la EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363Încă nu există evaluări

- Nonferrous Nuts For General UseDocument10 paginiNonferrous Nuts For General UserickjbastosÎncă nu există evaluări

- Nonferrous Nuts For General Use (Metric)Document10 paginiNonferrous Nuts For General Use (Metric)rickjbastosÎncă nu există evaluări

- Astm F 468Document11 paginiAstm F 468Ivan AlanizÎncă nu există evaluări

- ASTM F 467m-03aDocument9 paginiASTM F 467m-03aJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- ASTM F 468-03aDocument11 paginiASTM F 468-03aJORGE ARTURO TORIBIO HUERTA100% (1)

- F468 11377-1 PDFDocument11 paginiF468 11377-1 PDFAlejandro Valdés RojasÎncă nu există evaluări

- Monel K-500Document11 paginiMonel K-500koushkiÎncă nu există evaluări

- Astm F467Document6 paginiAstm F467MuhammadYusronAlfanyÎncă nu există evaluări

- F 467M - 01 - RJQ2N00TMDFBDocument9 paginiF 467M - 01 - RJQ2N00TMDFBAdrian GonzalezÎncă nu există evaluări

- F467MDocument10 paginiF467MMARCELO DOS SANTOS BARRETOSÎncă nu există evaluări

- Astm F467M 1997Document5 paginiAstm F467M 1997Jesse ChenÎncă nu există evaluări

- Nonferrous Nuts For General Use (Metric)Document8 paginiNonferrous Nuts For General Use (Metric)EstefaníaÎncă nu există evaluări

- ASTM F 467-03aDocument10 paginiASTM F 467-03aJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- F 468 - 03 - Rjq2oc0wmwDocument11 paginiF 468 - 03 - Rjq2oc0wmwSTAFFORDÎncă nu există evaluări

- ASTM F 468m-03a PDFDocument10 paginiASTM F 468m-03a PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- ASTM B743 Standard Specification For Seamless Copper Tube in CoilsDocument6 paginiASTM B743 Standard Specification For Seamless Copper Tube in CoilsDavid VegaÎncă nu există evaluări

- Nonferrous Nuts For General UseDocument10 paginiNonferrous Nuts For General Usejuniuni18100% (2)

- Astm F468M 1997Document7 paginiAstm F468M 1997Jesse ChenÎncă nu există evaluări

- F 468 - 98 - Rjq2oc05oaDocument10 paginiF 468 - 98 - Rjq2oc05oaSTAFFORDÎncă nu există evaluări

- Asme Sec Ii A Sa-751Document6 paginiAsme Sec Ii A Sa-751ronaldogeÎncă nu există evaluări

- Astm B 743 LWCDocument6 paginiAstm B 743 LWCCarlos PÎncă nu există evaluări

- F 467 - 01 Rjq2ny0wmueDocument9 paginiF 467 - 01 Rjq2ny0wmueMabel RomanÎncă nu există evaluări

- Nonferrous Bolts, Hex Cap Screws, Socket Head Cap Screws, and Studs For General UseDocument15 paginiNonferrous Bolts, Hex Cap Screws, Socket Head Cap Screws, and Studs For General Usejuniuni18Încă nu există evaluări

- A751 PDFDocument5 paginiA751 PDFGonzaloÎncă nu există evaluări

- Asme SB466Document9 paginiAsme SB466Stéphane LevasseurÎncă nu există evaluări

- Astm F467MDocument9 paginiAstm F467Mhouk sukÎncă nu există evaluări

- Astm A751Document5 paginiAstm A751Cristian OtivoÎncă nu există evaluări

- Astm F468-2012Document14 paginiAstm F468-2012Svetlana PerekopskayaÎncă nu există evaluări

- Astm B111Document9 paginiAstm B111kashif ehsanÎncă nu există evaluări

- By Authority of Legally Binding Document: The United States of AmericaDocument18 paginiBy Authority of Legally Binding Document: The United States of AmericaphlxuÎncă nu există evaluări

- F 2281 - 03 - RjiyodeDocument10 paginiF 2281 - 03 - Rjiyodekrutik100% (1)

- Specification for Welded Copper and Copper-Alloy Heat Exchanger TubeDocument11 paginiSpecification for Welded Copper and Copper-Alloy Heat Exchanger TubeJason LimÎncă nu există evaluări

- B466 PDFDocument6 paginiB466 PDFKikin K. Permata100% (1)

- Astm 494Document7 paginiAstm 494JOSEPH REFUERZO100% (1)

- SB 234Document9 paginiSB 234JolettitoÎncă nu există evaluări

- Astm B 171 B M .04Document7 paginiAstm B 171 B M .04FrengkiÎncă nu există evaluări

- SF-467 13Document10 paginiSF-467 13sudeep dsouzaÎncă nu există evaluări

- ASTM B 251 Cu and Cu Alloy TubeDocument8 paginiASTM B 251 Cu and Cu Alloy Tubearifin rizalÎncă nu există evaluări

- B 247 - 02 - Qji0ny0wmgDocument13 paginiB 247 - 02 - Qji0ny0wmgRudolfÎncă nu există evaluări

- LA Ravi Sir NC 2Document10 paginiLA Ravi Sir NC 2mangalamtestingbureaÎncă nu există evaluări

- SB 308Document8 paginiSB 308AnilÎncă nu există evaluări

- QCJ1TQ 1Document1 paginăQCJ1TQ 1JOSE CANTEROÎncă nu există evaluări

- SB 210Document12 paginiSB 210JolettitoÎncă nu există evaluări

- 72 MetaloDocument1 pagină72 MetalomangalamtestingbureaÎncă nu există evaluări

- ASTM A 751 - 07aDocument6 paginiASTM A 751 - 07analakasaÎncă nu există evaluări

- Astm B111Document9 paginiAstm B111mmlingÎncă nu există evaluări

- Astm B247Document14 paginiAstm B247Nav TalukdarÎncă nu există evaluări

- Astm F2924 - 14Document9 paginiAstm F2924 - 14SergiyÎncă nu există evaluări

- B 171Document7 paginiB 171manuel flores100% (1)

- F 2282 - 03 - RjiyodiDocument15 paginiF 2282 - 03 - RjiyodikrutikÎncă nu există evaluări

- A 0732 98 Fundicion Acero C & Aleado CoDocument6 paginiA 0732 98 Fundicion Acero C & Aleado CoIvan AlanizÎncă nu există evaluări

- Astm B 367 - 09Document6 paginiAstm B 367 - 09taker6Încă nu există evaluări

- B 221M - 02 - Qjiymu0Document14 paginiB 221M - 02 - Qjiymu0ramonaÎncă nu există evaluări

- Astm A751-2007Document6 paginiAstm A751-2007Luis Hoyos AvalosÎncă nu există evaluări

- Astm E53-02Document4 paginiAstm E53-02AlbertoÎncă nu există evaluări

- Astm B-251Document9 paginiAstm B-251David VegaÎncă nu există evaluări

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20De la EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Încă nu există evaluări

- Astm e 797 PDFDocument7 paginiAstm e 797 PDFrazormebackÎncă nu există evaluări

- Astm e 516 Rev A 1995 R 2005 PDFDocument10 paginiAstm e 516 Rev A 1995 R 2005 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Astm E164 19Document11 paginiAstm E164 19JORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- 2016Document1 pagină2016JORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- E 566 - 99 Standard Practice For Electromagnetic (Eddy-Current) Sorting of Ferrous Metals1 PDFDocument5 paginiE 566 - 99 Standard Practice For Electromagnetic (Eddy-Current) Sorting of Ferrous Metals1 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- E 691 - 99 Std. Prac. For Conducting An Interlaboratory Study To Determine The Precision ofDocument22 paginiE 691 - 99 Std. Prac. For Conducting An Interlaboratory Study To Determine The Precision ofJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- E 761 - 92 (Reapproved 2000) Std. Test Method For Compressive Strength of Sprayed Fire-ResisDocument2 paginiE 761 - 92 (Reapproved 2000) Std. Test Method For Compressive Strength of Sprayed Fire-ResisJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Astm E690-98 R04 E04 Et PDFDocument4 paginiAstm E690-98 R04 E04 Et PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Astm e 648 Rev A 2006 PDFDocument14 paginiAstm e 648 Rev A 2006 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- E 631 - 93a (Reapproved 1998) E1 Standard Terminology of Building Constructions1 PDFDocument46 paginiE 631 - 93a (Reapproved 1998) E1 Standard Terminology of Building Constructions1 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Astm E691-99Document22 paginiAstm E691-99Jorge ToribioÎncă nu există evaluări

- Astm E682-92 R00 PDFDocument8 paginiAstm E682-92 R00 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- E 570 - 97 Standard Practice For Flux Leakage Examination of Ferromagnetic Steel Tubular ProDocument6 paginiE 570 - 97 Standard Practice For Flux Leakage Examination of Ferromagnetic Steel Tubular ProJorge ToribioÎncă nu există evaluări

- ASTM F 467-03a PDFDocument10 paginiASTM F 467-03a PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- E 543 - 02 Standard Practice For Agencies Performing Nondestructive Testing1 PDFDocument11 paginiE 543 - 02 Standard Practice For Agencies Performing Nondestructive Testing1 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- ASTM F 467m-03a PDFDocument9 paginiASTM F 467m-03a PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Astm e 502 Rev A 2006 PDFDocument6 paginiAstm e 502 Rev A 2006 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Astm e 572 Rev A 2002 e 2006 R 2006Document10 paginiAstm e 572 Rev A 2002 e 2006 R 2006Jorge ToribioÎncă nu există evaluări

- Astm F 439-02 E03 PDFDocument8 paginiAstm F 439-02 E03 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- ASTM F 468m-03a PDFDocument10 paginiASTM F 468m-03a PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Astm F 441-02 PDFDocument7 paginiAstm F 441-02 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Astm F 442-99Document7 paginiAstm F 442-99JORGE ARTURO TORIBIO HUERTA100% (2)

- Astm F 438-04 PDFDocument7 paginiAstm F 438-04 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Astm F 593-02 E04 PDFDocument8 paginiAstm F 593-02 E04 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Astm F 437-99 PDFDocument4 paginiAstm F 437-99 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Astm F 568M-04 PDFDocument9 paginiAstm F 568M-04 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Datasheet PompaDocument8 paginiDatasheet PompaagusnnnÎncă nu există evaluări

- CNG Cylinder Inspection ManualDocument18 paginiCNG Cylinder Inspection Manualhasan.cepuÎncă nu există evaluări

- ESH Surveillance ChecklistDocument4 paginiESH Surveillance ChecklistIZZATI YAACOBÎncă nu există evaluări

- Irqb Guideline 6 Special Processes Rev01Document22 paginiIrqb Guideline 6 Special Processes Rev01Delong KongÎncă nu există evaluări

- Energization and Tie in Plan: ObjectiveDocument5 paginiEnergization and Tie in Plan: ObjectiveNajmul QamarÎncă nu există evaluări

- AISC Certification Standard ForDocument60 paginiAISC Certification Standard ForTry SmallÎncă nu există evaluări

- ELITech Earth Science Pvt. Ltd. - Company ProfileDocument25 paginiELITech Earth Science Pvt. Ltd. - Company ProfilesanchitagarwalismÎncă nu există evaluări

- Accident Prevention Onboard Ship at Sea and in PortDocument150 paginiAccident Prevention Onboard Ship at Sea and in PortMj BaloyoÎncă nu există evaluări

- WeeklyDocument84 paginiWeeklysdan100% (1)

- @airbus: Component Maintenance Manual With Illustrated Part ListDocument64 pagini@airbus: Component Maintenance Manual With Illustrated Part ListAnh Tuan PhamÎncă nu există evaluări

- Saep 20Document33 paginiSaep 20Daniel MeanaÎncă nu există evaluări

- End Truck Rt/Rs Manual: Installation Operating Maintenance & Spare PartsDocument29 paginiEnd Truck Rt/Rs Manual: Installation Operating Maintenance & Spare PartsKovács EndreÎncă nu există evaluări

- 38-Character Internal Quality Audit PlanDocument1 pagină38-Character Internal Quality Audit PlanTravisÎncă nu există evaluări

- Materials System SpecificationDocument11 paginiMaterials System Specificationnadeem shaikhÎncă nu există evaluări

- Unit 5 PomDocument32 paginiUnit 5 PomDebasis BanerjeeÎncă nu există evaluări

- GOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchDocument6 paginiGOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchShahid BhattiÎncă nu există evaluări

- Manual: Regulatory Food Safety AuditorDocument35 paginiManual: Regulatory Food Safety AuditorMonica SinghÎncă nu există evaluări

- Comments : 437AL, 438AR, 451AL, 452AR 460Document9 paginiComments : 437AL, 438AR, 451AL, 452AR 460Suman BajracharyaÎncă nu există evaluări

- Bolt Loading TypesDocument4 paginiBolt Loading TypesUfuk ÇİMENÎncă nu există evaluări

- What Is A Quality CultureDocument10 paginiWhat Is A Quality CultureHuseyn AgayevÎncă nu există evaluări

- Inoculation and HarvestingwebDocument7 paginiInoculation and HarvestingwebLeBinhÎncă nu există evaluări

- ISO 9000 Quality Standards in ConstructionDocument13 paginiISO 9000 Quality Standards in Constructionanon_414184376Încă nu există evaluări

- Ms Iso - Iec 17020 - 2012 PrepdfDocument6 paginiMs Iso - Iec 17020 - 2012 Prepdfmvijayk3Încă nu există evaluări

- Topic: Annex "B" General Principles On Consulting ServicesDocument5 paginiTopic: Annex "B" General Principles On Consulting ServicesGilbeys TangcawanÎncă nu există evaluări

- Catalog No. 2014-5Document84 paginiCatalog No. 2014-5tsikasÎncă nu există evaluări

- Field Attachment Report at Mtama WardDocument16 paginiField Attachment Report at Mtama WardDOTO SHINDAI0% (1)

- Lean Production & QualityDocument47 paginiLean Production & QualityOckouri BarnesÎncă nu există evaluări

- Technical Audit of Older Ammonia Plants: Ken Northcutt, Robert Collins, and S. MadhavanDocument12 paginiTechnical Audit of Older Ammonia Plants: Ken Northcutt, Robert Collins, and S. Madhavanvaratharajan g rÎncă nu există evaluări

- ESR 0330 Wheel Defect Manual: Engineering Standard Rolling StockDocument57 paginiESR 0330 Wheel Defect Manual: Engineering Standard Rolling StockRafael SchelbauerÎncă nu există evaluări

- Aboveground Storage Tank Facility Inspection Checklist PDFDocument4 paginiAboveground Storage Tank Facility Inspection Checklist PDFMohamed IbrahimÎncă nu există evaluări