Documente Academic

Documente Profesional

Documente Cultură

Pia03 Post Left Rod Level 2 PDF

Încărcat de

Juan Posada GTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pia03 Post Left Rod Level 2 PDF

Încărcat de

Juan Posada GDrepturi de autor:

Formate disponibile

A

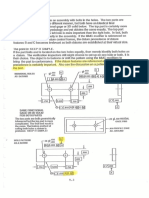

HEAT TREAT: CC6

CARBURIZE & HARDEN HRc 38-42

WITH A 0.6-1.2 mm TOTAL CASE DEPTH

PER WAA-M99A3-A

31.0 -PART TO BE TESTED FOLLOWING

4.8 HEAT TREATMENT PER SPEC: 15 $BEND TEST

4.0 FOR EMBRITTLEMENT CHECK

3.5

PT "A" ZINC SPEC : MECHANICALLY PLATE FINISH PER WSD-M1P85-A2

PLUS TRIVALENT CLEAR CHROMATE SEALER MUST BE APPLIED

+0.10 MUST MEET 48 HRS NO WHITE CORROSION,

9.00 8.0

0 96 HRS NO RED CORROSION CC7

CC A3 MUST BE FREE OF BURRS OR FLASHING WHICH MAY

0.3 A B C 8.0 R12.7 BE DETRIMENTAL TO SATISFACTORY ASSEMBLY,

R0.8 SAFE HANDLING, APPEARANCE OR FUNCTION.

A B

B UNLESS OTHERWISE SPECIFIED 1.5 A B C

R3.0

71.227 $

SUBSTANCE USE RESTRICTION: THE GLOBAL AUTOMOTIVE DECLARABLE

SUBSTANCE LIST (SEE http://www.gadsl.org) REGARDING

PROHIBITED AND DECLARABLE SUBSTANCE APPLIES TO ALL

MATERIALS USED IN THIS PART

2.0

R19.6

19.65 #0.30

R1.0

CC A4

8.35 PT "B"

8.25

SC A8

1.60 #0.20

CC A5

47.8 $

88.3 #1.5 A

1.60 #0.10

CC A1

30.0 $

2 30-Nov-13 ADDED HT SPEC 2148

4.5 #1.0 R0.25 #0.10

12.70 #0.08 1 24-May-11 REMOVED LEAD IN 1891

AFTER PLATING - 07-Sep-10 INITIAL RELEASE 1760

EXCEPT AT NOTCH 41.75 #0.50

AND POST TIPS 140.0 $ CHANGE DATE DESCRIPTION ECA APPROVED

CONTROLLED COPY SC A2 30.0 $ PROENGINEER NATIVE DATA

ECOPY IN CORPNAS NO MANUAL CHANGES

NOTES: 1.95 #0.20 METRIC THIRD ANGLE PROJECTION

RELEASED: DEC 10, 2013 DIMENSIONS SHOWN IN

MILLIMETERS

UNLESS OTHERWISE SHOWN

SC A = DESIGNATES SIGNIFICANT CHARACTERISTIC TOLERANCE UNLESS OTHERWISE SPECIFIED

#0.5 ONE PLACE DECIMAL

TO BE MONITORED PER CONTROL PLAN USING ATTRIBUTE GAUGING METHODS #0.25 TWO PLACE DECIMAL

#1.0 $ ON ALL ANGLES

CC A = DESIGNATES CRITICAL CHARACTERISTIC REFERENCE DWG DATE

07-Sep-10

TO BE MONITORED PER CONTROL PLAN USING ATTRIBUTE GAUGING METHODS DESIGNER

M. Brockman

SC V = DESIGNATES SIGNIFICANT CHARACTERISTIC DRAWN BY

E. Kayahara

TO BE MONITORED PER CONTROL PLAN USING VARIABLE MEASUREMENT MATERIAL

OR GAUGING METHODS SAE 1018 CC9

CUST. REV. NAME

CUST. REV.

CC V = DESIGNATES CRITICAL CHARACTERISTIC POST- LEFT ROD

REL LEVEL

REVISION

Wip

1.5

REL LEVEL

REVISION

Wip

1.6 TO BE MONITORED PER CONTROL PLAN USING VARIABLE MEASUREMENT

GAUGING METHODS

PART # A

BRANCH

PDM DATA

main BRANCH

DRAWING DATA

main

2215140_PIA03

WINDSOR MACHINE & STAMPING (2009) LTD

SCALE 10:1

CONTROLLED COPY

ECOPY IN CORPNAS

RELEASED: DEC 10,

2013

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Method Statement - Refrigerant PipingDocument7 paginiMethod Statement - Refrigerant PipingGirithar M SundaramÎncă nu există evaluări

- ASTM A581 A581M-95bDocument3 paginiASTM A581 A581M-95bFeteneÎncă nu există evaluări

- LH514 - OkokDocument6 paginiLH514 - OkokVictor Yañez Sepulveda100% (1)

- Graviola1 Triamazon, AntiCancer, InglesDocument2 paginiGraviola1 Triamazon, AntiCancer, InglesManuel SierraÎncă nu există evaluări

- Critical Changes To ASME and ISO GD&T Standards 2018Document31 paginiCritical Changes To ASME and ISO GD&T Standards 2018Juan Posada GÎncă nu există evaluări

- Advanced GD & TDocument95 paginiAdvanced GD & Tpavan_0380% (5)

- Critical Changes To ASME and ISO GD&T Standards 2018Document31 paginiCritical Changes To ASME and ISO GD&T Standards 2018Juan Posada GÎncă nu există evaluări

- GD T ExamplesDocument10 paginiGD T ExamplesJuan Posada GÎncă nu există evaluări

- To RQ Smoo HV Salum PartsDocument4 paginiTo RQ Smoo HV Salum PartsJuan Posada GÎncă nu există evaluări

- A New Approach For The Effectiveness of Coaxiality Tolerance VerificationDocument11 paginiA New Approach For The Effectiveness of Coaxiality Tolerance VerificationJuan Posada GÎncă nu există evaluări

- Hole Pattern RFSDocument3 paginiHole Pattern RFSJuan Posada GÎncă nu există evaluări

- Use Composite Tolerances To Control The Feature-to-Feature RelationshipDocument2 paginiUse Composite Tolerances To Control The Feature-to-Feature RelationshipJuan Posada GÎncă nu există evaluări

- 90399-01 - Lock PostDocument1 pagină90399-01 - Lock PostJuan Posada GÎncă nu există evaluări

- c2Document40 paginic2Juan Posada GÎncă nu există evaluări

- Composte TolDocument5 paginiComposte TolJuan Posada G100% (1)

- Geometric Dimensioning Tolerancing For Mechanical DesignDocument2 paginiGeometric Dimensioning Tolerancing For Mechanical DesignJuan Posada GÎncă nu există evaluări

- Unit 1 GD&T: Instructor: James ThornburghDocument42 paginiUnit 1 GD&T: Instructor: James ThornburghJuan Posada GÎncă nu există evaluări

- Obs Inf Worksheet 2013Document2 paginiObs Inf Worksheet 2013api-338002331Încă nu există evaluări

- EnglishDocument18 paginiEnglishSarah SiddiquiÎncă nu există evaluări

- 31. (NÂNG CAO) Đề soạn theo cấu trúc minh họa 2021 - Tiếng Anh - Đề 31 - DươngDocument15 pagini31. (NÂNG CAO) Đề soạn theo cấu trúc minh họa 2021 - Tiếng Anh - Đề 31 - DươngNguyễn Quế Anh100% (1)

- 300.91C - Fire Alarm System Pre-Test and Acceptance Test Checklist 3-27-14Document2 pagini300.91C - Fire Alarm System Pre-Test and Acceptance Test Checklist 3-27-14mthuyaÎncă nu există evaluări

- Sensors & Transducers: (Code: EI 401)Document4 paginiSensors & Transducers: (Code: EI 401)Mayukh BiswasÎncă nu există evaluări

- Static CMOS and Dynamic CircuitsDocument19 paginiStatic CMOS and Dynamic CircuitsAbhijna MaiyaÎncă nu există evaluări

- Assembly Manual, Operation and Maintenance Round Vibrating Screen Model: Tav-Pvrd-120Document15 paginiAssembly Manual, Operation and Maintenance Round Vibrating Screen Model: Tav-Pvrd-120Sandro Garcia Olimpio100% (1)

- Lecture Notes Unit-1 (Network Operating System) : Session: 2021-22Document17 paginiLecture Notes Unit-1 (Network Operating System) : Session: 2021-22Pradeep BediÎncă nu există evaluări

- Tabla QuimicaDocument12 paginiTabla QuimicaPablo PasqualiniÎncă nu există evaluări

- B.W.G. - Birmingham Wire Gauge: The Wall Thickness of Pipes - Gauge and Decimal Parts of An InchDocument3 paginiB.W.G. - Birmingham Wire Gauge: The Wall Thickness of Pipes - Gauge and Decimal Parts of An InchLuis Fernando Perez LaraÎncă nu există evaluări

- SMA - Core 1 - IEC62109-2 - 0 Test ReportDocument6 paginiSMA - Core 1 - IEC62109-2 - 0 Test ReportFurqan HamidÎncă nu există evaluări

- Evaluation of Global Research Trends in The Area of Food Waste D - 2020 - Food CDocument10 paginiEvaluation of Global Research Trends in The Area of Food Waste D - 2020 - Food CAliÎncă nu există evaluări

- Watercolor SecretsDocument60 paginiWatercolor Secretsmissdoisneau98% (47)

- Classic Plan: Dog/Cat BedDocument3 paginiClassic Plan: Dog/Cat BedRobson DiasÎncă nu există evaluări

- An Adaptive Power Oscillation Damping Controllerby STATCOM With Energy StorageDocument10 paginiAn Adaptive Power Oscillation Damping Controllerby STATCOM With Energy StorageChristian EmenikeÎncă nu există evaluări

- Toolbox Talks Working at Elevations English 1Document1 paginăToolbox Talks Working at Elevations English 1AshpakÎncă nu există evaluări

- 2019 BMS1021 Practice Questions Answers PDFDocument12 pagini2019 BMS1021 Practice Questions Answers PDFaskldhfdasjkÎncă nu există evaluări

- Opti Turn Tu 2004 V ManualDocument80 paginiOpti Turn Tu 2004 V ManualCharu NavneetÎncă nu există evaluări

- Photography Techniques (Intermediate)Document43 paginiPhotography Techniques (Intermediate)Truc Nguyen100% (2)

- MD 2 MidtermDocument31 paginiMD 2 MidtermRea Rebenque100% (1)

- DattadasDocument4 paginiDattadasJéssica NatáliaÎncă nu există evaluări

- Appetizer Summative TestDocument36 paginiAppetizer Summative TestArgelynPadolinaPedernalÎncă nu există evaluări

- Igorot Village: Get To Know..Document11 paginiIgorot Village: Get To Know..Elain RagosÎncă nu există evaluări

- Site AnalysisDocument20 paginiSite AnalysisCarlo RosaioÎncă nu există evaluări

- IPC 4552 Cuprins - ENIG PDFDocument3 paginiIPC 4552 Cuprins - ENIG PDFMarlon CornejoÎncă nu există evaluări

- L15 - Parallel Magnetic CircuitsDocument6 paginiL15 - Parallel Magnetic CircuitsParikshit MishraÎncă nu există evaluări