Documente Academic

Documente Profesional

Documente Cultură

How to Install Exterior Mouldings on Brick, Stone & Stucco

Încărcat de

MAXIMODRAGONTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

How to Install Exterior Mouldings on Brick, Stone & Stucco

Încărcat de

MAXIMODRAGONDrepturi de autor:

Formate disponibile

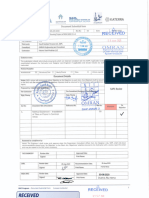

170 Pippin Rd.

Vaughan, Ontario, Canada L4K 4X9

Telephone: (905) 660-6338 Facsimile: (905) 660-6350

www.mouldexmouldings.com info@mouldexmouldings.com

How to install Mouldex Exterior Mouldings

Before beginning the installation of Mouldex Exterior Mouldings,

its vital that the surface be dry and free of all foreign materials.

This includes;

oil dust

form release agents paint

wax water repellents Brick face Existing stucco face wall Prefabricated EIFS panel Base coated wall

moisture frost

Substrate

Substrate Base coat ready for finish stucco,

and any other surface contamination that may interfere with the Brick, stone or finish stucco pre-fabricated EIFS panel, and

adhesive bonding process. levelled concrete/masonry

Once the surface is clean, youll need to determine whether or not

youll be using a backwrapping installation method.

If you are not using a backwrapping method, completely remove

the mesh from the rear of the moulding. Mesh thats been pulled

back from rear of moulding

If you are using a backwrapping method, peel the mesh from the

rear of the moulding.

Well go into more detail on this below.

Youre now ready to apply an approved adhesive which will

completely cover the rear of the moulding.

Adhesive method of application

Use a 3/8 stainless steel notched trowel to do this.

While the approved adhesive is still wet, immediately install moulding Mesh

and press it into place.

Nail/screw

with washer

Apply moulding

When backwrapping, parge over the peeled fibre mesh with an to exterior

Mesh

approved basecoat material. Depending on the size of the mounting surface

moulding, you may want to help support it in place until the Mounting Temporary attachment

adhesive has completely dried. (ie. use a mechanical fastener) surface until adhesive cures

When joining two pieces together, butt mouldings end to end

ensuring a tight fit and treat joint with mesh (min 2 on either side

of joint). Then, embed with an approved basecoat, feathering it and

creating a flush joint.

When joining two pieces to create a corner, mitre cut the two pieces

and butt joint at the mitre end to ensure a tight fit. Treat joint with

mesh (min 2 on either side) and embed with an approved basecoat, Butt joint Corner mitre joint

feathering it, creating a flush joint.

The after-market finish coat is now ready to be applied. Distributors of approved adhesives and basecoats;

Please ensure that;

Please call us so we can find an appropriate distributor in your area.

All mouldings are completely adhered and fully cured.

All fasteners are removed

All joints have been treated and sanded flush

S-ar putea să vă placă și

- Method Statement & Application Related Documents PDFDocument38 paginiMethod Statement & Application Related Documents PDFmahmoud IbrahemÎncă nu există evaluări

- FSEL Strain Gage For Concrete Rev 00Document7 paginiFSEL Strain Gage For Concrete Rev 00jbmune6683Încă nu există evaluări

- Polyseal AC Sealant: Superior 1-Component Acrylic SealantDocument2 paginiPolyseal AC Sealant: Superior 1-Component Acrylic SealantVaittianathan MahavapillaiÎncă nu există evaluări

- Flexrock ManualDocument4 paginiFlexrock ManualMark KoeningerÎncă nu există evaluări

- Installation Instructions TESCON VANADocument2 paginiInstallation Instructions TESCON VANAasdfdsafdsafds22332fÎncă nu există evaluări

- Fosroc Conbextra Epoxy Grouts Application GuideDocument3 paginiFosroc Conbextra Epoxy Grouts Application GuideChukwuma OgbonnaÎncă nu există evaluări

- Tile Adhesive Heavy Duty Technical Data Sheet 2020Document1 paginăTile Adhesive Heavy Duty Technical Data Sheet 2020Airis Joy RojasÎncă nu există evaluări

- McWaneDuctileConcreteLiningRepair TipSheet FINAL-2Document1 paginăMcWaneDuctileConcreteLiningRepair TipSheet FINAL-2Ludi D. LunarÎncă nu există evaluări

- 3M 9100 Z Web Mat TDSDocument5 pagini3M 9100 Z Web Mat TDSvivek jayswalÎncă nu există evaluări

- Resin Infusion of A Carbon FibreDocument14 paginiResin Infusion of A Carbon FibreMAXIMODRAGON100% (1)

- S Fiberglass Drywall Tape: HeetrockDocument2 paginiS Fiberglass Drywall Tape: HeetrockMartin RiosÎncă nu există evaluări

- Fiber Cement Board Installation InstructionsDocument24 paginiFiber Cement Board Installation InstructionsAnu dasÎncă nu există evaluări

- Guide to Installing StudLiner Concrete Protection ProductsDocument10 paginiGuide to Installing StudLiner Concrete Protection ProductssegomezpÎncă nu există evaluări

- Product Data Sheet: Thistle® One Coat PlasterDocument6 paginiProduct Data Sheet: Thistle® One Coat PlastergowthamÎncă nu există evaluări

- Tile Adhesive Original Technical Data Sheet 2020Document1 paginăTile Adhesive Original Technical Data Sheet 2020LA BoiserÎncă nu există evaluări

- Pre 049Document2 paginiPre 049Josip MedvedÎncă nu există evaluări

- Plastering Guide PDFDocument8 paginiPlastering Guide PDFStas ChirilaÎncă nu există evaluări

- Rubber Flooring Installation GuideDocument5 paginiRubber Flooring Installation GuidePista Cristiana-BeatriceÎncă nu există evaluări

- Application of Tile Grouts 0Document2 paginiApplication of Tile Grouts 0Insafians PowerÎncă nu există evaluări

- D A T A Install: Submerseal SystemDocument4 paginiD A T A Install: Submerseal SystemJHARPA NHYNHAÎncă nu există evaluări

- Manual Installation TilesDocument1 paginăManual Installation TilesAquaEnergyMexÎncă nu există evaluări

- TILE FIXING GUIDEDocument1 paginăTILE FIXING GUIDEStavros ApostolidisÎncă nu există evaluări

- Fosroc GMS Nitoplate LaminateDocument6 paginiFosroc GMS Nitoplate Laminatejohn paulÎncă nu există evaluări

- Mosaic Installation Guide 06.2023Document12 paginiMosaic Installation Guide 06.2023yusuf anwerÎncă nu există evaluări

- Backer RodDocument2 paginiBacker RodCassy AbulenciaÎncă nu există evaluări

- Forbo Installation Guidance Note Marmoleum-Sheet-2019Document8 paginiForbo Installation Guidance Note Marmoleum-Sheet-2019Daniel AguileraÎncă nu există evaluări

- INSTALLGUIDE CementDocument6 paginiINSTALLGUIDE CementvelevveraÎncă nu există evaluări

- IT - Ghid - Aplicare - Membrana - Izolatie - Bazine-Iazuri ArtificialeDocument8 paginiIT - Ghid - Aplicare - Membrana - Izolatie - Bazine-Iazuri Artificialeandrew_sfiÎncă nu există evaluări

- STEICOsill Timber Verarbeitung en IDocument3 paginiSTEICOsill Timber Verarbeitung en IHarrison LangÎncă nu există evaluări

- Guide To Epoxy GroutingDocument25 paginiGuide To Epoxy Groutingrize1159Încă nu există evaluări

- Building A DioramaDocument29 paginiBuilding A DioramaJuan RoldánÎncă nu există evaluări

- Ficha Técnica Seal-N-GripDocument4 paginiFicha Técnica Seal-N-GripGhislaine SousaÎncă nu există evaluări

- Composite Stone Veneer: Installation GuideDocument13 paginiComposite Stone Veneer: Installation GuideRajÎncă nu există evaluări

- Finishing Guide: For Thistle Plaster and Gyproc PlasterboardDocument15 paginiFinishing Guide: For Thistle Plaster and Gyproc Plasterboardahmed saadÎncă nu există evaluări

- Usg Sheetrock® Brand Durabond®Document4 paginiUsg Sheetrock® Brand Durabond®Horacio PadillaÎncă nu există evaluări

- One Off Fiberglass Foam Core BoatDocument15 paginiOne Off Fiberglass Foam Core Boatsjdarkman1930100% (2)

- Thin Brick Installation GuideDocument12 paginiThin Brick Installation GuideGlavanRafaelÎncă nu există evaluări

- T2 Global-CP03-C&S-MSB-XX-019941-B - W0 - T0 - 12974-3Document7 paginiT2 Global-CP03-C&S-MSB-XX-019941-B - W0 - T0 - 12974-3Areaya mahetemÎncă nu există evaluări

- Apparente, Colona, Corten and AllllDocument16 paginiApparente, Colona, Corten and Allllash.tgcpÎncă nu există evaluări

- MOS Installation of Tiles On Floors in Common AreasDocument8 paginiMOS Installation of Tiles On Floors in Common AreasabedÎncă nu există evaluări

- GRP Lamination Processing - Instructions PDFDocument34 paginiGRP Lamination Processing - Instructions PDFmuhammadkashikÎncă nu există evaluări

- TerrameshInstallationGuideNZ 0Document2 paginiTerrameshInstallationGuideNZ 0Jorge RosalÎncă nu există evaluări

- Notice Abri DeliceDocument32 paginiNotice Abri DeliceGuillaumeÎncă nu există evaluări

- ADVABOND_TDSDocument2 paginiADVABOND_TDSMohammed AbugharbiehÎncă nu există evaluări

- Laying Guidelines For MarbleDocument4 paginiLaying Guidelines For Marbledhirendra singhÎncă nu există evaluări

- Use Wood Panels as Wall FinishDocument18 paginiUse Wood Panels as Wall FinishLAGAN MARWAHÎncă nu există evaluări

- XLIGHT Revestimientos InterioresDocument4 paginiXLIGHT Revestimientos InterioresdandragutescuÎncă nu există evaluări

- Martini Absorb Installation Guide - 0421Document3 paginiMartini Absorb Installation Guide - 0421lac ngoÎncă nu există evaluări

- Ace E CatalogueDocument31 paginiAce E CatalogueanadinathÎncă nu există evaluări

- 4 RAZON Tile Adhesive Use ManualDocument5 pagini4 RAZON Tile Adhesive Use Manualshrikrishna rathodÎncă nu există evaluări

- 6 Practical MicrotechniqueDocument2 pagini6 Practical Microtechniquetube71393Încă nu există evaluări

- Montagekit Polystyrene: Strong, Solvent-Free Assembly Adhesive Based On Acrylic DispersionDocument2 paginiMontagekit Polystyrene: Strong, Solvent-Free Assembly Adhesive Based On Acrylic DispersionAmina ČivaÎncă nu există evaluări

- MonniSeal PU25Document3 paginiMonniSeal PU25VishwanathÎncă nu există evaluări

- Supreme Wall-Base Adhesive: BasebondDocument2 paginiSupreme Wall-Base Adhesive: BasebondYASHICA VAITTIANATHANÎncă nu există evaluări

- Masterflex Tapes, When Used To Protect Joints Above andDocument1 paginăMasterflex Tapes, When Used To Protect Joints Above andMichael AlbuquerqueÎncă nu există evaluări

- MasterSeal 726 - TDSDocument2 paginiMasterSeal 726 - TDSKhin Sandi KoÎncă nu există evaluări

- Lamination ProcedureDocument5 paginiLamination Proceduretrueman44Încă nu există evaluări

- Notice 72457S0 X70 Valodeal TMDocument24 paginiNotice 72457S0 X70 Valodeal TMDavid Peña PérezÎncă nu există evaluări

- Epoxy Grout Handbook - MasterFlowDocument17 paginiEpoxy Grout Handbook - MasterFlowaruncg2Încă nu există evaluări

- Addons Manual v2 75Document27 paginiAddons Manual v2 75Edwin Alexander ArocaÎncă nu există evaluări

- Machineable WaxDocument2 paginiMachineable WaxBarry WoodÎncă nu există evaluări

- Convert Picture Into 3D ModelDocument1 paginăConvert Picture Into 3D ModelMAXIMODRAGONÎncă nu există evaluări

- Celtic, Arabic and Other Designs CollectionDocument1 paginăCeltic, Arabic and Other Designs CollectionMAXIMODRAGONÎncă nu există evaluări

- Electroplating Simulations For Printed Circuit Board DesignersDocument11 paginiElectroplating Simulations For Printed Circuit Board DesignersMAXIMODRAGONÎncă nu există evaluări

- PEMFDocument8 paginiPEMFMAXIMODRAGONÎncă nu există evaluări

- Pulsed Electro Magnetic FieldDocument4 paginiPulsed Electro Magnetic FieldMAXIMODRAGONÎncă nu există evaluări

- Opamp Function GeneratorDocument2 paginiOpamp Function GeneratorchethaÎncă nu există evaluări

- 3-D Computer Vision Using Structured Light - Design Calibration PDFDocument46 pagini3-D Computer Vision Using Structured Light - Design Calibration PDFMAXIMODRAGONÎncă nu există evaluări

- Resin Infusion of A Carbon FibreDocument14 paginiResin Infusion of A Carbon FibreMAXIMODRAGON100% (1)

- JectsDocument32 paginiJectsMAXIMODRAGONÎncă nu există evaluări

- Cubierta de AcordeonDocument15 paginiCubierta de AcordeonMAXIMODRAGONÎncă nu există evaluări

- 3-D Computer Vision Using Structured Light - Design Calibration PDFDocument46 pagini3-D Computer Vision Using Structured Light - Design Calibration PDFMAXIMODRAGONÎncă nu există evaluări

- How To Fix A Tooth With CADDocument33 paginiHow To Fix A Tooth With CADMAXIMODRAGONÎncă nu există evaluări

- Build Your Own GaussmeterDocument15 paginiBuild Your Own GaussmeterMAXIMODRAGONÎncă nu există evaluări

- FAQ Mach3Document41 paginiFAQ Mach3MAXIMODRAGONÎncă nu există evaluări

- Converting An Inkjet Printer To Print PCBsDocument82 paginiConverting An Inkjet Printer To Print PCBsMAXIMODRAGON100% (2)

- Resin Infusion of A Carbon FibreDocument14 paginiResin Infusion of A Carbon FibreMAXIMODRAGON100% (1)

- Building Your Own Raw1.5Document48 paginiBuilding Your Own Raw1.5MAXIMODRAGON100% (1)

- A Complete Course in Astrology (Horoscope Interpretation)Document48 paginiA Complete Course in Astrology (Horoscope Interpretation)Niam Lahanna94% (35)

- 81 Infantile NeurosisDocument2 pagini81 Infantile NeurosisMAXIMODRAGONÎncă nu există evaluări

- Diy Organic Beauty Recipes Sample PDFDocument9 paginiDiy Organic Beauty Recipes Sample PDFMAXIMODRAGONÎncă nu există evaluări

- Resin Infusion of A Carbon FibreDocument14 paginiResin Infusion of A Carbon FibreMAXIMODRAGON100% (1)

- How To Estimate DeflectionDocument3 paginiHow To Estimate DeflectionMAXIMODRAGON100% (1)

- Meridianos AcupunturaDocument46 paginiMeridianos AcupunturaMAXIMODRAGON100% (3)

- How To Fix A Tooth With CADDocument23 paginiHow To Fix A Tooth With CADMAXIMODRAGONÎncă nu există evaluări

- Audio BiofeedbackDocument23 paginiAudio BiofeedbackMAXIMODRAGONÎncă nu există evaluări

- Top 5 Mental Math Methods in The WorldDocument3 paginiTop 5 Mental Math Methods in The WorldMAXIMODRAGONÎncă nu există evaluări

- Hack A Toaster Oven For Reflow SolderingDocument83 paginiHack A Toaster Oven For Reflow SolderingMAXIMODRAGONÎncă nu există evaluări

- Biomass Gasification For Hydrogen ProductionDocument9 paginiBiomass Gasification For Hydrogen ProductionCris CrisÎncă nu există evaluări

- Xpelair GX6 (90800AW) 6 Inch Axial Extract Fans Spec1Document2 paginiXpelair GX6 (90800AW) 6 Inch Axial Extract Fans Spec1Augustine Dharmaraj100% (1)

- Isorod Guide SpecDocument8 paginiIsorod Guide SpecmarkicivanÎncă nu există evaluări

- Curtain Wall EngineeringDocument12 paginiCurtain Wall EngineeringKayBee Datiles100% (2)

- en PDFDocument3 paginien PDFmarvin17Încă nu există evaluări

- Abcd. Proiect AdamDocument14 paginiAbcd. Proiect AdamSfiriac LauraÎncă nu există evaluări

- Weamco Truncated Cone BP112 PDFDocument2 paginiWeamco Truncated Cone BP112 PDFRajÎncă nu există evaluări

- How To Avoid Cracks in PlasterDocument3 paginiHow To Avoid Cracks in PlasterShativel ViswanathanÎncă nu există evaluări

- ARSENIC DISPOSAL PRACTICES IN THE METALLURGICAL INDUSTRY by P.A. RIVEROS PDFDocument26 paginiARSENIC DISPOSAL PRACTICES IN THE METALLURGICAL INDUSTRY by P.A. RIVEROS PDFFerudun AkyolÎncă nu există evaluări

- Calcium Folinate 1734Document3 paginiCalcium Folinate 1734Mulayam Singh YadavÎncă nu există evaluări

- Analysis of Fatigue Fracture of Tank Wagon Railway Axles: Cosmin LocoveiDocument5 paginiAnalysis of Fatigue Fracture of Tank Wagon Railway Axles: Cosmin LocoveiZoser KalengayiÎncă nu există evaluări

- Igcse e Electricity With MSCDocument94 paginiIgcse e Electricity With MSCaliÎncă nu există evaluări

- Guided Wave and WeldingDocument44 paginiGuided Wave and Weldingharoub_nas100% (1)

- Jurnal Reaktor Metatesis Propilen PDFDocument8 paginiJurnal Reaktor Metatesis Propilen PDFAnonymous 8UdbKWu2Încă nu există evaluări

- Koren - Reconfigurable Manufacturing SystemsDocument14 paginiKoren - Reconfigurable Manufacturing SystemsAhmed AtefÎncă nu există evaluări

- Mellitah Plant: Western Libya Gas ProjectDocument662 paginiMellitah Plant: Western Libya Gas ProjectAnas AhmedÎncă nu există evaluări

- Self Tapping Screw PDFDocument3 paginiSelf Tapping Screw PDFlutfi_ismailÎncă nu există evaluări

- Building Material Rate in MiriDocument18 paginiBuilding Material Rate in MiriJoanne WongÎncă nu există evaluări

- GRUNDFOS DATA BOOKLET FOR REWINDABLE SUBMERSIBLE MOTORSDocument50 paginiGRUNDFOS DATA BOOKLET FOR REWINDABLE SUBMERSIBLE MOTORSfrcarras11Încă nu există evaluări

- Lightweight Self-Consolidating Concrete - Statistical Modelling, Mixture Design and Performance EvaluationDocument417 paginiLightweight Self-Consolidating Concrete - Statistical Modelling, Mixture Design and Performance Evaluationshak543Încă nu există evaluări

- Leather Burnishing & Polishing: Existing ProcedureDocument6 paginiLeather Burnishing & Polishing: Existing ProcedurevinothjohnnashÎncă nu există evaluări

- Liquid Extraction OperationDocument19 paginiLiquid Extraction OperationOky TresiaÎncă nu există evaluări

- 07 Subsynchronous OscillationsDocument40 pagini07 Subsynchronous Oscillationssulemankhalid0% (1)

- FC - 00631-14Document5 paginiFC - 00631-14რაქსშ საჰაÎncă nu există evaluări

- Advanced FRP Panel Tank DesignDocument4 paginiAdvanced FRP Panel Tank DesignEstimasi ATI SurabayaÎncă nu există evaluări

- Thermal Expansion of Polytetrafluoroethylene (Teflon)Document4 paginiThermal Expansion of Polytetrafluoroethylene (Teflon)Josafat Cruz-PrietoÎncă nu există evaluări

- Automotive Fuels and Engines Chemical PerspectiveDocument13 paginiAutomotive Fuels and Engines Chemical PerspectiveTeshome DengisoÎncă nu există evaluări

- AP CRDA Basic Cost Of Materials 2016-2017Document57 paginiAP CRDA Basic Cost Of Materials 2016-2017Hari Krishna AaryanÎncă nu există evaluări

- DAPUS SkripsiDocument2 paginiDAPUS SkripsiIndrakoÎncă nu există evaluări

- 40-40I Flame DetectorDocument2 pagini40-40I Flame DetectorSumeet Sisir SarkarÎncă nu există evaluări