Documente Academic

Documente Profesional

Documente Cultură

CB52 / CBH52: Brazed Plate Heat Exchanger

Încărcat de

JerryChenDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CB52 / CBH52: Brazed Plate Heat Exchanger

Încărcat de

JerryChenDrepturi de autor:

Formate disponibile

CB52 / CBH52

Brazed Plate Heat Exchanger

General information

Alfa Laval introduced its first brazed plate heat exchanger

(BHE) in 1977 and has since continuously developed and opti-

mized its performance and reliability.

Brazing the stainless steel plates together eliminates the need

for gaskets and thick frame plates. The brazing material seals

and holds the plates together at the contact points ensuring

optimal heat transfer efficiency and pressure resistance. The

plate design guarantees the longest possible life.

The design options of the brazed heat exchanger are exten-

sive. Different plate patterns are available for various duties

and performance specifications. You can choose a standard

configuration BHE, or a unit designed according to your own

specific needs. The choice is entirely yours.

Typical applications

- HVAC heating/cooling

- Refrigerant applications

- Industrial heating/cooling

- Oil cooling

Working principles Particulars required for quotation

The heating surface consists of thin corrugated metal plates To enable Alfa Lavals representative to make a specific quota-

stacked on top of each other. Channels are formed between tion, specify the following particulars in your enquiry:

the plates and corner ports are arranged so that the two - required flow rates or heat load

media flow through alternate channels, usually in counter- - temperature program

current flow for the most efficient heat transfer process. - physical properties of liquids in question

- desired working pressure

Standard design - maximum permitted pressure drop

The plate pack is covered by cover plates. Connections are

located in the front or rear cover plate. To improve the heat Examples of connections

transfer design, the channel plates are corrugated.

Outside Inside Soldering Welding

threaded threaded

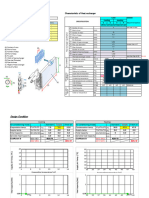

CB52 PED approval pressure/temperature graph* Standard data

PS bar / (PSI) S3 - S4 Min. working temperature see graph

S1 - S2

Max. working temperature see graph

Min. working pressure Vacuum

33 (479)

32 (464)

Max. working pressure see graph

31 (450) Volume per channel, litres (ga) 0.095 (0.025)

30 (435)

Max particle size mm (inch) 1.2 (0.05)

Max flowrate m3/h (gpm)* 14.5 (64)

Min no of plates 6

TS

-196 50 75 100 125 150 175 200 225 C Max no of plates 150

(-321) (122) (167) (212) (257) (302) (347) (392) (437) (F)

* Water at 5 m/s (16.4 ft/s) (connection velosity)

CBH52 PED approval pressure/temperature graph* Standard materials

PS bar / (PSI) S3 - S4 Cover plates Stainless steel

S1 - S2

Connections Stainless steel

50 (725)

Plates Stainless steel

Brazing material Copper

47 (682)

Standard dimension and weight*

45 (653)

CB52 and CBH52

43 (624)

A measure mm = 10 + (n x 2.4) +

3

41 (595) A measure inch = 0.4 + (n x 0.1) +

0.12

Weight** kg = 1.8 + (n x 0.22)

39 (566)

Weight** lb = 4.0 + (n x 0.48)

TS

-196 50 75 90 125 150 175 200 225 C ** excluding connections

(-321) (122) (167) (194) (257) (302) (347) (392) (437) (F)

(n = number of plates)

CB52 KHK approval pressure/temperature graph*

PS bar / (PSI) S3 - S4 112 (4.41)

S1 - S2

50 (1.97) A

36 (522)

S4 S1

TS

466 (18.34)

-302 150 C

526 (20.7)

(-148) (-100) (F)

CB52 / CBH52 - UL approval pressure/temperature graph*

PSI / (PS bar) S3 - S4 CB52 S3 - S4 CBH52

S1 - S2 CB52 S1 - S2 CBH52

653 (45)

S3 S2

450 (31)

TS

-319 437 F

(-195) (225) (C)

* For exact values please contact your local Alfa Laval representative.

PCT00105EN 0905 Alfa Laval reserves the right to change specifications without prior notification.

How to contact Alfa Laval

Up-to-date Alfa Laval contact

details for all countries are always

available on our website at

www.alfalaval.com.

S-ar putea să vă placă și

- CB52 / CBH52: Brazed Plate Heat ExchangerDocument2 paginiCB52 / CBH52: Brazed Plate Heat ExchangermarcellopiergiovanniÎncă nu există evaluări

- Alfa Laval Ac70x Product Leaflet enDocument2 paginiAlfa Laval Ac70x Product Leaflet enAangels PorrasÎncă nu există evaluări

- Alfa Laval CBH18DW: Brazed Plate Heat ExchangerDocument2 paginiAlfa Laval CBH18DW: Brazed Plate Heat ExchangerCosmin ScrieciuÎncă nu există evaluări

- 149-Giaflex cb110 cbh110 SLDocument2 pagini149-Giaflex cb110 cbh110 SLMohamed BelliliÎncă nu există evaluări

- Superheated Steam Condensate TankDocument4 paginiSuperheated Steam Condensate TankGanesh BhardwajÎncă nu există evaluări

- Alfa Laval DOC110: Brazed Plate Heat Exchanger For Oil CoolingDocument2 paginiAlfa Laval DOC110: Brazed Plate Heat Exchanger For Oil CoolingTantikorn JantoÎncă nu există evaluări

- Pipe Thickness Calculation AS Per ASME 31.3Document11 paginiPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRÎncă nu există evaluări

- CB16Document2 paginiCB16fredyÎncă nu există evaluări

- Superheated Steam SeparatorDocument4 paginiSuperheated Steam SeparatorGanesh BhardwajÎncă nu există evaluări

- Exchanger Tube Min ThicknessDocument2 paginiExchanger Tube Min ThicknessMohamed ElshehnyÎncă nu există evaluări

- Alfa DiscDocument2 paginiAlfa DiscHưng NguyễnÎncă nu există evaluări

- Examples E4.16.1/E4.6.1 and E4.6.2 BPVC VIII-1: ASME PTB-4-2013Document15 paginiExamples E4.16.1/E4.6.1 and E4.6.2 BPVC VIII-1: ASME PTB-4-2013ordenador90Încă nu există evaluări

- Technical Specification: Brazed Plate Heat ExchangerDocument1 paginăTechnical Specification: Brazed Plate Heat ExchangerSergio Solar melendezÎncă nu există evaluări

- Alfa Laval CB60 CoolerDocument2 paginiAlfa Laval CB60 Coolerkman548Încă nu există evaluări

- D:/dont Delete User/Downloads/ (Flange Analysis NC-3658-3)Document1 paginăD:/dont Delete User/Downloads/ (Flange Analysis NC-3658-3)deepakÎncă nu există evaluări

- Storage Tank Design Calculation - Api 650Document21 paginiStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- Piping Sizing Final Rev01 12Document1 paginăPiping Sizing Final Rev01 12aÎncă nu există evaluări

- DBL 810388 04 RK16A enDocument2 paginiDBL 810388 04 RK16A enVignesh NadimuthuÎncă nu există evaluări

- MP Condensate Flash VesselDocument4 paginiMP Condensate Flash VesselGanesh BhardwajÎncă nu există evaluări

- Ficha Tecnica Valvula Check 10 MilDocument1 paginăFicha Tecnica Valvula Check 10 MilTrujillo TrujilloÎncă nu există evaluări

- Allowable Stresses of Typical ASME Materials - Carbon Steel SA 516 Gr.70Document3 paginiAllowable Stresses of Typical ASME Materials - Carbon Steel SA 516 Gr.70Muhammed Mudafi ElhaqÎncă nu există evaluări

- Temprature GaugeDocument1 paginăTemprature GaugeKenneth EmbeleÎncă nu există evaluări

- Pipes. Wall Thickness Calculation According ASME B31.3Document86 paginiPipes. Wall Thickness Calculation According ASME B31.3Jeannie Tatiana Pérez Sánchez100% (4)

- 3 Not-Inst Alfalaval Echangeurs-Cb76Document2 pagini3 Not-Inst Alfalaval Echangeurs-Cb76crÎncă nu există evaluări

- EN6114Document17 paginiEN6114Andrei Cozma67% (3)

- Precision PipesDocument2 paginiPrecision PipesRamu PamuruÎncă nu există evaluări

- AHU-DX-coil Spec Sheet - 20160913 - AHU L5-01Document2 paginiAHU-DX-coil Spec Sheet - 20160913 - AHU L5-01fakir mohammadÎncă nu există evaluări

- Asme Viii Shell & Se HeadDocument5 paginiAsme Viii Shell & Se HeadSnr George RaczÎncă nu există evaluări

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 paginiSteam Drum, Water Wall & Evaporator - VWHA054Mani SunÎncă nu există evaluări

- Steam Injectors ARI CONA 651Document2 paginiSteam Injectors ARI CONA 651CalinÎncă nu există evaluări

- QR4798 16x12 600# HTF - CALCDocument3 paginiQR4798 16x12 600# HTF - CALCjasamaÎncă nu există evaluări

- Rosemount Seal m1199rtwDocument3 paginiRosemount Seal m1199rtwMiguel Jiménez FloresÎncă nu există evaluări

- Data Sheet RFQ Air Cooler HEDocument1 paginăData Sheet RFQ Air Cooler HEcharles bronsonÎncă nu există evaluări

- ASME B31 4 Calculator V1 1Document11 paginiASME B31 4 Calculator V1 1vazzoleralex6884100% (1)

- Pressure Vessel Calculation Report PDFDocument12 paginiPressure Vessel Calculation Report PDFVictor Fakoya50% (2)

- Asme Calculation of PCP Bottom Header Dated 15.03.2012Document9 paginiAsme Calculation of PCP Bottom Header Dated 15.03.2012ariyaÎncă nu există evaluări

- (H, Y) Ifc015b21sDocument3 pagini(H, Y) Ifc015b21sISI INGENIEROÎncă nu există evaluări

- EHB02 Technical Specifications: 1. External DimensionsDocument5 paginiEHB02 Technical Specifications: 1. External DimensionsArmandoCalderonÎncă nu există evaluări

- AlfaNova76 AlfaNovaHP76Document4 paginiAlfaNova76 AlfaNovaHP76ĒDīson CevallosÎncă nu există evaluări

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureDocument7 paginiPipe Thickness Calculation For Straight Pipe Under Internal PressureMakhdoom Ibad HashmiÎncă nu există evaluări

- Allowable Stresses of Typical ASME Materials - Carbon Steel PDFDocument3 paginiAllowable Stresses of Typical ASME Materials - Carbon Steel PDFMSÎncă nu există evaluări

- CIPRIANI A5 Saldobrasati SCDocument4 paginiCIPRIANI A5 Saldobrasati SCSebastian MirandaÎncă nu există evaluări

- B 84567 SB MM1 SPC ST 00 0301 - 1 - AOC - Seal Gas Mercury Guard BedDocument7 paginiB 84567 SB MM1 SPC ST 00 0301 - 1 - AOC - Seal Gas Mercury Guard BedpragatheeskÎncă nu există evaluări

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureDocument8 paginiPipe Thickness Calculation For Straight Pipe Under Internal Pressureionutlaur86Încă nu există evaluări

- Calculation Sheet: WT-CAL-CO2-003Document4 paginiCalculation Sheet: WT-CAL-CO2-003babu100% (1)

- Design of Cylindrical Shell Part 2Document14 paginiDesign of Cylindrical Shell Part 2Tito FebriantoÎncă nu există evaluări

- 1.1.2 Firefighting SystemDocument10 pagini1.1.2 Firefighting SystemChristos KarkotisÎncă nu există evaluări

- SHELLDocument6 paginiSHELLSalz EngineeringÎncă nu există evaluări

- Standard Bourdon Tube Pressure GaugesDocument6 paginiStandard Bourdon Tube Pressure GaugesMai Thế ToanÎncă nu există evaluări

- 3.5 KW Evaporator AC 30EQ 14H FDocument1 pagină3.5 KW Evaporator AC 30EQ 14H FVijayakumar S me19d029Încă nu există evaluări

- Basics of Pressure Piping For Junior EngineersDocument36 paginiBasics of Pressure Piping For Junior Engineersتدریس زبان ESLÎncă nu există evaluări

- Shell & Dish End CalculationDocument46 paginiShell & Dish End CalculationparveshÎncă nu există evaluări

- Tema Tubesheet Calculation SheetDocument1 paginăTema Tubesheet Calculation SheetSanjeev KachharaÎncă nu există evaluări

- Design Data: 4" Weldolet CalculationDocument2 paginiDesign Data: 4" Weldolet Calculationgrabetty100% (2)

- Individual Minor Equipment Design: Heat Exchanger (HX-101) : CHEN 4015: Chemical Engineering Design ProjectDocument29 paginiIndividual Minor Equipment Design: Heat Exchanger (HX-101) : CHEN 4015: Chemical Engineering Design ProjectrosieÎncă nu există evaluări

- Lab Evaluation of YSZ Coating Surface and Thermal Analysis For Plasma Sprayed Coated IC Engine PistonDocument35 paginiLab Evaluation of YSZ Coating Surface and Thermal Analysis For Plasma Sprayed Coated IC Engine PistonSurenÎncă nu există evaluări

- DBL 810474 03 UBK46 enDocument4 paginiDBL 810474 03 UBK46 enTheodoros AtheridisÎncă nu există evaluări

- FICHA TECNICA EHB04 - Tech - DatasheetDocument5 paginiFICHA TECNICA EHB04 - Tech - DatasheetLio LiverhÎncă nu există evaluări

- Materials Data for Cyclic Loading: Low-Alloy SteelsDe la EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsEvaluare: 5 din 5 stele5/5 (2)

- Instruction ManualDocument140 paginiInstruction ManualJerryChenÎncă nu există evaluări

- BRO OG Seaprotectsolutions 2012 11 en Tcm11 23350Document20 paginiBRO OG Seaprotectsolutions 2012 11 en Tcm11 23350JerryChenÎncă nu există evaluări

- Edible Oil Centrifuges 9997 1711 010Document6 paginiEdible Oil Centrifuges 9997 1711 010JerryChenÎncă nu există evaluări

- Alfanova 27 Aq Productleaftlet CHE00147ENDocument2 paginiAlfanova 27 Aq Productleaftlet CHE00147ENJerryChenÎncă nu există evaluări

- AGT Biodiesel Pretreatment PFT00374ENDocument6 paginiAGT Biodiesel Pretreatment PFT00374ENJerryChenÎncă nu există evaluări

- RSE 220 Parts Catalogue2Document94 paginiRSE 220 Parts Catalogue2JerryChen100% (2)

- MX Mixers PDFDocument2 paginiMX Mixers PDFJerryChen100% (1)

- Vap TheoryDocument38 paginiVap TheoryJerryChenÎncă nu există evaluări

- Ch-21 Sand CastingDocument156 paginiCh-21 Sand CastingDivya SoniÎncă nu există evaluări

- Staad Pro British ExampleDocument104 paginiStaad Pro British ExampleCt NaSihahÎncă nu există evaluări

- Vikings-Preaction FoamWater System Supplied by A Bladder TankDocument12 paginiVikings-Preaction FoamWater System Supplied by A Bladder TankHenry WuÎncă nu există evaluări

- Assan Panel Walls RockwoolDocument5 paginiAssan Panel Walls RockwoolFlorin MatisÎncă nu există evaluări

- Ba VMKR VMLKR VHKR EnglDocument28 paginiBa VMKR VMLKR VHKR EnglHiram Flores100% (1)

- Oil AshDocument13 paginiOil AshAmmarÎncă nu există evaluări

- Ferrocement BoatDocument10 paginiFerrocement BoatNihil In-lineÎncă nu există evaluări

- LamellaDocument3 paginiLamellaRomeo Padilla IIIÎncă nu există evaluări

- Moment Calculations - CORRECTDocument5 paginiMoment Calculations - CORRECTBipul PoudelÎncă nu există evaluări

- Electrical Design PrinciplesDocument12 paginiElectrical Design PrinciplesLJ IDANE ARANASÎncă nu există evaluări

- Is 1570 7Document18 paginiIs 1570 7Raj K Sharma100% (1)

- Morstar Overhead Cutouts: (Cầu Chì Tự Rơi Morstar)Document10 paginiMorstar Overhead Cutouts: (Cầu Chì Tự Rơi Morstar)Thùy PhanÎncă nu există evaluări

- Investigation On Mechanical Properties of Aluminum (6065) With Copper by PM TechniqueDocument4 paginiInvestigation On Mechanical Properties of Aluminum (6065) With Copper by PM TechniqueVinoth KumarÎncă nu există evaluări

- Moment Resisting Connections - SteelconstructionDocument13 paginiMoment Resisting Connections - SteelconstructionAniket Dube100% (2)

- Pipeline Integrity Management MSC (Penspen)Document7 paginiPipeline Integrity Management MSC (Penspen)Majeed Rumani0% (2)

- Prestressing DocumentDocument59 paginiPrestressing DocumentAmoula Ahmed100% (1)

- Thermodynamics ExercicesDocument4 paginiThermodynamics ExercicesElias Jose Akle VillarealÎncă nu există evaluări

- Building AcousticsDocument11 paginiBuilding AcousticsSindhura Valluri100% (1)

- Assignment AEP 2014Document5 paginiAssignment AEP 2014Sagar MohanÎncă nu există evaluări

- Eurocode 8 - General Rules and Seismic Actions PDFDocument22 paginiEurocode 8 - General Rules and Seismic Actions PDFmarineugenÎncă nu există evaluări

- IWM - Construction Material Recycling GuidebookDocument40 paginiIWM - Construction Material Recycling GuidebookAllan HakÎncă nu există evaluări

- Petrofisika TM2209 W10Document25 paginiPetrofisika TM2209 W10Hafiizhoh HanafiaÎncă nu există evaluări

- Prorox SL 950 SaDocument1 paginăProrox SL 950 SaHardiman ArbiÎncă nu există evaluări

- Cvp68 - Mini Project Synopsis: Title of The Project: Analysis and Design of Multistoried FrameDocument3 paginiCvp68 - Mini Project Synopsis: Title of The Project: Analysis and Design of Multistoried FrameSHAHBAZ M MAINUDDINÎncă nu există evaluări

- Jeet Final Project Report Phase-1Document31 paginiJeet Final Project Report Phase-1Abhi ChavanÎncă nu există evaluări

- Materials Science and Engineering by Callister Chapter 1 ReviewerDocument3 paginiMaterials Science and Engineering by Callister Chapter 1 ReviewerTy ztickÎncă nu există evaluări

- Jabal Al Ka'Aba BOQ ModifiedDocument81 paginiJabal Al Ka'Aba BOQ ModifiedJaime Manalili Landingin50% (2)

- Sustainable Production of Concrete Containing Discarded Beverage GlassDocument9 paginiSustainable Production of Concrete Containing Discarded Beverage Glassyeison100% (1)

- 2019 ASME Section VIII Division 1 SynopsisDocument58 pagini2019 ASME Section VIII Division 1 SynopsisCristian Xavier Avendaño BelloÎncă nu există evaluări

- HVAC TestDocument5 paginiHVAC TestFaizal Achmad100% (1)