Documente Academic

Documente Profesional

Documente Cultură

EBEN

Încărcat de

Aymen JuhsdiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

EBEN

Încărcat de

Aymen JuhsdiDrepturi de autor:

Formate disponibile

DSIGNATIONS ET PARTICULARITES DES BNISTERIES GRANDES ETAPES DE CONCEPTION

DESIGNATIONS AND SPECIAL FEATURES OF THE TRIM RFRENTIEL TECHNIQUE MAIN DESIGN STAGES

PARTS Garnissage

ZONE AVANT EBENISTERIES Dbut de projet : prendre connaissance des lments mis a disposition

Project start: be aware of elements available

FRONT ZONE Trimming TTECHNICAL Reference Architecture 5e de rfrence, style ext, brief style inter, premiers volumes environnement structure, feuillures, grains,

11 Garniture de montant de baie/A-pillar trim fiches CSTP/pice, Guide de conception

Garnissage du montant A avec ou sans capteur alarme avec ou sans textile

A pillar trimming - with or without alarm sensor - with or without textile TRIM

CEST QUOI LES PARTS ? A QUOI CA

EBENISTERIES

Reference architecture, ext style, inter style brief, environment structure preliminary volumes, rabbet, grains, CSTP/part

sheet, Design Guide

Vrifier rglementations ECE 21 (amnagement inter), ECE 125 (champs de vision conducteur)

Check ECE 21 regulations (interior arrangement), ECE 125 (driver's field of vision) SERT ? Prparer les consultations FNR : construction des premiers lments

Gestion des accostages avec PdB, GP, JEP, vitrage pare-brise

Management of the mating with the dashboard, Roof Trimming, Door Gasket, windscreen WHAT ARE TRIM PARTS? WHAT ARE THEY Prepare the supplier consultations: building of primary elements

11 2

Garniture de montant de baie + garniture sup pied avant/A- USED FOR? - suivre tablissement ST Projet bnisterie sur la base de la ST Mtier bnisteries IHPC_MPGI08_0086

pillar trim + 2 front pillar trim Les bnisteries ont pour fonctions principales : - follow drawing up of trim parts Project Technical Specification on the basis of team Technical Specification

Garnissage des montants A + A avec ou sans alarme avec ou sans textile The main functions of the trim parts are: IHPC_MPGI08_0086

A + A' pillar trimming - with or without alarm sensor - with or without textile Le masquage de la structure vhicule - provisionner quantits et localisation des zones gographiques - les interfaces de fixation pour

Vrifier rglementations ECE 21 (amnagement inter), ECE 125 (champs de vision conducteur) Masking vehicle structure dimensionnement conomique et physique des outillages des mtiers Structure et Garnissage

Check ECE 21 regulations (interior arrangement), ECE 125 (driver's field of vision) La participation lesthtique intrieure, la scurit passive, lacoustique. - supply - quantities and location of geographical areas - the mounting interfaces for economic and physical

Gestion des accostages avec PdB, GP, JEP, vitrages pare-brise et fenestron Participation in Internal aesthetics, passive safety, acoustics. sizing of the tools of the Structure and Trim teams

Management of the mating with the dashboard, Roof Trimming, Door Gasket, windscreen Le but nest pas seulement de concevoir une pice, il faut quelle soit ralisable, montable et - transmettre les incontournables du mtier MPGI aux FNRs consults :

3

3 Garniture longeron avant/Front

3

side member trim dmontable/remontable. - send the MPGI team's indispensables to the suppliers consulted:

Garnissage Longeron avant ou 3 garnissage Longeron entier The goal is not only to design a part, it must be achievable, should be easy to fit and N1 : Protections

Front side member trimming or "complete" side member trim disassemble or reassemble. No. 1: Protections

Soumise sollicitation appli dun effort de 80 DAN / 100 x 100 mm = pied utilisateur Chaque pice doit rpondre la synthse vhicule N2 : Aspect en vieillissement

Subject to stress applying of a force of 80 daN / 100 x 100 mm = user's foot Each part should respond to the vehicle summary No. 2: Appearance in aging

Gestion des accostages avec TH, JEP, PdB

Management of the mating with the Passenger Compartment Carpet, Door Gasket, dashboard

PRINCIPAUX DECOUPAGES PIECES SUIVANT N5 : Gomtrie neuf

Commande ouverture capot prendre en compte sur la pice Gauche SILHOUETTE No. 5: Geometry when new

N8 : Vibration renvoi ceinture

Bonnet opening control to be taken into account on the Left-hand part

4

4 Garniture cot dauvent/Vent side trim MAIN PARTS' CUTTINGS ACCORDING TO BODY No. 8: Safety belt vibration relay

Garnissage du cot de PdB - en fonction du dcoupage pices et du type de PdB SHAPE -

-

raliser les dparts pices dessus ou dessous JEP et dcoupage pices suivant :

start the parts above or below the Door Gasket and cutting of parts according to:

Dashboard side trimming - depending on the part cutting and the type of dashboard

Gestion des accostages avec PdB, JEP o RT Accostage

Management of the mating with the Dashboard, Door Gasket

Commande ouverture capot prendre en compte sur la pice Gauche

o RT mating line

Bonnet opening control to be taken into account on the Left-hand part BERLINES 4/5 PORTES o Composition vhicule demander lquipe projet

10

4/5 DOOR SALOONS o Vehicle Composition to be requested to the project team

ZONE AVANT PIED CENTRAL 1

5 o feuillure menante structure Cot dHabitacle, Fermeture Avant de Cot dHabitacle

FRONT CENTRAL PILLAR AREA 11 o driving rabbet structure Passenger Compartment Side, Front closure Passenger Compartment

5 Side (not sure with here)

5 Garniture suprieure pied central/Upper central pillar trim 13

o type de JEP 1 ou 2 lvre(s) - dans le futur 1 fiche interfaces ICOE/MPGI par type de JEP

Garnissage du montant B - avec ou sans marquage/obturateur AIRBAG avec ou sans textile

B pillar trimming - with or without AIRBAG marking/cap - with or without textile 4

MONOSPACE

6 8 o type of Door Gasket 1 or 2 lip(s) - in the future 1 ICOE/MPGI interfaces sheet per type of

Identifier type rglage en hauteur renvoi C/S : cach ou apparent

Identify type of height adjustment relay to C/S: hidden or visible

PEOPLE CARRIER Door Gasket -

Identifier le type de dflecteur Airbag Rideau : intgr ou spar - dfinir les types daccostage pice pice (soyage, tuilage, tuilo-soyage) RT Accostage

Identify the type of Curtain Airbag deflector: integrated or separated - define the "part by part" types of mating (dimpling, overlapping, overlapping-dimpling) Mating Technical

Vrifier rglementations ECE 21 (amnagement inter), ECE 16 (C/S) Reference Material

Check ECE 21 regulations (interior arrangement), ECE 16 (C/S) 3 - prendre en compte les contraintes APrs Vente exigences, dfinir ordre montage / dmontage

! Pice sujette habituellement difficults de montage - take into account the After Sales constraints requirements, define fitting/removal sequence

Part usually subject to fitting difficulties - prparer les infos transmettre aux FNRs consults pour chiffrage moules dinjection * :

Gestion des accostages avec JEP, GP, rglage renvoi sangle C/S

Management of the mating with the Door Gasket, Roof Trimming, strap adjustment relay C/S

BERLINE 3 PORTES OU COUP - prepare the information to be sent to the Suppliers consulted for cost-estimate of injection molds *:

o raliser les PdF techniques fournir les dimensions principales des pices

6

6 Garniture infrieure pied central/Lower central pillar trim 3 DOOR SALOON OR COUPE o make the technical PDFs provide the main dimensions of the parts

Garnissage du montant B 10

B pillar trimming o dfinir les paisseurs pour chaque pice voir RT Accostage pour ep en fin de pice

Vrifier les contraintes choc latral, rglementation ECE 16 (C/S) o define the thicknesses for each part refer to Mating Technical Reference Material for end of

Check the side impact constraints, ECE regulation 16 (C/S)

1 part thickness

Identifier le besoin dun enjoliveur de passage sangle C/S

Identify the requirement for a C/S strap passage trim

2

5 o pr-positionner les fixations et lments disostatisme Guide Fix standards + Bibliothque des

Gestion des accostages avec JEP, TH fix

Management of the mating with Door Gasket, Passenger Compartment Carpet

7 12 o pre-position the fastenings and isostatism elements Standard Fasteners Guide + Library of

7 Enjoliveur garniture infrieure pied central/ Lower central pillar fasteners

trim molding 6 13 * dterminer le type pour chaque pice (simple, portefeuille, ), la dimension (cubage, nb dempreintes, )

Passage de sangle C/S et la complexit (nombre de mouvements internes en matrice ou en poinon, pavs fixes, refroidissement,

C/S strap passage tonnage presse, )

Identifier besoin mono ou bi matire (EPDM) : viter transparence des lments techniques 9 * determine the type for each part (simple, portfolio, etc...), the dimension (cubic volume, quantity of

Identify requirement for mono or bi-material (EPDM): avoid transparency of technical elements 3 imprints, etc...) and the complexity (number of internal matrix in punch movements, fixed blocks, cooling,

Gestion de laccostage avec TH, sangle C/S 7

press tonnage, etc...)

Management of the mating with the Passenger Compartment Carpet, C/S strap

Suivre la ralisation des Plan De Forme Style : faisabilit style / technique

ZONE ARRIRE Follow the Shape Drawing style: style/technical feasibility

REAR AREA - participer aux runions de convergence style / technique

8 - take part in the style/technical convergence meetings

8 Garniture avant de passage de roue arrire/ Front Trim of rear - dterminer les directions de dmoulage principales inclus dans les archivages PFI

wheel arch - determine the main mould stripping directions included in the PFI archives

Garnissage entre de porte - peut intgrer un dormant de sige sur vhicule 4 portes - sassurer dobtenir les dpouilles suffisantes pour chaque pice en fonction des grains adopts (choix projet) pour

Door opening trim - can integrate a seat frame on 4 door vehicle sassurer du bon dmoulage Fichier grains

Vrifier rglementation ECE 16 (C/S) - ensure appropriate draft angles for each part according to the grains adopted (project choice) for ensuring correct

1 5

Check ECE regulation 16 (C/S) mould stripping Grains file

Gestion des accostages avec GLC, JEP, TC, Tapis sous Assises / planche talon, C/S 10

- sassurer du bon dmoulage (naturel ou avec mouvement) des zones techniques viter les contre-dpouilles:

Management of the mating with the boot side trim, Door Gasket, TC, Carpet under the Seats / faces inter des portes-agrafe ou clips naturels avec/sans pige retassure ou surpaisseur locale pour nervures

dashboard, C/S

9 - ensure correct mould stripping (natural or with movement) of the technical areas avoid die locks: internal

9 Garniture de longeron arrire/Rear side member trim face of the clip holders or natural clips, with or without shrinkage traps or localized extra thickness for

Garnissage longeron arrire sauf si garnissage longeron entier ribbing

Rear side member trimming unless "complete" side member trim - identifier et faire reprsenter les Plan de Joint validation style imprative

Soumise sollicitation appli dun effort de 80 DAN / 100 x 100 mm = pied utilisateur - identify and provide representation of the Seal Plane style validation is imperative

Subject to stress applying of a force of 80 daN / 100 x 100 mm = user's foot

Vrifier rglementation ECE 16 (C/S)

- assurer le respect du ECE 21 voir guide MPGI (en cours)

- ensure compliance with ECE 21 refer to MPGI guide (in progress)

Check ECE regulation 16 (C/S)

- intgrer les contraintes Choc (suivant type de pice, proximit / environnement) voir DC Projet SPAT

Gestion des accostages avec TH, tapis sous assises / planche talon, C/S

Management of the mating with the Passenger Compartment Carpet, Carpet under the Seats,

- integrate the Impact constraints (according to type of part, proximity/environment) refer to SPAT Project DC

3 9 - anticiper les sens de montage modification des formes ou dcoupage pices diffrents si ncessaire

dashboard, C/S

10 - anticipate the fitting directions if required, change of shapes or different parts cuttings

10 Garniture de custode/ Rear quarter panel trim - suivre larchivage des Plans De Forme incluant les plans de joint et toutes les directions de dmoulage

Garnissage des montants C et/ou D Pice simple ou multi-pices avec ou sans textile - track the Shape Drawing archiving including the mating lines and all the mould stripping instructions

C and/or D pillar trimming Single part or multi-part, with or without textile

Identifier le besoin dun renvoi et passage sangle C/S (rglable en hauteur ou non)

Identify the requirement for a C/S strap passage and relay (whether adjustable in height or not) Suivre ralisation DFinitions Numriques avec FNR : but = crer DFN RO

Identifier le type de dflecteur Airbag Rideau : intgr ou spar Track execution of Digital Definitions with supplier: aim = DFN RO creation

Identify the type of Curtain Airbag deflector: integrated or separated - sassurer que le FNR choisi dispose de la charte dchange CAO PSA (DFN 3D et plans 2D)

Vrifier rglementations ECE 21 (amnagement inter) et ECE 16 (C/S) - ensure that the selected Supplier has PSA's CAD exchange charter (3D and 2D DFN plans)

Check ECE 21 regulations (interior arrangement), ECE 16 (C/S) - participer aux Runions de Zone (RZ)

! Pice sujette habituellement difficults de montage

- participate in Zone meetings (RZ)

Part usually subject to fitting difficulties

- figer les interfaces structure au plus tt Guide Fixations standards + Bibliothque des fixations

Gestion des accostages avec GP, JEP, JEC, vitrage(s)

Management of the mating with the Roof Trimming, Door Gasket, JEC, window(s) - fix the structure interfaces at the earliest Standard Fasteners Guide + Library of fasteners

11 - transmettre tout lenvironnement vhicule + interfaces au FNR envois via BILBAO

11 Garniture support tablette/ Shelf support trim

Appui de tablette - rotation de la tablette - peut tre intgr la garniture de custode

- send the entire vehicle environment + interfaces to the supplier transmissions via BILBAO

- prendre en compte lenvironnement et suivre son volution suivi dans 3DCom et en direct avec les autres

Shelf support - shelf rotation - can be integrated to the rear quarter panel trim mtiers (privilgier la communication)

Identifier sollicitation pice / tablette AR

- take into account the environment and follow its development tracking in 3DCom and directly with the

Identify part / rear shelf stress

other teams (focus on communication)

! Pice sujette habituellement difficults de montage

Part usually subject to fitting difficulties - vrifier sens introduction agrafe dans porte agrafe en fct de :

Gestion des accostages avec (JEP), JEC, GLC, vitrage(s) suivant dcoupage adopt - verify clip insertion direction in clip holder according to:

Management of the mating with the (Door Gasket), JEC, boot side trim, window(s) according to o Isostatisme ex : agrafe bloque dans un sens = centreur ou bien liberts donner lagrafe

the cutting adopted o Isostatism e.g.: clips blocked in one direction = centering device or freeing up the clip

o Montage / dmontage pice Cahier de charges = 5 montages / dmontages

ZONE COFFRE o Part fitting/removal Specification = 5 fittings/removals

TRUNK AREA o Conditionnement / transport pas de perte dagrafe

12

12 Garniture latrale de coffre + composants internes/ Boot side trim o Packaging/Transport no loss of clips

+ internal components - prendre en compte les contraintes montage, ergonomie fiches APOQUA et ERGO doc

Garnissage passage de roue DMOV_MON06_0210, ST projet mtier CMONtage, Exigences gnriques MON

Wheel arch trim - take into account the fitting, ergonomic constraints APOQUA and ERGO sheets doc

Identifier les composants rapports (claireur, lampe, filet, crochet porte sac), faux plancher DMOV_MON06_0210, CMONtage team project ST, MON generic requirement

Identify the added components (lighting, lamp, net, bag-carrying hook), false floor

! Pice sujette habituellement difficults de montage

-

-

identifier les sens de dmoulage secondaires (zones techniques) inclus dans chaque DFN

identify the secondary mould stripping directions (technical areas) included in each DFN

Part usually subject to fitting difficulties

Gestion des accostages avec (JEP), JEC, TC, faux plancher, proximit dossier sige AR - respecter rgles matires plastique ex : ratio paisseur nervure la base : 0,7 x paisseur

Management of the mating with the (Door Gasket), JEC, TC, false floor, rear seat backrest - comply with plastic materials rules e.g.: ribbing thickness at the base: 0.7 x thickness

proximity - prendre en compte la problmatique des bruits parasites contacts mat plastique / structure + compatibilit matires plastique

13 - take into account the issues of interference noises plastic materials / structure contacts + plastic materials

13 Garniture de panneau arrire / Garniture seuil de coffre/Rear compatibility

panel trim / Boot sill trim - prendre en compte les contraintes choc positionnement des fixations, pas djection pice ou morceau

Garnissage Panneau ou Seuil de coffre (prise en compte gche coffre ou volet) - take into account the impact constraints location of fasteners, no ejection of part or piece

Panel or boot sill trimming (taken into account boot or hatch striker) - faire respecter les incontournables du mtier MPGI vrifications auprs du FNR

Soumise sollicitation appli dun effort de 80 DAN / 100 x 100 mm

Subject to stress applying of a force of 80 daN / 100 x 100 mm

- ensure that the MPGI team's indispensables are respected verify with the Supplier

- prendre en compte les demandes ACoustique Vhicule (isolation, absorption, extraction/recyclage dair),

Gestion des accostages avec JEC, GLC, TC, gche volet ou coffre sensibilisation doc IHPC_MPGI07_0281

Management of the mating with JEC, GLC, TC, boot or hatch striker

- take into account the Vehicle Acoustics requirements (insulation, absorption, air extraction/recycling),

sensitization doc IHPC_MPGI07_0281

- prvoir dans moules les zones de marquage logos, dateurs, matire, rfrence, ct, recyclage norme A102260

- make provisions for logo markings, in molds of the marked area logos, date markers, material, reference, side,

recycling A102260 standard

- vrifier les DFNs avant accord de lancement outillage Revue de conception RO

- verify the DFNs before starting the tooling RO Design Review

mise en plan 2D : prparer les officialisations pice

C/S : Ceintures de Scurit DFNs : DFinitions Numrique GLC : Garniture Latrale de Coffre JEP/JEC : Joint dEntre de Porte/Coffre RO : Ralisation Outillage TC : Tapis de Coffre ST : Spcification Technique

C/S: Safety belt DFNs: Digital Definition GLC: Boot Side Trim JEP/JEC: Door gasket RO: Tool Production TC: Boot Carpet ST: Technical Specification

CSTP : Conception Style Technique Prestation FNR : Fournisseur GP : Garnissage Pavillon PdB : Planche de Bord RT : Rfrentiel Technique TH : Tapis Habitacle

CSTP: Technical Style Design Services FNR: Supplier GP: Roof Trimming PdB: Dashboard RT: Technical Reference Material TH: Passenger Compartment Carpet

S-ar putea să vă placă și

- 3 Symbo TechnoDocument3 pagini3 Symbo TechnoCamara AbabacarÎncă nu există evaluări

- Présentation PFE FFDocument40 paginiPrésentation PFE FFWalid SahmoudÎncă nu există evaluări

- EMISYS - Trame Dossier Technique CAHDocument8 paginiEMISYS - Trame Dossier Technique CAHCamal Ahamed (Camal)Încă nu există evaluări

- TP Elaboration Des Gammes Pieces PrismatiquesDocument9 paginiTP Elaboration Des Gammes Pieces PrismatiquesYahia SamahÎncă nu există evaluări

- TP Elaboration Des Gammes Pieces CylindriquesDocument8 paginiTP Elaboration Des Gammes Pieces CylindriquesMakrem CherifÎncă nu există evaluări

- Formation AcoustiqueV4Document158 paginiFormation AcoustiqueV4Manuela VÎncă nu există evaluări

- Pro 2017Document14 paginiPro 2017Crazy ytÎncă nu există evaluări

- Presentation GiatDocument26 paginiPresentation GiatImad AllaliÎncă nu există evaluări

- Module 1 Precontrainte & Post Tension GeneraliteDocument34 paginiModule 1 Precontrainte & Post Tension GeneraliteAfolabi JacobÎncă nu există evaluări

- Devenir-C PDocument9 paginiDevenir-C PFatre 1980Încă nu există evaluări

- CV Marie-Ange LepercqDocument1 paginăCV Marie-Ange LepercqLEPERCQÎncă nu există evaluări

- EMEXDIS - PPT 2109 v.0Document17 paginiEMEXDIS - PPT 2109 v.0SAMBAÎncă nu există evaluări

- Cem 2Document1 paginăCem 2Abderraouf MEDJDOUBÎncă nu există evaluări

- La Programmation Des MOCN - Codes ISO PDFDocument8 paginiLa Programmation Des MOCN - Codes ISO PDFCherche Annonce AnnonceÎncă nu există evaluări

- Vérification Au Cisaillement Par Poinçonnement Selon L'eurocode 2 Dans RFEM - Dlubal SoftwareDocument1 paginăVérification Au Cisaillement Par Poinçonnement Selon L'eurocode 2 Dans RFEM - Dlubal Softwareali bin sefuÎncă nu există evaluări

- Ingénieurie SimultanéeDocument24 paginiIngénieurie SimultanéeFaten SlitiÎncă nu există evaluări

- Présentation PFE CMDocument45 paginiPrésentation PFE CMWakÎncă nu există evaluări

- TFM Marocetude - Com M16 Dossier de fabrication-partie1-FM-TFMDocument69 paginiTFM Marocetude - Com M16 Dossier de fabrication-partie1-FM-TFMPast NdayishimiyeÎncă nu există evaluări

- PACTE - Isolation Thermique Extérieur Par Enduit Sur Polystyrène ExpanséDocument37 paginiPACTE - Isolation Thermique Extérieur Par Enduit Sur Polystyrène ExpanséproutÎncă nu există evaluări

- 4-1 Découverte APIDocument8 pagini4-1 Découverte APIJimmy CastaingÎncă nu există evaluări

- CEN-TS 1992-4-1 - Conception-Calcul Des Éléments de Fixation Pour BétonDocument59 paginiCEN-TS 1992-4-1 - Conception-Calcul Des Éléments de Fixation Pour Bétonmalik atikÎncă nu există evaluări

- Projet Tutoré - Présentation PowerPoint Finale (Récupéré)Document17 paginiProjet Tutoré - Présentation PowerPoint Finale (Récupéré)altti bouayeÎncă nu există evaluări

- Presentation FEDDDocument37 paginiPresentation FEDDBenjamin SchottéÎncă nu există evaluări

- Caplp Ext 2023 GM Opt Prod Epreuve 1Document87 paginiCaplp Ext 2023 GM Opt Prod Epreuve 1Silver679Încă nu există evaluări

- M9 - Conception Et Dessin D'outillages de Production Version 3Document61 paginiM9 - Conception Et Dessin D'outillages de Production Version 3Taha ZianeÎncă nu există evaluări

- SDF 2021Document83 paginiSDF 2021Ayoub HouasliÎncă nu există evaluări

- Livret Metier Site InternetDocument67 paginiLivret Metier Site InternetValGuyotonÎncă nu există evaluări

- Menuiserie Batiment: Programme D'EtudesDocument87 paginiMenuiserie Batiment: Programme D'EtudesHanane EsiÎncă nu există evaluări

- EXP Doc MaintenanceDocument2 paginiEXP Doc MaintenanceAyoub OUBAHAÎncă nu există evaluări

- Reperage IsostatiqueDocument3 paginiReperage Isostatiquehamzabaggar170Încă nu există evaluări

- Support de TP GMAODocument31 paginiSupport de TP GMAOParc Elyes0% (1)

- 1033 AO88 AUX SCM 001 A02 Spécification Système de Détection D'intrusionDocument33 pagini1033 AO88 AUX SCM 001 A02 Spécification Système de Détection D'intrusionGooÎncă nu există evaluări

- Exemple Dossier de Compétence 2020 - V2Document3 paginiExemple Dossier de Compétence 2020 - V2guessousÎncă nu există evaluări

- Guide Immeubles Neufs BDDocument132 paginiGuide Immeubles Neufs BDakebayeriÎncă nu există evaluări

- Ponts Cadres - Manuel de L'utilisateurDocument22 paginiPonts Cadres - Manuel de L'utilisateurific69100% (6)

- GL 4Document36 paginiGL 4ramzi esprimsÎncă nu există evaluări

- Parrainage-Is AF 080902Document40 paginiParrainage-Is AF 080902Hasna FanidiÎncă nu există evaluări

- BACTUa PpsDocument34 paginiBACTUa Ppsanon_928248780Încă nu există evaluări

- Mode de Metre - GEPIDocument11 paginiMode de Metre - GEPILesmary MavoungouÎncă nu există evaluări

- Éléments de Fondation - Manuel de L'utilisateur PDFDocument18 paginiÉléments de Fondation - Manuel de L'utilisateur PDFAbdelilah AdamÎncă nu există evaluări

- Gamme SNA Blocs de Jonction EntrelecDocument156 paginiGamme SNA Blocs de Jonction EntrelecayssaÎncă nu există evaluări

- 0059 Chaudronnier D AtelierDocument9 pagini0059 Chaudronnier D AtelierFranc TsiguiaÎncă nu există evaluări

- Contexte & Environnement Ase: 29/06/2022 H.ARNANASDocument21 paginiContexte & Environnement Ase: 29/06/2022 H.ARNANASAHLAM ETTOUHAMIÎncă nu există evaluări

- Norme Française Homologuée: Septembre 1995Document20 paginiNorme Française Homologuée: Septembre 1995Conseil100% (1)

- Mvrdv-Cuiller-Doe-Fpr-0113-A - Adhesif Plancher CLTDocument9 paginiMvrdv-Cuiller-Doe-Fpr-0113-A - Adhesif Plancher CLTezd94332Încă nu există evaluări

- Fiche D Precisions Des Moyens de Serrage Au CoupleDocument7 paginiFiche D Precisions Des Moyens de Serrage Au CoupleOUSSAMA taibiÎncă nu există evaluări

- Liaison Porte-Pièce/pièce: Nom: Sts 1 CPRP Page 1 / 6Document6 paginiLiaison Porte-Pièce/pièce: Nom: Sts 1 CPRP Page 1 / 6Fares SlimaniÎncă nu există evaluări

- T065B0000210034PPTFDocument24 paginiT065B0000210034PPTFEvariste OuattaraÎncă nu există evaluări

- m4s2s69nt1 T Mainten PreventiveDocument8 paginim4s2s69nt1 T Mainten PreventiveJàMàl MejorÎncă nu există evaluări

- Ofppt: Royaume Du MarocDocument68 paginiOfppt: Royaume Du MarocAlim OsmoÎncă nu există evaluări

- Fiche J Contrôle Du Serrage Des Boulons HRDocument9 paginiFiche J Contrôle Du Serrage Des Boulons HRabdallah ahraracheÎncă nu există evaluări

- GL 2Document36 paginiGL 2Brian TebeckÎncă nu există evaluări

- Prototypage RapideDocument29 paginiPrototypage Rapideamine chabchoubÎncă nu există evaluări

- Fiche Autocontrole Bati ITE Enduit Int2Document4 paginiFiche Autocontrole Bati ITE Enduit Int2Julien RoussotÎncă nu există evaluări

- Power Adja SanogoDocument30 paginiPower Adja SanogoIssouf Ernest Junior CisseÎncă nu există evaluări

- Avis SQ Route 222 PDFDocument1 paginăAvis SQ Route 222 PDFAymen JuhsdiÎncă nu există evaluări

- Formation GSD - Partie 4 - Pièces plastiquesA3D PDFDocument9 paginiFormation GSD - Partie 4 - Pièces plastiquesA3D PDFAymen JuhsdiÎncă nu există evaluări

- Regle Des 3PDocument1 paginăRegle Des 3PAymen JuhsdiÎncă nu există evaluări

- Registre de ClasseDocument9 paginiRegistre de ClasseAymen JuhsdiÎncă nu există evaluări

- (Myriam Orquera) La Cotation Fonctionnelle PDFDocument36 pagini(Myriam Orquera) La Cotation Fonctionnelle PDFAymen JuhsdiÎncă nu există evaluări

- PDFDocument7 paginiPDFAymen JuhsdiÎncă nu există evaluări

- DémissionDocument1 paginăDémissionAymen JuhsdiÎncă nu există evaluări

- 4 Exercices Lecture SpecificationsDocument39 pagini4 Exercices Lecture SpecificationsMadalina Calbureanu100% (1)

- BonjourDocument1 paginăBonjourAymen JuhsdiÎncă nu există evaluări

- TP 1Document1 paginăTP 1djennati100% (1)

- DJE4394Document119 paginiDJE4394danÎncă nu există evaluări

- Année Prépa Electricité, Deuxième PartieDocument221 paginiAnnée Prépa Electricité, Deuxième PartieAbdelkader Faklani DouÎncă nu există evaluări

- 04 JSFT-echangeur-2012 GRESPI Fohanno PDFDocument21 pagini04 JSFT-echangeur-2012 GRESPI Fohanno PDFzermiÎncă nu există evaluări

- GPM Tle C 3e Edition.Document258 paginiGPM Tle C 3e Edition.Pierrot Jules AMOUSSOU100% (2)

- DS SDM S1 2015 CorrectionDocument2 paginiDS SDM S1 2015 CorrectiondsiscnÎncă nu există evaluări

- Api RestDocument8 paginiApi RestfogoÎncă nu există evaluări

- TD Regime de Neutre TTDocument4 paginiTD Regime de Neutre TTOlivier FLOHRÎncă nu există evaluări

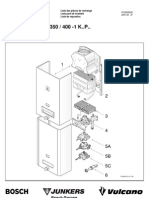

- W - 250 - 275 - 325 - 350 - 400 - 1 K..p..Document28 paginiW - 250 - 275 - 325 - 350 - 400 - 1 K..p..joviadoÎncă nu există evaluări

- GISEMENTDocument4 paginiGISEMENTTouré AbdoulÎncă nu există evaluări

- 3 - Modeles de Markov CachesDocument34 pagini3 - Modeles de Markov CachesWISSALÎncă nu există evaluări

- TF06 P09 MedianDocument4 paginiTF06 P09 MedianAyt Moha BrahimÎncă nu există evaluări

- Didacticiel Papier - Sphinx Iq 2 PDFDocument442 paginiDidacticiel Papier - Sphinx Iq 2 PDFAthenaDona100% (1)

- NF EN 1431 (Mai 2009)Document19 paginiNF EN 1431 (Mai 2009)Fatima BouhajaÎncă nu există evaluări

- FeuilletageDocument25 paginiFeuilletageLē JøkērÎncă nu există evaluări

- Chapitre 1 - Eléments de Physique NucléaireDocument69 paginiChapitre 1 - Eléments de Physique NucléaireMohamed El Hadi Redjaimia100% (1)

- ANNONCES ASSISTANTS MATERNELS-Disponibilités Secteur Lyautey Du 12 Juin 2020Document3 paginiANNONCES ASSISTANTS MATERNELS-Disponibilités Secteur Lyautey Du 12 Juin 2020younes amaraÎncă nu există evaluări

- Geometrie Pour Dao2 PDFDocument161 paginiGeometrie Pour Dao2 PDFlekouf43100% (1)

- CC 1 Analyse Natalia Borbón TorresDocument3 paginiCC 1 Analyse Natalia Borbón TorresNatalia Borbon TorresÎncă nu există evaluări

- Maths X PSI 1998 (Enoncé)Document7 paginiMaths X PSI 1998 (Enoncé)LM --Încă nu există evaluări

- Howto L3 IntervlanroutingDocument7 paginiHowto L3 IntervlanroutingWilford ToussaintÎncă nu există evaluări

- UE Cybersécurité-Initiation Metasploit v0.3Document17 paginiUE Cybersécurité-Initiation Metasploit v0.3didierÎncă nu există evaluări

- TD6 PhysiqueDocument4 paginiTD6 PhysiqueEric DeumoÎncă nu există evaluări

- Cours Lignes de Transmission Séance Adaptation D'impédance 2011 2012Document8 paginiCours Lignes de Transmission Séance Adaptation D'impédance 2011 2012benlamlihÎncă nu există evaluări

- Poly JavaDocument176 paginiPoly JavaLeonzoConstantiniÎncă nu există evaluări

- Unite 71 Manuel OpératoireDocument110 paginiUnite 71 Manuel OpératoireAbdessalem Bougoffa50% (2)

- TP Conduction CompletDocument10 paginiTP Conduction Complethamza layachi75% (4)

- Serco FDocument26 paginiSerco FRV PenrroiÎncă nu există evaluări

- PdM3 Guide Corrige Vrac Repros C4Document2 paginiPdM3 Guide Corrige Vrac Repros C4Eva BteichÎncă nu există evaluări

- Rapport Optimisation Sur MatlabDocument13 paginiRapport Optimisation Sur MatlabLino YETONGNONÎncă nu există evaluări