Documente Academic

Documente Profesional

Documente Cultură

7524 Sigmadur 520 (December 2014) - Unlocked

Încărcat de

Akhtar AnsariTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

7524 Sigmadur 520 (December 2014) - Unlocked

Încărcat de

Akhtar AnsariDrepturi de autor:

Formate disponibile

PRODUCT DATA SHEET December 12, 2014 (Revision of May 01, 2013)

SIGMADUR 520

DESCRIPTION

Two-component, high-build semi-gloss aliphatic acrylic polyurethane finish

PRINCIPAL CHARACTERISTICS

Easy application by roller and airless spray

Unlimited recoatable

Excellent resistance to atmospheric exposure conditions

Good color and gloss retention (aluminum version becomes grey)

Non-chalking, non-yellowing

Cures at temperatures down to -5C (23F)

Tough and abrasion resistant

Resistant to splash of mineral and vegetable oils, paraffins, aliphatic petroleum products and mild chemicals

Can be recoated even after long atmospheric exposure

COLOR AND GLOSS LEVEL

Full color range and aluminum as RAL 9006 avaiable

Semi-gloss

Ref. 7524 Page 1/6

PRODUCT DATA SHEET December 12, 2014 (Revision of May 01, 2013)

SIGMADUR 520

BASIC DATA AT 20C (68F)

Data for mixed product

Number of components Two

Mass density White: 1.4 kg/l (11.7 lb/US gal)

Aluminum: 1.1 kg/l (9.2 lb/US gal)

Volume solids White: 58 2%

Aluminum: 48 2%

VOC (Supplied) Directive 1999/13/EC, SED: max. 287 g/kg (white)

Directive 1999/13/EC, SED: max. 377 g/kg (aluminum)

max. 383.0 g/l (approx. 3.2 lb/gal) (white)

max. 405.0 g/l (approx. 3.4 lb/gal) (aluminum)

Recommended dry film thickness 50 - 75 m (2.0 - 3.0 mils) depending on system

Theoretical spreading rate White: 11.6 m/l for 50 m (465 ft/US gal for 2.0 mils)

Aluminum: 9.6 m/l for 50 m (385 ft/US gal for 2.0 mils)

Dry to touch 1 hour

Overcoating Interval Minimum: 6 hours

Maximum: Unlimited

Full cure after 4 days

Shelf life Base: at least 36 months when stored cool and dry

Hardener: at least 24 months when stored cool and dry

Notes:

- See ADDITIONAL DATA Spreading rate and film thickness

- See ADDITIONAL DATA Overcoating intervals

- See ADDITIONAL DATA Curing time

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

Substrate conditions

Previous coat (epoxy or polyurethane) must be dry and free from any contamination

Surface of previous coat should be sufficiently roughened if necessary

Substrate temperature and application conditions

Substrate temperature during application and curing down to -5C (23F) is acceptable; provided the substrate is free from

ice and dry

Substrate temperature during application and curing should be at least 3C (5F) above dew point

Relative humidity during application and curing should not exceed 85%

Premature exposure to early condensation and rain my cause color and gloss change

INSTRUCTIONS FOR USE

Ref. 7524 Page 2/6

PRODUCT DATA SHEET December 12, 2014 (Revision of May 01, 2013)

SIGMADUR 520

Mixing ratio by volume: base to hardener 88:12

The temperature of the mixed base and hardener should be above 10C (50F), otherwise extra thinner may be required to

obtain application viscosity

Adding too much thinner results in reduced sag resistance

Thinner should be added after mixing the components

Aluminum version has lower gloss than the standard version and the color could be different by application method

Induction time

None

Pot life

5 hours at 20C (68F)

Note: See ADDITIONAL DATA Pot life

Air spray

Recommended thinner

THINNER 21-06

Volume of thinner

5 - 10%, depending on required thickness and application conditions

Nozzle orifice

1.0 - 1.5 mm (approx. 0.040 - 0.060 in)

Nozzle pressure

0.3 - 0.4 MPa (approx. 3 - 4 bar; 44 - 58 p.s.i.)

Airless spray

Recommended thinner

THINNER 21-06

Volume of thinner

0 - 5%, depending on required thickness and application conditions

Nozzle orifice

Approx. 0.46 mm (0.018 in)

Nozzle pressure

15.0 MPa (approx. 150 bar; 2176 p.s.i.)

Ref. 7524 Page 3/6

PRODUCT DATA SHEET December 12, 2014 (Revision of May 01, 2013)

SIGMADUR 520

Brush/roller

Recommended thinner

THINNER 21-06

Volume of thinner

0 5%

Cleaning solvent

THINNER 90-53

ADDITIONAL DATA

Spreading rate and film thickness White

DFT Theoretical spreading rate

50 m (2.0 mils) 11.6 m/l (465 ft/US gal)

75 m (3.0 mils) 7.7 m/l (310 ft/US gal)

Spreading rate and film thickness Aluminum

DFT Theoretical spreading rate

50 m (2.0 mils) 9.6 m/l (385 ft/US gal)

75 m (3.0 mils) 6.4 m/l (257 ft/US gal)

Overcoating interval for DFT up to 75 m (3.0 mils)

Overcoating with... Interval -5C (23F) 0C (32F) 10C (50F) 20C (68F) 30C (86F) 40C (104F)

itself Minimum 24 hours 16 hours 8 hours 6 hours 5 hours 3 hours

Maximum Unlimited Unlimited Unlimited Unlimited Unlimited Unlimited

Note: Surface should be dry and free from any contamination

Ref. 7524 Page 4/6

PRODUCT DATA SHEET December 12, 2014 (Revision of May 01, 2013)

SIGMADUR 520

Curing time for DFT up to 75 m (3.0 mils)

Substrate temperature Dry to handle Full cure

-5C (23F) 24 hours 15 days

0C (32F) 16 hours 11 days

10C (50F) 8 hours 6 days

20C (68F) 6 hours 4 days

30C (86F) 5 hours 3 days

40C (104F) 3 hours 48 hours

Notes:

- Adequate ventilation must be maintained during application and curing (please refer to INFORMATION SHEETS 1433 and 1434)

- Premature exposure to early condensation and rain may cause color and gloss change

Pot life (at application viscosity)

Mixed product temperature Pot life

10C (50F) 7 hours

20C (68F) 5 hours

30C (86F) 3 hours

40C (104F) 2 hours

SAFETY PRECAUTIONS

For paint and recommended thinners see INFORMATION SHEETS 1430, 1431 and relevant Material Safety Data Sheets

This is a solvent-borne paint and care should be taken to avoid inhalation of spray mist or vapor, as well as contact between

the wet paint and exposed skin or eyes

Contains a toxic polyisocyanate curing agent

Avoid at all times inhalation of aerosol spray mist

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

Ref. 7524 Page 5/6

PRODUCT DATA SHEET December 12, 2014 (Revision of May 01, 2013)

SIGMADUR 520

REFERENCES

CONVERSION TABLES INFORMATION SHEET 1410

EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

SAFETY INDICATIONS INFORMATION SHEET 1430

SAFETY IN CONFINED SPACES AND HEALTH SAFETY, EXPLOSION HAZARD INFORMATION SHEET 1431

TOXIC HAZARD

SAFE WORKING IN CONFINED SPACES INFORMATION SHEET 1433

DIRECTIVES FOR VENTILATION PRACTICE INFORMATION SHEET 1434

RELATIVE HUMIDITY SUBSTRATE TEMPERATURE AIR TEMPERATURE INFORMATION SHEET 1650

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPGs specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any

third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER STATUTE OR ARISING OTHERWISE IN

LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE, ARE DISCLAIMED BY PPG. Any claim under this

warranty must be made by Buyer to PPG in writing within five (5) days of Buyers discovery of the claimed defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the

delivery of the product to the Buyer, whichever is earlier. Buyers failure to notify PPG of such non-conformance as required herein shall bar Buyer from recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to

be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or suggestions relating to the use of the PPG product, whether in

technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPGs knowledge, is reliable. The product and related information is designed for users having the requisite knowledge

and industrial skills in the industry and it is the end-users responsibility to determine the suitability of the product for its own particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no

control over either the quality or condition of the substrate, or the many factors affecting the use and application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such

use or the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This

sheet supersedes all previous versions and it is the Buyers responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at

www.ppgpmc.com. The English text of this sheet shall prevail over any translation thereof.

The PPG Logo, Bringing innovation to the surface., and all other trademarks herein are property of the PPG group of companies.

Ref. 7524 Page 6/6

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Astm A513 PDFDocument20 paginiAstm A513 PDFpradelles89% (9)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Intel Software License AgreementDocument7 paginiIntel Software License AgreementGhaderal MJÎncă nu există evaluări

- HDPE Piping SolutionsDocument107 paginiHDPE Piping SolutionsJEAN CARLOS SOTO BARRERAÎncă nu există evaluări

- MFJO770 / MVCP00096 : VAPOUR RECOVERY UNITY : ACTIVITY SCHEDULEDocument1 paginăMFJO770 / MVCP00096 : VAPOUR RECOVERY UNITY : ACTIVITY SCHEDULEAkhtar AnsariÎncă nu există evaluări

- Think and Grow Rich Made EasyDocument116 paginiThink and Grow Rich Made EasyAkhtar AnsariÎncă nu există evaluări

- Parts list for pressure vessel assemblyDocument8 paginiParts list for pressure vessel assemblyAkhtar AnsariÎncă nu există evaluări

- KPIs FOR MEASURING THE SUCCESS OF SHUTDOWN PDFDocument67 paginiKPIs FOR MEASURING THE SUCCESS OF SHUTDOWN PDFMohamed F Morsy60% (5)

- IEEE Guide For The Installation of Vertical Generators and Generator/Motors For Hydroelectric ApplicationsDocument13 paginiIEEE Guide For The Installation of Vertical Generators and Generator/Motors For Hydroelectric ApplicationsThor FunNÎncă nu există evaluări

- 20741B ENU TrainerHandbookDocument568 pagini20741B ENU TrainerHandbookDavid EscalierÎncă nu există evaluări

- Inspection Call Request Format - 47758 - 004 - Dated 04.08.2022Document1 paginăInspection Call Request Format - 47758 - 004 - Dated 04.08.2022Akhtar AnsariÎncă nu există evaluări

- Akhtar Ansari - TPI - FRT PDFDocument5 paginiAkhtar Ansari - TPI - FRT PDFAkhtar AnsariÎncă nu există evaluări

- Inspection Call Request Format - 441715 - 003 - Dated 04.08.2022Document1 paginăInspection Call Request Format - 441715 - 003 - Dated 04.08.2022Akhtar AnsariÎncă nu există evaluări

- MFJO709-820 Project Status UpdateDocument27 paginiMFJO709-820 Project Status UpdateAkhtar AnsariÎncă nu există evaluări

- Akhtar Ansari - TPI - FRT PDFDocument5 paginiAkhtar Ansari - TPI - FRT PDFAkhtar AnsariÎncă nu există evaluări

- Photo Annexure To IR No.189123-231221-01Document3 paginiPhoto Annexure To IR No.189123-231221-01Akhtar AnsariÎncă nu există evaluări

- Inspection Call Request Format - 46967 - 018 - Dated 04.08.2022Document1 paginăInspection Call Request Format - 46967 - 018 - Dated 04.08.2022Akhtar AnsariÎncă nu există evaluări

- Akhtar Ansari - TPI - FRT PDFDocument5 paginiAkhtar Ansari - TPI - FRT PDFAkhtar AnsariÎncă nu există evaluări

- ST 52 DIN 2391 Part 2 (Germany) : StandardsDocument1 paginăST 52 DIN 2391 Part 2 (Germany) : StandardsKandregula Mohan BabuÎncă nu există evaluări

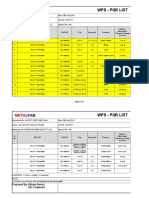

- Wps - PQR List: Page 1 of 4Document4 paginiWps - PQR List: Page 1 of 4Akhtar AnsariÎncă nu există evaluări

- EXCEL Formulas BibleDocument42 paginiEXCEL Formulas BibleParkash Chander RughaniÎncă nu există evaluări

- Akhtar Ansari - TPI - FRT PDFDocument5 paginiAkhtar Ansari - TPI - FRT PDFAkhtar AnsariÎncă nu există evaluări

- Akhtar Ansari - TPI - FRT PDFDocument5 paginiAkhtar Ansari - TPI - FRT PDFAkhtar AnsariÎncă nu există evaluări

- Akhtar Ansari - TPI - FRT PDFDocument5 paginiAkhtar Ansari - TPI - FRT PDFAkhtar AnsariÎncă nu există evaluări

- Akhtar Ansari - TPI - FRT PDFDocument5 paginiAkhtar Ansari - TPI - FRT PDFAkhtar AnsariÎncă nu există evaluări

- MFJO723 - As Built DrawingDocument9 paginiMFJO723 - As Built DrawingAkhtar AnsariÎncă nu există evaluări

- Attendance Sheet - 5S Housekeeping TrainingDocument1 paginăAttendance Sheet - 5S Housekeeping TrainingAkhtar Ansari100% (1)

- 5S Housekeeping Training Sign-In Sheet July 2018Document1 pagină5S Housekeeping Training Sign-In Sheet July 2018Akhtar AnsariÎncă nu există evaluări

- Rir 0002Document1 paginăRir 0002Akhtar AnsariÎncă nu există evaluări

- MFJO738A - RT Film - Pipe SpoolDocument2 paginiMFJO738A - RT Film - Pipe SpoolAkhtar AnsariÎncă nu există evaluări

- Memo StyleDocument5 paginiMemo StyleAkhtar AnsariÎncă nu există evaluări

- MFJO738A - Prssure Test CertificateDocument10 paginiMFJO738A - Prssure Test CertificateAkhtar AnsariÎncă nu există evaluări

- Memo StyleDocument5 paginiMemo StyleAkhtar AnsariÎncă nu există evaluări

- Load Test Report For Spreader Bar A & BDocument2 paginiLoad Test Report For Spreader Bar A & BAkhtar AnsariÎncă nu există evaluări

- MetalFab Middle East FZ LLC NDE Request for Tube to Tubesheet Welding Procedure QualificationDocument1 paginăMetalFab Middle East FZ LLC NDE Request for Tube to Tubesheet Welding Procedure QualificationAkhtar AnsariÎncă nu există evaluări

- 16-Gauge Foot-Operated Corner Notcher: Operating Instructions and Parts ManualDocument12 pagini16-Gauge Foot-Operated Corner Notcher: Operating Instructions and Parts ManualchellaliÎncă nu există evaluări

- ABB Zenon Template v.8.10 - User Manual ABB TemplateDocument48 paginiABB Zenon Template v.8.10 - User Manual ABB TemplateGilmarÎncă nu există evaluări

- A 0008Document100 paginiA 0008Lorna CortesÎncă nu există evaluări

- 4512-4XX Lexmark E350d, E352dn Service ManualDocument141 pagini4512-4XX Lexmark E350d, E352dn Service ManualKinder BlackÎncă nu există evaluări

- Jointing KabelDocument2 paginiJointing KabelPeri Edison GurusingaÎncă nu există evaluări

- BWP Catalogo de Partes FrenosDocument508 paginiBWP Catalogo de Partes FrenosLuis HernándezÎncă nu există evaluări

- CopyrightsDocument31 paginiCopyrightsxomilaaÎncă nu există evaluări

- IBX QST Tool User GuideDocument63 paginiIBX QST Tool User GuideRelu GarbanÎncă nu există evaluări

- XIAMETER™ MEM-0024 Emulsion: Features & BenefitsDocument2 paginiXIAMETER™ MEM-0024 Emulsion: Features & BenefitsLaban KantorÎncă nu există evaluări

- Remote Mounting Temperature Switch and Control: 12 SeriesDocument8 paginiRemote Mounting Temperature Switch and Control: 12 SeriesYsidro MundarainÎncă nu există evaluări

- Instruction Manual: Weather & Environmental MetersDocument12 paginiInstruction Manual: Weather & Environmental MetersRicardo ChavezÎncă nu există evaluări

- Airfiber AF-5G34-S45 QSGDocument24 paginiAirfiber AF-5G34-S45 QSGMariano_PanicciaÎncă nu există evaluări

- CLI EnterasysDocument396 paginiCLI EnterasysAlexandre SantanaÎncă nu există evaluări

- Material CasesDocument15 paginiMaterial Casesvinay sharmaÎncă nu există evaluări

- Dow Corning: 200 FluidDocument4 paginiDow Corning: 200 FluidRafael Saldanha LopesÎncă nu există evaluări

- Rose Windows Release Notes v7.0.0.4 IFIX03Document21 paginiRose Windows Release Notes v7.0.0.4 IFIX03Azazel SempaiÎncă nu există evaluări

- Improvement Request Form AdaptiveBMSDocument2 paginiImprovement Request Form AdaptiveBMSPablo AntezanaÎncă nu există evaluări

- ComputingNow1984 11Document120 paginiComputingNow1984 11Ted ThompsonÎncă nu există evaluări

- Indiage NeutraFlex LiteratureDocument2 paginiIndiage NeutraFlex LiteratureVinod ShelkeÎncă nu există evaluări

- Causes - Troubleshooting Open Bypass Fault F13, F14, F15 On SMC ...Document3 paginiCauses - Troubleshooting Open Bypass Fault F13, F14, F15 On SMC ...DanLorenaÎncă nu există evaluări

- Power Wave I400: MIG, Pulsed-MIG, Flux-Cored, Metal-Cored, TIG (Lift Start Only)Document6 paginiPower Wave I400: MIG, Pulsed-MIG, Flux-Cored, Metal-Cored, TIG (Lift Start Only)nobamoÎncă nu există evaluări

- Third Party NoticesDocument93 paginiThird Party NoticesTamara SilvaÎncă nu există evaluări

- Kov'R-Kote: Premium, Nonmetallic Thread Compound For Use On Drill Collars, Drill Pipe, Tubing, & CasingDocument1 paginăKov'R-Kote: Premium, Nonmetallic Thread Compound For Use On Drill Collars, Drill Pipe, Tubing, & CasingJeremias UtreraÎncă nu există evaluări

- 2012 Jay Feather Ultra Lite Owners ManualDocument101 pagini2012 Jay Feather Ultra Lite Owners ManualRachel Naiman WilsonÎncă nu există evaluări

- 57sales Outline eDocument34 pagini57sales Outline eblade1111Încă nu există evaluări

- Manual TV TCL UsaDocument17 paginiManual TV TCL UsaJose GutierrezÎncă nu există evaluări