Documente Academic

Documente Profesional

Documente Cultură

COMPATIBILITY OF KNOCKOUTS AND FITTINGS

Încărcat de

TinkyTonk86Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

COMPATIBILITY OF KNOCKOUTS AND FITTINGS

Încărcat de

TinkyTonk86Drepturi de autor:

Formate disponibile

ENGINEERING DEPARTMENT

BULLETIN

No. 71

June, 1965

Revised September 6, 1979

Reaffirmed April 1999

KNOCKOUT DIAMETERS AND FITTING DIMENSIONS

TO ASSURE MECHANICAL AND ELECTRICAL CONTINUITY

INTRODUCTION:

The Joint Sections Committee on Knockout Diameters and Fitting Dimensions reviewed the existing

industry practices and standards for knockout diameters and conduit fittings, and developed a table of

dimensional relationships which assure no opening in the enclosure at the conduit entrance under

normal conditions. Any situation which might result in an opening at the conduit entrance when a

maximum size knockout and a minimum size locknut or bushing are combined with maximum

off-centering of the conduit may be corrected by a minor readjustment of the conduit.

The Committee recommends that future designs of enclosures which include knockouts be tooled to

the nominal knockout diameters specified to allow a greater overlap for bushings or locknuts over the

enclosure opening, particularly if the conduit cannot be kept centered in the opening.

The Committee also reviewed the dimensions of existing conduit fittings and current installation

practices, and concluded that there is no reasonable and practical way to control the maximum

penetration of fittings or conduit and bushings into an enclosure when more than one conduit enters

the enclosure. The solution to this problem lies with good work practices; what is reasonable

penetration in one enclosure may be unacceptable in another.

GUIDELINES:

The following dimensions have been developed by the Joint Sections Committee on Knockout

Diameters and Fitting Dimensions and approved by the Codes and Standards Committee as a proposal

to be considered by NEMA Sections for inclusion in existing standards publications.

National Electrical 1

Manufacturers Association

1300 North 17th Street, Suite 1847

Rosslyn, VA 22209

(703) 841-3200

FAX (703) 841-5900

Distribution List:

Standards and Conformity Assessment Policy Committee

Codes and Standards Committee

Government Affairs Policy Committee

NEMA Executive Staff

National Electrical 2

Manufacturers Association

1300 North 17th Street, Suite 1847

Rosslyn, VA 22209

(703) 841-3200

FAX (703) 841-5900

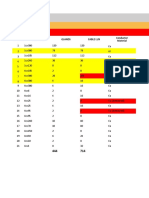

Table 71-1

COMPATIBILITY OF KNOCKOUT DIMENSIONS WITH LOCKNUTS, BUSHINGS,

AND METALLIC CONDUIT (IMC OR RIGID) TO ASSURE COORDINATIONA) b)

Nonmetallic Bushing With

Metallic Bushing With or Locknut on Inside of

Major Diameter of Without Insulated Throat Enclosure

External Thread Knockout Diameter e) f) (See Fig. 71-1) (See Fig. 71-2)

Overlap over Covering Overlap over

Trade Size of Diameter at Nominal Diameter Nominal

Conduit, Flange, Knockout, of Locknut, Knockout,

Nom. Min.c) Max.d) Min. Nom. Max. Min. Min. f) Min. Min. f)

Col. I Col. 2 Col. 3 Col. 4 Col. 5 Col. 6 Col. 7 Col. 8 Col. 9 Col. 10

Dim. P Dim. K Dim. B Dim. X Dim. B Dim. X

1/2 0.815 0.855 0.859 0.875 0.906 1.00 0.033 0.937 0.001

3/4 1.029 1.066 1.094 1.109 1.141 1.23 0.021 1.189 0.000

1 1.290 1.331 1.359 1.375 1.406 1.54 0.040 1.485 0.013

1-1/4 1.638 1.676 1.719 1.734 1.766 1.92 0.045 1.859 0.015

1-112 1.878 1.916 1.958 1.984 2.016 2.18 0.045 2.109 0.010

2 2.352 2.399 2.433 2.469 2.500 2.68 0.047 2.635 0.025

2-1/2 2.843 2.904 2.938 2.969 3.000 3.20 0.053 3.156 0.030

3 3.469 3.535 3.563 3.594 3.625 3.83 0.056 3.812 0.046

3-1/2 3.970 4.040 4.063 4.125 4.156 4.40 0.060 4.343 0.032

4 4.466 4.545 4.563 4.641 4.672 4.94 0.062 4.890 0.037

4-1/2 4.967 5.050 5.063 5.109 5.166 5.51 0.130 5.453 0.101

5 5.530 5.619 5.625 5.719 5.750 6.05 0.071 6.062 0.077

6 6.587 6.691 6.700 6.813 6.844 7.20 0.081 7.110 0.035

a) Dimensional changes in Cols. 2 (Dim. P), 5 (Dim. K), 7 (Dim. B), and/or 9 (Dim. B) may cause an incompatible assembly.

b) These dimensions are for knockout diameters for single or concentric types only and exclude any projection of breakout ears or tabs.

c) This dimension is the nominal major diameter of the thread at El (Ref: Fig. 4-7 of NEMA Standards Publication No. FB 1-1977) or the nominal diameter

or the intermediate metal conduit (Ref: UL 6-1976, ANSI/UL 514-1978, UL 1242-Jan. 1977 draft), whichever is less.

d) The maximum diameter of rigid conduit (Ref: ANSI C80.1-1977).

e) Dimensions for trade sizes of 1/2 through 1-1/4 are from Table 20.2 of ANSI/UL 514-1978. Minimum dimension for larger sizes is necessary to clear the

maximum diameter of the external thread (i.e., Col. 4 is greater than Col. 3).

f) The stated values are calculated: the minimum overlap (Dim. X) equals the minimum diameter (at flange or outer diameter of locknut) (Dim. B), minus

the minimum major diameter (Dim. P), divided by 2, minus the conduit clearance (Dim. C); where Dim. C equals the nominal knockout diameter (Dim. P).

The relationship is given by:

B-P

X= - (K—P)

2

(Refer to Fig. 71-3)

National Electrical 5

Manufacturers Association

1300 North 17th Street, Suite 1847

Rosslyn, VA 22209

(703) 841-3200

FAX (703) 841-5900

S-ar putea să vă placă și

- MACK Truck Electrical Wiring and Connections Manual CHU, CXU, GU, TD, MRU, LR SeriesDocument94 paginiMACK Truck Electrical Wiring and Connections Manual CHU, CXU, GU, TD, MRU, LR SeriesAlex Renne Chambi100% (9)

- AmpacityDocument74 paginiAmpacityMoavviz Suhail100% (1)

- Sample Load ComputationDocument12 paginiSample Load ComputationEric MendozaÎncă nu există evaluări

- Single Core & Multicore Flexible CablesDocument12 paginiSingle Core & Multicore Flexible Cablesdh24992499Încă nu există evaluări

- U00034-PL-MTO-0001 - MTO For Export PipelinesDocument7 paginiU00034-PL-MTO-0001 - MTO For Export PipelinesThiên KhánhÎncă nu există evaluări

- RESR001Document34 paginiRESR001ermusatÎncă nu există evaluări

- Supply & Installation of The Security Services For The Lta Karavi Weighbridge Station at Karavi, Ba, Fiji IslandsDocument32 paginiSupply & Installation of The Security Services For The Lta Karavi Weighbridge Station at Karavi, Ba, Fiji IslandsThaungMyintÎncă nu există evaluări

- Conductor Impedance Data (Cable Impedance)Document2 paginiConductor Impedance Data (Cable Impedance)NOELGREGORIO100% (2)

- BOQ Format - Electrical PDFDocument7 paginiBOQ Format - Electrical PDFKurama Basket100% (1)

- Brittle Fracture in Steel StructuresDe la EverandBrittle Fracture in Steel StructuresG.M. BoydÎncă nu există evaluări

- Weight Factor Plan for Piping ProjectDocument4 paginiWeight Factor Plan for Piping ProjectscottigiancarloÎncă nu există evaluări

- Timber Truss Design: ProjectDocument8 paginiTimber Truss Design: ProjectEvello MercanoÎncă nu există evaluări

- A Comparative Study of Live Loads For A Bridge Deck With Irc and Aashto Codes-Ijaerdv05i0290468 PDFDocument6 paginiA Comparative Study of Live Loads For A Bridge Deck With Irc and Aashto Codes-Ijaerdv05i0290468 PDFJuan Cantillano Tejada IIIÎncă nu există evaluări

- Catalog LadderDocument25 paginiCatalog Ladderjhherb31Încă nu există evaluări

- SHS11 - Electrical Installation Maintenance NCII - Q1 - Mod1 - Prepare Electrical and Hydraulic Tool - Version3 PDFDocument73 paginiSHS11 - Electrical Installation Maintenance NCII - Q1 - Mod1 - Prepare Electrical and Hydraulic Tool - Version3 PDFdomeld50% (2)

- National Electrical Code 2002 - Tabla 310.60 - PDFDocument11 paginiNational Electrical Code 2002 - Tabla 310.60 - PDFkabirseba100% (1)

- Strongwell Gridform Design GuideDocument352 paginiStrongwell Gridform Design GuideBintee PanchalÎncă nu există evaluări

- Flare CalculationDocument22 paginiFlare CalculationHomer SilvaÎncă nu există evaluări

- Building Utilities 2: Casulla, Cristine T. Bs in Architecture 3 University of LuzonDocument20 paginiBuilding Utilities 2: Casulla, Cristine T. Bs in Architecture 3 University of LuzonEreca NavarroÎncă nu există evaluări

- 2 SmaDocument38 pagini2 SmaKeima Junichirou katsuragiÎncă nu există evaluări

- Poles: Overhead Electric Distribution StandardsDocument16 paginiPoles: Overhead Electric Distribution StandardsBaris AybarsÎncă nu există evaluări

- CRR Corrosion Resistance Ratio ValuesDocument1 paginăCRR Corrosion Resistance Ratio ValuesabdulafoajjawiÎncă nu există evaluări

- Camperfiladas Asme 16 5Document8 paginiCamperfiladas Asme 16 5klara23Încă nu există evaluări

- Instrumentation Cable BSDocument42 paginiInstrumentation Cable BSShivaniÎncă nu există evaluări

- asset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document42 paginiasset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Axel DominiqueÎncă nu există evaluări

- Asset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Document26 paginiAsset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2salehmashrur 98Încă nu există evaluări

- Grinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataDocument4 paginiGrinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataСергей КолесниковÎncă nu există evaluări

- Overhead Electric Distribution StandardsDocument16 paginiOverhead Electric Distribution StandardsRet GenandoyÎncă nu există evaluări

- Z Purlin Spec SheetDocument2 paginiZ Purlin Spec SheetMeeÎncă nu există evaluări

- Design 1 Calculations: CAEE PDFDocument9 paginiDesign 1 Calculations: CAEE PDFazwanÎncă nu există evaluări

- 1Document71 pagini1miranda dajciÎncă nu există evaluări

- RC Design U 2017 v12.8Document71 paginiRC Design U 2017 v12.8mahmoodshowkiÎncă nu există evaluări

- (Fa-) Ttys, Ttycs, Ttycys (Fa-) Ttpys, Ttpycs, TtpycysDocument3 pagini(Fa-) Ttys, Ttycs, Ttycys (Fa-) Ttpys, Ttpycs, Ttpycystwo travellerÎncă nu există evaluări

- Coiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingDocument16 paginiCoiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingNardo AvalosÎncă nu există evaluări

- Technical Bulletin For Kwik BoltDocument3 paginiTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalÎncă nu există evaluări

- Technical Bulletin For Kwik BoltDocument3 paginiTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalÎncă nu există evaluări

- Grinnell Mechanical Products Flexible Coupling Technical Data General DescriptionDocument4 paginiGrinnell Mechanical Products Flexible Coupling Technical Data General DescriptionСергей КолесниковÎncă nu există evaluări

- Specification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byDocument13 paginiSpecification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreÎncă nu există evaluări

- RC Design U 2017 v12.4Document71 paginiRC Design U 2017 v12.4Ahmed EwisÎncă nu există evaluări

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 paginiStandard Pipe Schedule 40 ASTM A 53 Grades A and BAngel PintoÎncă nu există evaluări

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 paginiStandard Pipe Schedule 40 ASTM A 53 Grades A and Btarek eidÎncă nu există evaluări

- Power Stream Couplings-Specn SheetsDocument6 paginiPower Stream Couplings-Specn SheetsAmol PatkiÎncă nu există evaluări

- Ki NG Do M o F Thai L And: EDI CT OF GovernmentDocument14 paginiKi NG Do M o F Thai L And: EDI CT OF Government翁偉晟Încă nu există evaluări

- Curva Conduit Rgs X 90 Deg Ul UniverDocument12 paginiCurva Conduit Rgs X 90 Deg Ul UniveraasfaskjlÎncă nu există evaluări

- Universidad Nacional de Piura: "Año Del Diálogo y La Reconciliación Nacional"Document5 paginiUniversidad Nacional de Piura: "Año Del Diálogo y La Reconciliación Nacional"Vladimir Sebastián Changanaqué RamosÎncă nu există evaluări

- 20a Torque CalculationDocument11 pagini20a Torque CalculationRiyan EsapermanaÎncă nu există evaluări

- 20 EMT and Conduit Submittal SheetDocument2 pagini20 EMT and Conduit Submittal SheetAhmed mahmoudÎncă nu există evaluări

- Steel Wires For Prestressed Concrete - Catalogue PDFDocument8 paginiSteel Wires For Prestressed Concrete - Catalogue PDFDian Jaka PraharaÎncă nu există evaluări

- Piping Class Spec. - 1c9pe (Lurgi)Document8 paginiPiping Class Spec. - 1c9pe (Lurgi)otezgidenÎncă nu există evaluări

- SR 4Document12 paginiSR 4Parker333Încă nu există evaluări

- Concrete Fiberglass Rebar GuideDocument5 paginiConcrete Fiberglass Rebar GuideSubash Bastola100% (1)

- Grinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataDocument4 paginiGrinnell Mechanical Products Figure 909 Plain End Coupling For Steel Pipe - Patented & Patents Pending General Description Technical DataСергей КолесниковÎncă nu există evaluări

- Column With Uniaxial MomentDocument37 paginiColumn With Uniaxial MomentRONALD AYALA HUARACHIÎncă nu există evaluări

- NEPRO Conduit Pvc1Document16 paginiNEPRO Conduit Pvc1chaouch.najehÎncă nu există evaluări

- Hilti Anchor Development HIT RE 500 SDDocument3 paginiHilti Anchor Development HIT RE 500 SDKen SuÎncă nu există evaluări

- 17E Back LEd driver specificationsDocument1 pagină17E Back LEd driver specificationsguptajpcfÎncă nu există evaluări

- Astm B8 11Document4 paginiAstm B8 11Raul EirisÎncă nu există evaluări

- Victaulic OGS-200 Grooved End Fittings: 1.0 Product DescriptionDocument13 paginiVictaulic OGS-200 Grooved End Fittings: 1.0 Product DescriptionCinthya Yesenia Cruz MedinaÎncă nu există evaluări

- Catalogue Wire StrandDocument18 paginiCatalogue Wire StrandbronsenwijayaÎncă nu există evaluări

- Taco Brazed Plate HX Install ManualDocument11 paginiTaco Brazed Plate HX Install ManualTEMPÎncă nu există evaluări

- SprinklerBrochures Schedule10 40Document4 paginiSprinklerBrochures Schedule10 40Keshia Murillo PinnockÎncă nu există evaluări

- Driveline Components Catalog Center Yokes, Tube Yokes and Ball Stud Tube YokesDocument16 paginiDriveline Components Catalog Center Yokes, Tube Yokes and Ball Stud Tube YokesPrasadÎncă nu există evaluări

- C2™ Liner Setting Sleeve With Tieback ExtensionDocument5 paginiC2™ Liner Setting Sleeve With Tieback Extensionjosephbenetton100% (1)

- Dynabolt® Sleeve Anchors: Technical DataDocument1 paginăDynabolt® Sleeve Anchors: Technical DataCoco Aryan TundyÎncă nu există evaluări

- CABLE GLANDS HAZARDOUS AREA FLAMEPROOF EXD INCREASED SAFETY EXEDocument1 paginăCABLE GLANDS HAZARDOUS AREA FLAMEPROOF EXD INCREASED SAFETY EXEschmal1975Încă nu există evaluări

- RC Design U 2017 v13.2Document74 paginiRC Design U 2017 v13.2MazenMowafyÎncă nu există evaluări

- Bolt Capacities: Non-Preloaded Ordinary BoltsDocument1 paginăBolt Capacities: Non-Preloaded Ordinary BoltsSelvasathaÎncă nu există evaluări

- Printed in GermanyDocument8 paginiPrinted in Germanyengine wangÎncă nu există evaluări

- Computed Electron Micrographs And Defect IdentificationDe la EverandComputed Electron Micrographs And Defect IdentificationÎncă nu există evaluări

- Communication System Materials Supply Quotation SummaryDocument12 paginiCommunication System Materials Supply Quotation SummaryDaniel Ramos ZuñigaÎncă nu există evaluări

- Modify Electrical Circuits OfficeDocument2 paginiModify Electrical Circuits OfficeAbu NijamÎncă nu există evaluări

- SP-1099 Electrical Installation Practice ERD-63-01Document43 paginiSP-1099 Electrical Installation Practice ERD-63-01arjunprasannan7Încă nu există evaluări

- Optical Fibre CatalogueDocument52 paginiOptical Fibre CatalogueHudionoHoodÎncă nu există evaluări

- Gym Area Boq For Nri Club HouseDocument5 paginiGym Area Boq For Nri Club HouseRamesh Arjun TÎncă nu există evaluări

- Proximity switch literature for DNFT-PRX modelDocument1 paginăProximity switch literature for DNFT-PRX modelSamir ELÎncă nu există evaluări

- MK Electric Cable Tray Brochure (Middle East) PDFDocument150 paginiMK Electric Cable Tray Brochure (Middle East) PDFAnonymous tW1zTL2ltÎncă nu există evaluări

- Electrical Riser Diagram: EXISTING Electric Floor PLAN 1 E-1 SCALE: 3/16" 1'-0"Document1 paginăElectrical Riser Diagram: EXISTING Electric Floor PLAN 1 E-1 SCALE: 3/16" 1'-0"Raúl Carbonell HerreraÎncă nu există evaluări

- Manufacturing and pricing report for lighting and plumbing itemsDocument60 paginiManufacturing and pricing report for lighting and plumbing itemsyogoÎncă nu există evaluări

- Hiraya Building B (Hiti Base Bahay)Document109 paginiHiraya Building B (Hiti Base Bahay)Landia Russell LihaoÎncă nu există evaluări

- ALS200M2 High Performance Limit Switch BoxDocument2 paginiALS200M2 High Performance Limit Switch Boxesteban catrilÎncă nu există evaluări

- Standard Symbols For Key Map: 2006 FDOT Design StandardsDocument3 paginiStandard Symbols For Key Map: 2006 FDOT Design StandardsMUHAMMAD NAZRUL HAFIZ BIN NORRISHAMÎncă nu există evaluări

- R56 Checklist 2005Document7 paginiR56 Checklist 2005cz_ms100% (1)

- 2014 Winter Model Answer PaperDocument25 pagini2014 Winter Model Answer Papernavneet100% (1)

- Technical Specification for Conduits and Associated MaterialsDocument38 paginiTechnical Specification for Conduits and Associated Materialsthiya123Încă nu există evaluări

- Unit 4: Cable: Distribution Design SystemDocument24 paginiUnit 4: Cable: Distribution Design SystemScalperÎncă nu există evaluări

- CABLEDocument10 paginiCABLEkhalidÎncă nu există evaluări

- Street Lighting Design GuidelinesDocument14 paginiStreet Lighting Design GuidelinesSeph De LunaÎncă nu există evaluări

- Conductors Total QTY Remarks HP OR KVA Volts "FROM" END " TO " END From TO Load Gland Type RUN ConduitsDocument1 paginăConductors Total QTY Remarks HP OR KVA Volts "FROM" END " TO " END From TO Load Gland Type RUN ConduitsJohn Philip BuntalesÎncă nu există evaluări