Documente Academic

Documente Profesional

Documente Cultură

LRFD 1995

Încărcat de

Naresworo NugrohoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

LRFD 1995

Încărcat de

Naresworo NugrohoDrepturi de autor:

Formate disponibile

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

American Wood Council

Engineered and Traditional Wood Products

Load and Resistance Factor Design

for Engineered Wood Construction

A F & P A

Welcome to the Load and Resistance Factor Design seminar!

Copyright 2001 American Forest & Paper Association 1

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Presentation Outline

> Overview of LRFD

> What stays the same as ASD?

> What changes from ASD?

> ASCE 16-

16-95 Standard

> ASTM D5457-

D5457-93 basis for design values

> AF&PA LRFD Manual Package

> Case Studies: ASD vs. LRFD

This seminar will cover these topics.

Copyright 2001 American Forest & Paper Association 2

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

American Wood Council

Engineered and Traditional Wood Products

Overview of LRFD

A F & P A

Overview of LRFD

Copyright 2001 American Forest & Paper Association 3

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Design Process

Demand Capacity

Lets begin with design process. The underlying basic philosophy for

the process of structural design is that whatever demand is expected

from a structural system must be met at least by its capacity.

Copyright 2001 American Forest & Paper Association 4

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Design Process

Load

Support Conditions Demand

Geometry

Materials Capacity

Performance

Fire

Economics

Aesthetics

.

The structural design process fundamentally breaks down into five key

components. Others below the line are normally of secondary

importance to safety and serviceability concerns. The demand features

the type, magnitude, and placement of loads on the system and the

resulting actions on interaction with the systems formal geometry. The

capacity of the system is provided in combination by the judicious

choice of materials, section geometry, and an understanding of the way

the system behaves under demand. The subject matter of this seminar

will be dealing with the capacity side of the structural issue - featuring

wood as the material.

Copyright 2001 American Forest & Paper Association 5

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

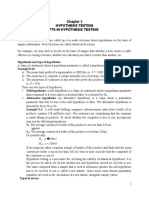

LRFD Design Concepts

Two Limit State concerns:

safety against failure or collapse

want statistical protection against failure

serviceability (performance in service)

want real-world measurable behavior

A limit state is the point at which the structure fails to serve its intended

purpose in some way. Two broad limit states can be identified for

structures: safety, and serviceability.

Copyright 2001 American Forest & Paper Association 6

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Serviceability

Unfactored loads

Mean material strength values

Serviceability limit states appraise the structure in terms of its everyday

usefulness. For this reason, it is important to know how well the

structure is actually performing. A way of seeing this, is to consider

average material strength values in combination with real load

magnitudes in the measure of actual performance.

Copyright 2001 American Forest & Paper Association 7

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Safety

Factored loads

Material strength values

Safety on the other hand can be thought of in statistical terms -

probability of failure, or conversely, survival. Using statistics, one can

appraise the safety of a structure in terms of measurable probability. In

the LRFD method, the tie to a statistical approach is achieved through

the use of load factors and material reference strengths modified by

reliability factors.

Copyright 2001 American Forest & Paper Association 8

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Property Variability

x

x = mean x x

x = standard deviation SCL

x

Relative Frequency

COVx =

x I-Joist

Glulam

Load MSR Lumber

Visually Graded

Lumber

Material Property Values

Lets look first at the capacity of side of the issue, specifically materials.

Here is a representation of the structural property variability among a

variety of wood products. The same statistical form shows up for all

other building products as well. Plotted here is the relative frequency of

occurrence against the actual property values from testing. Structural

testing in specific modes is performed on these products to produce the

data set that makes up these curves. Each curve (normal distributions

shown here) can be described by its statistical measures: mean,

standard deviation (a measure of the spread of the curve).

Copyright 2001 American Forest & Paper Association 9

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Statistical Model

Normal Distribution Curve for Load or Resistance

Based on actual physical measurements - data sets

The normal distribution curve has the inherent property, that the area

underneath it equals 1.0. This conveniently implies that the probability

of occurrence equals 100%. From this, one can determine for example

the structural property value that is appropriate for 5% of the sample

population. It can also be determined how many standard deviations

(the distance) it is away from the mean. Note that at the 5th%

percentile, 5 percent of the samples fail at this property value, while 95

percent of the samples survive.

Copyright 2001 American Forest & Paper Association 10

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Statistical Model

Normal Distribution Curves for Load, S , and Resistance, R

failure

Lets take two of these distributions: one for load (S), and one for

resistance (R); and plot them together. Each of the curves has its own

unique statistical description (mean and standard deviation values), and

may or may not have the same distribution type. Normal distribution

types are shown here, but there are many others, chosen to best fit or

model the test sample data points. Note that the resistance curve is to

the right of the load curve, and that curves overlap. The overlap implies

the region where load is greater than resistance, hence failure.

Copyright 2001 American Forest & Paper Association 11

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Statistical Model

Normal Distribution Curves for Safety Function, Z

fZ = fR - fS

mZ = mR - mS

z = R2 + S2

mz

=

z

The overlap, or failure zone, can be represented in a more useful way.

If the load and resistance distributions respectively are normalized to

the same type, then a performance distribution Z can be created by

subtracting the load distribution from the resistance distribution. The

statistics of Z are determined as seen in the slide, as well as fZ itself. In

this plot, the area under the fZ distribution that falls in the region of

property values less than zero, represents the probability of failure of

the structure in this particular mode of testing. Now a measurable

probability of failure is available. It can be further described in terms of

the number of standard deviations away from the mean of the

performance distribution. The greek letter , known as the safety index,

is used to describe this multiple. Thus, is directly tied to the

probability of failure.

Copyright 2001 American Forest & Paper Association 12

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Probability of Failure

Pf = one failure expected Pf

for x number of 5.2 1 : 10,000,000

structures designed 4.7 1 : 1,000,000

and built with a 4.2 1 : 100,000

given 3.7 1 : 10,000

3.2 1 : 1,000

2.7 1 : 100

2.2 1 : 10

For large values of , the probability of failure is very small. For small

values, the probability of failure is much larger.

Copyright 2001 American Forest & Paper Association 13

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Range on

Range for Wood Strength

Low Typical High

2.4 2.6 2.9

Pf 1 : 25 1 : 63 1 : 251

These are the typical values used in structural design in many

materials, not just wood. It is interesting to note the corresponding

probability of failure. These are levels that designers have been

historically been designing buildings for.

Copyright 2001 American Forest & Paper Association 14

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Safety Design Equation

Demand Capacity

n

i=1

Q Rn

How is actually used in design? is actually invisible in the design

process. It is tied to two other factors: the reliability index (used on

the capacity side of the equation), and the load factor (used on the

demand side of the equation). To design for any demand with any

material to a target , it is prudent to fix the value of the load factor

(standardized values for all materials), and derive reliability indices for

various structural properties of various materials. This process is

known as calibrating the reliability index.

Calibration needs to cover all of the relevant factors such as the load

and variability of the member strength based on species, grade, and

type of application. Generally, the 5th percentile of the strength data

test data is used for the resistance side, while the load statistics are

obtained from extensive studies of structures in all climatic zones and

with different occupancies.

Copyright 2001 American Forest & Paper Association 15

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Reliability Index Calibration

Example:

Bending strength

resistance of 2x8

lumber subjected

to Quebec City

snow load

A calibration example: the bending strength of 2x8 lumber subjected to

Quebec City snow load. What value would be appropriate for a target

of 2.6?

Copyright 2001 American Forest & Paper Association 16

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Reliability Index Calibration

Find range on reliability index such that for fixed factored

loads, a target is achieved.

100 % data

In this - ( fixed) correlation plot, the Quebec City snow load is

modeled with a lognormal distribution, while the bending strength of 2x8

lumber is modeled with four different distributions that are fit as closely

as possible to a complete data set of full-sized test results.

To give a target of 2.6, would range from 0.55 to 1.0 depending on

which mathematical model is used for the resistance. This shows how

sensitive is to the assumed distribution type.

Copyright 2001 American Forest & Paper Association 17

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Reliability Index Calibration

Example:

Bending strength

resistance of 2x8

lumber subjected

to Quebec City

snow load

Here is a cumulative probability plot of 2x8 bending strength. On the

plot is the complete test data set of full-sized specimens (In-Grade) and

two distribution models that are fit as closely as possible to the test

data. The test data comes from the 5th percentile MORs.

Copyright 2001 American Forest & Paper Association 18

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Reliability Index Calibration

Example:

Bending strength

resistance of 2x8

lumber subjected

to Quebec City

snow load

Critical region for

matching distribution

type to test data

Careful inspection of the test strength data reveals that, while the 100%

distribution curve fits the complete data set reasonably well, the model

doesnt represent the lower end of the data set at all.

The lower tail is the most important portion of the test population since

the low strength members are the ones most vulnerable to failure.

Another distribution model can be chosen for use in the calibration to

better represent the lower end of the test data set (the lower 15%).

This will ultimately produce a much narrower range of values.

Copyright 2001 American Forest & Paper Association 19

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD - Reliability Index Calibration

Find range on reliability index such that for fixed factored

loads, a target is achieved.

15% data

(lower tail)

= 0.85

gives

= 2.6 to 2.8

Re-plotting the - ( fixed) correlation using the lower tail model yields

a more satisfying result. In this case, the value of = 0.85 used for

bending strength is consistent with that found in the design code

equation.

The procedure to calibrate the code values with a probability analysis is

mathematically sophisticated, and is not typically a design issue. It is

useful however to be aware of the background to the design rules to

gain a better understanding of the issues affecting safety and reliability,

and in some cases to make rational decisions where the code does not

provide direction.

Copyright 2001 American Forest & Paper Association 20

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

American Wood Council

Engineered and Traditional Wood Products

What stays the same as ASD?

A F & P A

Copyright 2001 American Forest & Paper Association 21

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Allowable Stress Design

Same basic equation

format

GE

AN

Same adjustment

CH

factors T

NO

Same behavioral

ES

DO

equations

s

minor exceptions (e.g.

es

oc

moment gradients)

Pr

formatted for

n

sig

compatibility

De

The engineering procedures for applying Allowable Stress Design

methods to wood structures are published in ANSI/AF&PA NDS-1997.

All model codes have used or referenced the NDS for design of wood

for literally decades, so many designers are already familiar with its

contents.

LRFD does not alter the familiarity. Many of the ASD features that

designers have come to know have remained the same: basic equation

format, adjustment factors, behavioral equations. The LFRD Manual

has been formatted for compatibility with ASD.

In terms of application of LRFD principles, design process does not

change much. The demand side requires unfactored and factored

(new) load calculations. The capacity side remains in the same form.

Procedural steps are essentially the same as ASD for various structural

components.

Copyright 2001 American Forest & Paper Association 22

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

American Wood Council

Engineered and Traditional Wood Products

What changes from ASD?

A F & P A

Copyright 2001 American Forest & Paper Association 23

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD vs. ASD

Two new notations - and

Design loads (factored) for safety are bigger

Design loads (unfactored) for serviceability

are the same

Material resistance values are bigger

Load Duration factor changes to Time Effect

Factor

These are some of the distinguishing features of LRFD.

Copyright 2001 American Forest & Paper Association 24

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD vs. ASD

ASD

applied stress allowable stress

Theoretical safety

margin applied to

material stresses

Estimated

loads

Design

Load Adjusted

Resistance

Tested

material

strength

Design values

The way safety is addressed in the two approaches is fundamentally

different. ASD makes use of a theoretical safety margin that was

applied to material stresses. Controversy often surrounded the

theoretical safety margin its the lack of a rigorous basis of

determination. ASD also features the comparison of stresses in the

demand/capacity relations.

Copyright 2001 American Forest & Paper Association 25

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD vs. ASD

LRFD Member performance

factored load factored resistance factor

Load factors to

account for

variations in loads

Estimated

loads

Factored

Design Factored

Design

Tested

member

Load Resistance resistance

Design values

LRFD features a statistical basis for a measurable probability of failure

and thus insures a measurable level of safety. Factored load equations

(with few exceptions) are standardized across all material groups.

Resistance values are only modified by a reliability factor that varies by

material and mode of use. In the demand/capacity relations, loads or

moments are typically compared.

Copyright 2001 American Forest & Paper Association 26

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

ASCE LRFD Standard

Factored Load Combinations ASCE 7-93

1.4 D

1.2 D + 1.6 L + 0.5 (Lr or S or R)

1.2 D + 1.6 (Lr or S or R) + (0.5 L or 0.8 W)

1.2 D + 1.3 W + 0.5 L + 0.5 (Lr or S or R)

1.2 D + 1.0 E + 0.5 L + 0.2 S

0.9 D - (1.3 W or 1.0 E)

from any direction!

These are the six fundamental factored load combinations used for

safety analysis in LRFD. Reading into the symbology will yield what

kind of environmental event the structure is being exposed to. Many

more additional equations are derived from these when direction is

taken into account.

Copyright 2001 American Forest & Paper Association 27

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Safety Design Equation

Demand Capacity

n

i=1

Q Rn

This is the basic form of the demand / capacity relation for LRFD.

Copyright 2001 American Forest & Paper Association 28

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

ASCE LRFD Specification

Resistance Factors

Compression 0.90

Flexure 0.85

Tension 0.80

Shear 0.75

Connections 0.65

The LRFD resistance factors (or reliability indices) for wood are shown

here for member properties and connections. The lower the number,

the more vulnerable the material in the respective mode. Since these

indices vary by material, and by mode of use, many designers exploit

the reliability index factors from different materials to get the best from

them.

Copyright 2001 American Forest & Paper Association 29

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

ASCE LRFD Specification

Time Effect Factor

Dead Load 0.6

Occupancy Live 0.8

Snow Load 0.8

Wind / Earthquake 1.0

Impact 1.25

LRFD introduces a new terminology for time effect, formerly known as

load duration in ASD. The Time Effect factor is associated with

factors for various loads; replacing the ASD load duration factor CD.

LRFD also employs a new baseline of 10 minutes versus 10 years for

= 1.0.

Copyright 2001 American Forest & Paper Association 30

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

ASCE LRFD Specification

tied to Factored Load Equations:

Load Combination

1.4 D 0.6

1.2 D + 1.6 L + 0.5 (Lr or S or R) *

1.2 D + 1.6 (Lr or S or R) + (0.5 L or 0.8 W) 0.8

1.2 D + 1.3 W + 0.5 L + 0.5 (Lr or S or R) 1.0

1.2 D + 1.0 E + 0.5 L + 0.2 S 1.0

0.9 D - (1.3 W or 1.0 E) 1.0

* Lstorage = 0.7; Loccupancy = 0.8; Limpact = 1.25

Reduced to 3 general factors: 1.0 for lateral, 0.8 for gravity, 0.6 for

permanent; this approach is consistent with international codes. By

prescription, is tied to the LRFD load combination equation used.

Copyright 2001 American Forest & Paper Association 31

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Impact of Time Effect Factor

Accurate, but not over-precise

Easier for designers

1.0 lateral

0.8 gravity

0.6 permanent

Consistent with International Codes

This method of dealing with time effect has advantages.

Copyright 2001 American Forest & Paper Association 32

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Beam Example - UDL Simply Supported

Q

A, S, I

L

DEMAND LOADS LRFD ASD

Safety wf = Q w=Q

Serviceability wL= QL wL= QL

Heres an example comparing the two design processes. Consider a

simple beam under uniform load, with given section properties. We

have a displacement limit state (maximum) of span/360.

Both methods require determination of the safety and serviceability

demand loads. Note the inclusion of the prescribed load factor(s) in the

LRFD demand safety load. The serviceability loads are the same for

both approaches.

Copyright 2001 American Forest & Paper Association 33

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Beam Example - UDL Simply Supported

Safety Limit State 1

SHEAR LRFD ASD

wf L 2 v Fv A w L 2 Fv CD A

2 3 2 3

demand capacity demand capacity

Prime denotes inclusion of applicable C factors except CD

Here we consider two safety limit states: shear and flexure. The

demand / capacity relations for shear for this problem are shown.

ASD modifies the capacity with the CD factor for load duration. The

LRFD capacity equation includes the time effect factor and the

reliability factor for shear v. Note that factored LRFD loads are used in

the demand.

Copyright 2001 American Forest & Paper Association 34

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Beam Example - UDL Simply Supported

Safety Limit State 2

FLEXURE LRFD ASD

wf L2 b Fb S w L2 Fb CD S

8 8

demand capacity demand capacity

Prime denotes inclusion of applicable C factors except CD

The demand / capacity relations for flexure for this problem reveal much

the same in comparison

ASD modifies the capacity with the CD factor for load duration. The

LRFD capacity equation includes the time effect factor and the

reliability factor for bending b. Note again, that factored LRFD loads

are used in the demand.

Copyright 2001 American Forest & Paper Association 35

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Beam Example - UDL Simply Supported

Serviceability Limit State

DISPLACEMENT LRFD ASD

L 5 wL L4 L 5 wL L4

360 384 E I 360 384 E I

capacity demand capacity demand

The serviceability limit state considered here is maximum displacement

of span/360 under service load wL.

Note that both approaches use the same equation with very little

difference. The important note here is that LRFD uses unfactored

actual loads, just like ASD because you want a real measure of actual

performance.

In summary, the design process for wood has not changed. LRFD

requires the use of load and resistance factors that designers presently

skilled in steel and concrete design using LRFD already are familiar

with. But as will be seen, there are advantages to be gained with LRFD

in final section determination, especially if the problem is governed by a

safety limit state.

Copyright 2001 American Forest & Paper Association 36

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

American Wood Council

Engineered and Traditional Wood Products

ASCE 16-95 Standard

A F & P A

The Standard for LRFD Design in Wood is ASCE 16-95.

Copyright 2001 American Forest & Paper Association 37

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Chapter 2

Design Requirements

Reference conditions

dry use

normal temperature

untreated

Adjustment Factors

multi-part table

cover many products

numerical factors in product supplements

The reference conditions for wood design to this Standard are: dry use,

normal temperature, and untreated. Adjustment factors are applied (as

in ASD) to modify resistances for any conditions other than the

reference conditions. The adjustment factors are contained in a multi-

part table Table 2.6-1 that covers many products. Numerical factors are

also found in the product supplements.

Copyright 2001 American Forest & Paper Association 38

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Wet Service

End Use

CM wet service

Ct temperature

C pt preservative treatment

C rt fire-retardant treatment

CM - wet service factor

Copyright 2001 American Forest & Paper Association 39

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Wet Service Conditions

30

25

Wood EMC %

20

Temp 30 deg F

15 Temp 70 deg F

Temp 130 deg F

10

0

0 20 40 60 80 100

Relative Humidity %

Dry conditions of service are those in which the equilibrium moisture

content (EMC) of the wood in use will not exceed a maximum of 19%.

The graph, here, shows how wood in the right conditions of

environmental temperature and relative humidity can reach EMCs of

19% or more. This >19% regime is not only problematic for some of the

woods structural properties, but can also lead to early decay or other

durability problems.

Copyright 2001 American Forest & Paper Association 40

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Wet Service Conditions

110

%Strength at 12% Moisture Content

100

90

Impact Strength

80 Modulus of Elasticity

70 Modulus of Rupture

Crushing Strength

60

50

40

12 14 16 18 20 22 24 26 28 30

Moisture Content of Wood (%)

Here graphically, in somewhat general terms, is what happens to

various structural properties of wood in the region of high EMC.

Decreases in the structural properties are noted, especially for the

crushing strength Fc.

Copyright 2001 American Forest & Paper Association 41

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: CM Table

Wet Service Factor CM

Fb Ft Fv Fc Fc E

0.85 1.00 0.97 0.67 0.80 0.90

The LRFD values of CM for Wet Service are identical to those in the

NDS.

Copyright 2001 American Forest & Paper Association 42

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Wet Service

Bridge applications like this, exposed to moisture, would require CM in

design. The designer needs to be aware of conditions that could

generate high EMCs.

Copyright 2001 American Forest & Paper Association 43

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

AF&PA / ASCE 16-95: A F & P A

Composite Action

Adjustment Factors for Member Configuration

CC composite action

Cr load sharing

CF size

CL beam stability

CP column stability

Cb bearing area

Cf form

CE - composite action factor

Copyright 2001 American Forest & Paper Association 44

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

AF&PA / ASCE 16-95: A F & P A

Composite Action

CE composite action

1.00 nailed

1.10 nail-glued

1.15 joint-glued

NDS NDS

1997 2001

The LRFD Composite Action factor is not in the NDS 1997 or 2001

editions.

Copyright 2001 American Forest & Paper Association 45

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

AF&PA / ASCE 16-95: A F & P A

Load Sharing

Adjustment Factors for Member Configuration

CC composite action

Cr load sharing

CF size

CL beam stability

CP column stability

Cb bearing area

Cf form

Cr for load sharing applies to 3 or more members, spaced 2' o.c or less,

with a load distributing element connecting them.

Copyright 2001 American Forest & Paper Association 46

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

AF&PA / ASCE 16-95: A F & P A

Load Sharing

Cr load sharing

1.15 lumber

1.05 glulam; SCL

1.15 I-joists w/ VGR flanges

1.07 I-joists w/ MSR flanges

1.04 I-joists w/ SCL flanges

1.15 NDS NDS

only 1997 2001

Cr = 1.15 is found only for visually graded lumber in NDS 1997. The

LRFD Standard, as well as NDS 2001 now lists values of Cr for a

variety of wood products.

Copyright 2001 American Forest & Paper Association 47

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Load Sharing Example

This example of a 3-story Marriott is framed with numerous load sharing

members.

Copyright 2001 American Forest & Paper Association 48

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Chapter 4

Compression & Bearing

Pu c P

c = 0.90

Compression & bearing: compression resistance must exceed axial

compression stress due to factored loads. Note that the highest wood

reliability factor c = 0.90 is based on relative confidence in

compression design values over other modes.

Copyright 2001 American Forest & Paper Association 49

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

AF&PA / ASCE 16-95: A F & P A

Column Design

1997 NDS

The 1991 NDS uses one equation for column capacity. Note the c

values for solid sawn lumber, poles, and glulam.

Copyright 2001 American Forest & Paper Association 50

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

AF&PA / ASCE 16-95: A F & P A

Column Design

Column Stability Equation Cp

1+c 1+c 2

c

Cp =

2c

- [ 2c ] -

c

same form as NDS 1997 and 2001!

The LRFD version takes the same form as NDS column stability

equation.

Copyright 2001 American Forest & Paper Association 51

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Column Example Axial Load only

Safety Limit State

COMPRESSION LRFD ASD

Pu c P P P

demand capacity demand capacity

No CD !

Heres a column example comparing the two design processes. Both

ASD and LRFD methods require determination of the safety demand

loads. Note the inclusion of the prescribed load factor(s) in the LRFD

safety demand load.

ASD modifies the compression capacity with the CD factor for load

duration. The LRFD capacity equation includes the time effect factor

and the reliability factor for compression c. Note that factored LRFD

loads are used in the demand.

Copyright 2001 American Forest & Paper Association 52

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Column Example

Dead Load = 5500 lbs P

Live Load = 31500 lbs

L = 16 ft (each direction) L A, S, I

Ends pinned

Consider a pinned column under axial load, with given section

properties. This 16 foot unbraced column has applied dead and live

loads.

Copyright 2001 American Forest & Paper Association 53

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Column Example

DEMAND LOADS LRFD ASD

Safety Pu = Q P=Q

= 1.2 D + 1.6 L =D+L

= 1.2 (5500) + 1.6 (31500) = 5500 + 31500

= 57000 lbs = 37000 lbs

First we compute the demand loads for design for safety. LRFD uses

load factors applicable to the load type and typically results in a larger

numerical result that ASD.

Copyright 2001 American Forest & Paper Association 54

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Column Example Try 6 3/4 x 9 Glulam visually graded western

species, combination symbol #1

GEOMETRY

Section X-X Y-Y

Pinned end Pinned end

d = 9 in

Ked = 1.0 Keb = 1.0

b = 6.75 in

Ld = 16 ft Lb = 16 ft

A = 61 in2

Led = Ked Ld Leb = Keb Lb

L eb L ed

X-X Slenderness = max ,

b d

= 28

Y-Y

For this design, we try a 6 x 9 glulam (combination symbol 1).

From the section geometry, the cross-sectional area is found. The

column can buckle through the X-X or Y-Y directions depending upon

bracing present in each direction. It is important to check bracing

geometry and its relationship to section dimension. Here, the column is

unbraced over its entire height, so the column could buckle in the

direction of least section dimension (in the X-X plane here). Checking

the slenderness ratio gives us an appreciation for this. We want to use

the larger of the slenderness ratio with respect to the b and d section

dimensions. In this case, the least dimension direction, b, governs,

with a slenderness ratio of 28. This value is in line with what has been

called a long or skinny column.

Copyright 2001 American Forest & Paper Association 55

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Column Example Try 6 3/4 x 9 Glulam visually graded western

species, combination symbol #1

SERVICE CONDITIONS LRFD ASD

Adjustment Factors

Load duration (normal) ? = 0.8 CD = 1.0

Use (dry) CM 1.0 1.0

Treatment (none) Ct 1.0 1.0

Size (glulam) CF 1.0 1.0

Incising (none) Ci 1.0 1.0

Next, we consider the columns environment. Any changes from the

base environment for the wood must be reflected in the adjustment

factors. Note the adjustment factors for load duration are different

numerically for LRFD and ASD; the LRFD version being prescribed by

the load combination equation used.

Copyright 2001 American Forest & Paper Association 56

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Column Example Try 6 3/4 x 9 Glulam visually graded western

species, combination symbol #1

MATERIALS LRFD ASD

Fc 3720 psi 1550 psi

E E05 = 1,300,000 psi 1,500,000 psi

KCE (Glulam) - 0.418

c (Glulam) 0.9 0.9

f c (compression) 0.90

f s (stability) 0.85

For material design values, we can go to the Structural Glued

Laminated Timber Supplement for ASD, or the same title for LRFD (first

entry on page 14, Table 3.2) and extract the design values for

compression and MOE. For LRFD, we want the buckling, or

stability, or strength E (it has been called any of these) that is found

in the 5th percentile E column, E05. For ASD, we need the KCE

conversion factor for glulam (which part of a combination produces a 5th

percentile E value from a mean E). It is convenient now to also pull the

LRFD resistance factors for column compression and stability.

Copyright 2001 American Forest & Paper Association 57

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Column Example

CAPACITY LRFD ASD

Crushing Fc* = Fc Cm Ct Cf Ci Fc* = Fc CD Cm Ct Cf Ci

= (3720)(1.0 all) = (1550)(1.0 all)

= 3720 psi = 1550 psi

P0 = A Fc* A Fc*

= (61)(3720) = (61)(1550)

= 225990 lbs = 94162 lbs

The first limit state for columns is crushing: characteristic of short stocky

geometries. We compute the crushing strength in stress form as Fc*.

Note that the ASD formulation includes the load duration factor CD,

while LRFD does not. The crushing load is also computed as shown.

Copyright 2001 American Forest & Paper Association 58

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Column Example simplification for

rectangular sections

CAPACITY LRFD ASD

p 2E05Iy 2E 05 A K cEE

Buckling Pe = = FcE =

(K eL )

2

12 (Slendernes s)2 (Slendernes s)2

p 2 (1300000)(61) (0.418)(150 0000)

= =

12(28)2 (28)2

= 772 psi

= 80281 lbs

A Fc* = (61)(772)

= 47078 lbs

The second limit state is buckling: characteristic of slender geometries.

The column buckling equation is derived from the familiar Euler

formulation that is reflected in the LRFD expression for columns of all

geometries, but simplified further here for rectangular sections. Also,

the LRFD expression is formulated as a load through the multiplication

of the area term, A. Traditionally, the ASD expression for rectangular

cross sections is shown here computed as a stress. Note how KcE

wraps up the 12, pi, and E05 conversion terms of the LRFD expression.

The forms of both ASD and LRFD expressions are basically the same

for rectangular cross sections. Also note that the buckling load is

dramatically higher for LRFD than for ASD.

Copyright 2001 American Forest & Paper Association 59

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Column Example

CAPACITY LRFD ASD

sPe FcE

Cp c = c =

cP0 Fc*

(0.85)(8028 1) (772)

= =

(0.80)(0.9 0)(225990) (1550)

= 0.42 = 0.50

The slenderness of our column lies somewhere between the crushing

and buckling limit states. To find out where, we compute the Cp ratio.

Cp factors down the crushing strength based on the slenderness of our

column. Again, the forms of the buckling-crushing ratio ac are basically

the same for both ASD and LRFD. The values of Cp we come up with

are reasonable for and slender column a little on the fat side. Super-

skinny columns would produce very low values of Cp.

Copyright 2001 American Forest & Paper Association 60

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Column Example

CAPACITY LRFD ASD

1 + ac 1 + a c ac

Cp =

Cp 2c 2c c

= 0.39 = 0.46

c P = c P0 Cp P = A Fc* Cp

= (0.80)(0.90)(225990)(0.39) = (94162)(0.46)

= 64076 lbs = 43374 lbs

And the expression of the Cp equation is exactly the same for both ASD

and LRFD. Setting in the ac values gives the corresponding numerical

results. Finally we compute the capacity of our column using the

expressions in P at the bottom. Note again, the LRFD capacity value is

higher.

Copyright 2001 American Forest & Paper Association 61

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Application - LRFD vs. ASD

Column Example Axial Load only

Safety Limit State

COMPRESSION LRFD ASD

Pu c P P P

57000 lbs 64076 lbs 37000 lbs 43374 lbs

demand capacity demand capacity

demand

0.89 0.85

capacity

Now we compare the load demands to the column capacities for each

method. Our trial column works for this design for both methods. No

doubt, LRFD has higher numbers, but we can see the approximate

equivalence in the two methods through the demand/capacity ratio.

The two ratios are close within the accuracy of design, with LRFD

suggesting that slightly more of the column is being utilized than ASD.

In extreme cases, this may lead to slightly larger columns sooner with

LRFD, which is conservative. Overall, the design process for LRFD has

not changed from ASD, but in fact is remarkably similar.

Copyright 2001 American Forest & Paper Association 62

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Chapter 7

Mechanical Connections

Zu Z Z

Z = 0.65

Connection resistance must exceed factored loads. Note that z = 0.65

which represents the lowest relative confidence in design capacities in

wood. However, this reliability index is comparable to steel.

Copyright 2001 American Forest & Paper Association 63

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Mode IIIs

NDS

k3 D t s F em

Z =

1.6 ( 2 + R e ) K

LRFD

2.08 k 3 D ts F em

Z =

( 2 + R e ) K

The LRFD yield equations also take the same form as NDS. Example:

Mode IIIs - Localized side member crushing, single hinge at each shear

plane in main member.

Copyright 2001 American Forest & Paper Association 64

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Mode IIIs

In fact, the theory matched the test data.

Copyright 2001 American Forest & Paper Association 65

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Chapter 6

Structural Use Panels

describes special reference conditions

provides basic panel definitions

Design values provided separately

in supplement

NDS NDS

1997 2001

The LRFD Standard and NDS 2001 is expanded from NDS 1997

coverage, describing special reference conditions as well as basic panel

definitions. Design values are found in the LRFD and ASD 2001 Panels

Supplement.

Copyright 2001 American Forest & Paper Association 66

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Chapter 9

Shear Walls and Diaphragms

describes general design principles

Design values provided separately

in supplement

NDS NDS

1997 2001

Shearwalls and diaphragms, not covered in NDS 1997, are presented in

the LRFD as well as NDS 2001. Design values are found in the LRFD

and ASD 2001 Panels Supplement.

Copyright 2001 American Forest & Paper Association 67

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Chapter 10

Serviceability Considerations

Provided as a home for future updating

Maintains current philosophy:

Controlling code conditions apply

In terms of serviceability, ASCE 16-95 maintains the current philosophy

of applicable code provisions to provide a home for future updating.

There are many unique cases where serviceability is the governing limit

state which require special treatment or conformance to limiting criteria

that the designer must consider.

Copyright 2001 American Forest & Paper Association 68

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Chapter 10

Serviceability considerations for a roller coaster differ significantly from

a kitchen floor.

Copyright 2001 American Forest & Paper Association 69

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Appendix A3

Ponding

additional guidance for design of flat

or near-flat roofs

not in NDS 1997 or 2001!

NDS NDS

1997 2001

Guidance is provided in Appendix A3 for the design of flat wood roofs to

avoid ponding. Ponding is not covered in the current NDS.

Copyright 2001 American Forest & Paper Association 70

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

AF&PA / ASCE 16-95: Appendix A3

Example: 1 million square foot roof system for GE plant; good case for

ponding design.

Copyright 2001 American Forest & Paper Association 71

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

American Wood Council

Engineered and Traditional Wood Products

ASTM D5457-93 Basis for Design Values

A F & P A

ASTM D5457-93 Basis for Design Values

Copyright 2001 American Forest & Paper Association 72

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

ASTM Standard: D5457

Computing the

Reference Resistance

Values for Wood-

Based Materials and

Structural

Connections for

LRFD

ASTM D5457-93 Standard Procedure for Computing Reference

Resistance Values for Wood and Wood-Based Connections for LRFD is

beyond the scope of AF&PA or ASCE. This is the standard used to

determine and compile all the reference strength material data used by

the AF&PA / ASCE LRFD Standard.

Copyright 2001 American Forest & Paper Association 73

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

ASTM LRFD Standard

Format conversion

ASD Values LRFD Values

To arrive at the appropriate LRFD material resistance values, there are

2 approaches: first is soft conversion from ASD.

Copyright 2001 American Forest & Paper Association 74

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

ASTM LRFD Standard

Format conversion

2.16

KF =

s

Rn = KF f

Assuming a 3:1 live to dead load ratio gives the conversion factor of

2.16/f (where f is the ASD allowable stress). This relation allows soft

conversion of ASD allowable stress values such as those from NDS

Supplement.

Copyright 2001 American Forest & Paper Association 75

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Conversion Factor Comparison

Conversion Factor (Kc)

Roof Live

Snow

Conversion factor chosen = 2.16

Floor

Load Ratio

= Load ratios common for these applications

This Live/Dead load ratio was chosen to minimize impact on current

design practice. Under LRFD, roof strength capacities for snow will stay

about the same. Floor strength capacities will increase, which is OK

since they are typically deflection controlled. Roof strength capacities

will decrease for construction loads, which is probably OK since those

are being designed to the extreme limit in sun load areas like Arizona

Copyright 2001 American Forest & Paper Association 76

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

ASTM LRFD Data Conversion

Format conversion

ASD Values LRFD Values

Reliability-based conversion

Data Sets LRFD Values

The second method (hard conversion) in the ASTM standard allows

calculation of design values using actual material test data sets.

Copyright 2001 American Forest & Paper Association 77

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

ASTM LRFD Data Conversion

x

x = mean x x

x = standard deviation SCL

x

Relative Frequency

COVx =

x I-Joist

Glulam

Load MSR Lumber

Visually Graded

Lumber

Material Property Values

LRFD through the second approach will allow materials with lower

material property variability to take advantage of this characteristic in

the design process. This second approach moves toward true

reliability-based design (RBD).

Copyright 2001 American Forest & Paper Association 78

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

American Wood Council

Engineered and Traditional Wood Products

AF&PA LRFD Manual Package

A F & P A

AF&PA LRFD Design Resource Package

Copyright 2001 American Forest & Paper Association 79

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Manual Package

This package is a landmark for the industry bringing together all design

information for wood products in one manual.

Copyright 2001 American Forest & Paper Association 80

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Supplements

Design Values

Lumber

Glulam

Panels

Poles / Piles

Connections

Supplements provide LRFD resistance values and information for a

variety of wood products.

Copyright 2001 American Forest & Paper Association 81

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Guidelines

Proprietary

I-joist

SCL

Trusses

Hangers

No Design Values

LRFD Guidelines provide information only on proprietary products and

systems.

Copyright 2001 American Forest & Paper Association 82

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Guide Makeup

I-joist

20 details

design / construction

applicable beyond

LRFD

For example, the I-joist guideline provides graphical information and

details on how these products are assembled into a system. The

guidelines are applicable to both LRFD and NDS.

Copyright 2001 American Forest & Paper Association 83

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Manual

Manual

6 case studies

20 design examples

40 connection details

AF&PA / ASCE 16-95

Industry Landmark

design information for all

structural wood products

The LRFD Manual is an all-inclusive document containing the ASCE

Standard as well as other useful background, example, and technical

information.

Copyright 2001 American Forest & Paper Association 84

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Los Angeles Reservoir Cover

Project profiles and case studies of projects designed with LRFD, as

well details on how designers met the challenges of these designing

these projects in wood are presented. The Los Angeles reservoir cover

is one project profile described.

Copyright 2001 American Forest & Paper Association 85

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

Building Codes

Approval

SBCCI

ICBO

BOCA

ICC

The AF&PA / ASCE LRFD Standard is referenced by all model building

codes.

Copyright 2001 American Forest & Paper Association 86

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

American Wood Council

Engineered and Traditional Wood Products

Case Studies: ASD vs. LRFD

A F & P A

Copyright 2001 American Forest & Paper Association 87

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

ASD vs. LRFD

When we talk about ASD, we are referring to the NDS.

Copyright 2001 American Forest & Paper Association 88

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Benefits

Case Study

Glulam beams / columns

15% benefit

wind / crane / snow

ASD

D+L+W+S

LRFD

1.2 D + 1.3 W + 0.5 L + 0.5 S

The University of Maine Advanced Engineered Wood Composites Lab

was built with 30' glulam columns and 70' glulam beams. Refer to ASAE

Paper #984006 for details.

Copyright 2001 American Forest & Paper Association 89

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Benefits

Glulam Column

ASD

10 1/2 x 17 7/8

CRANE BEAM

30'-0"

22"

LRFD

10 1/2 x 15 1/8 25'-6"

LRFD resulted in columns for this project 15% smaller than ASD.

Copyright 2001 American Forest & Paper Association 90

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Benefits

Multi-Story Design

load combinations

headers / studs

up to 30% benefit

ASD

D+L+S

LRFD

1.2 D + 1.6 L + 0.5 S

Compare headers for this 2 story structure with roof and floor loads.

Multiple transient loads are treated with weighted factoring in LRFD, but

directly summed in ASD. This results in 30% smaller cross-sections.

Again, refer to ASAE Paper #984006 for details.

Copyright 2001 American Forest & Paper Association 91

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Benefits

Lumber SPF #2 30+10 (psf)

ASD 2 - 2x12

LRFD 2 - 2x10

40+10 (psf)

24'

In this typical 2-story building example, LRFD indicates 2-2x10 vs. 2-

2x12 #2 southern pine for ASD.

Copyright 2001 American Forest & Paper Association 92

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Benefits

Glulam 16F 30+10 (psf)

ASD 3 1/8 x 8 1/4

LRFD 3 1/8 x 6 7/8

40+10 (psf)

24'

Same example, but using glulam: LRFD indicates 3 1/8 x 6 7/8 vs. 3

1/8 x 8 1/4.

Copyright 2001 American Forest & Paper Association 93

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Benefits

LVL 1.8E 30+10 (psf)

ASD 2 - 1 3/4 x 7 1/4

LRFD 2 - 1 3/4 x 5 1/2

40+10 (psf)

24'

Same example, but using LVL 1.8E: LRFD indicates two 1-3/4"x7-1/4"

vs. two 1-3/4"x5-1/2" for ASD.

Copyright 2001 American Forest & Paper Association 94

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Benefits

Fire Design - Heavy Timber

ASD DCA #2, TR10

LRFD TR10

ASCE 7 - 95

1.2 D + Ak + (0.5L or 0.2S)

extraordinary event load

combinations

ASCE 7 - 95 permits load factoring for extraordinary event load

combinations based on probability of occurrence of live loads during a

fire.

Copyright 2001 American Forest & Paper Association 95

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

A F & P A

LRFD Problem / Solutions Manual

40 examples

prepared by:

Dr. Steve Cramer, P.E.

University of Wisconsin - Madison

Dr. Dan Wheat, P.E.

University of Texas - Austin

To aid the designer, a Worked Problems Manual for LRFD has been

produced to guide the designer through 40 typical design problems.

The manual is formatted for ease of use, filled with graphics,

explanatory notes, and arranged in an easy-to-follow approach to

process.

Copyright 2001 American Forest & Paper Association 96

AMERICAN FOREST & PAPER ASSOCIATION

American Wood Council

Engineered and Traditional Wood Products

Visit the American Wood Council A F & P A

@ Home

www.awc.org

Consult the AWC web site at www.awc.org for your first source for

wood information.

Or call the Help Desk at 1 800 AWC AFPA.

Copyright 2001 American Forest & Paper Association 97

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Report - Project8 - FRA - Surabhi - ReportDocument15 paginiReport - Project8 - FRA - Surabhi - ReportSurabhi Sood0% (1)

- ASTM E178 - 2008 - Standard Practice For Dealing With Outlying Observations PDFDocument18 paginiASTM E178 - 2008 - Standard Practice For Dealing With Outlying Observations PDFDeisy Rodriguez100% (3)

- MathematicsTeachingLearning 11626 7Document272 paginiMathematicsTeachingLearning 11626 7Ami Rah100% (3)

- 50 Deep Learning Technical Interview Questions With AnswersDocument20 pagini50 Deep Learning Technical Interview Questions With AnswersIkram Laaroussi100% (1)

- Advanced Statistics ProjectDocument2 paginiAdvanced Statistics ProjectBeing Indian17% (6)

- Method ValidationDocument36 paginiMethod ValidationesziepÎncă nu există evaluări

- Chapter 9: Introduction To The T StatisticDocument8 paginiChapter 9: Introduction To The T Statisticuser31415Încă nu există evaluări

- Report WritingDocument34 paginiReport Writingsunru24100% (3)

- Davison Full CVDocument18 paginiDavison Full CVVishnu Prakash SinghÎncă nu există evaluări

- Random VariablesDocument36 paginiRandom VariablesLene VelloÎncă nu există evaluări

- Probability DistributionDocument7 paginiProbability DistributionJeff balesÎncă nu există evaluări

- Bus 173 - 3Document19 paginiBus 173 - 3Mirza Asir IntesarÎncă nu există evaluări

- Valores de La Función de Distribución de Poisson:: PX X e KDocument1 paginăValores de La Función de Distribución de Poisson:: PX X e KRoxana MurguÎncă nu există evaluări

- Determining The Number of Factors in Exploratory and Confirmatory Factor AnalysisDocument16 paginiDetermining The Number of Factors in Exploratory and Confirmatory Factor AnalysisvesnaÎncă nu există evaluări

- Nonstationary Panels, Panel Cointegration, and Dynamic Panels PDFDocument337 paginiNonstationary Panels, Panel Cointegration, and Dynamic Panels PDFBhuwanÎncă nu există evaluări

- P R2Document17 paginiP R2Argielyn OracionÎncă nu există evaluări

- Barnes, Tiffany D., and Erin C. Cassese. 2017. American Party Women - A Look at The Gender Gap Within PartiesDocument15 paginiBarnes, Tiffany D., and Erin C. Cassese. 2017. American Party Women - A Look at The Gender Gap Within PartiesMack EncheeseÎncă nu există evaluări

- Examples Using The PLS Procedure: Example 1. Predicting Biological ActivityDocument72 paginiExamples Using The PLS Procedure: Example 1. Predicting Biological ActivityKalyan Raghav BollampallyÎncă nu există evaluări

- Reminders Per ChaptersDocument6 paginiReminders Per ChaptersMarian Joy Salvador AltarÎncă nu există evaluări

- Social Restriction of The Transgender CommunityDocument19 paginiSocial Restriction of The Transgender CommunityJoliane CalderaÎncă nu există evaluări

- Introduction To Statistics: Let's ReviewDocument8 paginiIntroduction To Statistics: Let's ReviewJason Lam LamÎncă nu există evaluări

- LEA Police ORG. and Planning (PRE - BOARD)Document4 paginiLEA Police ORG. and Planning (PRE - BOARD)Michael EgotÎncă nu există evaluări

- Tutorial 5Document5 paginiTutorial 5RUHDRAÎncă nu există evaluări

- Chapter 3Document12 paginiChapter 3Abdii Dhufeera100% (2)

- Efficiency of Image Analysis As A Direct Method in Spore Dimensions MeasurementDocument8 paginiEfficiency of Image Analysis As A Direct Method in Spore Dimensions MeasurementDr. Mustafa AlqaisiÎncă nu există evaluări

- P10 Meta-Learning Probabilistic Inference For PredictionDocument22 paginiP10 Meta-Learning Probabilistic Inference For PredictionSau L.Încă nu există evaluări

- Chapter 7 (Forecasting)Document37 paginiChapter 7 (Forecasting)IndiraÎncă nu există evaluări

- Module 13-Gage R&R AnalysisDocument32 paginiModule 13-Gage R&R Analysisramasamy_lÎncă nu există evaluări

- Sample Research Paper in Experimental PsychologyDocument6 paginiSample Research Paper in Experimental PsychologyzrpcnkrifÎncă nu există evaluări

- An Advanced Research Facility For The Virology Science and Technology InstituteDocument19 paginiAn Advanced Research Facility For The Virology Science and Technology InstituteMaykel De chavezÎncă nu există evaluări