Documente Academic

Documente Profesional

Documente Cultură

Im-Co-Fo-88 Summary Inspection Report of The Rig PTX 15 - Mar - 1

Încărcat de

JUAN JOSE VESGA RUEDATitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Im-Co-Fo-88 Summary Inspection Report of The Rig PTX 15 - Mar - 1

Încărcat de

JUAN JOSE VESGA RUEDADrepturi de autor:

Formate disponibile

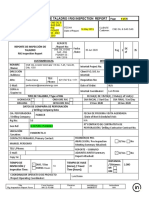

Report No:

MM DD YY

INSPECTION RIG REPORT Date: Page 1 of 30

01 04 04 17

CUSTOMER DATA INTERTEK DATA

Name: REPSOL - PER Intertek Project No.

Calle Begonias 415. Torre Begonias, Piso 13

Address: Client P.O./I.O. to Intertek: 4600006367

San Isidro, Lima 27, Per

Attn: Eng. Jorge Bobadilla Phone: Requisition No:

E-Mail : jebobadillaa@repsol.com Date of Order: 19/10/2015

Sebastian.maurutto@intertek.com; Intertek Contract

Copies to: Luis Bossa

jose.perez@intertek.com Coordinator:

RIG INSPECTION INFORMATION

Date(s) of Visit(s):

RIG INSPECTION CLASS:

TYPE OF RIG

Star Day End Day

WORKOVER ONSHORE RIG

MM DD YY MM DD YY

03 14 2017 03 21 2017

DRILLING OFFSHORE RIG

RIG COMPANY DATA Date of Next Scheduled Visit:

Rig Company: PETREX PER Rig Contract No.

Rig No: PETREX 5938 - PTX-15 Pre-Inspection Meeting

Yes No

Location: Sagary AX Summary Attached:

Primary

David Marmolejo

Contact: Summary Report Attached: Yes No

Phone: (51) 990311275 E-mail : david.marmolejo@petrex.com.pe

Comply with

Comply with Requirements No Comply with Requirements

Requirements Partially

INSPECTION DISPOSITION:

Nonconformance(s)

Placed on Hold Other (Explain)

Identified

INSPECTION

DAYS 9 days Project Coordinator: Luis Bossa

TIME :

Scope (Items to inspect)

No. ITEMS YES NO N/A

1 Drill site location

2 Training, PPE & General Safety, Records, Statistics

3 Mud Pump Area

4 Mud Mixing Area

5 Mud Tanks and Pits

6 Material Handling Equipment

7 Generator Area

8 Fire Protection

9 Fuel & Other Flamable Liquid Storage Tanks, Including Frack Tanks & Non- Flamable

Storage Tanks

10 Pipe Rack Area

11 Blow-Out Preventers

12 Derrick & Substructure

13 Drill Floor Area

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 1 of 33

14 Power and Hand Tools

15 Hoisting Tools, Hooks, Bails, Elevators and Other Related Equipment

16 Stairs, Ladders, Handrails & Guardrails

17 Carrier Unit

18 Hotwork, Welding & Flamable Cutting Operations

19 Specific Over water Operations (N/A)

20 Confined Spaces, Excavations & Hazardous Environments

21 Perforating Operations and Use of Explosives (N/A)

22 Special Services

23 Environmental Aspects

24 Quality Aspects

25 Rig Inspection

This report is made solely on the basis of the Clients instructions and/or information and materials supplied. It is not intended to be suggestions for any

particular course of action. Intertek does not accept a duty of care or any other responsibility to any person other than the Client in respect of this report and

only accepts liability to the Client insofar as is expressly contained in the terms and conditions governing Intertek's provision of services. Intertek makes no

warranties or representations either express or implied with respect to this report save as provided for in those terms and conditions.

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 2 of 33

Fig 1. Petrex 15 Peru

Petrex S.A. Is a 100% company of the Saipem group (www.saipem.com) that has been

operating in South America since 1983. Currently, they are operating in South America with a

fleet of more than seventy teams between Oil & Gas and Geothermal, Workover and Pulling

distributed in Peru, Venezuela, Colombia, Ecuador, Bolivia and Chile.

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 3 of 33

ITEM 1. Drill Site Location

General/Back Ground:

Rig Petrex 15 is located in Lote 57, Sagari BX location, well Sagari 4XD.

The Petrex 15 is located in next Geographical coordinates: -11,430716, -73,355451; attached

is the map of the location:

Fig 2. Location map Petrex 15 in Peru Area 57

Summary of Findings:

Pending to build dam to the camp engine.

Some wood bridges and wood stairs are pending to build.

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 4 of 33

Suggestions:

To build the camp engine dam.

To build the wood stairs and wood bridges in the location.

ITEM 2. Training, PPE & General Safety, Records, Statistics

General/Back Ground:

Safety guy has supplied all information required about Trainning, EPP, general safety,

records, and statistics, HSE plans, etc. All this information is in line with the industry

standards and regulations.

HEALTH AND SAFETY

Health and Safety are values of Petrex. They are committed to providing your employees with

healthy and safe workplaces and in line with what their Health and Safety Vision declares to

be a company where thousands of people are united by their passion for health and safety.

The HSE Management System has been the foundation on which Petrex has built his culture,

which is based on the guidelines of his parent company, customer and legal requirements

and his know-how. The HSE Management System is OHSAS 18001 certified.

The line that Petrex top management has outlined, through his Leadership in Health and

Safety Program (LiHS), lies in the empowerment of self-care for himself and for his partners;

This implies that it is necessary to stop operations when security is compromised.

LEADERSHIP IN HEALTH AND SAFETY

The LiHS Program is implemented from the following stages that are conducted in a

coordinated way. "LiHS Workshop", The LiHS Program begins with the experience of a highly

interactive and emotional workshop; Where managers, supervisors and the entire line of

command have the challenge of thinking differently about health and safety; With practical

tools for personal development as effective influential Leaders in Health and Safety.

"High Impact Moments," designed to help managers

demonstrate a visible commitment to our vision of Health and

Safety, aligning our workforce with the need for change,

empowering them to stop operations and intervene when

necessary.

"Five Stars Intervention" is an interactive workshop in which a

simple and practical tool is used for our workforce to perform

effective interventions without creating conflicts, both in unsafe

acts and also to reinforce safe acts.

"Leading Behaviors", this strategy focuses on five simple, transferable and "non-negotiable"

Behaviors; Carefully chosen. The goal of this Leading Behavior strategy is to challenge and

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 5 of 33

eliminate unsafe acts in a given environment and to accelerate the process of cultural change

brought about by the application of earlier phases.

"Choose Life," this new highly emotional and thoughtful workshop, was developed to impact

our collaborators on the understanding that a health problem can happen to them and

encourage them to make positive decisions about their health; Focusing specifically on

lifestyles, infectious and communicable diseases

Training.

Petrex has a clear HSE training plan; for operation and maintenance area. Petrex people are

trained to operate the man lift, Crain and fork lift; all training certificates are attached to this

report.

PPE

Petrex people use the EPP correctly.

General Safety

Petrex uses the program of permit to work - PTW, according with the Petrex procedure WI-

PTX-HSE-111-S. Petrex uses JSA procedure WI-PTX-HSE-111-S to all tasks they need; All

permit to work should have the JSA attached. In this project, Petrex is working with the

Repsol standards, using all Repsol PTW.

Petrex uses the program to tag/log out, according with the Petrex procedure WI-PTX-HSE-

008-S.

Petrex has an emergency response plan GP-PTX-HSE-063-S, but the specific emergency

plan for the 57 Block with Repsol Operations is in the document PTX-HSE-192-S, it includes

all operational emergency like blow out prevention plan, fire emergency, spills, H2S

emergency, all medical evacuation, etc; all of these emergencies will change depending of

the work area.

Summary of Findings:

Some signs arent posted and/or placed.

Suggestions:

To help to the HSE guy in order to keep all rig and camp area with all signs required.

ITEM 3. A. Mud Pump Area

General/Back Ground:

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 6 of 33

The rig has Three Mud Pumps Lewco, 1600 HP each one, liners 12, liner capacity 5 to 7

, maximum SPM 120, each one with a PD model L205K, a lube oil pump with electric motor

2 HP, a rod oiler pump with electric motor 3 HP, a pre-charge pump MCM 6*8*13 with

electric motor 100 HP. Each Mud Pump is powered by two DC traction motors 1.000 HP each

one.

For this well Sagari 4XD Petrex will use only 2 mud pumps (number 2 and 3); Mud Pump

number 1 is going back to Nuevo Mundo (Repsol Yard), then is going back to Ransa Petrex

yard located in Pucalpa.

Inspection Report done by NOV PLL 036-15 on 30/09/2015; Inspection Report done by SAIS

Cat III-SAIS-PTX-0033-311016 on 31/10/2016.

A manifold is assembled to connect the mud pumps; two outputs from this manifold feed the

double stand pipe, with a stand pipe manifold type H. The rotary hose is in good condition.

All valves were tested with 3.000 PSI. The mud pump 1 connection is correctly sealed with a

hammer union plug.

MUD PUMPS CHECK LIST

SATISFY

ITEM DESCRIPCION OPERACIN REMARKS

YES NO

1 Start of DC Traction Motors

2 Electrical cables condition

3 Junction boxes condition

4 Start of Blowers

5 Start of Precharge pump

liner

6 Start of washer

7 Start of lube oil pump

8 Lockout switch in the DC traction Motor

h in the

9 Lockout swit SCR

10 By pass alarm belt slip

lers

11 SPM signal in Dri console

12 Mud Pump Pressure in Drillers console

Pump

Pressure in

13 Mu

Mud Pump

14 Pressure Relief valve calibrated

15 PM maintenance updated

1

NDT inspection updated

17 Dampener charged with Ni

condition

18 Valve

19 Belts condition

20 Sheaves condition

21 Bearing Measurement

22 Crosshead slides measurement

f valves

23 Slope to the exhaust lines of pressure reli

24 Valves, seats, piston & liner condition

25 Pony ods &

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 7 of 33

clamps

26 Pony rod seals condition

27 High pressure lines condition

REMARKS:

Mud pumps in good condition, any strange noise or excessive vibration was founded.

Lines pressure test was performed up to 3,000 PSI.

Satisfactory test, equipment running properly.

Fig 3. Strength Test Mud Pump Supplied by Pason System

Fig 4. Strength Test Mud Pump manual grafic

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 8 of 33

In the test, the Mud pumps were running in good condition, any strange noise or excessive

vibration was founded. All auxiliary motors were working properly; any alarms.

Summary of Findings:

N/A

Suggestions:

N/A

ITEM 4. Mud Mixing Area

General/Back Ground:

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 9 of 33

3 mud mixers pumps MCM 6*8*14 with electric motor 100 HP.

MUD MIXING CHECK LIST

SATISFY

ITEM DESCRIPCION OPERACIN REMARKS

YES NO

1 Any leaks in the hammer unions

2 Any leaks in the valves

3 Good pressure in the system

y

4 Gauges working proper

5 Hopper working properly

6 Lighting system in good condition

7 Safety lines installed on the lighting system

8 A good and safety area to mix the chemicals

9 Firefighting equipment installed on site

REMARKS:

Many leaks were corrected, the hammer unions were loose.

Summary of Findings:

N/A

Suggestions:

N/A

ITEM 5. Mud Tanks and Pits

General/Back Ground:

The low pressure mud system has 3 Shale Shakers Mongoose, 1 mud cleaner 3 in 1 with

dessander with 2 cones 12 and desilter with 16 cones each one 4 and Shale shaker

mongoose; Vacuum degasser, 15 mud agitators 20 HP and one mud agitator 10 HP.

Return tank, 2 suction tanks, 1 active tank, 4 reserve tanks, each tank 250 Bbls. 3 mud

mixers pumps MCM 6*8*13 with electric motor 100 HP. All low mud pressure system was

tested; the mud was circulated by desilter and dessander; mud agitators were running

properly.

Not all mud tanks were installed in this well.

Summary of Findings:

Flexible coupling in agitator # 9 is in bad condition.

Shale Shaker junction box without all bolts installed on.

Ground cable in shale shaker vibrator motors arent connected.

Water pipe in the mud tanks is not correctly anchored.

Suggestions:

The flexible coupling should be changed. It is too large; as a suggestion, it is better to

install a short pipe, then to connect with the flexible coupling.

Junction boxes should have installed all bolts.

To connect all ground cables correctly.

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 10 of 33

To anchor the water pipe with safe devices.

The first three items were corrected.

ITEM 6. Material Handling Equipment

General/Back Ground:

The rig PTX 15 has a Fork lift Case mod 721D}; it is in good condition; all deviations founded

in the last inspection were corrected.

The rig PTX 15 has two cranes Mantis, one model 6010 with capacity for 30 Tons, and one

Model 9010 with capacity for 45 Tons. Both working properly.

The rig PTX 15 has a man lift Genie S-45; it is not working because the joystick is in bad

condition.

Summary of Findings:

The caterpillar pads of the mantis crane are in bad condition.

Man lift has the joystick is in bad condition.

Suggestions:

To change the caterpillar pads.

To change the joystick and test the man lift.

ITEM 7. Generator Area

General/Back Ground:

The rig has 5 Engine/Generator Sets, each one with a CAT Engine 1.101 kW with CAT

Generator 1400 kVA-980 kW@600 Vac; only three units were installed in this well. The rig

has a power House with a SCR System House designed by Legacy, 5 generator Bays and 4

SCR bays; Siemens rectifiers; 2 containers each one 20 Ft of length, to follow as a heli-rig.

Air conditioners are working properly.

MUD PUMPS TEST AT 80 SPM @ 2.500 PSI MP2 & MP3 AT SAME TIME @ 30 Minutes MAR 17-2017

ENGINE/GEN PARAMETERS SCR PARAMETERS

ITEM ENG/GEN ENG/GEN # ENG/GEN # ENG/GEN ENG/GEN

ITEM DESCRIPTION MP # 1 MP # 2 MP # 3

DESCRIPTION #1 2 3 #4 #5

ENGINE SPEED 1.201 1.201 VOLTS 398 392

FREQUENCY 60 60 AMPS 1.118 1.106

VOLTAGE 600 600 SCR BAY # 1 4 3

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 11 of 33

KW 540 525 ASSIGMENT SWITCH Tripping # 1

KVA 870 1.108 SCR BAY LOAD % 69,87 69,12

KVAR 701 979 SPM METER 80 80

AMPS 886 1.144 PRESSURE (PSI) 2500

PF 59,6 47 FLOW (GPM) Not tested

ENGINE LOAD

%

60 75 POWER LIMIT % 52,9

The test starts at 17:20. Test was successful. Maximum power to the engine/generator sets were 75%, working 2 generator units. SCR

bays were not too much loaded.

Load sharing should be adjusted.

MUD PUMPS TEST AT 80 SPM @ 3.000 PSI MP2 & MP3 AT SAME TIME @ 30 Minutes MAR 17-2017

ENGINE/GEN PARAMETERS SCR PARAMETERS

ITEM ENG/GEN ENG/GEN # ENG/GEN # ENG/GEN ENG/GEN

ITEM DESCRIPTION MP # 1 MP # 2 MP # 3

DESCRIPTION #1 2 3 #4 #5

ENGINE SPEED 1.201 1.201 VOLTS 399 395

FREQUENCY 60 60 AMPS 1.274 1.290

VOLTAGE 600 600 SCR BAY # 1 4 3

KW 623 579 ASSIGMENT SWITCH Tripping # 2

KVA 1.121 1.101 SCR BAY LOAD % 79,62 80,62

KVAR 949 930 SPM METER 80 80

AMPS 1.175 1.136 PRESSURE (PSI) 3.123

PF 54,4 52,8 FLOW (GPM) Not tested

ENGINE LOAD

% 94 78 POWER LIMIT % 63,2

The test starts at 18:10. Test was successful. Maximum power to the engine/generator sets were 78%, working 2 generator units. SCR

bays were not too much loaded.

Load sharing should be adjusted.

MUD PUMP TEST AT 90 SPM @ 2.500 PSI MP3 @ 30 Minutes MAR 17-2017

ENGINE/GEN PARAMETERS SCR PARAMETERS

ITEM ENG/GEN ENG/GEN # ENG/GEN # ENG/GEN ENG/GEN

ITEM DESCRIPTION MP # 1 MP # 2 MP # 3

DESCRIPTION #1 2 3 #4 #5

ENGINE SPEED 1.201 VOLTS 401

FREQUENCY 60 AMPS 1.128

VOLTAGE 600 SCR BAY # 3

KW 571 ASSIGMENT SWITCH Tripping # 2

KVA 1.062 SCR BAY LOAD % 70,5

KVAR 894 SPM METER 80

AMPS 1.082 PRESSURE (PSI) 2.596

PF 53,85 FLOW (GPM) Not tested

ENGINE LOAD

%

75 POWER LIMIT % 60,5

The test starts at 18:55. Test was successful. Maximum power to the engine/generator sets were 75%, working 1 generator unit. SCR

bays were not too much loaded.

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 12 of 33

ENGINE/GENERATORS SETS CHECK LIST

SATISFY

ITEM ELEMENT OR PART OBSERVATIONS

YES NO

1 Any fuel leaks

2 Any oil leaks

3 Any strange noise

4 Normal vibration

5 Oil level in the range

6 Water temperature in the range

7 Oil pressure in the range

8 Fuel pressure in the range

9 Engine PM applied All maintenan

10e

routine

s were

Exhaust with thermal protection

applied

.

11 Electrical panels in good condition

12 Label identification of Electrical panels

13 All variables displayed in the control panel

14 Order and cleanliness

extingu

isher in

15 Fire

place

16 Correct identification of the engine/gen units

17 Correct equipment lubrication

18 Rotating equipment with guards installed

19 Ground system connected correctly

20 Electrical installations in accordance with hazardous location

21 Lighting system working properly

22 Safety lines installed on the lighting system

23 Safety signs installed on

24 Emergency lighting working properly Emergency lights installed on

ing

Shut down system was tested locally (in the

properl

25 Shut down system wor engine/gen panel), and remotely (in the drillers

y

console); test was successful.

Pending to fix some plates in the engines room

26 Walking area

floor

27 Exciter in good condition

28 Heaters working properly

29 Magnetic pick up working properly

GENERAL REMARKS:

All engine/gen units are working properly.

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 13 of 33

SCR ROOM CHECK LIST

SATISFY

ITEM ELEMENT OR PART OBSERVATIONS

YES NO

roperly

1 Engine/generator control panels working

2 Correct identification of the engine/gen units

3 HMI showing all system

4 All variables displayed in the control panel

5 Label identification of Electrical panels

6 Order and cleanliness

place

7 Fire extinguisher in

m

connec

ted

8 Ground syst

correct

ly

9 Ground fault indicators working properly

10 Electrical installations in accordance with hazardous locations

11 Lighting system working properly

12 Emergency lighting working properl Tested succesfuly

1

Shut down system working properly

14 Safety signs installed on

15 Doors in good condition

16 Air conditioners working properly

17 Lock/tag out system This systems is followed correctly.

kers

calibrat

18 Power bre

ed

CC in

good

19 conditi

on

20 Insulation mat in good condition

GENERAL REMARKS:

Al engine/generator control panels working properly, all variables are displayed properly.

Main HMI is in good condition.

Drillers console HMI is opaque, as a recommendation, it is necessary to increase the light or to change the HMI.

The Rig PTX 15 has next HPU:

HPU for the manual power tongs Ezy torque system.

HPU for the Top Drive.

HPU for raising/lowering the substructure.

HPU CHECK LIST

SATISFY

ITEM ELEMENT OR PART OBSERVATIONS

YES NO

1 Electric Motors in good condition

2 Hydraulic motors working properly

3 Start/stop station in good condition

4 Electrical installations in accordance with hazardous locations

5 Ground system connected correctly

6 Correct rotation

7 Rotating equipment with guards installed

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 14 of 33

HPU CHECK LIST

8 Any leaks in the unions

9 Any leaks in the valves

10 Any strange noise

11 Normal Vibration

12 Equipment with identification

Depend of the equipment is the pressure, but it

13 Pressure System in the range

is working between 2.0000 to 3.000 PSI.

14 Relief valve calibrated

15 Shut down system working properly Only the TD HPU has shut down system.

GENERAL REMARKS:

HPU for raising/lowering the substructure have worked to raise the substructure, but the rig inspection start after 2 days.

HPU for TD is workin properly.

HPU for manual power tongs is working properly - Ezy torque.

The rig PTX 15 has installed two screw air compressors Atlas Copco model GA30P, each one

with an electric motor 30 kW; each air compressor has the air dryer included. A cold start air

compressor Atlas Copco 21,6 Kw

AIR COMPRESSORS CHECK LIST

SATISFY

ITEM ELEMENT OR PART OBSERVATIONS

YES NO

1 Oil seals in good condition Any leaks were observed.

2 Any strange noise

3 Normal vibration

4 Electric Motors in good condition

5 Hydraulic motors working properly

6 Start/stop station in good condition

7 Electrical installations in accordance with hazardous locations

8 Ground system connected correctly

9 Correct rotation

10 Rotating equipment with guards installed

11 Any air leaks in the unions

12 Any air leaks in the valves Pending to fix drain hose in air compressor # 1.

13 Equipment with identification

14 Pressure System in the range 120 PSI

Pressure control system working properly load regulator

15 The flapper valves close at 120 PSI.

system

16 Relief valve calibrated Relief valves calibrated.

17 Shut down system working properly Tested succesfuly

Updated certifications. 3 air tanks in the air

18 Air tanks in good condition conditioner room an one air tank in the

substructure.

19 Oil levels in the range

Maintenance was followed according with the

20 PM schedule applied

PM.

It is necessary to change a nipple that is welded

21 Air hoses in good condition on - It was changed before to sign the Rig

Acceptance Form.

22 Safety lines installed in the hammer unions The systems doesnt use hammer unions.

23 Air gauges in good condition All gauges working properly.

Dryer system is integrated to each air

24 Dryer system working properly

compressor.

25

General Remarks:

There are two 30-hp Atlas Copco screw type electric air compressors; An air compressor driven by diesel engine Cold air compressor.

The drying system is integrated into each compressor unit.

The compressors were tested for loading with empty tanks as follows:

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 15 of 33

AIR COMPRESSORS CHECK LIST

The air compressor endurance test was satisfactory.

Summary of Findings:

Floor plates between engine skid # 1 and air compressor skid arent installed

completely.

Top Drive control receptacle was dismounted; 2 cables in going inside the hole.

Cable trays have not installed completely the covers.

Cord grips not installed in the wall cabinets.

Cover of the power generator cables is not installed correctly.

Back up diesel engine Exhaust has not installed the thermal protector.

Cord grips not installed in the power transformer.

Fluorescent Light in the SCR plug panel board is broken.

Control and power cables have the wire outside from the cord grip.

Plug panel board without plate in spare place.

Power cables in the plug panel board without insulation boots.

External wires additional to the control wire of the cables are running in parallel with

the control cable.

Some ground connections are loose.

Suggestions:

All plates should be installed to avoid some incident. It was corrected.

Cables should be connected in its receptacle; the top drive cabin should be sealed.

All cover should be installed to avoid some incident.

If some hole is not used, it should be. It was corrected.

The cover should be installed correctly. It was corrected.

All hot surfaces should have installed the thermal protector.

If some hole is not used, it should be. It was corrected.

The cover should be changed.

All wire cables should be inside the plug barrel.

A plate should be installed on.

All connectors should have the insulator installed.

If the control cable has no more spares, it is better to install another cable with

additional spare cables.

To tight the loose connections.

ITEM 8. Fire Protection

General/Back Ground:

The rig PTX 15 has installed the firefighting equipment around the rig and the camp; all types

are correctly distributed. PTX has generated a Service Order, to do Maintenance to all

firefighting equipment.

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 16 of 33

The rig PTX 15 has as additional firefighting equipment a water & foam pump, powered by a

diesel engine.

All elements are in good condition. The water pump was not tested.

Summary of Findings:

Main camp alarm has not the battery installed.

Suggestions:

Battery should be installed before to start the operations.

ITEM 9. Fuel & Other Flamable Liquid Storage Tanks, Including Frack Tanks & Non-

Flamable Storage Tanks

General/Back Ground:

The rig has three diesel tanks, each one with a capacity of 12.600 Gls. Only two diesel tanks

were installed in this well. A daily tank was disconnected in this project.

Summary of Findings:

N/A

Suggestions:

N/A

ITEM 10. Pipe Rack Area

General/Back Ground:

More than two sets of pipe racks were advised in the location.

Summary of Findings:

N/A

Suggestions:

N/A

ITEM 11. Blow-Out Preventers

General/Back Ground:

The well control Equipment of Petrex Rig 15 is in good condition. The rig has an Accumulator

with 8 stations; 8 bottles (of 11 gals each one) only for the blind-shear station powered by 2 air

pumps. The main system has 42 bottles of 11 gals each one, powered by two electric motors

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 17 of 33

20 HP (only one at same time-one, it works as back up), and three air pumps.

The rig has a BOP 13 5/8 *10 K arranged as follow:

Annular Cameron 13 5/8 * 10 K

Single Ram BOP T3 13 5/8*10 K

Double Ram BOP T3 13 5/8*10 K

Drilling Spool 13 5/8* 10K with outputs 4 1/16*10 K and 2 1/16*10 K

BOP arrangement was tested successfully.

BOP TEST CHARTS:

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 18 of 33

ACCUMULATOR CHECK LIST

SATISFY

ITEM ELEMENT OR PART OBSERVATIONS

YES NO

1 Pneumatic pumps working properly

2 Guards installed

valve

calibra

3 Relief Calibrated at 3.500 PSI

ted

4 Y strainners in good condition

5 Air pressure supply in the range

6 Lube oil and water separator installed

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 19 of 33

ACCUMULATOR CHECK LIST

7 Air gauges installed

8 Air tanks in good condition

9 Triplex pump

he

plunge

10 Any leaks in

rs

11 AC Electric Motor

12 Chain/belt tight

13 Guards installed onbelts/chain

14 Pressure switch calibrated

15 Hydraulic lines without leaks

16

essure

17 Bottles with the Pre-charge NI p

with

updat

ed

18 Bottle NDT

inspec

tions

19 Valves in the bottles in good condition

20 Bottles bank in good condition

21 Valves in the bottles bank in good condition

on

22 Bottles bank Needle released valve in good condit

in

good

23 Bank gauge conditi

on

24 4 ways valves in good condition

25 Manifold regulator valve in good condition

26 Annular regulator valve in good condition

ion

27 Regulator valve of the annular regulator valve in good condi

gulato

r valve

in

28 Annular R good

conditi

on

29 Shear/blind Rams valve protected again involuntary actions

30 Accumulator gauges calibrated

31 Maintenance according with the PM

s

32 Quickly connection in the hose connectio

conditi

33 Dam in good on

34 Metalic protection in the hydraulic hoses

35 Hydraulic hoses protected in the trays

36 Alarms Panel in good condition

37 Remote controls working properly

38 Lighting system in good conditio

39 Ground syste

conne

cted

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 20 of 33

ACCUMULATOR CHECK LIST

Notes:

Start and stop pressures of the electric and pneumatic pumps were tested; Electric pumps start at 2,700 PSI and stop at 3,000 PSI; Pneumatic pumps

start at 2,650 PSI and stop at 2,950 PSI. Equipment according with the API Spec 53

The charging times of the accumulator were as follows:

Electrical System: Operating the two electric pumps and loading the 8 hydraulic banks, the accumulator charge time is 7'21 ".

Hydraulic System: Operating the three pneumatic pumps and loading a single hydraulic bank, the accumulator charge time is 6'14 ".

Operating the three pneumatic pumps (from 2,300 PSI only operated two pneumatic pumps), and loading the 8 hydraulic banks, the charge time of the

accumulator is 50'35 "- note: It is necessary to keep in mind that this time is done Very long due to the amount of bottles that you have to fill, then it is

not a deviation.

Electrical and pneumatic system: The two electric pumps and the three pneumatic pumps operate, and the 8 hydraulic banks are loaded, the battery

charge time is 6'18 ".

Pneumatic pumps were tested for Shear / Blind (5000 PSI system); The stop pressure of the pumps is at 4,150 PSI; The pumps start at 3,800 PSI; The

pressure is regulated to 1,500 PSI for Shear / Blind Rams. Load time up to 4,150 PSI was 10'34 ".

Tests satisfactory so far.

Summary of Findings:

Accumulator hydraulic oil is emulsified.

Connector used in the Accumulator control cable is too small compared with the cable

size.

Drain valve of the accumulator dam has not installed the plug.

Suggestions:

To check the oil, and check the use time, in order to do a plan to change.

Connectors should have the correctly size according with the cable they will use.

Drain valves should have installed the plugs in order to avoid nvoluntary operations.

ITEM 12. Derrick & Substructure

General/Back Ground:

Crown Cluster sheaves with 6 sheaves 60 each one inspected. 1 Sheave 60 for dead line.

Capacity 1.000.000 Lbs., Line Size 1 3/8. Crown manufactured by Drillmec. The Crown

looks in good condition; it has inspection level IV, done in 31/10/2016 inspected by NOV -

PLL 048-15 and level III done in 30/09/2015 inspected by SAIS-PTX-0033-311016

CROWN CHECK LIST

SATISFY

ITEM ELEMENT OR PART OBSERVATIONS

YES NO

1 Hand rails in good condition

2 Strobe light working properly

As an observation, Petrex has a

procedure to the lightning rod

3 Lightning rod in good condition connection, they dont use cable to

connect the lightning rod with the

ground, they use the structure as

4a

cond

uctor Sheaves with the cable protector installed correctly

.

5 Sheaves in good condition

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 21 of 33

CROWN CHECK LIST

6 Crown Bumper installed correctly

7 Crown block welding in good condition

8 Updated NDT inspections

n

good

9 Grease points and hoses condi

tion

NOTES:

When the inspection stars, the derrick was raised two days before, so all visual inspection was done by pictures taken.

As main recommendation for the future, is that the inspection should start before to raise the mast, in

rder to check many important parts of the rig.

The Derrick was Manufactured by Drillmec, static hook capacity 1.000.000 Lbs. with 12 lines;

Height 147 ft. Serial number 405-M01-01. it has inspection level IV, done in 15/04/2008 by

Drillmec the manufacturer, and level III done in 30/09/2015 done by NOV PLL 036-15

DERRICK CHECK LIST

SATISFY

ITEM ELEMENT OR PART OBSERVATIONS

YES NO

1 Fluorescent & flood lights in good condition Strobe light is working properly.

2 Fluorescent & flood lights with Safety lines installed on Lighting system in good condition.

3 Racking platform (Monkey board) in good condition

4 Anti-slip tape in the fingers

5 Racking platform Air Winch in good condition

6 Racking platform cable Air Winch in good condition

7 Rod Hangers

8 Hand rails of racking platform in good condition

9 Loosen parts

10 Stabbing board in good condition

11 Stabbing board Winches in good condition

12 Stabbing board cable Air Winch in good condition

13 Stabbing board Raising system in good condition

14 Ladders in good condition Protected, in good condition.

15 Safety line to climb to the derrick in good condition 2 guys can go up at same time.

16 All pins in good condition

17 All pins installed correctly

18 All pins with safety pin installed on

19 Derrick name plate installed on

20 Updated NDT inspections NDT updated.

21 Raising sheaves in good condition

22 Raising line in good condition

It was installed the last day of the rig

23 Scape system installed correctly inspection, to avoid problem with the

helicopter.

24 Signs posted in the area

NOTES:

When the inspection stars, the derrick was raised two days before, so all visual inspection was done by pictures taken.

As main recommendation for the future, is that the inspection should start before to raise the mast, in order to check many important parts of the

rig.

Substructure manufactured by Drillmec, Maximum static rotary load capacity 1.000.000 Lbs.,

setback capacity 600.000 Lbs., Total capacity 1.600.000 Lbs.; Height 30 Ft, Includes a

parallelogram type, raising system powered by two (2) hydraulic winches operating two (2)

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 22 of 33

sets of six (6) part raising lines, one (1) hydraulic power unit complete with remote control

panel, gauges, hoses and fittings and two (2) hydraulic break-over rams.

SUBSTRUCTURE CHECK LIST

SATISFY

ITEM ELEMENT OR PART OBSERVATIONS

YES NO

1 Shoes, pedestal or pivots in good condition

2 Holds

3 pins

4 Safety pins installed correctly

5 Support beams in good condition

6 Rotary beams in good condition

7 Substructure name plate installed on

8 Lighting system in good condition

9 All light with the safety line

10 Ladders in good condition

11 Order y cleanliness

12 Updated NDT installed

13 Raising system in good condition

14 Skidding system in good condition

15 Raising eyes in good condition

16 Set back Wood in good condition

17 Rig floor in good condition

18 Signs posted in the area

NOTES:

When the inspection stars, the derrick was raised two days before, so all visual inspection was done by pictures taken.

As main recommendation for the future, is that the inspection should start before to raise the mast, in order to check many important parts of the

rig.

The rig has Catwalk manufactures by Canrig, Mod PC3000-26-A-A-A-N-S, Max capacity

10.000 Lbs, S/N 300440, 600 Vac.

CATWALK CHECK LIST

SATISFY

ITEM ELEMENT OR PART OBSERVATIONS

YES NO

Original pipe rack cylinders were not

1 DS pipe racks working properly (up&down)

installed

Original pipe rack cylinders were not

2 ODS pipe racks working properly (up&down)

installed

3 DS Indexers working properly

4 ODS Indexers working properly

5 DS safety pin working properly

6 ODS safety pin working properly

7 DS kickers working properly

8 ODS kickers working properly

9 Skate working properly

arrier

worki

ng

10

prope

rly

11 Skate Cable in good condition Pending to lubricate the cable.

12 Drum cable in good condition Pending to lubricate the cable.

13 Safety sensors working properly All sensors were tested properly;

press

14 Hydrauli ure 3.100 PSI

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 23 of 33

CATWALK CHECK LIST

15 HPU working properly

A calibration of the stop points was

16 Catwalk frame in good condition

done.

17 Electrical Junction Boxes in good condition

18 Master control unit in good condition

e

contro

l in

As a recommendation, it is necessary to

19 Wireless Remo good

install a harness.

condi

tion

NOTES:

Encoder was changed; At the beginning the electricians had trouble to start the catwalk, but they can fix it.

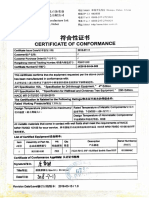

The Rig Petrex PTX 15 uses a drilling cable with a size 1- 3/8, Type 6x19S IWRC; the drilling

cable looks in good condition, any crush, any broken rows. New cable was installed on

15/11/2016. As a suggestion, is to install a roof in the drilling cable skid. Compliance

certificate attached.

The raising cable has 3,5 times raising and lowering the derrick. Petrex has a standard, to

use 10 times complete cycle, raising and lowering. The cable looks in good condition, has

compliance certificate; they will inspect the eyes after the third complete cycle.

The dead line anchor is manufactured by Hecules, model 120 T, with load cell sensor E551; It

was tested with the Pason Instrumentation system.

Summary of Findings:

Slack line detector air valve of the Man rider winch is not working properly.

Suggestions:

To adjust the air valve of the Slack line detector.

ITEM 13. Drill Floor Area

General/Back Ground:

The Drawworks National Mod 1320 UE, powered by 2 DC traction motor Joliet/C75ZB, each

one 1.000 HP, Drum size (diameter x length): 30 x 56 ; Grooved Drum type, with Brake

bands and auxiliary electric brake, El Magco Electric Eddy Current Brake, model 7040W,

manufactured by NOV, S/N ND114880W, Max RPM 600, Min Coolant flow rate 140, Max

input DC Voltage 250, Max input Amperage 78. The rig has not backup power system for El

magco Baylor Mod 7040. This system has not the backup power system.

DRAWWORKS CHECK LIST

ITEM ELEMENT OR PART SATISFY OBSERVATIONS

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 24 of 33

DRAWWORKS CHECK LIST

YES NO

1 Move up

2 Move down

3 Updated NDT inspection (brake bands, linkage, ring brakes, equalizer bar, etc)

4 DW transmission working properly (4 speeds)

5 DW working in all assignments

DWA Works in reverse only in

6 DW working in forward & reverse

tripping assignment.

7 Drum in good condition

8 Cathead working properly

9 Wear ring brakes and brake pads New pads installed

10 Wear linkages

11 Wear kick back rollers

12 Enough wraps on drum

13 Enough spare drill line

14 Lube oil pump working properly

15 Lube system without leaks

16 Oil gauges working properly

17 Air pressure gauges working properly

Pending to show the last analysis

18 Oil samples/ analyze frequency

taken.

19 Oil nozzles working properly

20 Chain in good condition

21 Chain lubrication properly

22 Wear on sprockets

23 Emergency brake working properly N/A

Two systems are installed; the

mechanical and the electronic

system. The mechanical system

breaks at 102% of the high calibrated

(only works when move up). The

24 Rig & floor saver system calibrated & working properly - Anti-collision System

electronic systems breaks at 100 %,

and show alarm at 90 %. When

move down, the alarm start at 10 %

of the high, and stop at 0% (around 5

).

25 Drawworks name plate installed on

26 Traction motors working properly

27 Traction motors couplings in good condition

Pending maintenance

28 Updated Maintenance to the DW

documentation.

Pending maintenance

29 Updated Maintenance to the traction motors

documentation.

30 Blowers working properly

31 Air intake filters installed on blowers suction

32 Insulation Resistance of traction motors Pending instrumentation registers.

33 Lighting system working properly

34 Fluorescent lights with Safety lines installed on

NOTES:

DW was tested successfully; all speeds work properly, the cathead, the inertia brake, etc.

As a recommendation, is to take care with the covers (to install good seals), in order to avoid that water go inside, and get mix with water.

ELECTRIC BRAKE CHECK LIST

ITEM ELEMENT OR PART SATISFY OBSERVATIONS

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 25 of 33

ELECTRIC BRAKE CHECK LIST

YES NO

Test successfully; Brake stop

1 Baylor brake working properly

completely the block.

2 Baylor brake Water flow

Air Gap Angle positions:

00 .0520 .040 .0450 .0590 .050 .05 = Prom 0,0493

Baylor brake gap 900 .040 .050 .0540 .040 .0560 .05 = Prom 0,0483

1800 .050 .050 .040 .050 .040 .05 = Prom 0,0466

3 Average Rotor Radial Clearance (Air Gap) Over Magnets (Without Paint or Other Build up), 2700 .040 .0530 .0590 .040 .0590 .046 = Prom 0,0495

in (mm) - 0.055-0.065 (1.397-1.651) Baylor Brake Model 7040 Specs 00 .0450 .0420 .0450 .050 .0450 .05 = Prom 0,0461

Total Prom = 0,048425 - The gap is below the maximum

according with the model specs.

4 Cooling system pumps working properly

Alarms were tested and simulated

5 Alarms of cooling system working properly

properly.

6 Relief valve calibrated properly

7 Electrical Junction Boxes in good condition

8 Joystic control working properly

F1-F31 4.07 Ohm >550

coils F2-F41 2.42 Ohm >550

9 Insullation resistanc F5-F71 4.07 Ohm >550

F6-F81 2.42 Ohm >550

10 Wiring system

11 Control system working properly

12 Operation at 50% when full position joystick Was tested successfully.

king

prope

13 Transformer wo

rly

14 Insulation resistance of transformer

15 Updated Maintenance

16 Baylor Brake name plate installed on

17 Air Clutch working properly N/A

18 Mechanical engage working properly Was tested properly.

wer

syste

19 Back up p This rig has not this system.

m

NOTES:

Control was tested without problems.

Two air winches Ingersoll Rand, each one with a capacity of 10.000 Lbs Ingersoll Rand,

models FA5A.

AIR WINCHES CHECK LIST

SATISFY

ITEM ELEMENT OR PART OBSERVATIONS

YES NO

1 Move up

2 Move down

3 Up&down labels stamped on

4 Shut of valve supply

5 Oil leaks and air leaks

6 Winch handle control returns to central position

7 Block to Handle system

8 Manual Brake system in good condition

Protective cage installed

10 Spooling cable device installed

11 Correct spooling cable

12 Condition of foundation bolts

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 26 of 33

AIR WINCHES CHECK LIST

13 Noise dampeners air exhaust installed

14 Condition of snatch-blocks

15 Cable condition

1

SWL indicator

17 Swivel installed in the end of cable

18 Cable running free in the derrick

19 Lube and water separator installed

20 Air Hose and air pipes in good condition

NOTES:

The ODS air winch has not the auxiliary manual brake installed, but it is not a deviation.

Slack line detector air valve of the Man rider winch is not working properly.

The rig PTX has a Top Drive Canrig Mod 1250AC-681, 1200 HP, 500 Tons, maximum torque

51.400 Lb-Ft, Continuous Torque Rating 51 400 ft-lb (69 700 Nm) @ 120 RPM , Maximum

Speed Rating 23 500 ft-lb (24920 Nm) @ 265 RPM, Brake Capacity 50 000 ft-lb 67 800 Nm,

Maximum Electric Motor Torque (Make-Up Limit is operator adjustable) 71 000 ft-lb 96 300

Nm, Torque Boost Torque Make-Up 24 000 ft-lb 32 500 Nm and Break Out 37 500 ft-lb 50

800 Nm, Quill Connection 6-5/8 Reg., Circulating Pressure Rating Standard 7.500 PSI,

electric motor GE B20 AC, 1 120 Amps, 690 VAC, 0 - 140 Hz; Hydraulic Power Unit Model

1220 Twin.

TOP DRIVE CHECK LIST

SATISFY

ITEM ELEMENT OR PART OBSERVATIONS

YES NO

1 Blower working properly

2 HPU # 1 working properly Work pressure at 2.300 PSI

3 HPU # 2 working properly Work pressure at 2.300 PSI

4 Electrical service Loop in good condition

5 Hydraulic service Loop in good condition

6 Lube pump working properly

7 Lube oil cooler working properly

8 Left rotation of handler

9 Right rotation of handler

10 Handler lock working properly

Spin rotation was set at 20 RPM and 30

11 Left rotation of the Spin

RPM in the HMI, working properly

12

Right rotation of the Spin

13 Break working properly

14 Links Extent

15 Links retract

16 Links float

17 Open LWCV

18 Close LWCV

19 Torque boost left rotate

20 Torque boost right rotate

21 BUWG up

22 BUWG down

23 Close Wrench Gripper Dies in good condition

24 Open Wrench Gripper

25 Drilling torque in the console

26 Drilling torque in the HMI

27 Electric Torque - Make up The make-up torque was set at 43.000

Lb-Ft; First the make-up was at 33.000

Lb-Ft, and after was tight at 43.000 Lb-

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 27 of 33

TOP DRIVE CHECK LIST

Ft.

It was tested with the initial make-up

28 Electric Torque - Break out torque; the break out was at 33.000 Lb-

Ft.

29 Hydraulic torque - Make up

Break

30 Hydraulic torque - out

31 Break working properly The break was tested at 35.000 Lb-Ft.

TD was rotating at 170 RPM. Any

32 RPM TD in HMI

strange noise.

33 BUWG Interlock with the DW Clutch TD as not this interlock.

h

34 Links interlock with the DW clut TD as not this interlock.

GENERAL REMARKS:

All test was successful

Pending to change the Hydraulic Service loop.

The Rig PTX 15 has rotary table National 37 , powered by DWA, 1.000 HP, Maximum

torque 35.000 Lb-ft, with master bushing Varco, Insert bowl N 1 (13- 3/8" & 11- 3/4"), N2

(10- 3/4" & 9- 5/8") and N3 (8- 5/8" & smaller).

Summary of Findings:

Joystick without the boot protector.

Slack line detector air valve of the Man rider winch is not working properly.

Suggestions:

To install new boot protector or to change the joystick, in order to protect the selector

against the rain.

To adjust the air valve of the Slack line detector.

ITEM 14. Power and Hand Tools

General/Back Ground:

The rig PTX 15 has a hydraulic wrench Hawkjaw model 100K-2GSR; it was tested making up

and breaking the drill pipe. Equipment working properly.

The rig PTX 15 has a set of manual power tongs HT-100; the manual power tongs were

tested making up and breaking with 40.000 Lb-Ft. Equipment working properly.

Summary of Findings:

N/A

Suggestions:

N/A

ITEM 15. Hoisting Tools, Hooks, Bails, Elevators and Other Related Equipment

General/Back Ground:

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 28 of 33

All Tools required for the operation are organized in the tool box. All tools were inspected

prior to start the last well, and for use time, they have less than 6 months, so they dont neet

to be inspected for this well.

Summary of Findings:

N/A.

Suggestions:

N/A

ITEM 16. Stairs, Ladders, Handrails & Guardrails

General/Back Ground:

The rig has the ladders and hand rails in good condition.

Summary of Findings:

N/A

Suggestions:

N/A

ITEM 17. Carrier Unit (N/A)

General/Back Ground:

N/A

Summary of Findings:

N/A

Suggestions:

N/A

ITEM 18. Hotwork, Welding & Flamable Cutting Operations

General/Back Ground:

Welding area is in good condition; all electrical parts are in good condition.

Summary of Findings:

Cutting hose is twisted.

Suggestions:

To change the cutting hose.

ITEM 19. Specific Operations (N/A)

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 29 of 33

General/Back Ground:

N/A

Summary of Findings:

N/A

Suggestions:

N/A

ITEM 20. Confined Spaces, Excavations & Hazardous Environments (N/A)

General/Back Ground:

N/A

Summary of Findings:

N/A

Suggestions:

N/A

ITEM 21. Perforating Operations and Use of Explosives (N/A)

General/Back Ground:

N/A

Summary of Findings:

N/A

Suggestions:

N/A

ITEM 22. Special Services (N/A)

General/Back Ground:

N/A

Summary of Findings:

N/A

Suggestions:

N/A

ITEM 23. Environmental Aspects

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 30 of 33

General/Back Ground:

Petrex has the procedure to handle the hazardous materials; it is the Petrex procedure WI-

PTX-HSE-1124

Petrex environmental management system, developed on the basis of ISO 14001, serves to

guide and channel it declared environmental commitments in Petrex HSE Policy. The main

environmental commitment of Petrex is the prevention of pollution of the environment,

translated into the identification of environmental aspects and the identification of control

measures to mitigate the potential impacts.

Environmental campaigns have proved to be an effective means to translate the

environmental commitments in real form by raising the environmental awareness of a specific

issue by which Petrex seeks to generate certain behaviors in their collaborators.

Inter-drill competition called "Green Drill" is an initiative that promotes the participation of all

employees, and is oriented to maintain clean and orderly work environments.

Summary of Findings:

Water leaks in the Rig battery bathroom.

Camp engine has not dam installed.

Suggestions:

All leaks should be corrected, in order to keep low water consumption.

To build the dam to the camp engine.

ITEM 24. Quality Aspects

General/Back Ground:

Petrex SA has developed a Quality Management System for all its South American

operations. This is certified in ISO 9001, by TV Rheinland with reach to the headquarters of

Peru, Venezuela, Colombia and Bolivia.

The Quality Management System of Petrex S.A. Is a key instrument for the efficient

management of the processes of Petrex S.A. And serves them to ensure the satisfaction of

their customers and to meet the relevant requirements of the interested parties.

The Quality Policy of Petrex S.A. Is approved by the Managing Director and is revised

whenever necessary in order to guarantee its suitability.

Summary of Findings:

N/A

Suggestions:

N/A

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 31 of 33

ITEM 25. Rig Inspection

General/Back Ground:

The purpose of any Rig acceptance is to ensure that the contracted Rig is able to perform the

drilling and / or workover program safely, efficiently, and cost effectively.

The rig inspection was conducted in good shape and order, getting all information of each

asset, like maintenance, inspection certificates, tests, etc. done to each one.

All information required was supplied by The Rig Manager Assistant and the HSE Guy.

Al rig inspection certificates were updated, due that the last NDT rig inspection was done 3

months before.

For this purpose, load tests and verification of critical safety and operating systems will be

developed on the Rig PTX 15. During this process, attempts were made to simulate the

drilling conditions as closely as possible to ensure the effective operation of the systems in

accordance with the contracted requirements.

Summary of Findings

All findings can be checked in the photographic report; Just an item with a priority of 2

level was founded; it is the fault in the man rider air winch.

Suggestions:

To solve the main deviation founded in the rig inspection.

OVERALL CONCLUSIONS

The Rig is in good condition; it was performed stress tests, which were satisfactory, obtaining

a maximum load for the system of 63%, being able to say that the drill is in capacity to

develop the SAGARY 4XD well, object of the contract between Repsol and Petrex.

Distribution Attachments Inspectors Signature

XXXXXXXXXXX NCRs, Observations,

Inspection Program,

attendance list

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 32 of 33

JJVESGA

Organization Title/Subject Number

Intertek Industry Services Summary Inspection Report of the Rig IM-CO-FO-88

Owner Approved by Date Revision Page

Arnol Caldern Hugoberto Alcazar 08/02/2016 B 33 of 33

S-ar putea să vă placă și

- Section 4 - SLB GUIDELINE - Attachment 14 - SLB Rig Acceptance CriteriaDocument34 paginiSection 4 - SLB GUIDELINE - Attachment 14 - SLB Rig Acceptance CriteriaWilson RiveraÎncă nu există evaluări

- Inspection of The Mast and SubstructureDocument18 paginiInspection of The Mast and Substructurecmrig74Încă nu există evaluări

- ERP Travelling Block - Hook BlockDocument9 paginiERP Travelling Block - Hook BlocknobodymagdesignÎncă nu există evaluări

- Idc 37 Rig Move PlanDocument15 paginiIdc 37 Rig Move PlanKarim Lehtihet100% (1)

- Rig Personnel Job DescriptionsDocument6 paginiRig Personnel Job DescriptionsKachur Aleksey100% (1)

- Arabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasingDocument6 paginiArabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasinginfonexusÎncă nu există evaluări

- Rig InventoryDocument17 paginiRig Inventorysaa6383100% (1)

- API5b Changes in 16th EditionDocument4 paginiAPI5b Changes in 16th EditionMostafa FikryÎncă nu există evaluări

- Rig Manager Pre-Rig-Move Check List Sea Boss Move No:: Task To Be Performed: InitialsDocument1 paginăRig Manager Pre-Rig-Move Check List Sea Boss Move No:: Task To Be Performed: Initialssaeed ghafooriÎncă nu există evaluări

- Sop Iii-306 R00Document23 paginiSop Iii-306 R00Bepdj100% (1)

- Pick Up Drill PipeDocument5 paginiPick Up Drill PipeinfonexusÎncă nu există evaluări

- Arabian Drilling Company Rig Specific Procedure AD - 32 Pick Up Drill PipeDocument4 paginiArabian Drilling Company Rig Specific Procedure AD - 32 Pick Up Drill Pipehosam aliÎncă nu există evaluări

- Floorman-Tasks & ProjDocument9 paginiFloorman-Tasks & ProjAmeerÎncă nu există evaluări

- Halliburton Pre-Spud ChecklistDocument10 paginiHalliburton Pre-Spud ChecklistLijo JohnÎncă nu există evaluări

- Rig Move Procedures DevelopmentDocument31 paginiRig Move Procedures DevelopmentCarlos Santos100% (1)

- Drilling Rig Inspection Checklist: (Day) (Month) (Year)Document3 paginiDrilling Rig Inspection Checklist: (Day) (Month) (Year)Dusty PinkÎncă nu există evaluări

- Naveed Comp Super CVDocument4 paginiNaveed Comp Super CVAnonymous XZ6MogÎncă nu există evaluări

- Rig Inspection & SurveyDocument102 paginiRig Inspection & SurveyhshobeyriÎncă nu există evaluări

- Land RigDocument11 paginiLand RigLala KamarudheenÎncă nu există evaluări

- Handrill - Training Matrix - Drilling CrewsDocument2 paginiHandrill - Training Matrix - Drilling Crewsnashrul_izzuanÎncă nu există evaluări

- 7.1 Inspection TeamDocument70 pagini7.1 Inspection TeamWalid BdeirÎncă nu există evaluări

- Mast and Dwks Lowering ChecklistDocument5 paginiMast and Dwks Lowering Checklistjinyuan74Încă nu există evaluări

- Drilling Rig Checklist Rev1Document29 paginiDrilling Rig Checklist Rev1Abdulsani3357Încă nu există evaluări

- SPDC Standard Drilling Procedures Manual Site: CHA Pter 07Document39 paginiSPDC Standard Drilling Procedures Manual Site: CHA Pter 07Agaba Idu100% (1)

- Well Handover CertificateDocument1 paginăWell Handover Certificateeng7mohamed7hashimÎncă nu există evaluări

- Attachment D Pre Rig Move ChecklistDocument2 paginiAttachment D Pre Rig Move ChecklistJennifer WangÎncă nu există evaluări

- EPHH-GPC-Final Report-Nationa Rig & Stack equip-V2-SignedDocument65 paginiEPHH-GPC-Final Report-Nationa Rig & Stack equip-V2-SignedAmir100% (1)

- Mast and Dwks Raising ChecklistDocument4 paginiMast and Dwks Raising Checklistjinyuan74Încă nu există evaluări

- Rig Inspection Workshop: Land Rigs, Platform Rigs and Jack-Up RigsDocument2 paginiRig Inspection Workshop: Land Rigs, Platform Rigs and Jack-Up Rigsjohangomezruiz100% (1)

- Wellsite Leader Checklist Rig # 41Document3 paginiWellsite Leader Checklist Rig # 41IgorCencičÎncă nu există evaluări

- Job Description - Senior Drilling SupervisorDocument1 paginăJob Description - Senior Drilling SupervisorYougchu Luan100% (1)

- Man-Riding Checklist - OHSE-PR-010-FM-01-03 (002) 1Document1 paginăMan-Riding Checklist - OHSE-PR-010-FM-01-03 (002) 1cmrig740% (1)

- 9.1.4 Admasco Rig Move Procedure PDFDocument52 pagini9.1.4 Admasco Rig Move Procedure PDFkhaled100% (2)

- Tesco Corporation: Unit #: Date: Operating DaysDocument1 paginăTesco Corporation: Unit #: Date: Operating Daysboy tryadiÎncă nu există evaluări

- 02 - FIP CT M PC 10.2 2009feb11 ExtDocument4 pagini02 - FIP CT M PC 10.2 2009feb11 ExtKarla HernandezÎncă nu există evaluări

- Saudi Aramco Telecom Equipment InstallationDocument5 paginiSaudi Aramco Telecom Equipment InstallationaymenmoatazÎncă nu există evaluări

- Classification of Drilling EquipmentDocument32 paginiClassification of Drilling EquipmentJose BarreroÎncă nu există evaluări

- ! BOP Failure Presentation - 1473859760 - 2Document23 pagini! BOP Failure Presentation - 1473859760 - 2toxa0707Încă nu există evaluări

- TDM 100 Mechanical Systems Manual Revision March 2010Document63 paginiTDM 100 Mechanical Systems Manual Revision March 2010Chaouki BoukhamlaÎncă nu există evaluări

- Drill Pipe Float Valves, Pullers, Baffle Plates & Float Subs GuideDocument27 paginiDrill Pipe Float Valves, Pullers, Baffle Plates & Float Subs GuideKeshav Pujeri100% (1)

- Eye Bolt Inspection Report: Last of ExaminationDocument7 paginiEye Bolt Inspection Report: Last of ExaminationRonniÎncă nu există evaluări

- Rig Stacking Strategies for Long Term LayupDocument14 paginiRig Stacking Strategies for Long Term LayupJeril PhilipÎncă nu există evaluări

- SLB Land Rig BRDocument9 paginiSLB Land Rig BRIkhwan100% (1)

- Floor Man Written ExamDocument8 paginiFloor Man Written ExamAboZaidÎncă nu există evaluări

- Rig Handling and Installation Procedure DALIADocument269 paginiRig Handling and Installation Procedure DALIACarlos Gloogh100% (1)

- Responsibilities of Rig Superintendent StudyDocument7 paginiResponsibilities of Rig Superintendent StudyAnonymous VNu3ODGavÎncă nu există evaluări

- Rig Move Plan TO ABHD 155 AD-68Document20 paginiRig Move Plan TO ABHD 155 AD-68yousef nÎncă nu există evaluări

- Audit Report Century 14 Rev 1Document51 paginiAudit Report Century 14 Rev 1agusnurcahyo66Încă nu există evaluări

- Training Requirements - Rig Inspection ChecklistDocument4 paginiTraining Requirements - Rig Inspection ChecklistAchraf Ben DhifallahÎncă nu există evaluări

- Mobile Rigs - The Core of Drilling InnovationDocument9 paginiMobile Rigs - The Core of Drilling InnovationIkhwanÎncă nu există evaluări

- International Limited International Limited: JC JCDocument5 paginiInternational Limited International Limited: JC JCMichael OkwuwaÎncă nu există evaluări

- TubestarDocument29 paginiTubestarPernando Saga100% (1)

- Baoji Engineering YM-16IIF Hydraulic Cathead Operations ManualDocument22 paginiBaoji Engineering YM-16IIF Hydraulic Cathead Operations ManualDhrubajyoti BoraÎncă nu există evaluări

- Safety Alert: From The International Association of Drilling ContractorsDocument1 paginăSafety Alert: From The International Association of Drilling ContractorsJohnHynesÎncă nu există evaluări

- Checklist (For Any Land Rig)Document13 paginiChecklist (For Any Land Rig)Kachur AlekseyÎncă nu există evaluări

- DDZ Series Elevator Wear Data RutongDocument2 paginiDDZ Series Elevator Wear Data RutongIsrael AyllonÎncă nu există evaluări

- IM-CO-FO-88 SUMMARY INSPECTION REPORT OF THE RIG PIONEER 53 - CANACOL OCT 2018 - RevDocument28 paginiIM-CO-FO-88 SUMMARY INSPECTION REPORT OF THE RIG PIONEER 53 - CANACOL OCT 2018 - RevJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- D6255-SIR FormatDocument4 paginiD6255-SIR Formatnisha_khanÎncă nu există evaluări

- Synthetics Rubber Indonesia Pile InspectionDocument2 paginiSynthetics Rubber Indonesia Pile InspectionDenny SyafwalufiÎncă nu există evaluări

- Certificate of Conformance FZ35-70-13 5-8" - 10000 Psi Double Ram BOP SERIAL - 01180046CDocument1 paginăCertificate of Conformance FZ35-70-13 5-8" - 10000 Psi Double Ram BOP SERIAL - 01180046CJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Mud Pump PartsDocument84 paginiMud Pump PartsGhinet Teodor-ioanÎncă nu există evaluări

- Mud Pump Parts ExpendablesDocument82 paginiMud Pump Parts ExpendablesAnonymous Yo43Kif0Încă nu există evaluări

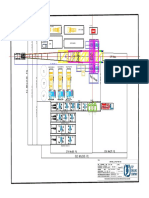

- 1.layout Rig 1503 Meters - Dos Mud Pump-ModeloDocument1 pagină1.layout Rig 1503 Meters - Dos Mud Pump-ModeloJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- 1.layout Rig 1503 Five Mud TanksDocument1 pagină1.layout Rig 1503 Five Mud TanksJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- 1.layout Rig 1503 Meters - Dos Mud Pump-ModeloDocument1 pagină1.layout Rig 1503 Meters - Dos Mud Pump-ModeloJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Rig 1503 Structure - Skidding System-Layout1Document1 paginăRig 1503 Structure - Skidding System-Layout1JUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Rig 1503 Structure - Skidding System-Layout1Document1 paginăRig 1503 Structure - Skidding System-Layout1JUAN JOSE VESGA RUEDAÎncă nu există evaluări

- IM-CO-FO-88 SUMMARY INSPECTION REPORT OF THE RIG PIONEER 53 - CANACOL OCT 2018 - RevDocument28 paginiIM-CO-FO-88 SUMMARY INSPECTION REPORT OF THE RIG PIONEER 53 - CANACOL OCT 2018 - RevJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Fa150Kg and Fa150Kgi Series Man Rider Air Winch: Conversion KitDocument4 paginiFa150Kg and Fa150Kgi Series Man Rider Air Winch: Conversion KitJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Deep Sea 4120 ManualDocument30 paginiDeep Sea 4120 Manualw.priatmadi100% (1)

- Force Five Infinity Air WinchesDocument40 paginiForce Five Infinity Air WinchesJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Mud Gas Separator Poor Boy Degasser - Well Control - Netwas Group OilDocument6 paginiMud Gas Separator Poor Boy Degasser - Well Control - Netwas Group OilJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- 1.layout Rig 1503 Five Mud TanksDocument1 pagină1.layout Rig 1503 Five Mud TanksJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- CNE Oil & Gas Rig InspectionDocument35 paginiCNE Oil & Gas Rig InspectionJUAN JOSE VESGA RUEDA100% (1)

- Rig Pioneer 53 - 25-10-2019 - 9-24Document14 paginiRig Pioneer 53 - 25-10-2019 - 9-24JUAN JOSE VESGA RUEDAÎncă nu există evaluări

- 170 - PLC I-O Rack 0Document16 pagini170 - PLC I-O Rack 0JUAN JOSE VESGA RUEDAÎncă nu există evaluări

- 110 - Generator PDFDocument25 pagini110 - Generator PDFJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Front: Mud Pump Power End Inspection Data SheetDocument1 paginăFront: Mud Pump Power End Inspection Data SheetJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Eaton Freedom ContactStarters Sell Sheet PDFDocument121 paginiEaton Freedom ContactStarters Sell Sheet PDFJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- 000 - System PDFDocument38 pagini000 - System PDFJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Cutler - Hammer AN16GN0AB Datasheet PDFDocument242 paginiCutler - Hammer AN16GN0AB Datasheet PDFJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- cUTLER HAMMER - HEATERS - 687 - Elec08Document1 paginăcUTLER HAMMER - HEATERS - 687 - Elec08JUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Calculating Accumulator Bottle Requirements for Surface BOP SystemDocument1 paginăCalculating Accumulator Bottle Requirements for Surface BOP SystemJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Cutler - Hammer AN16GN0AB Datasheet PDFDocument242 paginiCutler - Hammer AN16GN0AB Datasheet PDFJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- 171 - PLC I-O Rack 1Document13 pagini171 - PLC I-O Rack 1JUAN JOSE VESGA RUEDAÎncă nu există evaluări

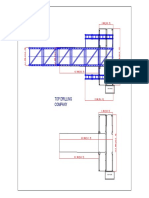

- LEGACY Automation, Power & Design: Petrex Helo Transportable - 600V System Elevation-Skid 1Document3 paginiLEGACY Automation, Power & Design: Petrex Helo Transportable - 600V System Elevation-Skid 1JUAN JOSE VESGA RUEDAÎncă nu există evaluări

- 07-1121 DWG Index - Electrical - Rev.cDocument3 pagini07-1121 DWG Index - Electrical - Rev.cJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Pilot Device Connection DiagramDocument21 paginiPilot Device Connection DiagramJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- 120 - SCR PDFDocument30 pagini120 - SCR PDFJUAN JOSE VESGA RUEDAÎncă nu există evaluări

- Strategic Thinking and SWOT of AMCDocument9 paginiStrategic Thinking and SWOT of AMCFranzel Ruth NovicioÎncă nu există evaluări

- Arrival Notice PDFDocument2 paginiArrival Notice PDFalianzalogicaÎncă nu există evaluări

- Process Design EngineeringDocument196 paginiProcess Design EngineeringAriyanto Purnomo IlBewokll100% (2)

- Equipments Used For Examination of The Female Reproductive SDocument11 paginiEquipments Used For Examination of The Female Reproductive Ssuleiman AbdullahiÎncă nu există evaluări

- Transpo - Midterm FocusDocument23 paginiTranspo - Midterm FocusVanessa Evans CruzÎncă nu există evaluări

- PLC Io ListDocument4 paginiPLC Io ListVaibhav ShrivastavÎncă nu există evaluări

- Environmental Sustainability of Ateneo de Naga University in S/Y 2018-2019Document12 paginiEnvironmental Sustainability of Ateneo de Naga University in S/Y 2018-2019Ludwig Claude LelisÎncă nu există evaluări

- Discretization of The Markov Regime Switching AR (1) Process: Yan Liu Wuhan UniversityDocument13 paginiDiscretization of The Markov Regime Switching AR (1) Process: Yan Liu Wuhan UniversityAbinash MishraÎncă nu există evaluări

- Automobile EngineeringDocument73 paginiAutomobile EngineeringSolomon Durairaj71% (7)

- Trauma ToraksDocument30 paginiTrauma ToraksRichas Interisti SumatraÎncă nu există evaluări

- Technical Guide Pigment&Coating Colour PreparationDocument18 paginiTechnical Guide Pigment&Coating Colour PreparationHuy NguyenÎncă nu există evaluări

- Tpde r13 Aprilmay 15Document4 paginiTpde r13 Aprilmay 15P S HARSHITAÎncă nu există evaluări

- Predictive MaintenanceDocument17 paginiPredictive Maintenancejimmy_d_nasutionÎncă nu există evaluări

- Infection and Infectious ProcessDocument44 paginiInfection and Infectious Processpandey omkarÎncă nu există evaluări

- Samsung YP-ST5 - Quick GuideDocument2 paginiSamsung YP-ST5 - Quick GuidegarneliÎncă nu există evaluări

- Maths Chapter on Circles ExercisesDocument38 paginiMaths Chapter on Circles ExercisesHemant KumarÎncă nu există evaluări

- Salman Sweets Case StudyDocument7 paginiSalman Sweets Case StudySadaqat MajeedÎncă nu există evaluări

- Simplified Analysis of 'Out, Out' - Robert FrostDocument3 paginiSimplified Analysis of 'Out, Out' - Robert FrostSANDREA RUTHÎncă nu există evaluări

- Soal Semester Genap 2019 Kelas XII Bahasa InggrisDocument9 paginiSoal Semester Genap 2019 Kelas XII Bahasa InggrisWalid UmarÎncă nu există evaluări

- Vocational Training in A 132 KV SubstationDocument69 paginiVocational Training in A 132 KV SubstationRahul SahaÎncă nu există evaluări

- Fuel Transfer Pump - Disassemble: Shutdown SISDocument3 paginiFuel Transfer Pump - Disassemble: Shutdown SISjasleenÎncă nu există evaluări

- AAP 851 Vamp 30 Repair Manual 195212 OCRDocument210 paginiAAP 851 Vamp 30 Repair Manual 195212 OCRNicholasÎncă nu există evaluări

- Gen Physics 1 Wk3Document10 paginiGen Physics 1 Wk3Hannah Bianca RegullanoÎncă nu există evaluări

- Yank 1943jul09 PDFDocument24 paginiYank 1943jul09 PDFjohn obrienÎncă nu există evaluări

- Thervupettagam January 2024 - EnglishDocument198 paginiThervupettagam January 2024 - EnglishMukesh KannanÎncă nu există evaluări

- Digital Unit Plan Template Unit Title: Kinetic Molecular Theory of Gases Name: Jill Jermain Content Area: Chemistry Grade Level: 10 GradeDocument4 paginiDigital Unit Plan Template Unit Title: Kinetic Molecular Theory of Gases Name: Jill Jermain Content Area: Chemistry Grade Level: 10 Gradeapi-365215054Încă nu există evaluări

- Lámina ParacetamolDocument2 paginiLámina ParacetamolAndrea Alvarado RoÎncă nu există evaluări

- Developing The Whole PersonDocument17 paginiDeveloping The Whole PersonDaphne LavardoÎncă nu există evaluări

- Jehbec To 2024Document1 paginăJehbec To 2024jennymarchival79Încă nu există evaluări

- Patient Information: Corp.: Bill To:: Doc. No: LPL/CLC/QF/2806Document1 paginăPatient Information: Corp.: Bill To:: Doc. No: LPL/CLC/QF/2806Modi joshiÎncă nu există evaluări