Documente Academic

Documente Profesional

Documente Cultură

Plano Mecanico de Detalle - Py Utp

Încărcat de

nelsonDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Plano Mecanico de Detalle - Py Utp

Încărcat de

nelsonDrepturi de autor:

Formate disponibile

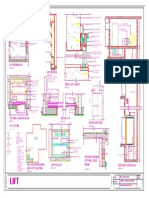

+16400mm

R.C.C. LINTEL 250 X 150MM.

500.0

COUNTER WEIGHT +14050mm

350.0

GUIDE

FRICTION SHEAVE +13200mm

3 ROPES @ 12.5 mm DIA. EACH 10MM DIA. ANCHOR BOLT. FRICTION SHEAVE

2000.0

500.0

3 ROPES @ 12.5 mm DIA. EACH

1200.0

OF CAR GUIDE

8MM DIA. BOLTED JOINTS. MACHINE SUPPORTING

ISMC 125 X 65

2200.0

230 MM THK. BRICK WALL. +10050mm 2.5MM THK. M.S. PLATE.

500MM WIDE VENTILATOR. 60MM DIA. ROLLERS.

1330.0

4000.0

500.0

MACHINE SUPPORTING

ISMC 125 X 65

17190.0

850.0

500.0

10MM THK. M.S. RAILS.

+6900mm

575

ELEVATOR ROOM

ELEVATOR ELECTRICAL

POWER SWITCH.

800 CONTROLS. 2.5MM THK. M.S. PLATE FIXED

1200.0

150.0

TO SHUTTER.

1000.0

700.0

+3750mm 20MM THK. GYPSUM SHUTTER.

1750 TOP CLEARANCE

LAMINATED WITH 2MM S.S.

COUNTER WEIGHT GUIDE

TERRACE FLOOR

500.0

2850.0

ground level. 2.5MM THK. HAIRLINE

500.0

S.S.SHEET.

OF CAR GUIDE

GUIDE RAILS. 20 mm THK. FLOORING.

+600mm

230.0

500 X 150 mm R.C.C. BEAM.

LIFT ROOM PLAN ALUMINIUM FOOTBOARD

PROFILE. 115mm THK. BRICK WALL.

M.S. ANGLES TO FIX 12 mm THK. PLASTER. B

KEY SECTION THE FOOTBOARD.

150.0

2200.0 250 X 150 mm R.C.C. LINTEL.

150.0

150MM THK. R. RC.C. SHEAR WALL. 10MM DIA. ANCHOR BOLT. 18 GAUGE HAIRLINE

2080 CLEAR ENTRANCE

STAINLESS STEEL

10MM THK. M.S. LIFT CAGE.

ISMC 75 X 40 COUNTER ELEVATOR CONTROLS.

100.0

200.0 200.0 WEIGHT GUIDE RAIL.

1500 CAGE INSIDE 10 MM THK. M.S. LIFT DETAIL AT A AND B

14530 CLEAR LIFT WELL HEIGHT

745

CAGE.

2000.0

1620.0

2MM THK. HAIRLINE S.S. SHEET. 100.0 100.0

ISMC 150 X 75

548.0 452.0 ELEVATOR SHAFT

1800 DIST. BETWEEN BRACKETS LIFT

150 MM THK. R.C.C.

478.0 478.0 ENTRANCE

SHEAR WALL.

ISA 70 X 50 FIXING

800

578.0

100.0

JUNCTION BOX . 150.0 100.0 ANGLE.

150.0

550.0 452.0

A

2100.0

100.0

180

s.s.hairline

252.0

230 M THK. BRICK WORK. laminated shutters

100.0 ISA 50X50

15 MM THK CERAMIC ANGLE CLEAT.

1000.0

TILE CLAD FIXING BOLT.

150.0 1900.0 150.0

finished floor level.

LIFT WELL AND CAR PLAN DETAIL AT C

150.0 1900.0 150.0 DOOR ELEVATION

2080 CLEAR ENTRANCE

LIFT SYSTEM

150.0

2700

20.0

100.0

ELECTRIC HYDRAULIC

180.0

KEY DESIGN 650.0 650.0 LIFT

255.0

191.0

MACHINE ABOVE BUILDING

670.0

CONSIDERATIONS FOOTPRINT ENTRANCE

1:1 ROPED

(VARIABLES AFFECTING LIFT CAR ABOVE

150.0

150.0

ELEVATORS SYSTEM

1770.0

SPRING

350.0

DESIGN)

MACHINE ABOVE

2:1 ROPED

1. NO.OF FLOORS TO BE

175

180

LIFT CAR FRAME OF STEEL

1230 PIT DEPTH

SERVED

CHANNELS.

180

2. FLOOR TO FLOOR ENTRENCE

LOBBY 525.0

900.0

MACHINE BELOW DISTANCE JUNCTION BOX .

300.0

1:1 ROPED 3. POPULATION OF EACH 150.0

700.0

FLOOR PIT FLOOR LVL.

500.0

4. LOCATION OF BUILDING

5. SPECIALIZED

M.S. LADDER FOR LIFT

PIT.

SECTION SHOWING

SERVICES WITHIN THE

160.0

BUILDING. LIFT WELL EDGE

250.0

6. TYPE OF BUILDING

7.

OCCUPANCY.

MAXIMUM PEAK KEY PLAN OF BUILDING LIFT PIT PLAN BEAM HOISTWAY SECTION AA'

DEMAND IN

PASSENGERS PER FIVE WITH LIFT LOCATION

MINUTE PERIOD.

SCALE 1:250

DATE : CURSO: PROYECTO INTEGRADOR

PROYECTO INTEGRADOR LIFT SYSTEM UNIVERSIDAD TECNOLOGICA DEL PERU

RAUL ROCA - LUIS VICENTE - NELSON AGUILAR

S-ar putea să vă placă și

- Cargo Lift Provides Cost-Saving OperationDocument2 paginiCargo Lift Provides Cost-Saving OperationK. Mehedi HasanÎncă nu există evaluări

- Medifaith BiotechDocument29 paginiMedifaith BiotechBabarÎncă nu există evaluări

- Technical Data Sheet: Digital Energy™ Uninterruptible Power SupplyDocument6 paginiTechnical Data Sheet: Digital Energy™ Uninterruptible Power SupplyFiroze Zia HussainÎncă nu există evaluări

- Penta Product 2019Document47 paginiPenta Product 2019Arnoud NegraoÎncă nu există evaluări

- Ankur Biomass Gasifier SystemsDocument2 paginiAnkur Biomass Gasifier Systemsamu_cbe1443Încă nu există evaluări

- Feeder Protection RelayDocument16 paginiFeeder Protection RelaygealifeÎncă nu există evaluări

- Heuristic Design of Pressure Swing Adsorption: A Preliminary StudyDocument19 paginiHeuristic Design of Pressure Swing Adsorption: A Preliminary StudyAntonio Lopez PerezÎncă nu există evaluări

- Notes:: CheniereDocument1 paginăNotes:: CheniereMonse LÎncă nu există evaluări

- Alimak Scando 450: Construction HoistsDocument4 paginiAlimak Scando 450: Construction Hoistsbert cruzÎncă nu există evaluări

- Reyrolle 5 Catalog Edition 7Document86 paginiReyrolle 5 Catalog Edition 7Resad HajdarevicÎncă nu există evaluări

- LG SignageDocument29 paginiLG SignageVila Keang100% (1)

- Improve Goods Handling with Mitsubishi Freight ElevatorsDocument9 paginiImprove Goods Handling with Mitsubishi Freight ElevatorsNayef FtouniÎncă nu există evaluări

- Ankur Scientific biomass energy solutionsDocument43 paginiAnkur Scientific biomass energy solutionsMarceloÎncă nu există evaluări

- Practical Solutions... Practical Solutions... at Level! at Level!Document6 paginiPractical Solutions... Practical Solutions... at Level! at Level!PSKUMAR2012Încă nu există evaluări

- Cranes, Hoists and Lifts: Heavy Duty Hydraulic Utility CranesDocument2 paginiCranes, Hoists and Lifts: Heavy Duty Hydraulic Utility CranesGenaire Limited100% (1)

- Smart Storage Technologies: Smartstorage - Co.inDocument9 paginiSmart Storage Technologies: Smartstorage - Co.insmartstoragetechÎncă nu există evaluări

- Silo Grain Handling PlantDocument4 paginiSilo Grain Handling Plantchavan bhattÎncă nu există evaluări

- 651R PF00295Document12 pagini651R PF00295intrudentalertÎncă nu există evaluări

- Digital Signage Videowall LG VS SamsungDocument9 paginiDigital Signage Videowall LG VS SamsungRiyanto A. ManafÎncă nu există evaluări

- CS Parque Eolico Palmatir Uruguay SPDocument68 paginiCS Parque Eolico Palmatir Uruguay SPjuliocanalesÎncă nu există evaluări

- (419175521) Cotizacion Listada JacmotorDocument3 pagini(419175521) Cotizacion Listada JacmotorLUISÎncă nu există evaluări

- 2019 Digital Signage Catalogue - LEDDocument22 pagini2019 Digital Signage Catalogue - LEDhardikÎncă nu există evaluări

- F-Pack: The Lift PackageDocument4 paginiF-Pack: The Lift PackageyounesÎncă nu există evaluări

- Dwyer DM 2000Document2 paginiDwyer DM 2000Jos Albo FerÎncă nu există evaluări

- GasTec As Series PSA Oxygen PlantDocument2 paginiGasTec As Series PSA Oxygen PlantyoanÎncă nu există evaluări

- K68i PC ManualDocument101 paginiK68i PC ManualjjcanoolivaresÎncă nu există evaluări

- PW2014 Single Metallic SteelDocument32 paginiPW2014 Single Metallic SteelMauricio Cesar Molina ArtetaÎncă nu există evaluări

- User Manual PW636i en V2.20Document45 paginiUser Manual PW636i en V2.20mn090078dÎncă nu există evaluări

- Abbacus: Metal Enclosed Capacitor BankDocument36 paginiAbbacus: Metal Enclosed Capacitor BankDrago AndrijevicÎncă nu există evaluări

- 7SR51 Numerical Relay DatasheetDocument33 pagini7SR51 Numerical Relay DatasheetSUSOVAN BISWAS100% (2)

- O'Brien Met-Track Workstation Bridge CranesDocument16 paginiO'Brien Met-Track Workstation Bridge Cranesdf_campos3353Încă nu există evaluări

- Guia de Productos e InsumosDocument44 paginiGuia de Productos e InsumosCaioAJT100% (1)

- P12686 0000 9009 01 PDFDocument1 paginăP12686 0000 9009 01 PDFthanhÎncă nu există evaluări

- PSA Oxygen Generator Tech-Proposal WG-STD-3 With Piston BoosterDocument17 paginiPSA Oxygen Generator Tech-Proposal WG-STD-3 With Piston BoosterSimon Alissou100% (1)

- Technical and Field Experience of Downdraft Gasifier ForDocument18 paginiTechnical and Field Experience of Downdraft Gasifier ForJarus YdenapÎncă nu există evaluări

- Hangzhou Chenrui Air Separator Installation Manufacture CO., LTDDocument10 paginiHangzhou Chenrui Air Separator Installation Manufacture CO., LTDTonyÎncă nu există evaluări

- PowerFlex400 Fault CodesDocument2 paginiPowerFlex400 Fault CodesAdrian ChiriacÎncă nu există evaluări

- EXKAL Training 0418Document56 paginiEXKAL Training 0418ErickÎncă nu există evaluări

- Index Page 002 002 Modelos Engl PDFDocument19 paginiIndex Page 002 002 Modelos Engl PDFMarinaldo Ribeiro0% (1)

- Eti Fuses PDFDocument2 paginiEti Fuses PDFCaseyÎncă nu există evaluări

- Eaton Cutler-Hammer Motor Control Center Info Cat.71.01t.e. - 2 PDFDocument42 paginiEaton Cutler-Hammer Motor Control Center Info Cat.71.01t.e. - 2 PDFDaniel Ajailla AveÎncă nu există evaluări

- Activated Carbon Filter PDFDocument10 paginiActivated Carbon Filter PDFDon Clerance Denzil WeerakkodyÎncă nu există evaluări

- Siemens - SF6 GIS - ArregloDocument7 paginiSiemens - SF6 GIS - ArregloRogelio RevettiÎncă nu există evaluări

- Hypertherm PowerMax 125Document4 paginiHypertherm PowerMax 125vudinhnambrÎncă nu există evaluări

- SBEC4000 Parts NumbersDocument88 paginiSBEC4000 Parts NumbersRyan WilsonÎncă nu există evaluări

- XL3 4000A enclosures - A complete solution for your distribution needsDocument32 paginiXL3 4000A enclosures - A complete solution for your distribution needsarunÎncă nu există evaluări

- Comitrol Processor Model 1700: Controlled Particle Size ReductionDocument2 paginiComitrol Processor Model 1700: Controlled Particle Size ReductionNguyễn Lê Anh KhoaÎncă nu există evaluări

- 6 GFMF 150 DatasheetDocument2 pagini6 GFMF 150 DatasheetHamad YousafaniÎncă nu există evaluări

- PTHC-200DC ManualDocument24 paginiPTHC-200DC ManualAlaa Abu KhurjÎncă nu există evaluări

- SVP-43763-DWG-ELE-RSAB-008 - GA Capacitor Bank B - R02Document12 paginiSVP-43763-DWG-ELE-RSAB-008 - GA Capacitor Bank B - R02septa ibnuÎncă nu există evaluări

- New DC Inverter U-Match TSG (3) GreeDocument134 paginiNew DC Inverter U-Match TSG (3) Greediab awadÎncă nu există evaluări

- 1 - IGARD GCHK-100 Mining Relay Instruction ManualDocument21 pagini1 - IGARD GCHK-100 Mining Relay Instruction ManualJhann Oliva GalvezÎncă nu există evaluări

- MFM - 2012 ABB Adda PresentationDocument69 paginiMFM - 2012 ABB Adda PresentationMr.SonerÎncă nu există evaluări

- SIP5 6MD85-86 V04.00 Manual C015-3 EsDocument880 paginiSIP5 6MD85-86 V04.00 Manual C015-3 Esgusfaj100% (1)

- FREJA300-306-Win5 4 UG en V03Document204 paginiFREJA300-306-Win5 4 UG en V03apofviewÎncă nu există evaluări

- LIFT Layout1Document1 paginăLIFT Layout1nikita chawlaÎncă nu există evaluări

- LIFTDocument1 paginăLIFTaanchal thamanÎncă nu există evaluări

- 8 PIECES 16 Mm. Diameter Vertical Bars: 10 Mm. Lateral Ties SPACED 5 at 50 MM, 7 at 100 MM, REST at 150 MM O.CDocument1 pagină8 PIECES 16 Mm. Diameter Vertical Bars: 10 Mm. Lateral Ties SPACED 5 at 50 MM, 7 at 100 MM, REST at 150 MM O.CLloyd DeeÎncă nu există evaluări

- Description: WF3 WF2 WF1Document1 paginăDescription: WF3 WF2 WF1Emmanuel Milla-gracia GarilÎncă nu există evaluări

- Aim High Classroom Labels and OrganizersDe la EverandAim High Classroom Labels and OrganizersÎncă nu există evaluări

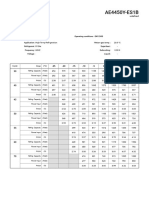

- Display & Signal DescriptionDocument13 paginiDisplay & Signal DescriptionnelsonÎncă nu există evaluări

- Selection Software GraphsDocument1 paginăSelection Software GraphsnelsonÎncă nu există evaluări

- Selection Software Data ListDocument1 paginăSelection Software Data ListnelsonÎncă nu există evaluări

- Product data sheet for RM35LM33MW liquid level control relayDocument6 paginiProduct data sheet for RM35LM33MW liquid level control relaynelsonÎncă nu există evaluări

- Trabajo Autonomo MATRICEZDocument2 paginiTrabajo Autonomo MATRICEZnelsonÎncă nu există evaluări

- Mohammad R. Mestarihi: About Me ObjectiveDocument1 paginăMohammad R. Mestarihi: About Me ObjectiveMhmd MsttÎncă nu există evaluări

- CH 22 Solutions ManualDocument22 paginiCH 22 Solutions Manuallmbrn0415Încă nu există evaluări

- DionWIred Black FridayDocument13 paginiDionWIred Black FridayAmon SimelaneÎncă nu există evaluări

- I Am Sharing 'Pregnancy Shady' With YouDocument48 paginiI Am Sharing 'Pregnancy Shady' With YouNouran AlaaÎncă nu există evaluări

- Sample ResumeDocument3 paginiSample Resumeapi-380209683% (6)

- Cost and Benefit Analysis of Outsourcing From The Perspective of Datapath LTDDocument59 paginiCost and Benefit Analysis of Outsourcing From The Perspective of Datapath LTDranzlorenzoo100% (1)

- LaQshya Labour Room Quality Improvement InitiativeDocument2 paginiLaQshya Labour Room Quality Improvement InitiativeHimanshu SharmaÎncă nu există evaluări

- Otis Brochure Gen2life 191001-BELGIUM SmallDocument20 paginiOtis Brochure Gen2life 191001-BELGIUM SmallveersainikÎncă nu există evaluări

- "The Meeting of Meditative Disciplines and Western Psychology" Roger Walsh Shauna L. ShapiroDocument13 pagini"The Meeting of Meditative Disciplines and Western Psychology" Roger Walsh Shauna L. ShapiroSayako87Încă nu există evaluări

- Defender 90 110 Workshop Manual 5 WiringDocument112 paginiDefender 90 110 Workshop Manual 5 WiringChris Woodhouse50% (2)

- Njhs Application EssayDocument4 paginiNjhs Application Essaycjawrknbf100% (2)

- Title Page Title: Carbamazepine Versus Levetiracetam in Epilepsy Due To Neurocysticercosis Authors: Akhil P SanthoshDocument16 paginiTitle Page Title: Carbamazepine Versus Levetiracetam in Epilepsy Due To Neurocysticercosis Authors: Akhil P SanthoshPrateek Kumar PandaÎncă nu există evaluări

- Solution Manual For Contemporary Project Management 4th EditionDocument15 paginiSolution Manual For Contemporary Project Management 4th EditionDanaAllendzcfa100% (77)

- Ragavendhar Seeks Entry Software JobDocument2 paginiRagavendhar Seeks Entry Software JobfferferfÎncă nu există evaluări

- Nelson Sanchez GE Module October 2020Document92 paginiNelson Sanchez GE Module October 2020Nneg Gray0% (1)

- Rumi and ReligionDocument2 paginiRumi and ReligionJustin LiewÎncă nu există evaluări

- Case Analysis of CriminologyDocument12 paginiCase Analysis of CriminologyinderpreetÎncă nu există evaluări

- FAI - Assignment Sheet (Both Assignments)Document5 paginiFAI - Assignment Sheet (Both Assignments)Wilson WongÎncă nu există evaluări

- Asian Games African Games: Beach VolleyballDocument5 paginiAsian Games African Games: Beach VolleyballJessan Ybañez JoreÎncă nu există evaluări

- CH 21Document70 paginiCH 21Shakib Ahmed Emon 0389Încă nu există evaluări

- Painter CardDocument1 paginăPainter CardPraveen RANAÎncă nu există evaluări

- Metal Oxides Semiconductor CeramicsDocument14 paginiMetal Oxides Semiconductor Ceramicsumarasad1100% (1)

- Technical Bro A4 UK LR NEW v2Document45 paginiTechnical Bro A4 UK LR NEW v2Roxana NegoitaÎncă nu există evaluări

- TR-Pharmacy Services NC IIIDocument135 paginiTR-Pharmacy Services NC IIIAljon Fortaleza Balanag100% (2)

- Pahang JUJ 2012 SPM ChemistryDocument285 paginiPahang JUJ 2012 SPM ChemistryJeyShida100% (1)

- Larong Lahi Week 15 18Document7 paginiLarong Lahi Week 15 18CJAY SOTELOÎncă nu există evaluări

- Mitosis Quiz: Answers Each Question. Write The Answer On The Sheet ProvidedDocument5 paginiMitosis Quiz: Answers Each Question. Write The Answer On The Sheet ProvidedJohn Osborne100% (1)

- Benedict - Ethnic Stereotypes and Colonized Peoples at World's Fairs - Fair RepresentationsDocument16 paginiBenedict - Ethnic Stereotypes and Colonized Peoples at World's Fairs - Fair RepresentationsVeronica UribeÎncă nu există evaluări

- Generate Ideas with TechniquesDocument19 paginiGenerate Ideas with TechniquesketulÎncă nu există evaluări

- OJT Form 03 Performance EvaluationDocument2 paginiOJT Form 03 Performance EvaluationResshille Ann T. SalleyÎncă nu există evaluări