Documente Academic

Documente Profesional

Documente Cultură

DFX and DFSS How QFD Integrates Them

Încărcat de

Harshad KhireDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DFX and DFSS How QFD Integrates Them

Încărcat de

Harshad KhireDrepturi de autor:

Formate disponibile

QUALITY FUNCTION DEPLOYMENT

DFX and DFSS:

How QFD

Integrates Them

by Jui-Chin Jiang, Ming-Li Shiu and Mao-Hsiung Tu

D

esign for excellence (DFX) and design for to integrate them effectively by using quality func-

Six Sigma (DFSS) have been two of the tion deployment (QFD).

most popular concepts in quality man- It is a good starting point to understand the

agement in recent years, but very little has been roots of the words excellence, Six Sigma and

written comparing DFX and DFSS. This article quality. Aristotle might have been the first per-

aims to clarify the differences between them in son to talk on the subject of quality in any system-

concept and application and further identify how atic way.1 In his book Metaphysics, he gave four

definitions of quality and later summarized them

with two basic meanings: differences of real sub-

stance and mode of a subject in motion, of itself.

In 50 Words Good (excellence) and bad (inferiority) are parts of

Or Less the latter mode.

Simply speaking, there are two aspects of quali-

Quality function deployment provides an ty, according to Aristotle: different quality and

good quality. Discussions of quality have revolved

architecture that can effectively position around these two aspects since Aristotles time.2

and combine design for excellence and Whether youre creating different quality or try-

ing to achieve good quality, you must build quality

design for Six Sigma.

into a product when it is planned and designed.

Quality built in at this stage has the maximum

By combining these methods, manufactur- return in terms of cost benefits and customer satis-

ers can differentiate a product in terms of faction. It far surpasses the improvements brought

about by relying separately on promotional efforts

quality prior to the actual production

in selling or detection and modification in manu-

process. facturing after a product is released. DFX and

DFSS both help build quality into the design stage.

QUALITY PROGRESS I OCTOBER 2007 I 45

QUALITY FUNCTION DEPLOYMENT

Design for Excellence 8. Environmental friendliness: The products

DFX has evolved and is still evolving from manufacturing process, use and disposal are

design for manufacturability. By manufacturability, free of environmental pollution and hazards.

we mean the ease with which a product or compo- 9. Psychological characteristics: Product aesthet-

nent can be produced. Historically, designers have ics as perceived by the users five senses and

overlooked manufacturability and have concen- the sensibility that relates to the users think-

trated their efforts on function, features and ing, feeling and discerning about a product.

appearance of their products. However, concentrat- It should be pointed out that DFX objectives are

ing on manufacturability during product design all the desirable factors a product should theoreti-

has great cost benefits.3 cally have. In practice, DFX objectives are met by a

Today, a limited series of design objectives companys selective quality characteristics.

function, features and appearanceeven when

manufacturability is added, is not enough to pro-

Design for Six Sigma

vide the most competitive, economical and benefi- Six Sigma is a disciplined and highly quantita-

cial design to customers and society over the long tive approach to improving product or process

run.4 quality. The goal is to reduce defects to no more

DFX is intended to provide designers with an than 3.4 per million opportunities. Six Sigma was

objective deployment framework and a means to introduced at Motorola and has been adopted and

achieve all desirable dimensions of quality. DFX generalized by numerous companies, such as

can be viewed as a design approach that deals with Allied Signal and General Electric.

Aristotles different quality while focusing on the Companies that have adopted Six Sigma have

right thing to design. realized that once they have hit a five sigma wall

When we look at research in this field, two and progress has come to a standstill, the only way

renowned examples are the eight quality dimen- to surpass this wall is to apply DFSS. DFSS is a rigor-

sions David Garvin proposed5 and the internal ous approach to designing products from the begin-

structure of quality Noriaki Kano proposed.6 Based ning to ensure customer requirements are met.7

on these ideas, we propose nine dimensions of DFSS can be viewed as a design approach that

quality, or DFX objectives: deals with Aristotles good quality and a focus on

1. Higher functional performance: Higher effect how to design the right thing right. DFSS follows

levels of a products main operating character- the define, measure, analyze, design and verify

istics. (DMADV) phases during design projects. The core

2. Physical performance: Dimension, volume concept of DMADV implementation is to gradual-

and weight of a product. ly flow down new products critical-to-quality

3. User friendliness: How easily a product is characteristics to functional design, detailed design

used. and process control variables, and then flow up

4. Reliability and durability: Reliability refers to capability to meet these requirements.8

how free of failure a product is during a peri-

od of time. Durability refers to a products Quality Function Deployment

lifespan. QFD is a method of new product development

5. Maintainability and serviceability: How easy under the umbrella of total quality management. It

it is to restore a products usability after a fail- is a process for systematically converting cus-

ure. tomers demands into design quality, and it

6. Safety: How free of injury and hazard the pro- deploys quality over design targets and major

ducts user is. quality assurance (QA) points, or milestones, used

7. Compatibility and upgradeability: Compati- throughout the product development process.

bility refers to the ease of combining a product QFD was conceived in Japan in the late 1960s

with another product. Upgradeability refers to while Japanese industries were departing from

the ease of incorporating improved or addi- their postwar mode of product development,

tional features into a product. which had essentially involved imitation and copy-

46 I OCTOBER 2007 I www.asq.org

FIGURE 1 Comprehensive Quality Function Deployment System

Finished product

quality characteristics

Market evaluation

Demanded quality

items Competitive analysis

3

Complaints/claims

2

3 Planned quality

1

1. Primary 2

3 Selling points

2. Secondary 3

Kanos attractive

quality survey

3. Tertiary Competitive analysis

Design target setting

Setting

Specification tolerance design

target

Key quality characteristic list

Bottleneck engineering list

Cost deployment

Parts

Component unit specifications

Bottleneck engineering list

FTA/FMEA

Subsystems Key component/part list

Supplier feasibility and capability survey

Production specifications

Bottleneck engineering list

FTA/FMEA

Processes

Key control item list

Quality assurance process sheet

Shopfloor management system design

FTA = fault tree analysis

FMEA = failure mode effects analysis

ing, and were moving toward original product simultaneously.11 The objective of each deployment

development. At that time, there was recognition is as follows:

of the importance of designing quality into new Quality deployment is to systematically de-

products, but there was a lack of guidance on how ploy customers demanded quality over the

to achieve it. design targets and major QA milestones used

Companies were already inspecting for quality, throughout the product development process.

but it was happening at the manufacturing site Technology deployment is to extract any bot-

after new products had been produced.9 tleneck engineering (BNE) that hinders quality

Yoji Akao first presented the QFD concept and and solve it at the earliest possible time.

method to solve these problems, and QFD has con- Cost deployment is to achieve the target cost

tinued to spread since Shigeru Mizuno and Akao while keeping a balance with quality.

published their first book on the topic in 1978.10 Reliability deployment is to prevent failures

To ensure smooth product development, Akao and their effects through early prediction.

constructed a comprehensive QFD system that Figure 1 shows the concept in an integrated way.

considers quality, technology, cost and reliability The first step for QFD implementation is to

QUALITY PROGRESS I OCTOBER 2007 I 47

QUALITY FUNCTION DEPLOYMENT

decide on a target market and formulate a product R&D personnel view the subsystem or component

portfolio strategy. Then, a survey is conducted unit (also known as a building block) of the inter-

with the markets customers, and a demanded- mediate layer of the product architecture as the

quality deployment chart is made. design unit. As a result, a subsystems deployment

According to market evaluation information is necessary to allocate the specification tolerance

such as competitive analysis and claims analysis, of the finished products quality characteristics to

the company might conduct quality planning and relevant component units.

determine the new products individuality or sell- In the design stage, the product must effectively

ing points. Kanos attractive quality survey helps prevent a recurrence of the existing products design

to conduct product planning for creating attractive problems as well as the new products potential

quality.12 design problems. To that end, a fault tree analysis

Customers express demanded qualities by (FTA) and failure mode effects analysis (FMEA) can

be employed. With respect to parts and materials

needed for constructing subsystems, deployment is

required, and an evaluation of the suppliers feasi-

bility and capability should be conducted.

Like product design, process Products are made through processes and com-

pleted by assembling semifinished products.

design must effectively prevent Therefore, a semifinished product and its specifica-

tions defined by the subsystems deployment are

a recurrence of the existing made using process deployment and design and

by deciding specifications of process conditions

processs design problems and (also known as production specifications).

Like product design, process design must effec-

the potential design problems tively prevent a recurrence of the existing processs

design problems and the potential design problems

of the new process. of the new process. This can be done by drawing

on equipment FTA and process FMEA.

Based on process deployment and FMEA infor-

mation, a QA process sheet (also known as control

plan) can be created to provide an overview of

information needed for process control. The design

directly describing and perceiving what product of the shop floor management system needed to

quality is. However, demanded qualities must be execute the QA process sheet, which is part of the

converted to quality characteristicsthat is, the process design, ensures that before a product

technical language a companys R&D personnel enters mass production, adequate preparations are

use to understand how to technically achieve the already in place to achieve manufacturing QA.

demanded qualities. Only in this way is it possible The foregoing quality deployment, which

to materialize them through development technol- includes technology and reliability, can realize cus-

ogy. tomers demanded qualities and failure free quali-

Therefore, it is necessary to carry out a quality ties, yet it might increase the cost as a result. By

characteristics deployment of the finished product using market evaluation information to decide the

to transform product quality from the world of the target cost of the finished product, and by corre-

customer into the world of technology. The compa- sponding to quality deployment flows to set up

ny can choose design specification values accord- cost targets for materials and labor, a balance

ing to competitive analysis and extract the BNE, between QA and cost reduction can be achieved.

which hinders the realization of the design quality.

When a product is designed and developed, Integrating DFX and DFSS

rather than directly designing the entire product, QFDs structural integrity when dealing with

48 I OCTOBER 2007 I www.asq.org

FIGURE 2 QFD Toward DFX and DFSS Positioning and Integration

All desirable dimensions of quality

Finished product

quality characteristics

Market evaluation

DFX

Demanded quality Product target cost identification

items Competitive analysis Value proposition

3

Complaints/claims development/positioning

2

3 Planned quality Design characterization

1

1. Primary 2

3

Selling points and differentiation

2. Secondary 3 Kanos attractive

quality survey

3. Tertiary Competitive analysis

Design target setting

Setting

Specification tolerance design

target

Key quality characteristic list

Bottleneck engineering list

Cost deployment

Parts DFSS

Optimal (Six Sigma) product

Component unit specifications specifications development

Bottleneck engineering list and tolerance allocation

FTA/FMEA Product specifications

Subsystems Key component/part list design verification

Supplier feasibility and capability survey Optimal process conditions

design and verification

Shopfloor management system

design and verification

Production specifications

Bottleneck engineering list

FTA/FMEA

Processes

Key control item list

Quality assurance process sheet

Shopfloor management system design

DFX = design for excellence

FTA = fault tree analysis

FMEA = failure mode effects analysis

critical issues (quality, technology, cost and reliabil- developed based on the selection of quality

ity) of new product development helps position niches (one X or several Xs).

and integrate DFX and DFSS, as illustrated in In the design stage of demanded quality char-

Figure 2. acterization, the design targets that can sup-

DFX is a design method that deals with port the value proposition are set.

Aristotles different quality. It can integrate with Product design for the DFX and its verifica-

QFD in converting demanded qualities into quality tion can then be conducted downstream.

characteristics. In other words, it ensures that: DFSS can integrate with QFD in tolerance design

In planning all desirable dimensions of and process design of a product. That is, after set-

demanded quality, a value proposition is ting the design targets (also known as nominal val-

QUALITY PROGRESS I OCTOBER 2007 I 49

QUALITY FUNCTION DEPLOYMENT

ues) of quality characteristics, reference is made to In this example, a chart is used to deploy all

specification values, actual performance and demanded qualities of the headlamp. All the

process capability of similar products developed in columns in the quality planning section are used to

the past. This is done to develop a product specifi- prioritize the demanded qualities that can support

cation tolerance with Six Sigma design quality and the companys market positioning and that are con-

allocate the tolerance to related subsystems, com- sidered selling points. When demanded qualities

ponent units, parts and materials. are converted into substitute quality characteristics,

Moreover, DFSS also includes the design and R&D personnel must base the differentiation on tech-

verification of optimal process conditions and shop nical measures that can achieve the selling points.

floor management systems to ensure the manufac- For instance, to make sure the demanded quality

turing of semifinished products can achieve Six lamp shines brightly becomes a quality charac-

Sigma design quality. teristic, R&D personnel must determine a target

Using the quality deployment of a headlamp as value for the technical measure, transmissivity,

an example,13 Figure 3 shows QFD integrated with with a great difference from that of competitors

the DFX and DFSS in Figure 2 (p. 49). headlamps and make it have significant brightness.

FIGURE 3 QFD Integrated With DFX and DFSS

Quality Flux distribution value Flux of light Efficiency Quality planning

characteristics Flux Low Bright- Deman-

distri- beam/ ness of Reflec- Color Air Competi- Abso- ded

bution Lens high Aiming light Trans- tion temper- Electric tight- Filament Impor- tive Planned Level- Selling lute quality

Demanded quality value size beam angle source missivity factor ature power Voltage ness strength tance analysis quality up rate points weight weight

Bright enough to see well

Quality chart (two-dimensional matrix of demanded-quality deployment

Can see distant objects

Lamp shines brightly

chart and quality characteristics deployment chart)

Broad beam

Quality planning for the

Shines with directional stability

Light does not scatter companys market positioning

Can see close objects well and sales proposition

Low beam is bright enough

Broad beam

Shines with directional stability

Can see well even under adverse

conditions

Can see well in poor weather

conditions

Coordinates with steering wheel Design target setting for

Can see well even when vehicle

bounces

technical differentiation that

Direction of beam correct under can communicate the

no-load condition

companys positioning

JIS 4

require- 160 7.5

Specification nominal value

ment 1

(up/down,

left/rigt) cd/mm2 0.9 min 0.9 min 3000K

37.5/

50W 12.8 V

0.2

a. p.

impact

95 min

Tolerance design for Six Sigma

Specification tolerance quality by analyzing historical

process control data and

Headlamp

capability studies

Unit holding mechanism

Left retaining ring

Right retaining ring

deployment chart

Tolerance allocation to

Subsystems

Left mounting ring

Right mounting ring lower level characteristics

Bolt

Unit

Lens

Reflector

Product and process detail

Bulb design and verification

= Low corresponding strength

= Moderate corresponding strength

= High corresponding strength

JIS = Japanese industry standard

SAE = Society of Automotive Engineers

50 I OCTOBER 2007 I www.asq.org

Assume we set the transmissivity value to be 0.9 Society for Quality Control), Vol. 13, No. 1, 1983, pp. 61-70.

minimum. As for the decision of the specification 12. Kano, Attractive Quality and Must-be Quality, see

tolerance for making 0.9 minimum, the nominal reference 1.

value, we can use the data on variance and process 13. Mizuno, Quality Function Deployment: A Company-

Wide Quality Approach, see reference 10.

capability obtained from the analysis of historical

process control data to calculate the tolerance

width required for Six Sigma quality. This toler- JUI-CHIN JIANG is an associate pro-

ance is then allocated to lower level characteristics fessor in the department of industrial

by simultaneously using the subsystems deploy- engineering at Chung Yuan Christian

ment chart.

University (CYCU) in Taiwan. He is

The development of the headlamp follows the

also the chair of the universitys quali-

remaining product and process development.

ty research center. Jiang has a doctor-

Meanwhile, other quality deployment charts are

used, and the Six Sigma target values are flowed ate in industrial engineering from

down to accomplish the detail designs and their Cleveland State University in Ohio.

verifications.

DFX and DFSS are two design methods that

have been used in recent years for effective new

product development. But, more and more, new MING-LI SHIU earned a doctorate in

product development requires combining the two. industrial engineering at CYCU.

QFD offers a structure for linking and integrating

them. It uses the resultant synergy to create an

advantage for product development.

REFERENCES

1. Noriaki Kano, Nobuhiko Seraku, FumioTakahashi and

MAO-HSIUNG TU is the president of

Shimichi Tsuji, Attractive Quality and Must-be Quality,

Quality (Journal of the Japanese Society for Quality Control), Vol.

D&N Business Consulting Co. in

14, No. 2, 1984, pp. 147-156. Hsin-Chu City, Taiwan. He received his

2. Ibid. MBA from City University of Seattle.

3. James Bralla, Design for Excellence, McGraw-Hill, 1996. He was formerly the chief corporate

4. Ibid. consultant of the companywide quality

5. David Garvin, Competing on the Eight Dimensions of

improvement office of Philips Taiwan and won the Deming

Quality, Harvard Business Review, November-December

1987, pp. 101-109. Application Prize in 1991 and the Japan Quality Medal

6. Noriaki Kano, Quality Management in Management (Nihon Quality Control Prize) in 1997.

Engineering, Quality, Vol. 17, No. 1, 1987, pp. 23-39.

7. Jiju Antony and Ricardo Banuelas, Design for Six

Sigma, Manufacturing Engineer, February 2002, pp. 24-26.

8. Gerald Hahn, Necip Doganaksoy and Roger Hoerl,

The Evolution of Six Sigma, Quality Engineering, Vol. 12,

No. 3, 2000, pp. 317-326.

9. Yoji Akao and Glenn Mazur, The Leading Edge in QFD:

Past, Present and Future, International Journal of Quality & Please

Reliability Management, Vol. 20, No. 1, 2003, pp. 20-35.

comment

10. Shigeru Mizuno and Yoji Akao (eds.), Quality Function

If you would like to comment on this article,

Deployment: A Company-Wide Quality Approach, JUSE Press,

please post your remarks on the Quality Progress

1978.

11. Yoji Akao, Tadatoshi Ono, Akira Harada, Hideharu Discussion Board at www.asq.org, or e-mail

Tanaka and Kazuo Iwasawa, Quality Deployment Includ- them to editor@asq.org.

ing Cost, Reliability and Technology (part one)Design of

Quality, Cost and Reliability, Quality (Journal of the Japanese

QUALITY PROGRESS I OCTOBER 2007 I 51

S-ar putea să vă placă și

- BROCHURE Certified Lean Six Sigma Yellow Belt Course Sept 2019Document2 paginiBROCHURE Certified Lean Six Sigma Yellow Belt Course Sept 2019Chuckie GarciaÎncă nu există evaluări

- Multivari CHARTSDocument16 paginiMultivari CHARTSanujkumartyagi9275Încă nu există evaluări

- Global Supplier Quality System AssessmentDocument11 paginiGlobal Supplier Quality System AssessmentPvinoth000Încă nu există evaluări

- Walking the Design for Six Sigma Bridge with Your CustomerDe la EverandWalking the Design for Six Sigma Bridge with Your CustomerÎncă nu există evaluări

- Primer On Lean Six Sigma - NRCDocument54 paginiPrimer On Lean Six Sigma - NRCJim WolfeÎncă nu există evaluări

- Ford DFSSDocument8 paginiFord DFSSiangardiner.iow5796100% (1)

- Example Resoponses IGCSE BUSINESS STUDIESDocument66 paginiExample Resoponses IGCSE BUSINESS STUDIESBhaskar Chaudhari67% (6)

- Mini - Tab For STADocument83 paginiMini - Tab For STAmilanstr100% (1)

- Vendor Selection and DevelopmentDocument24 paginiVendor Selection and DevelopmentAnmol Jain100% (1)

- Elementary Quality Assurance ToolsDocument19 paginiElementary Quality Assurance ToolsignaunaqÎncă nu există evaluări

- World Class ManufacturingDocument10 paginiWorld Class ManufacturingAhmed ElgazarÎncă nu există evaluări

- Shanin DOE - Six SigmaDocument7 paginiShanin DOE - Six SigmaBennett Matthews100% (1)

- Six Sigma ToolsDocument92 paginiSix Sigma ToolsjoseggÎncă nu există evaluări

- The Plan For Every PartDocument7 paginiThe Plan For Every PartAlpha SamadÎncă nu există evaluări

- Construction of A Pasig Riverside Green Building Condominium in Downtown ManilaDocument38 paginiConstruction of A Pasig Riverside Green Building Condominium in Downtown ManilaMehrad SarabandiÎncă nu există evaluări

- Shainin Tools PDFDocument17 paginiShainin Tools PDFDEVIKA PHULEÎncă nu există evaluări

- Lean AccountingDocument5 paginiLean AccountingjohnoomsÎncă nu există evaluări

- Leader Standard Work V1.0Document3 paginiLeader Standard Work V1.0SudhagarÎncă nu există evaluări

- Lean Six Sigma in The Service Industry by Alessandro Laureani PDFDocument14 paginiLean Six Sigma in The Service Industry by Alessandro Laureani PDFnaacha457Încă nu există evaluări

- Day 1 - 01. Lean 2.0 Strategic (English Ver.) PDFDocument50 paginiDay 1 - 01. Lean 2.0 Strategic (English Ver.) PDFKim HeidelynÎncă nu există evaluări

- Marine Lubricant ChartDocument12 paginiMarine Lubricant ChartHarshad KhireÎncă nu există evaluări

- Six SigmaDocument13 paginiSix Sigmashafvan_786Încă nu există evaluări

- Unit 17 Quality Management in Toyota AssignmentDocument12 paginiUnit 17 Quality Management in Toyota AssignmentMeinaka Thyagarajan MeinuÎncă nu există evaluări

- ManufacturaDocument87 paginiManufacturaMiguel Angel GarcíaÎncă nu există evaluări

- A Set-Up Reduction Tool For Continuous ImprovementDocument31 paginiA Set-Up Reduction Tool For Continuous ImprovementPriyang ShahÎncă nu există evaluări

- Shingo PrizeDocument38 paginiShingo Prizemuneerpp100% (1)

- Sebros QMS ManualDocument44 paginiSebros QMS ManualRambir KaushikÎncă nu există evaluări

- 02-06-03 Coletta-Earley Lean 3P Advantage PDFDocument48 pagini02-06-03 Coletta-Earley Lean 3P Advantage PDFshan4600Încă nu există evaluări

- Lecture 08 Design For X (DFX)Document22 paginiLecture 08 Design For X (DFX)chitra2010Încă nu există evaluări

- Electric Motors & Mechanical LoadsDocument84 paginiElectric Motors & Mechanical LoadsHarshad Khire100% (1)

- Lean Six Sigma Project CharterDocument1 paginăLean Six Sigma Project CharterPedro KÎncă nu există evaluări

- Pizza Lean GameDocument20 paginiPizza Lean GamemarceloÎncă nu există evaluări

- Integration Between Shipbuilding CAD Systems and A Generic PLM Tool in Naval Projects. Computer Science and ApplicationsDocument11 paginiIntegration Between Shipbuilding CAD Systems and A Generic PLM Tool in Naval Projects. Computer Science and ApplicationsHarshad Khire100% (1)

- Integration Between Shipbuilding CAD Systems and A Generic PLM Tool in Naval Projects. Computer Science and ApplicationsDocument11 paginiIntegration Between Shipbuilding CAD Systems and A Generic PLM Tool in Naval Projects. Computer Science and ApplicationsHarshad Khire100% (1)

- Lean Suggested Readings and ReferencesDocument30 paginiLean Suggested Readings and ReferencessigmasundarÎncă nu există evaluări

- Design For Six Sigma - An OverviewDocument50 paginiDesign For Six Sigma - An OverviewDiana BlueseaÎncă nu există evaluări

- 5 Why's-1 Presentacion1engfinalDocument19 pagini5 Why's-1 Presentacion1engfinalkarthikkandaÎncă nu există evaluări

- Lean Lego Simulation 8-4-04Document10 paginiLean Lego Simulation 8-4-04robertsimonis100% (2)

- Master Black Belt Statistician in USA Resume John DubucDocument2 paginiMaster Black Belt Statistician in USA Resume John DubucJohnDubucÎncă nu există evaluări

- World Class ManufacturingDocument32 paginiWorld Class ManufacturingUng Kok Aik100% (1)

- DFSS PDFDocument47 paginiDFSS PDFRajkumar VijÎncă nu există evaluări

- Application Guidelines ShingoDocument17 paginiApplication Guidelines Shingoislouma2Încă nu există evaluări

- Alphatronic Propulsion Control SystemsDocument26 paginiAlphatronic Propulsion Control SystemsHarshad Khire100% (4)

- The DFSS Checklist You Need To Avoid Doing It WrongDocument1 paginăThe DFSS Checklist You Need To Avoid Doing It Wrongmido nasseÎncă nu există evaluări

- OpMan-Chapter 6 - QualityDocument57 paginiOpMan-Chapter 6 - QualityTrina Mae RodriguezÎncă nu există evaluări

- Six Sigma Quality Improvement at BD CompanyDocument10 paginiSix Sigma Quality Improvement at BD CompanyJLuisCarterÎncă nu există evaluări

- 5 9 Ravichandran Slides PDFDocument26 pagini5 9 Ravichandran Slides PDFss2mrattriÎncă nu există evaluări

- " Oncept Ustomer": SolutionsDocument1 pagină" Oncept Ustomer": SolutionsJac DÎncă nu există evaluări

- Bimbo, S.A.Document17 paginiBimbo, S.A.Gerardo De Paz RoblesÎncă nu există evaluări

- PH MeasurementDocument22 paginiPH MeasurementLuis VilelaÎncă nu există evaluări

- Lean - Standard WorkDocument9 paginiLean - Standard WorkBalaji SÎncă nu există evaluări

- Design Review Based On Failure Mode 1-Day Workshop by TetrahedronDocument2 paginiDesign Review Based On Failure Mode 1-Day Workshop by TetrahedrontetrahedronÎncă nu există evaluări

- Lean Six Sigma CrosswordDocument1 paginăLean Six Sigma CrosswordexamplecgÎncă nu există evaluări

- Design For Manufacturability DFM DFMA Training - Engineers EdgeDocument2 paginiDesign For Manufacturability DFM DFMA Training - Engineers EdgeKeith AdminÎncă nu există evaluări

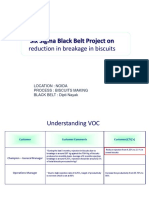

- Six Sigma Black Belt Project On: Reduction in Breakage in BiscuitsDocument42 paginiSix Sigma Black Belt Project On: Reduction in Breakage in BiscuitsHombing Haryanto100% (2)

- Visual Factory ConceptDocument2 paginiVisual Factory Concept91ifthiÎncă nu există evaluări

- Oee For Operators Overall Equipment Effectiveness PDFDocument2 paginiOee For Operators Overall Equipment Effectiveness PDFRayÎncă nu există evaluări

- Fish Bone Diagram: Yellow Belt RefresherDocument33 paginiFish Bone Diagram: Yellow Belt RefresherSnehasish PadhyÎncă nu există evaluări

- Quality Function Deployment (QFD) : Mohan Khond Mechanical Engineering Department College of Engineering, PuneDocument18 paginiQuality Function Deployment (QFD) : Mohan Khond Mechanical Engineering Department College of Engineering, Punesan_02Încă nu există evaluări

- SMED single minute exchange of die A Complete Guide - 2019 EditionDe la EverandSMED single minute exchange of die A Complete Guide - 2019 EditionÎncă nu există evaluări

- Applying PDCA A3 Thinking and Problem SolvingDocument23 paginiApplying PDCA A3 Thinking and Problem SolvingAndrei Timofeev100% (2)

- FEIGENBAUM + Ishikawa + TaguchiDocument7 paginiFEIGENBAUM + Ishikawa + Taguchiaulia rakhmawatiÎncă nu există evaluări

- QFD CourseDocument19 paginiQFD CourseSanjeev NawaniÎncă nu există evaluări

- Lect14r6oct 06 Pom World Class Manufacturing 110908135935 Phpapp01 PDFDocument80 paginiLect14r6oct 06 Pom World Class Manufacturing 110908135935 Phpapp01 PDFVivek KumarÎncă nu există evaluări

- Shainin Vs Six SigmaDocument4 paginiShainin Vs Six Sigmabaro4518Încă nu există evaluări

- Kaizen Case StudyDocument44 paginiKaizen Case StudyTanmoy ChakrabortyÎncă nu există evaluări

- Using System Tools in Projects 438 v1 PDFDocument287 paginiUsing System Tools in Projects 438 v1 PDFMonika Saxena AhujaÎncă nu există evaluări

- Shanin Techniques Jo MoorenDocument3 paginiShanin Techniques Jo MoorenAnonymous X0iytQQYJ6Încă nu există evaluări

- Training Within IndustryDocument5 paginiTraining Within Industryapi-313899066Încă nu există evaluări

- Lean Six Sigma Black Belt Outline PDFDocument4 paginiLean Six Sigma Black Belt Outline PDFYo GoldÎncă nu există evaluări

- 2 - Analyze - X SiftingDocument55 pagini2 - Analyze - X SiftingParaschivescu CristinaÎncă nu există evaluări

- Cutting of Sand Production EstimatingDocument27 paginiCutting of Sand Production EstimatingHarshad KhireÎncă nu există evaluări

- Composite Concrete Cryogenic TankDocument12 paginiComposite Concrete Cryogenic TankLv WanyÎncă nu există evaluări

- Cjme 2016 0815Document2 paginiCjme 2016 0815Harshad KhireÎncă nu există evaluări

- LUMIX G9 Mirrorless Camera Kit, 20.3 Megapixels Plus 80 Megapixel High-Resolution Mode, 5-Axis Dual I.S2 - DC-G9LKDocument341 paginiLUMIX G9 Mirrorless Camera Kit, 20.3 Megapixels Plus 80 Megapixel High-Resolution Mode, 5-Axis Dual I.S2 - DC-G9LKAlfonso CalderonÎncă nu există evaluări

- Fea ToolsDocument2 paginiFea ToolsFadely PaddiyatuÎncă nu există evaluări

- Composite Concrete Cryogenic TankDocument12 paginiComposite Concrete Cryogenic TankLv WanyÎncă nu există evaluări

- Michael NewmanDocument26 paginiMichael NewmanHarshad KhireÎncă nu există evaluări

- NTU Marine EngineeringDocument2 paginiNTU Marine EngineeringHarshad KhireÎncă nu există evaluări

- Bilge System ShipDocument98 paginiBilge System ShipHarshad KhireÎncă nu există evaluări

- 2 Foran v80 Launch DateDocument2 pagini2 Foran v80 Launch DateHarshad KhireÎncă nu există evaluări

- How To Manage Sister Ships On A Shipbuilding Cad Tool. The Applicability ConceptDocument11 paginiHow To Manage Sister Ships On A Shipbuilding Cad Tool. The Applicability ConceptHarshad KhireÎncă nu există evaluări

- 0-Sensing Elements and SystemsDocument33 pagini0-Sensing Elements and SystemsFahad NaseemÎncă nu există evaluări

- 2Din3Dworld COMPIT PDFDocument10 pagini2Din3Dworld COMPIT PDFHarshad KhireÎncă nu există evaluări

- Engineering Design Graphics Into The 21st CenturyDocument15 paginiEngineering Design Graphics Into The 21st CenturyHarshad KhireÎncă nu există evaluări

- 1.1 Discuss Definitions of Quality in Terms of Business and Services ProvisionDocument10 pagini1.1 Discuss Definitions of Quality in Terms of Business and Services ProvisionRunaway ShujiÎncă nu există evaluări

- Scheme - e Fifth Semester - PG, PTDocument46 paginiScheme - e Fifth Semester - PG, PTC.K. VishwakarmaÎncă nu există evaluări

- Company Profile UsmDocument8 paginiCompany Profile Usmnishantnamdeo75Încă nu există evaluări

- Lesson Plan TQM-NewDocument7 paginiLesson Plan TQM-Newtmuthu123Încă nu există evaluări

- Quiz AnswersDocument4 paginiQuiz AnswersSabrina MedeirosÎncă nu există evaluări

- Report On Operation of KapcoDocument45 paginiReport On Operation of KapcoZunaira RasheedÎncă nu există evaluări

- RMT 558 AbstractDocument15 paginiRMT 558 AbstractSui Ling GohÎncă nu există evaluări

- UshaDocument141 paginiUshaimranjani.skÎncă nu există evaluări

- Buckman Catalogo GeneralDocument16 paginiBuckman Catalogo GeneralJose Barturen VillalobosÎncă nu există evaluări

- Organization: Welcome To Our PresentationDocument13 paginiOrganization: Welcome To Our Presentationdicky saputraÎncă nu există evaluări

- Total Quality ManagementDocument10 paginiTotal Quality ManagementJamel torresÎncă nu există evaluări

- EU-GMP.2002 - Annex - 16 (Certification by A Certified Person and Batch Release)Document10 paginiEU-GMP.2002 - Annex - 16 (Certification by A Certified Person and Batch Release)bvsc77035Încă nu există evaluări

- MKTG6Document12 paginiMKTG6Himanshu SharmaÎncă nu există evaluări

- MGT C301 Operations Management (Prelim Notes)Document4 paginiMGT C301 Operations Management (Prelim Notes)Dre AclonÎncă nu există evaluări

- Tbs M Quality Management PlanDocument25 paginiTbs M Quality Management PlanKumudha Gani100% (1)