Documente Academic

Documente Profesional

Documente Cultură

Iapg - Pinpoint Completion Technology in The Vaca Muerta Shale A Case Study (Presentation) - v3

Încărcat de

lmjustinianoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Iapg - Pinpoint Completion Technology in The Vaca Muerta Shale A Case Study (Presentation) - v3

Încărcat de

lmjustinianoDrepturi de autor:

Formate disponibile

PINPOINT COMPLETION

TECHNOLOGY IN THE VACA

MUERTA SHALE: A CASE STUDY

Luciano Fucello, NCS Multistage

AGENDA:

Introduction

Completion

Production analysis

Completion costs

Conclusions

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

INTRODUCTION

2 wells in the same PAD

o Well BCeCF-101 => Pinpoint

o Well BCeCF-102 => Plug & Perf

Both wells targeting Vaca Muerta

Comparison of completion methodology, RTA

analysis and production simulation k, A, SRV, OOIP

and cluster efficiency (benchmark)

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

COMPLETION: Methodology

BCeCf-101h - PINPOINT BCeCf-102h - PLUG & PERF

60 coiled tubing shifted sleeves 18 frac stages / 54 entry points

installed

3 perforation clusters per frac stage

o 58 stimulated

Average spacing ~24.9m between o Isolated by bridge plugs

sleeves 10 perforations per cluster / 0.5 m

Isolation inside casing with resettable Average spacing ~24.5m between

bridge plug on CT BHA

clusters

Annular frac

No frac plug drillout Required frac plug drillout

Pinpoint frac isolation tool (see

schematic)

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

COMPLETION: Frac Design

Similar treatments Some differences

Hybrid fluid design Fluid volumes and distribution of fluid type

Increasing proppant size 100 mesh to 20/40 Injection Rate

Proppant size distribution

Average per entry point Lateral length

Well BCeCf-101h BCeCf-102h

Entry Point Spacing (m) 24.9 24.5

Slickwater (bbls) 1,636 -24% 1,172

Gel (bbls) - 20

Crosslink (bbls) 915 1,210

Total Fluid (bbls) 2,551 2,403

100 mesh (lbs) 16,144 12,315

40/70 sand (lbs) 45,121 47,220

40/80 Sinterlite (lbs) 40,937

30/50 sand (lbs) 35,739

30/60 Sinterlite (lbs) 26,418 35,433

20/40 Wanli (lbs) 29,028 29,980

+35%

Total (lbs) 157,648 160,687

Injection Rate (bpm) 23.3 17.3

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

COMPLETION: Instantaneous Shut-In Pressure

7,500 7,500

7,000

>1,000 psi difference 7,000 >600 psi difference

ISIP (psi)

ISIP (psi)

6,500 6,500

6,000 6,000

5,500 5,500

5,000 5,000

1 4 7 10 13 16 19 22 25 28 31 34 37 40 43 46 49 52 55 58 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Stage Number Stage Number

BCeCF-101h BCeCF-102h

Individual entry point ISIPs (BH data) Only ISIP data available (surface)

Show end of job pressure variability Shows some variability even with

averaging effect of 3 clusters

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

COMPLETION: Breakdown Pressure (BH gauge)

8,500

8,000 BCeCF-101h Formation Breakdown

Deadstring Breakdown

Pressure

7,500

Pressure (psi)

7,000 Individual entry point breakdown

pressures

6,500

Show early job pressure variability

6,000 Deadstring data (BH)

58 of 60 zones treated (~96.7%)

5,500 >1,500 psi difference on BCeCf-101h

5,000 NO DATA ON EFFICIENCY ON

1 4 7 10 13 16 19 22 25 28 31 34 37 40 43 46 49 52 55 58

BCeCF-102h

Stage Number

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

COMPLETION: Bottom Hole Gauge Data Evaluation

Only available on BCeCf-101h well

Near wellbore restriction

o Indication of fracture

complexity

o Relatively moderate and

declines during the

treatments

Proppant distribution

o Interpreted as being good

o Minimal proppant bridging

Real time net pressure indication

o CT deadstring

o Avoid screen out

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

COMPLETION: Bottom Hole Gauge Data Evaluation

IMMEDIATE

COMMUNICATION

12%

REGAINED

ISOLATION GOOD

7% ISOLATION

55%

LATE

COMMUNICATION

26%

Communication between stages - Only available on BCeCf-101h well

Zonal pressure isolation evaluation

o Reasonable with most communication being slight in nature

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

PRODUCTION EVALUATION: Basic Comparison

Comparison of production rate and

Calculated BH Pressure (psi)

Choke management calculated bottomhole flowing pressure

Oil Rate (stb/d)

Similar lateral length (1500 m)

Both wells navigate in the same

section

Both wells exhibit choke change at

different times

Pressures measured at surface (BH

Calc)

No tubing installed

Normalized time (months)

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

PRODUCTION ANALYSIS: Basic Comparison

Cumulative Gas Prod (MMscf)

Cumulative Oil Prod (Mstb)

Normalized time (months) Normalized time (months)

Comparison of oil and gas production volumes

Shows similar profiles with the BCeCF-101 performing slightly better

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

PRODUCTION EVALUATION: Rate Transient Analysis

Linear flow specialized plot analysis

Normalized Pressure (psi/(bbl/d))

Slope inversely

Slope is inversely proportional to proportional to

contacted Area

connected fracture area (Ak)

Geomechanical effects with choke

changes (depletion of the SRV)

Plug & Perf

(102h)

BCeCF-101h (pinpoint) 40% more

connected area Slope is inversely proportional

Pinpoint to connected fracture area

(101h)

Oil Linear Superposition time (d1/2)

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

PRODUCTION EVALUATION: Rate Transient Analysis

Flowing material balance (FMB)

Oil Normalized Rate ((bbl/d)/psi)

Quantifying the contacted Original Pinpoint

(101h)

Oil in Place (OOIP)

Extrapolation of this plot yields a

rough estimate of SRV Plug & Perf

Geomechanical effects with choke (102h)

Geomechanical

changes (depletion of the SRV) effects

BCeCF-101h (pinpoint) 60% more

SRV

Normalized Oil Cumulative Production (Mstb)

Rough Estimate of SRV

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

PRODUCTION EVALUATION: Benchmark

Enhanced Fracture Region (EFR) model by Stalgorova and Mattar (2012)

Accounting for differences in lateral length, stage count and entry point spacing

Fracture properties (length and conductivity) are assumed to be identical between

the two wells

Geological and geomechanical overprint is identical for these wells

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

PRODUCTION EVALUATION: Benchmark

BCeCF-101h (PINPOINT) - Numerical

model history match well production

data

History matching

Determination K1, K2, Xf, Xi, Le, Ye

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

PRODUCTION EVALUATION: Benchmark

Oil rate - 100% Cluster Efficiency Oil rate - Actual Cluster Efficiency

BCeCF-102h (PLUG & PERF) -

Numerical model history match well

production data

Production simulation

K1, K2, Xf, Xi, Le, Ye as calculated

The cumulative difference in oil

production over the time period

of interest (5 months) is 11,358

STB

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

COMPLETION COST: Comparison

Comparison of bundled completion costs

Include only those expenditures directly associated with the specific completion

methodology employed

The cost of proppant and other variable costs not associated specifically with the

style of completion were not included in the totals

Savings of approximately 9% for the comparable Pinpoint costs vs the Plug&Perf

completion costs

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

CONCLUSIONS

Cost and production benefits were realized by the

application of the pinpoint completion method.

RTA analysis of well performance suggests a

greater stimulated reservoir volume (fracture

area) is produced by the pinpoint completion

method, and that a larger hydrocarbon volume is

contacted by the completion as a result.

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

QUESTIONS

PINPOINT COMPLETION TECHNOLOGY IN THE VACA MUERTA SHALE: A CASE STUDY

S-ar putea să vă placă și

- FLC2000 and Wellbore StrengtheningDocument10 paginiFLC2000 and Wellbore StrengtheningKinni ShenoldÎncă nu există evaluări

- AHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetDocument17 paginiAHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetbinishÎncă nu există evaluări

- Bearing Design-30.0m - PSCDocument5 paginiBearing Design-30.0m - PSCSHARATH VASUPRADA100% (1)

- IADC Dull Grading - Roller Cone BitsDocument2 paginiIADC Dull Grading - Roller Cone BitsYasir IrfanÎncă nu există evaluări

- IADC Dull Grading - Roller Cone BitsDocument2 paginiIADC Dull Grading - Roller Cone BitsYasir IrfanÎncă nu există evaluări

- Design of Bolts Carrying Crane BeamDocument12 paginiDesign of Bolts Carrying Crane BeamOmar SalahÎncă nu există evaluări

- Omni DTDocument2 paginiOmni DTCHEKOUFI SaidÎncă nu există evaluări

- Steam Path Audit of Steam Turbine - CompressDocument38 paginiSteam Path Audit of Steam Turbine - CompressTc UmtÎncă nu există evaluări

- Lampiran - 1 Contoh Perhitungan Tebal Perkerasan Kaku Metode AASHTO 1993Document3 paginiLampiran - 1 Contoh Perhitungan Tebal Perkerasan Kaku Metode AASHTO 1993AtyatamaÎncă nu există evaluări

- Mr. Emmanuel E.N Ibe - 3-Story Building Bill New-4-6Document3 paginiMr. Emmanuel E.N Ibe - 3-Story Building Bill New-4-6Aloh Kelvin UchechiÎncă nu există evaluări

- Pressure AnalysisDocument11 paginiPressure AnalysisTarak Abuziad100% (1)

- 29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodDocument1 pagină29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodJunaid MateenÎncă nu există evaluări

- Digital Readout Unit Settings: KN MM KN % Mm/dak KN % Mm/dak MM MM KN KNDocument2 paginiDigital Readout Unit Settings: KN MM KN % Mm/dak KN % Mm/dak MM MM KN KNOpu DebnathÎncă nu există evaluări

- Kill SheetDocument4 paginiKill SheetAnwar FauzenÎncă nu există evaluări

- IKCP0-GCF-WTSI-35-002 INTERCONNECTION WIRING DIAGRAM FOR WTS - ÷+S+÷-Ñ +Document104 paginiIKCP0-GCF-WTSI-35-002 INTERCONNECTION WIRING DIAGRAM FOR WTS - ÷+S+÷-Ñ +rizkidwir43Încă nu există evaluări

- AHRI Standard 885-2008 Duct Discharge Calculation SpreadsheetDocument16 paginiAHRI Standard 885-2008 Duct Discharge Calculation SpreadsheetANWARÎncă nu există evaluări

- Catálogo de SeccionalizadorDocument19 paginiCatálogo de SeccionalizadorLuis LizárragaÎncă nu există evaluări

- Scotch Yoke Actuator Selecting Tool: Valve Tag SDV-3003Document1 paginăScotch Yoke Actuator Selecting Tool: Valve Tag SDV-3003Javier LopezÎncă nu există evaluări

- Column Supporting DiscontinuousDocument40 paginiColumn Supporting DiscontinuousRohan JaiswalÎncă nu există evaluări

- Cakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DataDocument6 paginiCakasa Cakasa: Sea Water Filter Inlet Ine Input Description Unit General DatasterlingÎncă nu există evaluări

- Stochastic in Highway EngineerDocument38 paginiStochastic in Highway EngineerDonlot DonlotanÎncă nu există evaluări

- Hoja de Calculo para DiafragmasDocument1 paginăHoja de Calculo para DiafragmasPaul Oswaldo Zapata JuarezÎncă nu există evaluări

- Ahu 1 2FDocument1 paginăAhu 1 2FAhmed AliÎncă nu există evaluări

- Hoja de Calculo para MurosDocument1 paginăHoja de Calculo para MurosPaul Oswaldo Zapata JuarezÎncă nu există evaluări

- 320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POWERED BY 3066 ENGINE (XEBP7645 - 03) - DocumentaciónDocument6 pagini320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POWERED BY 3066 ENGINE (XEBP7645 - 03) - Documentaciónjohana ruiz cervantesÎncă nu există evaluări

- Pier Sheet Hollow r0Document1 paginăPier Sheet Hollow r0Varun VermaÎncă nu există evaluări

- Compare Ic Chip CatvDocument15 paginiCompare Ic Chip CatvDuong Thuy NgacÎncă nu există evaluări

- Bridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-19Document5 paginiBridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-19Madhusudan ShewalkarÎncă nu există evaluări

- UntitledDocument4 paginiUntitledLuis Alfredo Atencia VillarealÎncă nu există evaluări

- VT IPV 21 BDI 90116 enDocument20 paginiVT IPV 21 BDI 90116 enEraldo MendesÎncă nu există evaluări

- PT Gunanusa Utama Fabricators: Calculation SheetDocument25 paginiPT Gunanusa Utama Fabricators: Calculation Sheetriandi100% (1)

- Hoja de Calculo para DiafragmasDocument1 paginăHoja de Calculo para DiafragmasPaul Oswaldo Zapata JuarezÎncă nu există evaluări

- SFH 6315Document10 paginiSFH 6315Mohamed Ezzat MareeÎncă nu există evaluări

- Catalogo BC60Document28 paginiCatalogo BC60Ivailo ZapryanovÎncă nu există evaluări

- Pressure SpecificationsDocument6 paginiPressure SpecificationsHamid EssarboutiÎncă nu există evaluări

- Hire ChargesDocument40 paginiHire Chargesnagaraj_qce3499Încă nu există evaluări

- Concrete Spec Japek 2 ElevatedDocument1 paginăConcrete Spec Japek 2 ElevatedjimdabrondÎncă nu există evaluări

- Turbine Fuel Shut Off Valve: Model 4420EDocument11 paginiTurbine Fuel Shut Off Valve: Model 4420EfranmyflamesÎncă nu există evaluări

- Software Verification: AISC-360-10 Example 002Document9 paginiSoftware Verification: AISC-360-10 Example 002Mohamed Abo-ZaidÎncă nu există evaluări

- Examen Parcial 01 - IC - C6Document2 paginiExamen Parcial 01 - IC - C6Bryan PerezÎncă nu există evaluări

- Oro AgoDocument4 paginiOro AgoAbdulyekini AhmaduÎncă nu există evaluări

- Champ Ion PackerDocument2 paginiChamp Ion PackerCHO ACHIRI HUMPHREYÎncă nu există evaluări

- Catálogo PBP 10-12 - IngDocument3 paginiCatálogo PBP 10-12 - IngmarcosÎncă nu există evaluări

- 4P Multiple Conventional Hydraulic Fracturing Modeling in Directional Wells. Historical Case Well PN3 1 Pumping Treatment Thru BLT Gas Lift Installation in Offshore RiglesDocument26 pagini4P Multiple Conventional Hydraulic Fracturing Modeling in Directional Wells. Historical Case Well PN3 1 Pumping Treatment Thru BLT Gas Lift Installation in Offshore RiglesBrayan Herrera CastilloÎncă nu există evaluări

- MCCB Abh403cDocument3 paginiMCCB Abh403chakiman.irecÎncă nu există evaluări

- IPC Medium-Pressure Internal Gear Pumps: Technical Data SheetDocument20 paginiIPC Medium-Pressure Internal Gear Pumps: Technical Data SheetNutrición SaludableÎncă nu există evaluări

- Py51a06h DDR 19 17mar05Document2 paginiPy51a06h DDR 19 17mar05Cleevh MabialaÎncă nu există evaluări

- P-Way PlanDocument10 paginiP-Way PlanAditya arya singhÎncă nu există evaluări

- EECS240 - Spring 2008 Comparator Gain-Bandwidth: Lecture 20: ComparatorsDocument4 paginiEECS240 - Spring 2008 Comparator Gain-Bandwidth: Lecture 20: ComparatorsnadeemjuttÎncă nu există evaluări

- Centrifugal Pump CalculationDocument8 paginiCentrifugal Pump CalculationLorenzoÎncă nu există evaluări

- Llames Sched of LoadDocument6 paginiLlames Sched of LoadJosh'z LlamesÎncă nu există evaluări

- 1.equipment List WITH CM ONLY DCBL & MDODocument18 pagini1.equipment List WITH CM ONLY DCBL & MDOmukherjeemohul25Încă nu există evaluări

- PT Gunanusa Utama Fabricators: Calculation SheetDocument27 paginiPT Gunanusa Utama Fabricators: Calculation SheetriandiÎncă nu există evaluări

- SDU Ver142beta1 - Demo Print 1 PDFDocument12 paginiSDU Ver142beta1 - Demo Print 1 PDFreza khÎncă nu există evaluări

- Denison HydraulicsDocument48 paginiDenison HydraulicsPartagon PowÎncă nu există evaluări

- Ipvp 6-80 101 Voith PumpDocument24 paginiIpvp 6-80 101 Voith Pumppapinaidu2Încă nu există evaluări

- Piping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaDocument3 paginiPiping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaElias EliasÎncă nu există evaluări

- Nadir PlazaDocument55 paginiNadir Plazaeno khanÎncă nu există evaluări

- Hoja Tecnica Indoor Unit Fan Coil Media Presion Estatica DCDocument4 paginiHoja Tecnica Indoor Unit Fan Coil Media Presion Estatica DCHerrera Jorge AgustínÎncă nu există evaluări

- CorbelDocument2 paginiCorbelAbdullah Al MamunÎncă nu există evaluări

- Pictures FormatDocument4 paginiPictures FormatMichelle BulawanÎncă nu există evaluări

- LIS Dharampur Churu Tubewell Submersible2Document2 paginiLIS Dharampur Churu Tubewell Submersible2Rishav ChaudharyÎncă nu există evaluări

- ReedHycalog Performance SummaryDocument1 paginăReedHycalog Performance SummarylmjustinianoÎncă nu există evaluări

- W3V13 - Drilling - HandoutDocument6 paginiW3V13 - Drilling - HandoutzoeÎncă nu există evaluări

- Solutions CatalogDocument72 paginiSolutions CataloglmjustinianoÎncă nu există evaluări

- Final Slides Baker Hughes: Downhole VibrationsDocument10 paginiFinal Slides Baker Hughes: Downhole VibrationsJames BourneÎncă nu există evaluări

- W1V4 - Introduction To EP - HandoutDocument7 paginiW1V4 - Introduction To EP - HandoutGiovanny LizarazoÎncă nu există evaluări

- W1V6 - Origin of Hydrocarbon Resources2 - HandoutDocument13 paginiW1V6 - Origin of Hydrocarbon Resources2 - HandoutDanilson Paulo MelicioÎncă nu există evaluări

- Mechanical-Hydraulic Shock ToolDocument1 paginăMechanical-Hydraulic Shock ToollmjustinianoÎncă nu există evaluări

- Performance Summary - Conventional Coring Sabalo 101IDocument1 paginăPerformance Summary - Conventional Coring Sabalo 101IlmjustinianoÎncă nu există evaluări

- MKT-001 Rev 02 Rotary Shoulder Handbook RSDocument116 paginiMKT-001 Rev 02 Rotary Shoulder Handbook RSArsalan AhmadÎncă nu există evaluări

- Nozzle InstallationDocument6 paginiNozzle InstallationlmjustinianoÎncă nu există evaluări

- HORAS - Shock ToolDocument1 paginăHORAS - Shock ToollmjustinianoÎncă nu există evaluări

- Tabla-Conversión de Unidades: by Marcelo Hirschfeldt - 1Document0 paginiTabla-Conversión de Unidades: by Marcelo Hirschfeldt - 1lmjustinianoÎncă nu există evaluări

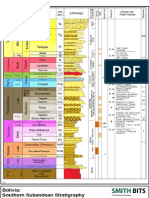

- Southern Subandean StratigraphyDocument1 paginăSouthern Subandean StratigraphylmjustinianoÎncă nu există evaluări

- E Totco USDocument2 paginiE Totco USlmjustinianoÎncă nu există evaluări

- Kicks and Gas MigrationDocument42 paginiKicks and Gas MigrationJohnny Sanchez100% (1)

- Southern Subandean StratigraphyDocument1 paginăSouthern Subandean StratigraphylmjustinianoÎncă nu există evaluări

- HDD Presentation 2Document32 paginiHDD Presentation 2lmjustiniano50% (2)

- Multilateral Vs - HorizontalDocument26 paginiMultilateral Vs - HorizontallmjustinianoÎncă nu există evaluări

- Sand Control FINALDocument90 paginiSand Control FINALAbdelHamid Abdo100% (1)

- Mini FracDocument26 paginiMini Fracvignesh100% (1)

- Stimulation Question Sheet: Choose The Correct AnswerDocument6 paginiStimulation Question Sheet: Choose The Correct AnswerIbrahim SalahudinÎncă nu există evaluări

- Darcy Fourcheimer and ErgunDocument2 paginiDarcy Fourcheimer and ErgunSebastian Zarate VilelaÎncă nu există evaluări

- Module - 1 Introduction Hydraulic FracturingDocument43 paginiModule - 1 Introduction Hydraulic FracturingAjay SuriÎncă nu există evaluări

- Thesis - Arash Dahi - Analysis of Hydraulic Fracture Propagation in Fractured Reservoirs (2009) PDFDocument216 paginiThesis - Arash Dahi - Analysis of Hydraulic Fracture Propagation in Fractured Reservoirs (2009) PDFRahulprabhakaran VannostranÎncă nu există evaluări

- Section 9 - ProppantsDocument18 paginiSection 9 - ProppantsIllimination Illuminated MinisatanÎncă nu există evaluări

- Spe 199712 MSDocument26 paginiSpe 199712 MSJamesÎncă nu există evaluări

- Toughen Up: Mitigate Erosion For High-Volume Proppant CompletionsDocument6 paginiToughen Up: Mitigate Erosion For High-Volume Proppant CompletionsSiver AbdullahÎncă nu există evaluări

- Fracturing ManualDocument426 paginiFracturing ManualXPEGADOXÎncă nu există evaluări

- Cased Hole Sand Control Techniques BR PDFDocument8 paginiCased Hole Sand Control Techniques BR PDFjorge_h_riveroÎncă nu există evaluări

- Choosing A Perforation Strategy PDFDocument0 paginiChoosing A Perforation Strategy PDFAjendra SinghÎncă nu există evaluări

- Proppant Selection For Hydraulic Fracture Production Optimization in Shale PlaysDocument15 paginiProppant Selection For Hydraulic Fracture Production Optimization in Shale PlaysRanggaÎncă nu există evaluări

- Petron Business PlanDocument62 paginiPetron Business PlanDesiree de la Rosa100% (2)

- Proppant TablesDocument20 paginiProppant TablesManuel ChÎncă nu există evaluări

- ProppantDocument12 paginiProppantNeha AhiraoÎncă nu există evaluări

- Reservoir Stimulation TechniquesDocument18 paginiReservoir Stimulation TechniquesMvrnaidu MithraÎncă nu există evaluări

- Liu 2018Document29 paginiLiu 2018Umair KhanÎncă nu există evaluări

- FracCourse 2007Document311 paginiFracCourse 2007Maria Jose CuellarÎncă nu există evaluări

- Coiled Tubing FundamentalsDocument114 paginiCoiled Tubing FundamentalsCARLOS RODRIGUEZÎncă nu există evaluări

- M.reynolds PrintDocument48 paginiM.reynolds PrintDanilson Paulo MelicioÎncă nu există evaluări

- Hydraulic FracturingDocument30 paginiHydraulic FracturingKeith WarlickÎncă nu există evaluări

- International Journal of Coal Geology: A B C C D e C ADocument17 paginiInternational Journal of Coal Geology: A B C C D e C AAllanÎncă nu există evaluări

- Acid FracturingDocument5 paginiAcid FracturingShamit RathiÎncă nu există evaluări

- DFIT Example - High PermDocument54 paginiDFIT Example - High Permamramazon88Încă nu există evaluări

- 13 - Baker Hughes - Kennedy enDocument36 pagini13 - Baker Hughes - Kennedy enSpecule100% (1)

- WO2019209312A1.Polyamine Polyethers As Nonemulsifier ComponentsDocument34 paginiWO2019209312A1.Polyamine Polyethers As Nonemulsifier ComponentsLê Công100% (2)

- Schlumberger 2012 ArDocument100 paginiSchlumberger 2012 ArUma Maheshwaraa50% (2)

- Microseismic Mapping of Hydraulic FractureDocument42 paginiMicroseismic Mapping of Hydraulic FractureMohamed Ibrahim ShihataaÎncă nu există evaluări