Documente Academic

Documente Profesional

Documente Cultură

Lan PDF

Încărcat de

Aldo ApazzaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lan PDF

Încărcat de

Aldo ApazzaDrepturi de autor:

Formate disponibile

K ELECTRICAL

B

SECTION

LAN SYSTEM C

E

CONTENTS

CAN CAN Communication Circuit Check ........................ 13 F

Component Inspection ............................................ 15

PRECAUTIONS .......................................................... 2 ECM/COMBINATION METER INTERNAL CIR-

Precautions for Supplemental Restraint System CUIT INSPECTION ............................................. 15 G

(SRS) AIR BAG and SEAT BELT PRE-TEN- CAN SYSTEM (TYPE 2) ........................................... 16

SIONER .................................................................. 2 System Description ................................................. 16

Precautions For Trouble Diagnosis .......................... 2 Component Parts and Harness Connector Location... 16

CAN SYSTEM ....................................................... 2 H

Wiring Diagram CAN ..................................... 17

Precautions For Harness Repair .............................. 2 Work Flow ............................................................... 18

CAN SYSTEM ....................................................... 2 CHECK SHEET ................................................... 19

CAN COMMUNICATION ............................................ 3 CHECK SHEET RESULTS (EXAMPLE) ............. 19 I

System Description .................................................. 3 CAN Communication Circuit Check ........................ 20

CAN Communication Unit ........................................ 3 Component Inspection ............................................ 22

TYPE 1 .................................................................. 3 ECM/COMBINATION METER INTERNAL CIR- J

TYPE 2 .................................................................. 5 CUIT INSPECTION ............................................. 22

TYPE 3 .................................................................. 5 CAN SYSTEM (TYPE 3) ........................................... 23

CAN SYSTEM (TYPE 1) ............................................. 6 System Description ................................................. 23

System Description .................................................. 6 LAN

Component Parts and Harness Connector Location... 23

Component Parts and Harness Connector Location..... 6 Wiring Diagram CAN ..................................... 24

Wiring Diagram CAN ....................................... 7 Work Flow ............................................................... 25

Work Flow ................................................................ 8 CHECK SHEET ................................................... 26 L

CHECK SHEET ..................................................... 9 CHECK SHEET RESULTS (EXAMPLE) ............. 27

CHECK SHEET RESULTS (EXAMPLE) ............. 10 CAN Communication Circuit Check ........................ 27

ECM Circuit Check ................................................. 12 Component Inspection ............................................ 29 M

TCM Circuit Check ................................................. 12 ECM/TCM INTERNAL CIRCUIT INSPECTION... 29

Combination Meter Circuit Check .......................... 13

Revision: May 2004 LAN-1 2003 Sentra

PRECAUTIONS

[CAN]

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) AIR BAG and SEAT

BELT PRE-TENSIONER EKS003A9

The Supplemental Restraint System such as AIR BAG and SEAT BELT PRE-TENSIONER, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions For Trouble Diagnosis EKS003AA

CAN SYSTEM

Do not apply voltage of 7.0V or higher to the measurement terminals.

Use the tester with its open terminal voltage being 7.0V or less.

Precautions For Harness Repair EKS003AB

CAN SYSTEM

Solder the repaired parts, and wrap with tape. [Frays of twisted

line must be within 110 mm (4.33 in).]

PKIA0306E

Do not perform bypass wire connections for the repair parts.

(The spliced wire will become separated and the characteristics

of twisted line will be lost.)

PKIA0307E

Revision: May 2004 LAN-2 2003 Sentra

CAN COMMUNICATION

[CAN]

CAN COMMUNICATION PFP:23710

A

System Description EKS003K5

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec- B

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. C

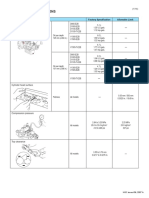

CAN Communication Unit EKS003K6

Go to CAN system, when selecting your CAN system type from the following table. D

Body type Sedan

Axle 2WD

E

Engine QG18DE QR25DE

Transmission A/T M/T A/T

CAN system type 1 2 3 F

LAN-6, "CAN SYSTEM LAN-16, "CAN SYSTEM LAN-23, "CAN SYSTEM

CAN system trouble diagnosis

(TYPE 1)" (TYPE 2)" (TYPE 3)"

: Applicable G

TYPE 1

System diagram H

LAN

LKIA0132E

Input/output signal chart

T: Transmit R: Receive L

Combination

Signals ECM TCM

Meter

Accelerator pedal position signal T R M

Output shaft revolution signal R T

A/T self-diagnosis signal R T

Closed throttle position signal T R

Wide open throttle position signal T R

Stop lamp switch signal R T

Overdrive control switch signal R T

O/D OFF indicator signal T R

Engine speed signal T R

Engine coolant temperature signal T R

Vehicle speed signal R T

Fuel level sensor signal R T

Malfunction indicator lamp signal T R

Revision: May 2004 LAN-3 2003 Sentra

CAN COMMUNICATION

[CAN]

Combination

Signals ECM TCM

Meter

ASCD SET lamp signal T R

ASCD CRUISE lamp signal T R

Revision: May 2004 LAN-4 2003 Sentra

CAN COMMUNICATION

[CAN]

TYPE 2

System diagram A

D

LKIA0133E

Input/output signal chart

T: Transmit R: Receive E

Signals ECM Combination Meter

Engine speed signal T R

F

Engine coolant temperature signal T R

Vehicle speed signal R T

Fuel level sensor signal R T G

Malfunction indicator lamp signal T R

ASCD SET lamp signal T R

H

ASCD CRUISE lamp signal T R

TYPE 3

System diagram I

LAN

L

LKIA0107E

Input/output signal chart

T: Transmit R: Receive M

Signals ECM TCM

Accelerator pedal position signal T R

Output shaft revolution signal R T

A/T self-diagnosis signal R T

Wide open throttle position signal T R

Overdrive cancel signal T R

Revision: May 2004 LAN-5 2003 Sentra

CAN SYSTEM (TYPE 1)

[CAN]

CAN SYSTEM (TYPE 1) PFP:23710

System Description EKS003K7

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

Component Parts and Harness Connector Location EKS003K8

LKIA0131E

Revision: May 2004 LAN-6 2003 Sentra

CAN SYSTEM (TYPE 1)

[CAN]

Wiring Diagram CAN EKS003K9

LAN

WKWA0149E

Revision: May 2004 LAN-7 2003 Sentra

CAN SYSTEM (TYPE 1)

[CAN]

Work Flow EKS003KA

1. Print all the data of SELF-DIAG RESULTS for ENGINE and A/T displayed on CONSULT-II.

PKIA8260E

2. Print all the data of CAN DIAG SUPPORT MNTR for ENGINE and A/T displayed on CONSULT-II.

PKIA8343E

3. Attach the printed sheet of SELF-DIAG RESULTS and CAN DIAG SUPPORT MNTR onto the check

sheet. Refer to LAN-9, "CHECK SHEET" .

4. Based on the CAN DIAG SUPPORT MNTR results, put check marks onto the items with UNKWN or

NG in the check sheet table. Refer to LAN-9, "CHECK SHEET" .

NOTE:

If NG is displayed on "INITIAL DIAG (initial diagnosis)" as CAN DIAG SUPPORT MNTR for the diag-

nosed control unit, replace the control unit.

5. According to the check sheet results (example), start inspection. Refer to LAN-10, "CHECK SHEET

RESULTS (EXAMPLE)" .

Revision: May 2004 LAN-8 2003 Sentra

CAN SYSTEM (TYPE 1)

[CAN]

CHECK SHEET

A

LAN

LKIA0514E

Revision: May 2004 LAN-9 2003 Sentra

CAN SYSTEM (TYPE 1)

[CAN]

CHECK SHEET RESULTS (EXAMPLE)

Case 1

Replace ECM.

LKIA0515E

WKIA2937E

Case 2

Replace TCM.

WKIA2938E

WKIA2939E

Revision: May 2004 LAN-10 2003 Sentra

CAN SYSTEM (TYPE 1)

[CAN]

Case 3

Check ECM Circuit. Refer to LAN-12, "ECM Circuit Check" . A

D

WKIA2940E

Case 4 E

Check TCM Circuit. Refer to LAN-12, "TCM Circuit Check" .

WKIA2941E

Case 5 I

Check combination meter Circuit. Refer to LAN-13, "Combination Meter Circuit Check"

LAN

WKIA2942E

M

Case 6

Check CAN communication Circuit. Refer to LAN-13, "CAN Communication Circuit Check" .

WKIA2943E

Revision: May 2004 LAN-11 2003 Sentra

CAN SYSTEM (TYPE 1)

[CAN]

ECM Circuit Check EKS003KB

1. CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check the terminals and connector of ECM for damage, bend and loose connection (control module-side

and harness-side).

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect ECM connector.

2. Check resistance between ECM harness connector F59 termi-

nals 94 (L) and 86 (Y).

94 (L) 86 (Y) : Approx. 108 132

OK or NG

OK >> Replace ECM.

NG >> Repair harness between ECM and TCM.

WKIA0257E

TCM Circuit Check EKS003KC

1. CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check the terminals and connector of TCM for damage, bend and loose connection (control module-side

and harness-side).

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2. CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect TCM connector.

2. Check resistance between TCM harness connector F56 termi-

nals 5 (L) and 6 (Y).

5 (L) 6 (Y) : Approx. 54 66

OK or NG

OK >> Replace TCM.

NG >> Repair harness between TCM and ECM.

WKIA0258E

Revision: May 2004 LAN-12 2003 Sentra

CAN SYSTEM (TYPE 1)

[CAN]

Combination Meter Circuit Check EKS003KD

1. CHECK CONNECTOR A

1. Turn ignition switch OFF.

2. Check terminals and connector of combination meter for damage, bend and loose connection (meter-side B

and harness-side).

OK or NG

OK >> GO TO 2. C

NG >> Repair terminal or connector.

2. CHECK HARNESS FOR OPEN CIRCUIT D

1. Disconnect combination meter connector.

2. Check the following.

E

Without tachometer:

Resistance between combination meter harness connector M30

terminals 34 (L) and 35 (Y).

F

34 (L) 35 (Y)

: Approx. 108 132

(Without tachometer)

G

WKIA0259E

I

With tachometer:

Resistance between combination meter harness connector M30

terminals 38 (L) and 39 (Y).

J

38 (L) 39 (Y)

: Approx. 108 132

(With tachometer)

OK or NG LAN

OK >> Replace combination meter.

NG >> Repair harness between combination meter and TCM.

L

WKIA1042E

CAN Communication Circuit Check EKS003KE M

1. CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check following terminals and connector for damage, bend and loose connection (meter-side, control

module-side and harness-side).

Combination meter

TCM

ECM

Between combination meter and ECM

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

Revision: May 2004 LAN-13 2003 Sentra

CAN SYSTEM (TYPE 1)

[CAN]

2. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ECM connector, TCM connector and harness connector F26.

2. Check continuity between ECM harness connector F59 termi-

nals 94 (L) and 86 (Y).

94 (L) 86 (Y) : Continuity should not exist.

OK or NG

OK >> GO TO 3.

NG >> Repair harness between ECM and harness connector

F26.

Repair harness between ECM and TCM.

WKIA0257E

3. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F59 terminals 94

(L), 86 (Y) and ground.

94 (L) ground : Continuity should not exist.

86 (Y) ground : Continuity should not exist.

OK or NG

OK >> GO TO 4.

NG >> Repair harness between ECM and harness connector

F26.

Repair harness between ECM and TCM.

WKIA0262E

4. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect combination meter connector.

2. Check continuity between harness connector M58 terminals 6

(L) and 15 (Y).

6 (L) 15 (Y) : Continuity should not exist.

OK or NG

OK >> GO TO 5.

NG >> Repair harness between harness connector M58 and

combination meter.

WKIA0263E

5. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between harness connector M58 terminals 6 (L),

15 (Y) and ground.

6 (L) ground : Continuity should not exist.

15 (Y) ground : Continuity should not exist.

OK or NG

OK >> GO TO 6.

NG >> Repair harness between harness connector M58 and

combination meter.

WKIA0264E

Revision: May 2004 LAN-14 2003 Sentra

CAN SYSTEM (TYPE 1)

[CAN]

6. ECM/COMBINATION METER INTERNAL CIRCUIT INSPECTION A

Check components inspection. Refer to LAN-15, "ECM/COMBINATION METER INTERNAL CIRCUIT

INSPECTION" .

OK or NG B

OK >> Connect all the connectors and diagnose again. Refer to LAN-8, "Work Flow" .

NG >> Replace ECM and/or combination meter.

C

Component Inspection EKS003KF

ECM/COMBINATION METER INTERNAL CIRCUIT INSPECTION

Remove ECM and combination meter from vehicle.

D

Check resistance between ECM terminals 94 and 86.

Check resistance between combination meter terminals 34 and

35 (Without tachometer).

E

Check resistance between combination meter terminals 38 and

39 (With tachometer).

Resistance value () F

Unit Terminal

(Approx.)

ECM 94 86

WKIA0265E

Combination meter

G

34 35

(Without tachometer) 108 - 136

Combination meter

38 39 H

(With tachometer)

LAN

Revision: May 2004 LAN-15 2003 Sentra

CAN SYSTEM (TYPE 2)

[CAN]

CAN SYSTEM (TYPE 2) PFP:23710

System Description EKS003KG

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

Component Parts and Harness Connector Location EKS003KH

WKIA0266E

Revision: May 2004 LAN-16 2003 Sentra

CAN SYSTEM (TYPE 2)

[CAN]

Wiring Diagram CAN EKS003KI

LAN

WKWA0150E

Revision: May 2004 LAN-17 2003 Sentra

CAN SYSTEM (TYPE 2)

[CAN]

Work Flow EKS008XT

1. Print all the data of SELF-DIAG RESULTS for ENGINE displayed on CONSULT-II.

PKIA8260E

2. Print all the data of CAN DIAG SUPPORT MNTR for ENGINE displayed on CONSULT-II.

PKIA8343E

3. Attach the printed sheet of SELF-DIAG RESULTS and CAN DIAG SUPPORT MNTR onto the check

sheet. Refer to LAN-19, "CHECK SHEET" .

4. Based on the CAN DIAG SUPPORT MNTR results, put check marks onto the items with UNKWN or

NG in the check sheet table. Refer to LAN-19, "CHECK SHEET" .

NOTE:

If NG is displayed on "INITIAL DIAG (initial diagnosis)" as CAN DIAG SUPPORT MNTR for the diag-

nosed control unit, replace the control unit.

5. According to the check sheet results (example), start inspection. Refer to LAN-19, "CHECK SHEET

RESULTS (EXAMPLE)" .

Revision: May 2004 LAN-18 2003 Sentra

CAN SYSTEM (TYPE 2)

[CAN]

CHECK SHEET

A

J

WKIA2944E

CHECK SHEET RESULTS (EXAMPLE)

Case 1 LAN

Replace ECM.

WKIA2945E

Revision: May 2004 LAN-19 2003 Sentra

CAN SYSTEM (TYPE 2)

[CAN]

WKIA2946E

Case 2

Check CAN communication Circuit. Refer to LAN-20, "CAN Communication Circuit Check" .

WKIA2947E

CAN Communication Circuit Check EKS003KK

1. CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check following terminals and connector for damage, bend and loose connection (meter-side, control

module-side and harness-side).

Combination meter

ECM

Between combination meter and ECM

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ECM connector and harness connector F26.

2. Check continuity between ECM harness connector F59 termi-

nals 94 (L) and 86 (Y).

94 (L) 86 (Y) : Continuity should not exist.

OK or NG

OK >> GO TO 3.

NG >> Repair harness between ECM and harness connector

F26.

WKIA0257E

Revision: May 2004 LAN-20 2003 Sentra

CAN SYSTEM (TYPE 2)

[CAN]

3. CHECK HARNESS FOR SHORT CIRCUIT A

Check continuity between ECM harness connector F59 terminals 94

(L), 86 (Y) and ground.

94 (L) ground : Continuity should not exist. B

86 (Y) ground : Continuity should not exist.

OK or NG C

OK >> GO TO 4.

NG >> Repair harness between ECM and harness connector

F26.

D

WKIA0262E

4. CHECK HARNESS FOR OPEN CIRCUIT E

Check continuity between ECM harness connector F59 terminals 94

(L), 86 (Y) and harness connector F26 terminals 6 (L), 15 (Y).

F

94 (L) 6 (L) : Continuity should exist.

86 (Y) 15 (Y) : Continuity should exist.

OK or NG G

OK >> GO TO 5.

NG >> Repair harness.

H

WKIA0271E

5. CHECK HARNESS FOR SHORT CIRCUIT I

1. Disconnect combination meter connector.

2. Check continuity between harness connector M58 terminals 6 J

(L) and 15 (Y).

6 (L) 15 (Y) : Continuity should not exist.

LAN

OK or NG

OK >> GO TO 6.

NG >> Repair harness between harness connector M58 and

combination meter. L

WKIA0263E M

6. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between harness connector M58 terminals 6 (L),

15 (Y) and ground.

6 (L) ground : Continuity should not exist.

15 (Y) ground : Continuity should not exist.

OK or NG

OK >> GO TO 7.

NG >> Repair harness between harness connector M58 and

combination meter.

WKIA0264E

Revision: May 2004 LAN-21 2003 Sentra

CAN SYSTEM (TYPE 2)

[CAN]

7. CHECK HARNESS FOR OPEN CIRCUIT

1. Check the following.

Without tachometer:

Continuity between harness connector M58 terminals 6 (L), 15

(Y) and combination meter harness connector M30 terminals 34

(L), 35 (Y).

6 (L) 34 (L)

: Continuity should exist.

(Without tachometer)

15 (Y) 35 (Y)

: Continuity should exist.

(Without tachometer)

WKIA0274E

With tachometer:

Continuity between harness connector M58 terminals 6 (L), 15

(Y) and combination meter harness connector M30 terminals 38

(L), 39 (Y).

6 (L) 38 (L)

: Continuity should exist.

(With tachometer)

15 (Y) 39 (Y)

: Continuity should exist.

(With tachometer)

OK or NG

OK >> GO TO 8.

WKIA1105E

NG >> Repair harness.

8. ECM/COMBINATION METER INTERNAL CIRCUIT INSPECTION

Check components inspection. Refer to LAN-22, "ECM/COMBINATION METER INTERNAL CIRCUIT

INSPECTION" .

OK or NG

OK >> Connect all the connectors and diagnose again. Refer to LAN-18, "Work Flow" .

NG >> Replace ECM and/or combination meter.

Component Inspection EKS003KL

ECM/COMBINATION METER INTERNAL CIRCUIT INSPECTION

Remove ECM and combination meter from vehicle.

Check resistance between ECM terminals 94 and 86.

Check resistance between combination meter terminals 34 and

35 (Without tachometer).

Check resistance between combination meter terminals 38 and

39 (With tachometer).

Resistance value ()

Unit Terminal

(Approx.)

ECM 94 86

WKIA0265E

Combination meter

34 35

(Without tachometer) 108 - 136

Combination meter

38 39

(With tachometer)

Revision: May 2004 LAN-22 2003 Sentra

CAN SYSTEM (TYPE 3)

[CAN]

CAN SYSTEM (TYPE 3) PFP:23710

A

System Description EKS003KM

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec- B

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. C

Component Parts and Harness Connector Location EKS003KN

WKIA0276E

G

LAN

Revision: May 2004 LAN-23 2003 Sentra

CAN SYSTEM (TYPE 3)

[CAN]

Wiring Diagram CAN EKS003KO

WKWA0151E

Revision: May 2004 LAN-24 2003 Sentra

CAN SYSTEM (TYPE 3)

[CAN]

Work Flow EKS008XU

A

1. Print all the data of SELF-DIAG RESULTS for ENGINE and A/T displayed on CONSULT-II.

PKIA8260E

2. Print all the data of CAN DIAG SUPPORT MNTR for ENGINE and A/T displayed on CONSULT-II. E

H

PKIA8343E

3. Attach the printed sheet of SELF-DIAG RESULTS and CAN DIAG SUPPORT MNTR onto the check

sheet. Refer to LAN-26, "CHECK SHEET" . I

4. Based on the CAN DIAG SUPPORT MNTR results, put check marks onto the items with UNKWN or

NG in the check sheet table. Refer to LAN-26, "CHECK SHEET" .

J

NOTE:

If NG is displayed on "INITIAL DIAG (initial diagnosis)" as CAN DIAG SUPPORT MNTR for the diag-

nosed control unit, replace the control unit.

5. According to the check sheet results (example), start inspection. Refer to LAN-27, "CHECK SHEET LAN

RESULTS (EXAMPLE)" .

Revision: May 2004 LAN-25 2003 Sentra

CAN SYSTEM (TYPE 3)

[CAN]

CHECK SHEET

WKIA2948E

Revision: May 2004 LAN-26 2003 Sentra

CAN SYSTEM (TYPE 3)

[CAN]

CHECK SHEET RESULTS (EXAMPLE)

Case 1 A

Replace ECM.

WKIA2949E

E

Case 2

Replace TCM.

F

WKIA2950E I

Case 3

Check Can communication Circuit. Refer to LAN-27, "CAN Communication Circuit Check" .

J

LAN

M

WKIA2951E

CAN Communication Circuit Check EKS003KQ

1. CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check following terminals and connector for damage, bend and loose connection (control module-side

and harness-side).

TCM

ECM

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

Revision: May 2004 LAN-27 2003 Sentra

CAN SYSTEM (TYPE 3)

[CAN]

2. CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ECM connector and TCM connector.

2. Check continuity between ECM harness connector F54 termi-

nals 33 (L) and 34 (Y).

33 (L) 34 (Y) : Continuity should not exist.

OK or NG

OK >> GO TO 3.

NG >> Repair harness between ECM and TCM.

LKIA0006E

3. CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F54 terminals 33

(L), 34 (Y) and ground.

33 (L) ground : Continuity should not exist.

34 (Y) ground : Continuity should not exist.

OK or NG

OK >> GO TO 4.

NG >> Repair harness between ECM and TCM.

LKIA0007E

4. CHECK HARNESS FOR OPEN CIRCUIT

Check continuity between ECM harness connector F54 terminals 33

(L), 34 (Y) and TCM harness connector F56 terminals 5 (L), 6 (Y).

33 (L) 5 (L) : Continuity should exist.

34 (Y) 6 (Y) : Continuity should exist.

OK or NG

OK >> GO TO 5.

NG >> Repair harness.

WKIA0277E

5. ECM/TCM INTERNAL CIRCUIT INSPECTION

Check components inspection. Refer to LAN-29, "ECM/TCM INTERNAL CIRCUIT INSPECTION" .

OK or NG

OK >> Connect all the connectors and diagnose again. Refer to LAN-25, "Work Flow" .

NG >> Replace ECM and/or TCM.

Revision: May 2004 LAN-28 2003 Sentra

CAN SYSTEM (TYPE 3)

[CAN]

Component Inspection EKS003KR

ECM/TCM INTERNAL CIRCUIT INSPECTION A

Remove ECM and TCM from vehicle.

Check resistance between ECM terminals 33 and 34.

B

Check resistance between TCM terminals 5 and 6.

Resistance value ()

Unit Terminal

(Approx.) C

ECM 33 34

108 - 136

TCM 56

D

PKIA0298E

LAN

Revision: May 2004 LAN-29 2003 Sentra

CAN SYSTEM (TYPE 3)

[CAN]

Revision: May 2004 LAN-30 2003 Sentra

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Omm KubotaDocument38 paginiOmm KubotaHafizhKiranaÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- SRS System Precautions and ProceduresDocument56 paginiSRS System Precautions and ProceduresAldo ApazzaÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- F4a41 - F4a42 - W4a42 - F4a51 - F5a51Document4 paginiF4a41 - F4a42 - W4a42 - F4a51 - F5a51Aldo Apazza100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- D905 D1105 V1505 D1105-T V1505-TDocument1 paginăD905 D1105 V1505 D1105-T V1505-TAldo ApazzaÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Check your wheels and tires for road noise issuesDocument6 paginiCheck your wheels and tires for road noise issuesAldo ApazzaÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- At PDFDocument760 paginiAt PDFAldo ApazzaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- AJUSTES Y TORQUE MOTORES KUBOTA SERIE D (EPA Tier 2)Document17 paginiAJUSTES Y TORQUE MOTORES KUBOTA SERIE D (EPA Tier 2)Julio GuerreroÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Diesel Engine: 05-E3B SERIES, 05-E3Bg SeriesDocument130 paginiDiesel Engine: 05-E3B SERIES, 05-E3Bg SeriesAldo ApazzaÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Jacobsen - d1105 PartsDocument72 paginiJacobsen - d1105 Partstheunauthorised0% (1)

- EmDocument196 paginiEmJeff KleinÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Diesel Engine: 05-E3B SERIES, 05-E3Bg SeriesDocument130 paginiDiesel Engine: 05-E3B SERIES, 05-E3Bg SeriesAldo ApazzaÎncă nu există evaluări

- WW PDFDocument10 paginiWW PDFAldo ApazzaÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- AJUSTES Y TORQUE MOTORES KUBOTA SERIE D (EPA Tier 2)Document17 paginiAJUSTES Y TORQUE MOTORES KUBOTA SERIE D (EPA Tier 2)Julio GuerreroÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Ec PDFDocument1.864 paginiEc PDFAldo ApazzaÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- PG PDFDocument56 paginiPG PDFAldo ApazzaÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- BL PDFDocument120 paginiBL PDFAldo ApazzaÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- RaxDocument10 paginiRaxtomallor101Încă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- RF PDFDocument18 paginiRF PDFAldo ApazzaÎncă nu există evaluări

- Rsu PDFDocument14 paginiRsu PDFAldo ApazzaÎncă nu există evaluări

- MTC PDFDocument92 paginiMTC PDFAldo ApazzaÎncă nu există evaluări

- Se PDFDocument6 paginiSe PDFAldo ApazzaÎncă nu există evaluări

- SB PDFDocument12 paginiSB PDFAldo ApazzaÎncă nu există evaluări

- Starting & Charging System GuideDocument34 paginiStarting & Charging System GuideAldo ApazzaÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Ps PDFDocument28 paginiPs PDFAldo ApazzaÎncă nu există evaluări

- Engine Lubrication GuideDocument22 paginiEngine Lubrication GuideAldo ApazzaÎncă nu există evaluări

- Di PDFDocument56 paginiDi PDFAldo ApazzaÎncă nu există evaluări

- MT PDFDocument190 paginiMT PDFAldo ApazzaÎncă nu există evaluări

- Parking Brake System: SectionDocument4 paginiParking Brake System: SectionAldo ApazzaÎncă nu există evaluări

- Ma PDFDocument38 paginiMa PDFAldo ApazzaÎncă nu există evaluări

- LT PDFDocument48 paginiLT PDFAldo ApazzaÎncă nu există evaluări

- Narrative ReportDocument7 paginiNarrative ReportJeLo ReaNdelarÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Knowledge Sharing Session ON THE Topic OF "Statistical Quality Control Tools"Document14 paginiKnowledge Sharing Session ON THE Topic OF "Statistical Quality Control Tools"Ashutosh RawatÎncă nu există evaluări

- Tle9 Computer System Servicing Module 3Document24 paginiTle9 Computer System Servicing Module 3Ardee DuculanÎncă nu există evaluări

- 7 Quality Tools for Process ImprovementDocument76 pagini7 Quality Tools for Process ImprovementPappuRamaSubramaniamÎncă nu există evaluări

- 7qc Tools ExplanationDocument64 pagini7qc Tools ExplanationRajÎncă nu există evaluări

- 7QC Tools for Problem SolvingDocument3 pagini7QC Tools for Problem SolvingshubhamÎncă nu există evaluări

- Tle - Ict - CSS: Quarter 1 - Module 1: Applying Quality Standards (AQS)Document40 paginiTle - Ict - CSS: Quarter 1 - Module 1: Applying Quality Standards (AQS)Reymond Pabriga SumayloÎncă nu există evaluări

- Quality Assurance 6 PDF FreeDocument149 paginiQuality Assurance 6 PDF FreeBeto VilanculoÎncă nu există evaluări

- 5S Implementation Guide for Lean SitesDocument24 pagini5S Implementation Guide for Lean Sitesjgprasad100% (1)

- CPHQ Exam Practice 2Document21 paginiCPHQ Exam Practice 2Doodi Aljameel100% (2)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 7 QC ToolsDocument16 pagini7 QC ToolsNeeraj AroraÎncă nu există evaluări

- Chapter 11Document70 paginiChapter 11Esther TobingÎncă nu există evaluări

- QC Story - BPS Template FY 23 Supplier SamratDocument39 paginiQC Story - BPS Template FY 23 Supplier SamratPrabal Pratap SinghÎncă nu există evaluări

- Application of Quality ToolsDocument20 paginiApplication of Quality ToolsNishant Singh100% (1)

- Operations Management ASSIGNMENTDocument36 paginiOperations Management ASSIGNMENTKiruthika nagarajanÎncă nu există evaluări

- TQM Question BankDocument20 paginiTQM Question BankbhuvansparksÎncă nu există evaluări

- Form K Accreditation Body (Ab) Witness Assessment Check SheetDocument5 paginiForm K Accreditation Body (Ab) Witness Assessment Check Sheet44abcÎncă nu există evaluări

- Mssl-Cqa Presents E - Module On "7 QC Tools"Document10 paginiMssl-Cqa Presents E - Module On "7 QC Tools"Sourabh pathakÎncă nu există evaluări

- 03 TQMDocument44 pagini03 TQMimran27pk100% (1)

- 4M Change TrackingDocument2 pagini4M Change TrackingMd sameerÎncă nu există evaluări

- Unit 2 Basic Data Collection and Analysis ToolsDocument7 paginiUnit 2 Basic Data Collection and Analysis Toolsleonard dela cruzÎncă nu există evaluări

- Master of Business Administration - MBA Semester 2 MB0044-Production & Operations ManagementDocument47 paginiMaster of Business Administration - MBA Semester 2 MB0044-Production & Operations ManagementASR07Încă nu există evaluări

- Basic 7 Tools of QualityDocument37 paginiBasic 7 Tools of Qualityberry trisnamuktiÎncă nu există evaluări

- 7 QC Tools 7 Quality Tools Process Improvement ToolsDocument14 pagini7 QC Tools 7 Quality Tools Process Improvement ToolsYan Lin KyawÎncă nu există evaluări

- Basic Seven ToolsDocument33 paginiBasic Seven ToolsSin TungÎncă nu există evaluări

- 7QC ToolsDocument48 pagini7QC ToolsSudhagarÎncă nu există evaluări

- GE 8077 - TQM Principles and ToolsDocument36 paginiGE 8077 - TQM Principles and ToolsmenakadevieceÎncă nu există evaluări

- QCC & 7qc ToolsDocument160 paginiQCC & 7qc ToolsGopala Gopala100% (2)

- Module 4 Note D SSQMDocument20 paginiModule 4 Note D SSQMSaszzÎncă nu există evaluări

- 7-QC Tools: 1) Run ChartDocument10 pagini7-QC Tools: 1) Run Chartkevin21790Încă nu există evaluări