Documente Academic

Documente Profesional

Documente Cultură

5110B Performance Report II (PR00269)

Încărcat de

suwarjitechnicDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

5110B Performance Report II (PR00269)

Încărcat de

suwarjitechnicDrepturi de autor:

Formate disponibile

Caterpillar Product Information

Performance Report

August, 2000

Caterpillar 5110B ME

Job Purpose Measure the productivity of Caterpillar 5110B ME

Job Site Appalachian coal mine, U.S.A.

Study Date 24 August, 2000

Material Blasted sandstone and shale overburden 2750 lbs/LCY

Loading Tools Caterpillar 5110B Mass Excavator 9.4 yd (7.2 m)

For Dealer Sales Personnel

Caterpillar Confidential Green

Haul Units Payloader 350 (50 ton)

Observers John Ingle, Mining Shovel Group, Caterpillar Inc.

Jerry Risley, Mining Shovel Group, Caterpillar Inc.

Brian Redpath, Mining Shovel Group, Caterpillar Inc.

Rick Roddis, Mining Shovel Group, Caterpillar Inc.

Written By James Humphrey, Mining Shovel Group, Caterpillar Inc.

Significant Results The 5110B achieved a production rate of nearly 1500 tons ( 1300

tonnes) per 50 min. hr. with cycle times averaging 19.3 seconds per

cycle.

Test Procedure Machine cycles were timed using a portable computer and software.

During each cycle four separate time segments were collected. The

sum of the segment averages was taken as the total cycle time per

pass, then a standard truck exchange time of 0.7 minutes was used to

develop the production estimate.

Payload was gathered from a truck weigh scale system. Over the

course of the test 26 trucks were weighed and 94 cycles timed.

Machine Configuration 5110B

Boom 24.9 ft (7.6m)

Stick 11.1 ft (3.4m)

Bucket 9.4 yd (7.2 m)

Machine Weight 275,000 lb. (125 tonne)

Net Power 696 hp (519 kW)

Hydraulic Power 1085 hp (809 kW)

Breakout Force 112,725 lb. (501 kN)

Crowd Force 98,775 lb. (439 kN)

Rated Bucket Payload 14.3 ton (13 tonne)

. 2000 Caterpillar PR00269

Caterpillar Confidential Green

Job Description The 5110B in this application was loading a blasted interbedded shale and

sandstone overburden into 50 tons trucks. The shovel was operating from a

bench about 15 ft. (5 m.) above the floor. The trucks reversed in on the floor

level and were positioned so that the shovel needed to swing only about 45,

which provided for very efficient loading.

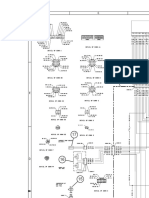

Typical Loading Position

Typical Digging Face

. 2000 Caterpillar PR00269

Caterpillar Confidential Green

Results The 5110B achieved an average cycle time of only 19.3 seconds over the nearly

100 cycles. The calculated production rate was 1,464 tons (1,329 tonnes) per 50

minute hour, which equates to about 1,750 tons (1,600 tonnes) per 60 minute

hour. Using an estimated in situ density of about 3600 lbs/BCY (2.1

tonnes/BCM), this equates to over 800 BCY (600 BCM) per 50 minute hr.

These production rates were derived using a standardized 0.7 minute exchange

time between trucks so that the results could be compared with other 5110B

production studies. However, the actual exchange time between trucks

averaged less than half this standard value, which resulted in actual production

rates of over 2,300 tons (2,100 tonnes) per 60 minute hour.

The calculated average bucket load was only 12.5 tons (11.4 tonnes) this is

apparently about 17% less than rated. However in fact the shovel was only

using partial buckets on the 4th pass so as not to overload the trucks. The first 3

passes on each truck had a larger payload than the average. The trucks had

average payloads of 50.9 tons (46.3 tonnes).

Avg Dump Time (sec) 2.9

Avg Swing Empty Time (sec) 3.8

Avg Load Time (sec) 4.7

Avg Swing Loaded Time (sec) 7.8

Avg Loader Cycle Time (sec) 19.3

Avg Bucket Fill Factor (%) 96.5

Avg Passes/Truck 4.1

Avg Truck Load Time (min) 1.0

Caterpillar standard Truck Exchange (min) 0.7

Avg Trucks/Hour 34.5

Avg Bucket Payload (tons) 12.5

Avg Truck Payload (tons) 50.9

System Production (tons/50 min. hr) 1,464

System Production (BCY/50 min. hr)* 810

Metric Summary

Avg Bucket Payload (tonnes) 11.3

Avg Truck Payload (tonnes) 46.2

System Production (tonnes/50 min. hr) 1,329

System Production (BCM/50 min. hr)* 620

* Volumes are estimates based on 3600 lbs/BCY (2.1 tonnes/BCM)

Standardized truck exchange was used to enable comparison with other

studies, actual time was less than half of this standard

The information contained herein is intended for circulation only to Caterpillar and dealer employees whose duties

require knowledge of such reports and is intended exclusively for their information and training. It may contain

unverified analysis and facts observed by various Caterpillar or dealer employees. However, effort has been made to

provide reliable results regarding any information comparing Caterpillar built and competitive machines. Effort has

been made to use the latest available spec sheet and other material in the full understanding that these are subject to

change without notice.

Any reproduction of this release without the foregoing explanation is prohibited.

. 2000 Caterpillar PR00269

Caterpillar Confidential Green

S-ar putea să vă placă și

- Analisis-Ekonomi-Usaha-Ayam-Petelur-Cv.-Santoso-Farm-Di-Desa-Kerjen-Kecamatan-Srengat-Kabupaten-Blitar-Economic-Analysis-Of-Layer-At-CV.-“Santoso-Farm”-In-Kerjen-Village-Srengat-Subdistrict-Blitar-Regency.pdfDocument156 paginiAnalisis-Ekonomi-Usaha-Ayam-Petelur-Cv.-Santoso-Farm-Di-Desa-Kerjen-Kecamatan-Srengat-Kabupaten-Blitar-Economic-Analysis-Of-Layer-At-CV.-“Santoso-Farm”-In-Kerjen-Village-Srengat-Subdistrict-Blitar-Regency.pdfsuwarjitechnicÎncă nu există evaluări

- AC SchematicDocument6 paginiAC SchematicsuwarjitechnicÎncă nu există evaluări

- DM 45 LP Track Adjuster Only SN 7958Document7 paginiDM 45 LP Track Adjuster Only SN 7958suwarjitechnicÎncă nu există evaluări

- 7188Document518 pagini7188suwarjitechnic100% (2)

- 8271Document698 pagini8271suwarjitechnic100% (2)

- 5110B Prod Bulletin (TEJB7050)Document40 pagini5110B Prod Bulletin (TEJB7050)suwarjitechnic100% (2)

- Shovel Loading GuidesDocument20 paginiShovel Loading Guidessuwarjitechnic100% (1)

- 5110B Performance Report I (PR00263)Document5 pagini5110B Performance Report I (PR00263)suwarjitechnicÎncă nu există evaluări

- 5110B Prod Bulletin (TEJB7050)Document40 pagini5110B Prod Bulletin (TEJB7050)suwarjitechnic100% (2)

- 5110B Prod Bulletin (TEJB7050)Document28 pagini5110B Prod Bulletin (TEJB7050)suwarjitechnicÎncă nu există evaluări

- 375 - 375L Specalog (AEHQ3850) PDFDocument28 pagini375 - 375L Specalog (AEHQ3850) PDFsuwarjitechnic100% (1)

- 5110b Me Perf Rep (Texr0388)Document6 pagini5110b Me Perf Rep (Texr0388)suwarjitechnicÎncă nu există evaluări

- 365B L Your Working Advantage (AEDC0603-01)Document16 pagini365B L Your Working Advantage (AEDC0603-01)suwarjitechnic100% (1)

- 365B Service Tool ListDocument4 pagini365B Service Tool ListsuwarjitechnicÎncă nu există evaluări

- 365BL Prod Bulletin (TEJB6080)Document40 pagini365BL Prod Bulletin (TEJB6080)suwarjitechnic100% (3)

- 365BL II Specalog (Aehq5373-01 (1) )Document28 pagini365BL II Specalog (Aehq5373-01 (1) )suwarjitechnic100% (1)

- 365B L Your Working Advantage (AEDC0603-01)Document12 pagini365B L Your Working Advantage (AEDC0603-01)suwarjitechnicÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- High School Students' Attributions About Success and Failure in Physics.Document6 paginiHigh School Students' Attributions About Success and Failure in Physics.Zeynep Tuğba KahyaoğluÎncă nu există evaluări

- Assignment Nutrition and HydrationDocument17 paginiAssignment Nutrition and Hydrationmelencio olivasÎncă nu există evaluări

- APPSC Calender Year Final-2017Document3 paginiAPPSC Calender Year Final-2017Krishna MurthyÎncă nu există evaluări

- II092 - Horiz & Vert ULSs With Serial InputsDocument4 paginiII092 - Horiz & Vert ULSs With Serial InputsJibjab7Încă nu există evaluări

- Ecg Quick Guide PDFDocument7 paginiEcg Quick Guide PDFansarijavedÎncă nu există evaluări

- US Army Medical Course MD0722-100 - Microbiology For The Veterinary SpecialistDocument114 paginiUS Army Medical Course MD0722-100 - Microbiology For The Veterinary SpecialistGeorges100% (2)

- Traditional vs. Enterprise Risk Management - How Do They DifferDocument4 paginiTraditional vs. Enterprise Risk Management - How Do They DifferJaveed A. KhanÎncă nu există evaluări

- Optical Fiber Communication Unit 3 NotesDocument33 paginiOptical Fiber Communication Unit 3 NotesEr SarbeshÎncă nu există evaluări

- Bakery Ind HygieneDocument104 paginiBakery Ind Hygienelabie100% (1)

- Cheap TBE Inverter TeardownsDocument33 paginiCheap TBE Inverter TeardownsWar Linux92% (12)

- ISBAR For Clear CommunicationDocument6 paginiISBAR For Clear Communicationmehara1920Încă nu există evaluări

- Laughter, It Is Good For YouDocument2 paginiLaughter, It Is Good For YouClaire B.L.Încă nu există evaluări

- Qi Gong & Meditation - Shaolin Temple UKDocument5 paginiQi Gong & Meditation - Shaolin Temple UKBhuvnesh TenguriaÎncă nu există evaluări

- Mass SpectrometryDocument49 paginiMass SpectrometryUbaid ShabirÎncă nu există evaluări

- Ifm Product Innovations PDFDocument109 paginiIfm Product Innovations PDFJC InquillayÎncă nu există evaluări

- HEYER VizOR - Product List - 1015Document7 paginiHEYER VizOR - Product List - 1015kalandorka92Încă nu există evaluări

- RCM Design and ImplementationDocument34 paginiRCM Design and ImplementationRozi YudaÎncă nu există evaluări

- Gmail - RedBus Ticket - TN7R20093672Document2 paginiGmail - RedBus Ticket - TN7R20093672Bappa RoyÎncă nu există evaluări

- Indiana Administrative CodeDocument176 paginiIndiana Administrative CodeMd Mamunur RashidÎncă nu există evaluări

- BRC1B52-62 FDY-F Ducted Operation Manual - OPMAN01!1!0Document12 paginiBRC1B52-62 FDY-F Ducted Operation Manual - OPMAN01!1!0Justiniano Martel67% (3)

- Senographe Crystal: The Choice Is Crystal ClearDocument7 paginiSenographe Crystal: The Choice Is Crystal ClearmuhammadyassirÎncă nu există evaluări

- Monitoring AlkesDocument41 paginiMonitoring AlkesEndangMiryaningAstutiÎncă nu există evaluări

- For Hand Grip Strength: NormsDocument7 paginiFor Hand Grip Strength: NormsPraneethaÎncă nu există evaluări

- 10.0 Ms For Scaffolding WorksDocument7 pagini10.0 Ms For Scaffolding WorksilliasuddinÎncă nu există evaluări

- Aircaft Avionics SystemDocument21 paginiAircaft Avionics SystemPavan KumarÎncă nu există evaluări

- Ajr.09.2772 Grading Neuroforaminal StenosisDocument4 paginiAjr.09.2772 Grading Neuroforaminal StenosisOscar NogueraÎncă nu există evaluări

- AppendicitisDocument7 paginiAppendicitisTim LuoÎncă nu există evaluări

- Workshop Manual Transporter 2016 19-29Document157 paginiWorkshop Manual Transporter 2016 19-29samueleÎncă nu există evaluări

- Week 1 Seismic WavesDocument30 paginiWeek 1 Seismic WavesvriannaÎncă nu există evaluări

- Harmonized Household Profiling ToolDocument2 paginiHarmonized Household Profiling ToolJessa Mae89% (9)