Documente Academic

Documente Profesional

Documente Cultură

5110B - L Prod Bulletin (TRJB9047)

Încărcat de

suwarjitechnicTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

5110B - L Prod Bulletin (TRJB9047)

Încărcat de

suwarjitechnicDrepturi de autor:

Formate disponibile

Caterpillar Product Information

Product Bulletin

January 2003

Cat 5110B/5110B L

Hydraulic Excavators

For Dealer Sales Personnel

This document supplements information in the Specalog. All product

content in this document will be available on CAT.com after product

launch. Marketing content will be available only on secured dealer

extranets and by accessing the PDF in the Electronic Sales Library.

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Productivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Durability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Versatility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Transportability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Machine Positioning Strategy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Superior Productivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reliable Performance and Durability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Low Operating Cost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Smooth Handling, Efficient Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Competitive Situation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cat 5110B vs. Komatsu PC1250SP-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cat 5110B vs. Hitachi EX1200-5 BE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cat 5110B vs. Liebherr R984C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cat 5110B L vs. Komatsu PC1250LC-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cat 5110B L vs. Hitachi EX1200-5 BE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cat 5110B L vs. Liebherr R984C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Train. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Undercarriage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operators Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Booms and Sticks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Buckets and Ground Engaging Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Serviceability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Customer Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Overview

Cat 5110B Mass Excavator

Cat 5110B L Hydraulic Excavator

The Caterpillar 5110B/5110B L Hydraulic Excavator is designed for mining, quarrying,

heavy construction and material handling applications. Weighing 127-129 metric tons

(140-142 U.S. tons), the 5110B establishes a new size class and is ideally suited for

loading Cat 773E trucks and other 45- to 55-metric ton capacity (50- to 60-ton)

trucks in four passes. The 5110B is also capable of loading trucks with capacities as

large as 90 metric tons (100 tons), such as the Cat 777D.

The Cat 5110B Hydraulic Excavator is the newest excavator in the Cat mass excavator

line-up and offers customers a new choice in excavator size and performance. Designed

and built for superior strength and durability in the most demanding digging condi-

tions, this new machine provides higher production and better pass matches than

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 3

Overview

competitive 100- to 110-metric ton general purpose excavators. Yet the 5110B is as

versatile and transportable as 110-metric ton machines. In North America, the 5110B

ships in six truck loads.

The 5110B will be offered in three configurations to match a range of applications.

Designed for mining and heavy construction applications, the current mass excavation

configuration is built to meet the performance, reliability and durability standards

expected of Caterpillar equipment. Mass excavator buckets range from 6.2 to 10.4 cubic

meters (8.1 to 13.6 cubic yards). The general purpose configuration is optimized for

construction, trenching and pipelaying. The material handling configuration, will be best

suited for industrial applications.

The 5110B features superior breakout and crowd forces and a long and wide

undercarriage. The combination creates a stable machine with aggressive digging

capabilities for high productivity. Proven Caterpillar components the Cat 3412E

HEUI engine and proportional priority pressure compensating hydraulics ensure

smooth performance and high reliability at a lower cost-per-ton. The electronically

controlled engine delivers the power to keep material moving at 758 gross/696 net

horsepower (565/519 kW).

The 5110B stands out from the competition in the areas of productivity, reliability,

durability, safety, transportability, customer service and versatility.

Productivity

With the largest available heavy duty rock bucket in its class, the 5110B/5110B L

swings a 15 to 25% greater payload, produces higher digging forces, and moves more

tons-per-hour than the competition. With PPPC hydraulic control, an independent

swing hydraulic circuit, and electronically controlled pumps and engine, the 5110B

can efficiently and economically apply full hydraulic power on demand.

Reliability

The 5110B/5110B L is designed to provide the customer maximum machine avail-

ability. Field proven Cat components are matched to the machine for smooth,

responsive performance and high reliability. Parts commonality with the large Cat

machine line-up ensures maximum parts availability, lower repair costs and reduced

downtime. The 5110B uses the same engine as the 773E, 990, D10R, and 24H; same

swing drives as 5130B and 5230B; same cab as 345B; same main control valve as

385, 5130B and 5230B; same track links as D10R; and same track tensioning system

as the 5130B.

4 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Overview

Durability

The 5110B/5110B L is designed for significantly longer structural and service life

than the competition. The machine incorporates robust design features for superior

structural strength and durability. Additionally, it is designed to be economically

rebuildable, for added service life.

Versatility

With a variety of boom and stick options and wide range of work tools, the 5110B L

provides maximum versatility to accomplish a wide range of jobs.

Safety

Some 5110B/5110B L safety features include:

Ladder. Wide, stationary ladder allows the operator to mount and dismount the machine

while maintaining three points of contact at all times with steps and hand holds.

Service Access. Most routine servicing can be accomplished from ground level.

A cross walkway provides service access to all main maintenance points.

Bulk head. A bulk head wall separates the engine from the pump room, minimizing

heat exposure to the hydraulic system.

Minimally-pressurized Hydraulic Tank. Reduces oil discharge in the event of a leak.

Access Lighting. Permits 24-hour boarding and service access.

Operator Station. The front windshield is standard laminated glass; the right and

rear windows are impact resistant polycarbonate. The cab is quiet.

Walkways. Slip-resistant steel materials provide reliable access in broad range of

climatic and operating conditions.

Standards. Designed, tested and self-certified to national and international standards.

Shut Off Switches. Switches are located in the engine compartment and at ground

level for safe shutdown.

Control Lever. Hydraulic activation control lever prevents hydraulics from oper-

ation when in locked position.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 5

Overview

Secondary Egress. Secondary or emergency egress from the cab is provided out

the rear window.

Electrical System Disconnect. Disconnect switch is located outside the battery

compartment to lock out the electrical system.

Travel Alarm. Exterior warning sounds when the travel circuit is activated.

Swing and Travel Brakes. Swing brake automatically engages when operator leaves

hydraulic controls untouched for 8 seconds. Travel brakes engage when machine

is not moving.

Transportability

Despite its greater weight, the 5110B/5110B L is transportable in the same number

of U.S. legal truck loads as the competition. Balanced lift eyes are provided on all

major structures. Hydraulic and grease lines are designed to disconnect quickly and

cleanly. The result is a machine with reduced assembly and disassembly time and

cost.

Customer Support

Caterpillar and the worldwide dealer network provide customer support that is

unmatched in the industry. Cat dealers offer a range of maintenance services to help

protect your investment. Field service, parts availability and product support is superior

to the competition, and enable customers to operate longer with lower operating costs

and less downtime.

6 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Machine Positioning Strategy

Superior Productivity

High bucket fill factors and fast cycle times drive the 5110Bs productivity. This

machine is capable of loading 55 metric ton (60 ton) haulers in well under two

minutes, and is pass matched to the 773E Off-Highway Truck. Intelligent on-demand

hydraulics deliver quick lift and swing performance to meet that goal. Machine

stability is enhanced with a long undercarriage and wide track gauge for a 10 percent

larger footprint. High drawbar pull aids maneuverability.

Productivity is more than quick cycle times it also requires a full bucket load.

Superior breakout and crowd forces combine to provide a competitive advantage

in bucket loading. Additionally, the 5110B has a 15 to 25% larger bucket than the

competition and has demonstrated more than a 30% productivity advantage.

Reliable Performance and Durability

The 5110B/5110B L is designed to meet the reliability and durability expectations of

Cat customers. With a greater operating weight and superior structural design features,

the 5110B provides reliable performance and durability well beyond the competition.

Structures are validated using computer Finite Element Analysis and are double-

checked by strain gauge testing in the field.

The 5110B incorporates many design features for superior structural strength and

long life, including:

Cross roller swing bearing. Mining-duty bearing provides stiffer design with greater

contact area than competitive ball bearing designs.

Swing bearing mounting. Bolted directly to machined surface on carbody to

eliminate welds in critical stress area.

Surface tension transfer welding. Enhanced weld geometry process eliminates

need for back bars in confined weld areas and improves reliability.

Castings. Heat-treated castings in high load areas of frame, stick and boom,

ensure smooth transition of stresses into structures.

Thermal stress relieving. Stress relieved boom, stick and carbody weldments

reduce residual stresses and provide longer structural life.

Break-in coatings. Manganese-iron-phosphate coated bushings provide initial

lubrication for trouble-free startup.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 7

Machine Positioning Strategy

The 5110B is designed for superior performance in extreme temperatures. Hydraulic

cooling system with extra large cooling capacity meets ambient temperature rating of

50C (122F), while optional high ambient cooling raises this rating to 55C (131F).

The 5110B cooling system is quiet and meets 1999 European sound regulations.

Electronic Monitoring System III (EMS III) alerts the operator to conditions in

critical systems throughout the machine, so potential problems are caught and

corrected early, preventing costly downtime. EMS II also improves reliability by

notifying the operator of potential problems before catastrophic failure occurs.

Compared with competitive machines in this size class, the 5110B is 15 to 20% larger

by operating weight. However, when comparing smart weight (i.e. components,

structural steel and drive system) after removing dumb weight (i.e. counterweight

and fluids), customers actually get 20 to 30% more working machine. This relates

directly to strength, durability and production.

Low Operating Cost

The 3412E Hydraulic Electronic Unit Injection (HEUI) engine offers the most

efficient fuel injection system available today. Injection, timing, duration, and pressure

are optimized continuously, based on sensor input for RPM, air pressure, temperature,

etc. Solid state electronics eliminate repair costs associated with mechanical injection.

Engine history is stored in memory to allow service personnel to monitor engine

performance and diagnose preventative repairs.

Implement and travel circuits conserve fuel by using a closed-center, load sensing

hydraulic system. The system delivers oil flow according to demand instead of

circulating oil flow continuously, and needlessly consuming fuel. The independent

hydraulic cooling system has variable speed capability, with fan rotation speed

determined by input from temperature sensors, and draws only the power required by

current conditions. Automatic Engine Speed Control automatically reduces engine

RPM when controls are left untouched for four seconds.

The fuel tank holds enough fuel for two shifts at an average load factor, maximizing

machine availability. Optional automatic lubrication reduces manual maintenance

required every ten hours. Walk-around access to the engine and pumps makes routine

visual checks easy.

The undercarriage, with sealed and greased track, is lifetime lubricated and automat-

ically tensioned for maintenance-free duty.

8 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Machine Positioning Strategy

Smooth Handling, Efficient Hydraulics

Technology advanced hydraulics allow the Cat 5110B/5110B L to respond to

operator actions with predictable, smooth operation.

Cat pressure-compensating valves regulate flow to the actuators in the implement

circuit, delivering only as much flow as the operator requests, even when other

functions in the circuit are receiving higher flow. Intelligent hydraulics deliver oil to

all desired circuits without having to modulate some of the other circuits.

Proportional priority enables every circuit to receive the amount of flow determined

by the operator control setting during normal operation. When demand exceeds

system capacity, such as during simultaneous travel and linkage operations, flow is

divided proportionally between the circuits according to demand.

Electronic underspeed control prevents excess engine lugging. This electronic

protection makes it unnecessary to maintain a reserve of engine power, maximizing

fuel efficiency.

The Cat 5110B hydraulic system consists of durable, proven components, including

Cat XT hose and couplings. A dedicated piston pump drives the independent swing

circuit for fast, consistent cycle performance.

An optional auxiliary valve with control arrangement allows the 5110B to operate

high pressure tools such as thumbs, hammers, shears and crushers.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 9

Competitive Situation

The 5110Bs three primary mass excavator competitors in the 80- to 140-metric ton

(90- to 150-ton) class are the Komatsu PC1250SP-7, Hitachi EX1200-5 BE, and

Liebherr 984C. Komatsu and Hitachi compete worldwide. Liebherrs efforts are

focused primarily in Europe, Africa and the Middle East.

Cat 5110B vs. Komatsu PC1250SP-7

Weight Class Caterpillar Komatsu Cat

100+ Ton 5110B PC1250SP-7 Advantage

Mass Excavators Units Metric English Metric English %

Operating Weight tonne (ton) 127 (140) 110 (121) +15

Smart Weight* tonne (ton) 108 (119) 92 (101) +17

Net Power (SAE) kW (hp) 514 (689) 485 (651) +6

Hydraulic Flow L/min (gpm) 1800 (476) 1617 (427) +11

Breakout Force kN (kip) 586 (132) 502 (113) +17

Crowd Force kN (kip) 458 (103) 395 (89) +16

Bucket Capacity m3 (yd3) 7.6 (9.9) 6.7 (8.8) +13

Payload tonne (ton) 13.7 (15.1) 12 (13.2) +14

Dump Height m (ft) 8.6 (28.2) 8.5 (27.8) +1

Reach @ Ground Level m (ft) 13.5 (44.3) 13.7 (44.9) 1

Maximum Dig Depth m (ft) 7.9 (25.9) 7.9 (25.9) 0

Drawbar Pull kN (kip) 846 (190) 686 (154) +23

Footprint m2 (ft2) 26.2 (282) 23 (248) +14

*Operating weight less fluids and counterweight

A brief review of specs reveals that the 5110B is larger than the Komatsu machine

most significantly almost 20% larger in smart weight and with a nearly 15% larger

bucket. This relates to a weight-to-capacity ratio of about 13.7 metric tons/m3 for the

Komatsu, slightly lighter-duty than the 14.2 metric tons/m3 for the 5110B. The

PC1250 uses an electronic open centered hydraulic system and does not have an

independent swing circuit, further effecting productivity. Therefore, the Komatsu

requires the use of manual mode selection switches to set hydraulic priorities.

Additionally, the Komatsu swing function suffers loss of hydraulic flow when the

other functions are operating. With 6% less power, 11% less hydraulic flow, and

2% less hydraulic relief, the PC1250 generates 17% less bucket force than the 5110B,

all of which adds up to a noticeable difference in production.

Much like the 5110B, the PC1250 uses a cross walkway for engine access, however

access is limited to one side only. The side-by-side engine/hydraulic cooling system

on the Komatsu is not as efficient as the independent system used on the 5110B.

Additionally, the pump room is accessible only from one point (the end) and is

mounted rather low, both of which result in a poor working space. Despite recent

improvements, the bulkhead separating the pump room from the engine still provides

the poorest protection of all the competitors. Neither the engine nor the pump room

have covered or lighted access.

10 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Competitive Situation

The Komatsu PC1250 is a relatively new machine released mid 2002, and is an

enhanced version of the PC1100. Although many improvements have been added

such as increased horsepower, hydraulic flow and additional weight, the PC1250 still

does not match up to the 5110B.

Structurally, the top plate of the carbody is not a single plate design like the 5110B.

The PC1250 plate is cut and welded to accommodate the swing bearing mounting

ring, unlike the single solid top plate of the 5110B that has better structural integrity.

Cat 5110B vs. Hitachi EX1200-5 BE

Weight Class Caterpillar Hitachi Cat

100+ Ton 5110B EX 1200-5 BE Advantage

Mass Excavators Units Metric English Metric English %

Operating Weight tonne (ton) 127 (140) 109 (120) +17

Smart Weight* tonne (ton) 108 (119) 89 (98) +22

Net Power (SAE) kW (hp) 514 (689) 478 (641) +8

Hydraulic Flow L/min (gpm) 1800 (476) 1485 (392) +21

Breakout Force kN (kip) 586 (132) 550 (124) +7

Crowd Force kN (kip) 458 (103) 412 (93) +11

Bucket Capacity m3 (yd3) 7.6 (9.9) 5.6 (7.3) +36

Payload tonne (ton) 13.7 (15.1) 10.1 (11.1) +36

Dump Height m (ft) 8.6 (28.2) 8.0 (26.3) +7

Reach @ Ground Level m (ft) 13.5 (44.3) 13.4 (43.9) +1

Maximum Dig Depth m (ft) 7.9 (25.9) 7.9 (26.0) 1

Drawbar Pull kN (kip) 846 (190) 617.8 (139) +37

Footprint m2 (ft2) 26.2 (282) 23.1 (249) +14

*Operating weight less fluids and counterweight

As with the other competitive machines, the 5110B is larger than the EX1200. With

22% more smart weight and a 36% larger bucket, the 5110B out classes Hitachi.

Further affecting productivity, the EX1200 uses an open-centered hydraulic system

and does not have an independent swing circuit. Therefore, it requires the use of

manual mode selection switches to set hydraulic priorities. Additionally, the swing

function suffers loss of hydraulic flow when the other functions are operating. With

13% less gross engine power (8% less net), 21% less hydraulic flow, and 2% less

hydraulic relief, the EX1200 generates 7% less bucket force than the 5110B. Hydraulic

flow and power is significantly less than the 5110B, resulting in much slower speeds.

A production study showed that the 5110B is about 30% more productive than the

Hitachi machine.

The EX1200 uses a cross walkway engine access much like the 5110B, however

engine access is limited to one side only. Engine access is a step below deck cavity,

which further limits workspace. The side-by-side engine/hydraulic cooling system is

not as efficient as the independent system used on the 5110B. The pump room is

accessible only from one side (the end) and is at the end of the walkway, limiting

crane access and working space. Additionally, neither the engine nor the pump room

have covered or lighted access.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 11

Competitive Situation

Cat 5110B vs. Liebherr R984C

Weight Class Caterpillar Liebherr Cat

100+ Ton 5110B R984C Advantage

Mass Excavators Units Metric English Metric English %

Operating Weight tonne (ton) 127 (140) 111 (122) +14

Smart Weight* tonne (ton) 108 (119) 89 (98) +22

Net Power (SAE) kW (hp) 514 (689) 499 (669) +3

Hydraulic Flow L/min (gpm) 1800 (476) 1819 (481) 1

Breakout Force kN (kip) 586 (132) 550 (124) +7

Crowd Force kN (kip) 458 (103) 416 (94) +10

Bucket Capacity m3 (yd3) 7.6 (9.9) 6.7 (8.8) +13

Payload tonne (ton) 13.7 (15.1) 12.1 (13.3) +13

Dump Height m (ft) 8.6 (28.2) 9.2 (30.0) 6

Reach @ Ground Level m (ft) 13.5 (44.3) 13.7 (44.9) 1

Maximum Dig Depth m (ft) 7.9 (25.9) 8.1 (26.4) 2

Drawbar Pull kN (kip) 846 (190) 867 (195) 2

Footprint m2 (ft2) 26.2 (282) 23.2 (250) +13

*Operating weight less fluids and counterweight

As with the other competitors the 5110B is larger than the Liebherr. With 22% more

smart weight and a 13% larger bucket, the 5110B out-classes this competitor. Of

the three competitors, the 984C has the largest operating weight at 111.1 metric tons,

however 17% of that weight is the 19-metric ton counterweight. As a result, the 984C

has about the same smart weight as the Hitachi EX1200. The 984C has a similar

smart weight-to-capacity ratio of relatively light 13.3 metric tons/m3, significantly

less than the 5110Bs 14.2 metric tons/m3.

The 984C does not have a crosswalk, which hampers access for inspection and

maintenance. It uses a tandem hydraulic and engine cooling system that is much less

efficient than the independent system on the 5110B. The 984C only has a single

swing drive, which concentrates all of the swing forces to one point on the swing gear

and causes most of the wear on the front half of the swing gear. The top plate of the

carbody is not a single plate design like the 5110B. The 984C plate is cut and welded

to accommodate the swing bearing mounting ring, unlike the single solid top plate of

the 5110B that has better structural integrity.

The 984C uses a hydraulic system with similar power and flow characteristics to the

5110B, despite this, the 984C only produces stick and bucket forces about equal to

the EX1200, giving the 5110B a 7% bucket and 10% stick force advantage. Addition-

ally, the 5110B has a 21% advantage in swing torque. All of these factors combined

give the 5110B a significant production advantage.

12 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Competitive Situation

The 5110B Ls three primary mass excavator competitors in the 80- to 140-metric

ton (90- to 150-ton) class are the Komatsu PC1250LC-7, Hitachi EX1200-5 BE and

Liebherr 984C. Komatsu and Hitachi compete worldwide. Liebherrs efforts are

focused primarily in Europe, Africa and the Middle East.

Cat 5110B L vs. Komatsu PC1250LC-7

Weight Class Caterpillar Komatsu Cat

100+ Ton 5110B L PC1250LC-7 Advantage

Mass Excavators Units Metric English Metric English %

Operating Weight tonne (ton) 129 (142) 113 (125) +13

Smart Weight* tonne (ton) 109 (120) 95 (105) +14

Net Power (SAE) kW (hp) 514 (689) 485 (651) +6

Hydraulic Flow L/min (gpm) 1800 (476) 1617 (427) +11

Breakout Force kN (kip) 527 (119) 422 (94.8) +25

Crowd Force kN (kip) 391 (88) 327 (73.5) +20

Bucket Capacity m3 (yd3) 6 (7.8) 5 (6.5) +20

Payload tonne (ton) 10.8 (11.9) 9 (9.8) +20

Dump Height m (ft) 10 (32.6) 9 (29.5) +11

Reach @ Ground Level m (ft) 16 (52.5) 16 (52.5) 0

Maximum Dig Depth m (ft) 10.5 (34.4) 10.4 (34.2) +1

Drawbar Pull kN (kip) 846 (190) 686 (154) +23

Footprint m2 (ft2) 29.3 (315) 29.3 (315) 0

*Operating weight less fluids and counterweight

A brief review of specs reveals that the 5110B L is larger than the Komatsu machine

most significantly almost 15% larger in smart weight and with a 20% larger bucket.

The weight-to-capacity ratio of both machines is equal, calculating to be between 18 to

20 metric tons/m3. The PC1250 uses an electronic open centered hydraulic system

and much like its predecessor, the PC1100, the PC1250 does not have an independent

swing circuit. The Komatsu requires the use of a manual mode selection switch to set

hydraulic priorities. Additionally, the Komatsu swing function suffers loss of hydraulic

flow when other functions are operating. Both the 5110B L and the PC1250 offer the

heavy lift mode option, which enhances lift capability by approximately 10%. With

6% less power and 11% less hydraulic flow, the PC1250 generates 25% less bucket force

and 20% less crowd force than the 5110B L, all of which adds up to a noticeable

difference in production capability.

Much like the 5110B L, the PC1250 uses a cross walkway for engine access,

however access is limited to one side only. The side-by-side engine/hydraulic cooling

system on the Komatsu is not as efficient as the independent system used on the

5110B L. Additionally, the pump room is accessible only from one point (the end)

and is mounted rather low, both of which results in a poor working space. Despite

recent improvements, the bulkhead separating the pump room from the engine still

provides the poorest protection of all the competitors. Neither the engine nor the

pump room have covered or lighted access.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 13

Competitive Situation

The Komatsu PC1250LC is a relatively new machine, released mid 2002, and is an

enhanced version of the PC1100. Although many improvements have been added,

such as increased horsepower, hydraulic flow and vehicle weight, the PC1250LC still

does not match up to the 5110B L.

Structurally, the top plate of the carbody is not a single plate design like the 5110B L.

The PC1250 plate is cut and welded to accommodate the swing bearing mounting

ring, unlike the single solid top plate of the 5110B L that has better structural integrity.

Cat 5110B L vs. Hitachi EX1200-5 BE

Weight Class Caterpillar Hitachi Cat

100+ Ton 5110B L EX1200-5 Advantage

Mass Excavators Units Metric English Metric English %

Operating Weight tonne (ton) 129 (142) 108 (119) +16

Smart Weight* tonne (ton) 109 (120) 91 (98) +20

Net Power (SAE) kW (hp) 514 (689) 478 (641) +8

Hydraulic Flow L/min (gpm) 1800 (476) 1485 (392) +21

Breakout Force kN (kip) 527 (119) 457 (103) +15

Crowd Force kN (kip) 391 (88) 330 (74) +18

Bucket Capacity m3 (yd3) 6 (7.8) 4 (5.2) +50

Payload tonne (ton) 10.8 (11.9) 7.2 (7.9) +50

Dump Height m (ft) 10 (32.6) 9.4 (29.6) +10

Reach @ Ground Level m (ft) 16 (52.5) 16.1 (49.2) +2

Maximum Dig Depth m (ft) 10.5 (34.4) 10.4 (30.6) +3

Drawbar Pull kN (kip) 846 (190) 618 (139) +37

Footprint m2 (ft2) 29.3 (315) 23.1 (249) +1

*Operating weight less fluids and counterweight

As with the other competitive machines, the 5110B L is larger than the EX1200.

With 20% more smart weight and a 50% larger bucket, the 5110B L outclasses the

Hitachi. Further affecting productivity, the EX1200 uses an open-centered hydraulic

system and does not have an independent swing circuit. Therefore, it requires the use

of manual mode selection switches to set hydraulic priorities. Additionally, the swing

function suffers loss of hydraulic flow when the other functions are operating. With

8% less net engine power, and 21% percent less hydraulic flow, the EX1200 generates

15% less bucket force than the 5110B L. Hydraulic flow and power is significantly

less than the 5110B L, resulting is much slower speeds. A production study showed that

the 5110B L is significantly more productive than the Hitachi machine.

The EX1200 uses a cross walkway engine access much like the 5110B L, however

engine access is limited to one side only. Engine access is a step below deck cavity,

which further limits workspace. The side-by-side engine/hydraulic cooling system is

not as efficient as the independent system used on the 5110B L. The pump room is

accessible only from one side (the end) and is at the end of the walkway, limiting

crane access and working space. Additionally, neither the engine nor the pump room

have covered or lighted access.

14 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Competitive Situation

Cat 5110B L vs. Liebherr R984C

Weight Class Caterpillar Liebherr Cat

100+ Ton 5110B L R984C Advantage

Mass Excavators Units Metric English Metric English %

Operating Weight tonne (ton) 129 (142) 114 (124) +14

Smart Weight* tonne (ton) 109 (120) 90 (100) +20

Net Power (SAE) kW (hp) 514 (689) 499 (669) +3

Hydraulic Flow L/min (gpm) 1800 (476) 1819 (481) 1

Breakout Force kN (kip) 527 (119) 550 (124) 4

Crowd Force kN (kip) 391 (88) 346 (78) +13

Bucket Capacity m3 (yd3) 6 (7.8) 3.9 (5.1) +28

Payload tonne (ton) 10.8 (11.9) 7 (7.7) +28

Dump Height m (ft) 10 (32.6) 10.7 (32.8) 1

Reach @ Ground Level m (ft) 16 (52.5) 16.3 (49.9) 0

Maximum Dig Depth m (ft) 10.5 (34.4) 10.5 (30.7) +3

Drawbar Pull kN (kip) 846 (190) 872 (196) 3

Footprint m2 (ft2) 29.3 (315) 23.3 (251) +56

*Operating weight less fluids and counterweight

As with other competitors the 5110B L is larger than the Liebherr. With 20% more

smart weight and a 28% percent larger bucket, the 5110B L out-classes this competitor.

As a result, the 984C has a similar smart weight-to-capacity ratio of relatively light

18.9 metric tons/m3, significantly less than the 5110B Ls 21.8 metric tons/m3. Of the

three competitors, the 984C has the largest operating weight at 114 metric tons,

however 16% of that weight is the 19-metric ton counterweight.

The 984C does not have a crosswalk, which hampers access for inspection and

maintenance. It uses a tandem hydraulic and engine cooling system that is much less

efficient that the independent system on the 5110B L. The 984C only has a single

swing drive, which concentrates all of the swing forces to one point on the swing gear

and causes most of the wear on the front half of the swing gear. The top plate of the

carbody is not a single plate design like the 5110B L. The 984C plate is cut and

welded to accommodate the swing bearing mounting ring, unlike the single solid top

plate of the 5110B L that has better structural integrity.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 15

Hydraulics

Hydraulics. Powerful Cat hydraulics deliver the power and control needed to keep material moving.

High breakout and stick forces maximize bucket loads. Cat PPPC hydraulic system delivers flow on

demand for smooth, efficient operation of implements, regardless of load.

Load Sensing Hydraulics. Load sensing

variable flow displacement pumps and pressure

compensating control system continually monitor

hydraulic power requirements and adjusts flow

and pressure to match. Pressure sensing hydraulics

ensures system uses only necessary flow and

horsepower for cooler running hydraulics,

increased component life and greater fuel

efficiency. Load sensing hydraulic system

delivers high breakout and crowd forces

regardless of engine speed.

Flow On Demand. Unique four-pump system

three for implement and travel, and one for

swing delivers flow on demand to maximize

hydraulic efficiency. Pressure and flow

compensation deliver only as much flow as needed

to reduce heat buildup and component wear.

Hydraulic System. The 5110B hydraulic system PPPC Valves. PPPC valves regulate flow to every

provides efficient transfer of power from engine actuator in the implement circuit. Intelligent

to buckets, tracks, and swing drives for smooth, hydraulics deliver oil to each function

multitasking operations. Engine communicates proportionally according to demand without

with hydraulic system to adjust pumps to having to modulate some of the functions.

maximize engine power. Hydraulic fluid is

filtered on low pressure side and screens are used Automatic Flow Proportioning. When flow is

on high pressure side for clean operation. Load required by more than one function at a time

sensing hydraulic system delivers high breakout (e.g. boom up and stick out), automatic flow

and crowd forces regardless of engine speed. proportioning divides required flow for each

Efficient, high-pressure hydraulics deliver fast function according to demand to ensure smooth,

cycle times for greater productivity. precise, multifunction operation.

PPPC System. Cat Proportional Priority Pressure Proportional Joystick Movement. Intelligent

Compensating (PPPC) hydraulic system assures PPPC system varies hydraulic oil flow in direct

smooth, efficient operation and controllability. proportion to joystick lever movement for

PPPC valves regulate flow to actuators in smooth, predictable operation and greater

implement circuit. Load sensing signal from operator efficiency.

the valves constantly adjust pump pressure

and deliver oil to each function proportionally, Electronically Controlled Pumps. Computer

according to demand, without having to controlled pumps regulate and match hydraulic

modulate some of the functions. Implements output to engine power for maximum engine

(boom, stick and bucket) work at a constant hydraulic power transfer efficiency. Hydraulic

speed regardless of machine load and engine system draws full engine power for precise,

speed for efficient, multifunction operation. full-powered hydraulic response.

16 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Hydraulics

3 4

1

6

14

7 8

13

10

12

9

11

Hydraulic System Schematic

Pump Design. Electronically controlled pumps output is combined, then directed through the

have been field proven in the most demanding main valve, as needed, to the boom, stick and

conditions for performance, durability and bucket cylinders and/or travel motors based on

reliability. Integral impeller supercharges the demand. Pumps work together to produce flow

pump to prevent cavitation. Rebuildable pumps only on demand for a cooler running system and

reduce repair costs. High reliability reduces longer lasting components.

costly downtime.

Swing System. An independent, dedicated

Electronic Underspeed Control. Load sensing swing pump powers the swing hydraulic system.

control system destrokes the pumps during This allows the 5110B to swing under full power,

hydraulic system overload to prevent excessive regardless of boom, stick, bucket and travel

engine lugging. Thus, the engine operates in its demand, for quick, full-powered swing

most efficient range at all times, for superior performance. During loading operations,

fuel efficiency. hydraulic loaders only momentarily reach top

swing speed, making acceleration more important.

Implement and Travel Systems. Intelligent With its independent, open-center load sensing

closed-center load sensing system produces flow swing system, the 5110B is geared and

on demand for maximum hydraulic efficiency. powered to insure fast swing acceleration with

Three variable-displacement pumps are circuited uninterrupted application of power. High-pressure

to the main PPPC valve to act as a one-pump hydraulic system delivers fast cycle times.

system, providing equal access to flow. Pump

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 17

Hydraulics

Auxiliary Hydraulics. An optional auxiliary valve

with control arrangement allows the 5110B L

to operate high-pressure tools such as thumbs,

hammers, shears and crushers. Flow settings can

be adjusted to meet specific tool requirements.

A separate medium pressure circuit is available

for functions such as rotate.

Hydraulic Cooling. Independent of engine

cooling, separate variable-capacity temperature-

sensing hydraulic cooling system with dedicated

core radiator provides cooling on demand to

maximize hydraulic efficiency. Extra-large

standard cooling capacity allows operation in

Hydraulic Tank. Oval shaped hydraulic tank

ambient temperatures up to 50C (122F).

reduces hydraulic system complexity. Reinforced

Optional high ambient cooling package provides

steel construction with additional top and bottom

additional cooling in extremely hot conditions

plating, edge channels and internal cross ribbing

by increasing cooling capacity sufficient for

for added strength and protection. Minimally-

operation in 55C (131F) ambient temperatures.

pressurized design reduces risk of excessive

Hydraulic Demand Fan. Hydraulic oil cooling fan oil discharge if a leak occurs. Vacuum breaker

is separate from engine cooling fan to maximize valve lets in filtered air to prevent cavitation.

hydraulic efficiency. Temperature-controlled Sight gauge allows for easy inspection of oil

variable speed fan provides cooling on demand to level from cross walkway.

maintain optimum hydraulic fluid temperature

Hydraulic System Filtration. Advanced filtration

for greater fuel economy.

system uses 35-micron absolute (10-micron

Cat Hydraulic Hose. Field proven Cat XT high- nominal) reverse-flow hydraulic fluid filters

pressure hydraulic hose is exceptionally strong in the hydraulic tank. Proven, environmental

and durable for high system reliability and long friendly filters designed for quick changes

life in the most demanding conditions. Reusable without spills. These eight return filters

couplings provide superior, leak free performance six main filters, and two for case drains are

and prolong hose assembly life. initially fitted with 5-micron absolute filters for

first 250 hours of operation to insure a clean

system at startup. Additionally, three 200-micron

high-pressure screens filter the pump discharge

lines one single and one double in the main

implement lines, and one single in the swing

lines. High pressure screens clean oil on the

high pressure side where there is the highest

potential for damage. To further reduce risk of

contamination, the pilot system uses a 15-micron

filter and the hydraulic tank fill point uses a

550 micron screen. Advanced filtration system

provides dependable hydraulic system operation

and long component life.

18 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Power Train

Power Train. The Cat 3412E turbocharged engine delivers high horsepower to maximize productivity.

Field proven for reliable performance in the most demanding applications, the 3412E offers superior

fuel efficiency, lower emissions, reduced engine noise and lower operating costs.

Cylinder Head. One-piece, high tensile strength

gray iron casting resists twisting and dynamic

flexing. High coolant passages provide optimum

piston ring cooling.

Cylinder Liners. Cast iron alloy cylinder liners

are induction hardened for high reliability and

long life. Precision honing provides superior

cross hatch for maximum oil control. Liner

flange is roll burnished to protect against cracking.

Pistons. Large bore stroke single-piece piston

design minimizes internal stresses and increases

component life. Steel alloy casting with low

crevice bowl design has cast-in oil gallery for

optimum cooling. High compression ratio and

high fuel injection pressures improve emissions

and performance while reducing fuel consumption.

Engine. Cat 3412E HEUI engine delivers

Twin Turbochargers. Turbochargers are

reliable power with low emissions, excellent fuel

carefully matched to engine rating for optimum

economy, and traditional Caterpillar durability.

performance. Advanced bearing system and

Engine is matched to hydraulic pump output for

improved aerodynamics provide excellent

smooth, multitasking operation.

response, altitude compensation, and lower

emissions. ECM continually monitors turbo

Engine Design. The 3412E four-stroke, air-to-air

performance and delivers optimum fuel-to-air

after cooled (ATAAC) engine features large

ratio for greater efficiency.

structures and a low RPM rating for excellent

durability and long life. The 12-cylinder design

Air-to-Air Aftercooler. Air-to-Air Aftercooler

features two banks of six cylinders with dual air

(ATAAC) uses advanced air-to-air heat

cleaners, dual turbochargers, dual exhaust, and

exchanger to deliver superior cooling and long

dual mufflers. High ratio of displacement to

engine life. Air-to-air heat exchanger cools

power translates into long life to overhaul

outside inlet air to optimize combustion and fuel

because there is more iron to withstand heat

economy. ATAAC cools hot high pressure air

and fatigue stresses.

from turbochargers to reduce exhaust

temperatures and extend component life.

Cylinder Block. Stress-relieved, one-piece high

tensile strength cast iron alloy cylinder block

with thick, high strength cast iron walls, is

stabilized to maintain internal dimension under

all operating conditions. Thick walls and deep-

skirted lower structure provide durability,

strength and rigidity.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 19

Power Train

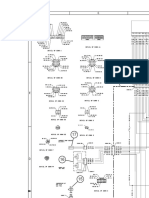

1 Ground Bolt

2 Disconnect Switch

3 Battery (24V)

11 4 Breaker (15A)

5 Vehicle Connector

6 Main Power Relay

7 Keyswitch

8 10-Position Throttle

9 9 One Touch Idle Down Switch

7 19 10 Ground Level Shutdown

3 Switches (2x)

MACHINE

+ - 12 11 AESC Enable Switch

ECM

12 Machine Control Module

13 Control Valve Warm-Up Solenoid

10 14 Inlet Air Temp Sensor

8 15 Right and Left Turbo Inlet

Pressure Sensors

16 Ether Starting Aid Switch

2 17 PowerShift Pressure Sensor

PowerShift Solenoid

6 18 Cat Data Link

18 19 ET or ECAP Service Tool

4

20 Engine ECM

21 EMS II Console

16

1 5

ENGINE

ECM

20

21

14

15 17

13

Machine Electronic Control Module System

Electronic Control Module. The engine Automatic Altitude Compensation. ECM matches

Electronic Control Module communicates atmospheric pressure with elevation providing

with Machine Control Module and Electronic full engine power up to 3050 m (10,000 ft).

Monitoring System, and function together as Above that elevation, it automatically derates

the electronic brains of the coordinated power engine to maintain proper fuel-to-air mixture for

system. The computerized power system senses clean, efficient combustion. Compensation also

operating conditions and power requirements protects turbos from overheating in low oxygen

and adjusts engine for most efficient operation atmospheric conditions.

at all times. There is minimal wasted engine

horsepower because engine output is based Oil Temperature Compensation. ECM

on operator demand and job conditions. automatically compensates for effects of oil

temperature on fuel injector timing and delivery.

ECM Monitoring. Input from sensors allow the Activates cold mode timing when oil temperature

ECM to monitor and control injection, timing, decreases below 60C (140F).

injection pressure, engine cooling fan speed,

ether starting aid, and hydraulic pumps to adjust Fuel Temperature Compensation. ECM

to any operating conditions. In the event of a automatically compensates for effects of fuel

problem, the ECM automatically warns operator temperature to maintain optimum fuel-to-air

and derates engine, if necessary. mixture for clean combustion.

20 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Power Train

3 4 1 Hydraulic Pumps

1 TO

ENGINE

2 Oil Filter

3 Lube Pump

2

4 Fuel Injectors (12x)

5 Injection Actuation Pressure Control Valve

6 Injection Actuation Pressure Sensor

6 7 7 Fuel Supply Passage

5 8 Fuel Tank

9 Fuel Pressure Regulator

10 HEUI ECM

9

8 11 Fuel Temperature Sensor

12 Engine Oil Pressure Sensor

13 Turbocharger Outlet Pressure Sensors

10 14 Coolant Flow Switch

17

15 EMS II

21

16 Machine ECM

17 Batteries

18 Atmospheric Pressure Sensor

16

19 Engine Oil Temperature Sensor

20

20 Engine Coolant Temperature Sensor

15 21 Engine Speed/Timing Sensors

19 11

12

13

18

14

Engine Electronic Control Module System

Coolant Flow Protection. ECM monitors coolant threshold, load sensing control destrokes pumps

flow and automatically warns operator and to prevent lugging. Hydraulic pumps use full

derates engine if flow ceases. engine power without maintaining costly power

reserves for optimum fuel efficiency.

Air Pressure Sensor Calibration. ECM measures

turbocharger performance and automatically HEUI Fuel System. Cats proprietary fuel system

calibrates fuel delivery for optimum performance. utilizes hydraulically actuated, electronically

controlled, unit injectors and electronically

Low Oil Pressure Protection. ECM monitors oil monitors operator and sensor inputs to optimize

pressure and automatically warns operator and engine performance, reliability, emissions and

derates engine if pressure is low. fuel efficiency. HEUI fuel system independently

controls injection over entire engine operating

Diagnostic Capability. ECM records and stores speed range for precise control of injection

event information for diagnostic troubleshooting. pressure, timing and duration. Flexible unit

Event information, engine history, and injectors are tuned for optimum engine

instantaneous data can be downloaded from ECM performance at any crank angle, for a cost

using Cat Data Link with Electronic Technician. effective, environmentally clean system.

Adjustment-free hydraulic actuation fuel system

Electronic Underspeed Control. ECM constantly has fewer moving parts, making it quieter and

monitors hydraulic system demand and matches more reliable than traditional systems. High

hydraulic pump output with engine speed for injection pressures over entire engine speed

maximum engine to hydraulic power transfer range provide better fuel efficiency, cold starts,

efficiency. When hydraulic demand goes beyond and low speed engine response.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 21

Power Train

Injection Pressure. HEUI fuel system determines Cold Start Mode. On start-up, ECM checks

injection pressure by electronically controlling engine jacket water temperature. If temperature

high pressure actuating oil. High injection is below 60C (140F), electronic governor

pressures generate better fuel atomization for elevates idle speed and retards timing to extend

more complete combustion with higher energy piston and liner life.

release and lower emissions. Electronic injection

pressure control improves fuel economy, low

speed engine response, and smoke and

particulate reduction.

Injection Timing. Infinitely variable,

electronically controlled fuel injection timing

can be injected at any crank angle for efficient

fuel delivery in any operating conditions.

ECM monitors engine oil temperature and

controls timing and RPM for better cold and hot

starts. Optimum timing is set at every speed and

load point for infinite control of injection timing,

improved performance, and reduced emissions,

smoke and noise.

Injection Duration. HEUI fuel system

electronically controls injection duration by

changing duration and pressure to optimize fuel

delivery. System automatically adjusts duration

depending on speed requirements and load

conditions to improve engine performance

and fuel economy.

Automatic Engine Speed Control. Maximizes fuel

efficiency and reduces engine noise by reducing AMOCS Cooling System. Exclusive two-pass

engine speed when hydraulic controls are advanced modular cooling system provides high

inactive. If hydraulic controls are not activated ambient cooling capacity for greater cooling

for four seconds, engine speed is reduced from efficiency. Modular radiator use seven replaceable

high to low idle. Operator can activate control and interchangeable cores for quick and easy

to suit application, such as between truck loading serviceability. If damage occurs, there is no need

cycles. Feature can be deactivated from cab for to replace whole radiator. Optional high ambient

complete operator control. cooling package for extremely hot conditions

allows sufficient cooling up to 55C (131F)

Ether Starting Aid. Helps ensure engine starting ambient temperature.

in extreme cold operating conditions. ECM controls

ether injection until coolant reaches 10C (50F)

or engine speed exceeds 1200 rpm. Manual mode

allows operator to inject a precise quantity of

ether as required.

22 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Undercarriage

Undercarriage. The Cat 5110B is designed with a high ground clearance, wide track gauge, and long

standard track for excellent stability, maneuverability and lift capacity. Maintenance-free sealed and

greased track with automatic track tensioning deliver long service life.

Long Undercarriage. The 5110B L features a

lengthened undercarriage to better tackle rough

terrain on heavy construction job sites. The longer

frame creates additional front and rear stability

for greater lift capacity and reach capability.

Guarded Components. Travel motors, brakes

and final drives are integrated within track roller

frame for impact and shock protection from

rocks and other hazards. Hydraulic lines are

routed through guarded passages for protection

and long service life.

Travel Motors. Independent, two-speed, bent-axis

travel motors deliver smooth power to tracks and

allow counter-rotation for spot turns. Two-speed

travel provides fast travel on flat floor and full

power on turns and slopes. Hydraulic actuation

ensures smooth shifts.

Stable Design. Proven undercarriage design and

rugged structures assure outstanding durability

Final Drives. Final drives are three-stage planetary

in extreme conditions. Wide track gauge, large

with case-hardened gears. Two large tapered

undercarriage and high ground clearance provide

roller bearings support sprocket loads. The final

excellent stability, maneuverability and lift capacity.

drive assembly and hydraulically released, spring

applied, multi-plate parking brake mounts as a

Track Roller Frames. Durable Cat frames hold

single unit to the track roller frame. Track motor

moving undercarriage components rigidly in place

can be pulled out independently to simplify

and absorb high force travel loads transmitted

servicing of brakes.

from carbody. Rugged design offers high

resistance to shock and vibration. Box beam

design with internal stiffening plates provide

increased strength. Mounting faces on frames

are machined for a tight, secure fit of carbody

to frames.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 23

Undercarriage

Assembly Alignment Guides. Self-aligning

grooves on track roller frames allow easy

alignment of carbody to frame for quick machine

assembly and disassembly.

Sealed and Greased Track. Track is sealed and

greased for maintenance-free duty. Grease

lubrication seals protect track link from abrasive

wear for long track pin and bushing inner wear

life. Large links, pins and bushings are designed

for demanding mining applications.

Track Links. Robust track links are structurally

designed to handle tremendous shock loads

transferred from machine to tracks. Solid pins

with positive pin retention increase track strength.

Track Shoes. Multiple shoe options allow shoes

to be matched to the application and underfoot

Rollers and Sprockets. Durable, single-flange

conditions. All shoes are fabricated with double

track rollers rotate on large-diameter, solid shafts

grousers and clipped corners.

for heavy duty operation. Carrier rollers are

mounted on structural supports integral to the

Automatic Track Tensioning. Hydraulically

track roller frame, compared with traditional

controlled track tensioning maintains constant

bolt-on support towers, for exceptional durability.

tension for optimum traction and adjustment-free

Sprockets are heat-treated and teeth are induction

duty. Hydraulic recoil protects the system in the

hardened for toughness. Wear reduced tooth

event a rock becomes wedged between the idler

design allows track chain to engage alternating

and track.

pairs of teeth for even wear and long life.

24 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Structures

Structures. Structural components are the backbone of the 5110Bs durability. Heavy-duty castings

used in high load areas and fabricated box section components create a rugged machine. Thermally

stress relieved front structures and carbody provide unsurpassed strength for long structural life.

Swing frame, stick and boom with heavy duty castings shown in red.

Robust Design. The 5110B is designed with Swing Frame. High-strength steel I-beam

robust structural components for heavy-duty construction provides outstanding resistance to

mining applications. Structures are designed fore-and-aft bending loads from front linkage

and built to absorb high impact shock loads and and counterweight. Reinforced steel gussets and

twisting forces for superior structural durability, side plates provide optimum strength against

reliability and long life. torsion loads. Heat-treated castings in boom foot

pedestal area provide superior structural strength

Heavy Duty Castings. Heat-treated castings used and durability. Low-carbon, low-alloy steel is

extensively in high load areas on swing frame, fully repairable without pre-heating.

stick and boom, ensure smooth flow of stresses

for long-term structural durability.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 25

Structures

Front Structures. Durable front linkage is sturdy Carbody. Designed and built to withstand

and strong, yet light enough for fast cycle times. demanding digging, swing, and travel loads.

Box-section design provides unsurpassed rigidity Carbody structures are thermally stress relieved

and strength. High strength steels used in critical after fabrication for long structural life. Internal

areas insure impact and wear resistance in gussets add strength to H-shaped box section

difficult digging conditions. Thermally stress design to resist torsional bending. Top and

relieved structures reduce residual stresses for bottom plates are single plate construction with

longer structural life. Heat treated castings in no welded joints for maximum structural

high load areas add exceptional strength and integrity. Top plates are inclined to reduce

durability. material buildup.

26 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Structures

Swing Drives. Swing force is provided by dual,

two-stage planetary swing drives, powered by

proven Cat fixed displacement piston motors.

The two drives are located at the 12 and 6 oclock

positions for symmetrical load and wear

distribution, and long life. Torque transmitting

components are forged from high-alloy steel,

quenched and tempered for added strength.

Quality pinions are machined to AGMA class 8

Swing bearing (cutaway) standards for longer component life. Spring

applied and hydraulically released multiple wet

Swing Bearing. Mining-duty swing bearing is disc brakes are integral to the swing drives for

designed to accommodate demanding forces added durability. These parking brakes hold the

transmitted through the bearing between the upper structure securely in place after it has

carbody and swing frame. Unique cross roller stopped. The brakes engage automatically when

bearing design provides greater contact area than hydraulic controls are untouched for eight

traditional ball bearings for superior stability and seconds and release when the operator moves

long life. Efficient roller geometry results in the joystick or hydraulic controls.

lower frictional losses with reduced heat buildup.

Swing bearing is mounted directly to a machined Track Roller Frames. Designed and fabricated

surface on carbody, significantly differentiating to provide structural strength and absorb stress

the 5110B from the competition. Bolting swing loads transmitted from carbody to tracks. Upper

bearing directly to carbody eliminates collar structure weight and forces are distributed evenly

welds and provides exceptional structural across track roller frames for long-term durability.

strength and durability. Bearing rings are made Box beam design with internal stiffening plates

of specially heat-treated steel. Raceways are provides excellent strength and rigidity.

induction hardened to protect against surface

wear while preserving structural toughness in the Sticks and Booms. All sticks and booms feature

main bearing body. large welded box section structures with multi-

plate fabrications in high-stress areas to reduce

weight and enhance rigidity. Structures are

thermally stress relieved to maximize fatigue

life and durability. Internal baffle plate design

minimizes weight for optimum performance and

fast cycle times.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 27

Structures

Finite Element Analysis of Swing Frame

Link Pins. The 5110B utilizes a proven Cat link Finite Element Analysis. Finite element analysis,

pin design for superior reliability and durability. used in the design phase, identifies high load

Large, sturdy pins at main joints provide side-to- areas and optimizes design weight to ensure high

side rigidity and strength to front linkage. Pins reliability and long structural life.

are through-hardened for toughness and strength,

and case-hardened and chrome plated for wear Heavy Duty Access Points. Durable service

resistance. platforms, crosswalk, ladders and handrails

use industrial strength grating, skid plates and

Pivot Castings. Heavy-duty heat-treated pivot railings for long life in extreme conditions.

castings in the boom cylinder pivot area ensure Vibration resistant mountings on crosswalk

long-term reliability and structural life. extend service life in harsh mining applications.

Boom Foot Castings. Heavy duty castings are

used in boom foot area to handle high force

boom loads.

28 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Operators Station

Operators Station. The roomy, quiet cab promotes operator comfort and ease of operation for

maximum, shift-long productivity. Controls are positioned within easy reach of the operator for greater

control, convenience and reduced fatigue. Large windows provide excellent all-around visibility.

Spacious Cab. Roomy cab provides comfortable Hydraulic Actuation Lever. Manually applied

working environment for hours of high hydraulic actuation lever on left console cuts off

productivity. Quiet, enclosed cab has interior pilot pressure for joysticks, travel control and

sound levels of 71 db(A) to reduce operator fatigue. electrical power to prevent accidental startup

and operation when exiting the cab.

Joystick Controls. Easily accessible operator

controls provide sure, precise maneuvering for Anti-Drift Function. Optional anti-drift valve

high productivity and low operator fatigue. keeps the front linkage steady during delicate

Joystick console height is adjustable independently lifting operations.

of the seat for full operator comfort. Left joystick

controls swing and stick functions; right joystick Heavy Lift Mode. Optional feature provides

controls boom and bucket; left joystick button increased lifting capability with excellent

controls horn; right joystick button controls one- controllability when lifting heavy loads.

touch idle down function.

Third Pedal Straight Travel. Optional straight

Travel Controls. Two rocker pedals with detachable travel pedal allows straight, forward travel

hand levers control steering and travel functions. using a single pedal instead of the standard

Foot controls allow operator to move machine two pedal design.

while working front linkage or swinging machine.

Suspension Seat. Fully adjustable suspension

seat provides height and weight adjustments,

lumbar support, wide arm/wrist rests, and wide

retractable seatbelt for full operator comfort

and support.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 29

Operators Station

Monitoring System. Cat Electronic Monitoring EMS III Console. EMS III console displays vital

System III provides integrated machine system machine health information and alerts operator of

monitoring for optimum performance and high impending or abnormal conditions. Analog gauges,

reliability. EMS III continuously monitors message center, condition alert indicators and

machine conditions and alerts operator of potential operator controls are combined in a single

problems to protect machine and reduce risk of console for ease of use. EMS III provides service

catastrophic failure. Monitoring system interfaces technicians with diagnostic troubleshooting

with machine control module, electrical system capabilities to increase machine availability

and engine control module and displays status of and reduce costly downtime.

various systems on easy to use EMS III console.

Performance can be monitored regularly by Quad Gauge. Four easy-to-read analog gauges

service technicians for efficient systems diagnosis constantly display:

and preventative maintenance, improving

machine reliability and reducing costly downtime. Engine Coolant Temperature

Hydraulic Oil Temperature

Engine Oil Pressure

Fuel Level

30 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Operators Station

Operator Mode. One-touch toggle switch allows Message Center. Nine alert indicators warn

operator to scroll through machine operating the operator of the 30 most critical abnormal

parameters and diagnostic events. System displays: machine conditions. The six digit status display

window identifies over 150 diagnostic events.

Service Hour Meter The numeric message center also displays

14 different machine operating parameters,

Engine RPM as well as information from the eight other

display modes.

Engine Coolant Temperature

Service Mode. EMS III displays nine service

Hydraulic Oil Temperature modes in status display window. Four set-up

modes are used to configure machine and

Engine Oil Pressure autolube. Five diagnostic modes are used to

quickly localize mechanical and electrical

Fuel Level problems. Service modes display:

Engine Oil Temperature Operator Mode

Air Filter Restriction Pressure Diagnostic Clearing Mode

Inlet Air Temperature Switch Status Mode

System Voltage Travel Timer Mode

Throttle Position History Mode

Autolube Pressure Alert System. Three levels of warning alerts

operator of problems during machine operation.

Power Shift Pressure

Level I - Advisory. Gauge or alert indicator

Injector Actuation Pressure flashes. Machine or system needs attention.

Diagnostic Scrolling Level II - Operator Action Advised. Action lamp

flashes, gauge or alert indicator flashes. Operator

must evaluate and correct situation before

continuing work.

Level III - Immediate Shutdown Advised. Action

alarm sounds, lamp flashes, gauge or alert

indicator flashes. Demands immediate shutdown

to prevent serious damage to system or machine.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 31

Operators Station

Windows. Large, wide windows provide Cab Riser. Optional tall cab riser on 5110B L

excellent all-around visibility. Retractable front enhances visibility into trucks during same

windshield provides large viewing area. Lower level loading.

front window provides view of the tracks. Upper

left side door window slides open for excellent Cab Mounts. Double wall pressed cab shell

ventilation. Polycarbonate skylight provides an and platform are mounted to the cab riser with

unobstructed upward view. Rear window serves resilient mounts to reduce noise, vibration and

as an emergency exit for operator safety. operator fatigue.

Automatic Climate Control. Fully automatic FOGS. Optional Falling Object Guarding

system with air conditioner, heater and defroster Structure (FOGS) provides protection for

maintains constant cab temperature for operator and machine. Guards protect top of

comfortable operation in any weather condition. cab and windshield. Windshield guard swings

Positive air pressure ventilation system helps seal open for glass cleaning.

cab from dust. Fresh air filter removes dust and

particles before fresh air is circulated through cab.

A second internal filter cleans recirculated air.

32 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Booms and Sticks

Booms and Sticks. Stick and boom combinations are designed to deliver a wide range of reach and

digging forces. Two lengths of booms general purpose and mass excavation and five types of

sticks are available to ensure optimum machine versatility and application match.

Mass Excavation Boom. Designed for high

production loading, the mass excavation boom

offers significantly higher digging forces and

allows the use of larger buckets. Two sticks are

available for this boom.

General Purpose Boom. Designed to optimize

reach, digging force and bucket capacity on the

5110B L, the general purpose boom is ideal for

a wide range of applications such as digging,

loading, lifting and trenching. Three sticks are

available for this boom.

Stick Construction. All sticks are made of high-

tensile strength steel using a large box section

design with interior baffle plates and an

additional bottom plate to protect against rock

damage. Sticks are stress relieved for long life.

Boom and Stick Selection. Longer boom and

Mass Excavation Sticks. Two stick lengths

stick arrangements are designed to maximize

offer optimum productivity in various digging

digging depth and reach capabilities in a variety

conditions. Each stick is application-matched

of mining and heavy construction applications.

with specific boom and bucket combinations.

Boom Construction. All booms feature large

Short ME Stick (3.4 m). Short mass excavation

welded box section structures with multi-plate

stick is built to deliver higher digging forces and

fabrications in high-stress areas to reduce weight

swing heavier payloads. Designed for use with

and enhance rigidity. Castings are used in high

the largest heavy-duty rock buckets.

stress areas such as boom cylinder pivot and foot.

Booms are thermally stress relieved to maximize

Long ME Stick (4.1 m). Optional longer stick

fatigue life and durability while minimizing

provides additional reach and digging depth.

weight for optimum performance.

Designed for higher capacity, medium duty

buckets.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 33

Booms and Sticks

General Purpose Sticks. Three stick lengths are Long GP Stick (5.5 m). Offers the largest

designed to optimize productivity in various working envelope for greater reach and

applications. Each stick is application-matched versatility. Designed for medium buckets.

with specific boom and bucket combinations.

Work Tools. The 5110B L offers an assortment of

Short GP Stick (3.6 m). Features a tighter working tools and attachments designed to accommodate

envelope to maximize penetration and digging numerous applications. Choose from a wide

forces. Designed for use with the largest buckets. variety of Cat designed and manufactured work

tools matched specifically for special reach and

Medium GP Stick (4.5 m). Best suited for dig requirements.

trenching, excavating and general construction

applications. Designed for higher capacity buckets.

34 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators January 2003

Buckets and Ground Engaging Tools

Buckets and Ground Engaging Tools. Aggressive bucket designs and efficient linkage geometry deliver

superior bucket fill factors. A wide selection of buckets and ground engaging tools provide a match for

every application to ensure optimal machine performance.

Medium Duty Bucket

High Productivity. Aggressive Cat bucket designs

deliver unmatched productivity in demanding Medium Duty Buckets. Intended for mass

applications. High crowd force at cutting edge excavation in low abrasion, unconsolidated

improves material penetration. High breakout and materials such as top soils, clays or sands.

stick forces combine to maximize bucket loads. Unique bucket design with semi-spade edge

provides optimum penetration and high

Bucket Design. Durable Cat buckets are designed production fill factors in low impact applications.

for maximum operating efficiency and long

service life when matched to required digging

forces. Unique bucket design and linkage

geometry optimize bucket fill. Curved floor

design promotes high breakout force and smooth

material flow.

January 2003 TEJB9047 Cat 5110B/5110B L Hydraulic Excavators 35

Buckets and Ground Engaging Tools

Tips. Penetration tips maximize penetration in

densely compacted or interlocked materials to

maximize productivity. General Purpose tips

extend tip life in high wear applications. Abrasion

resistant material provides optimum tip life in

highly abrasive conditions and lowers operating

costs. Rock bucket tips are vertically pinned, and

coal and medium duty bucket tips are side pinned

for fast on-site replacement.

Adapters. Two-strap adapters provide maximum

support for tips. Crested corner adapters on hard

rock buckets provide greater strength and

smoother stress transition.

Edge Covers. Edge protectors for heavy duty rock

buckets protect bucket edge from wear in

Heavy Duty Rock Bucket materials with moderate to high wear rates.

Edge protectors are vertically pinned for easy

replacement.