Documente Academic

Documente Profesional

Documente Cultură

Refinery Process Design Notes - For IITG

Încărcat de

Nipen ParekhTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Refinery Process Design Notes - For IITG

Încărcat de

Nipen ParekhDrepturi de autor:

Formate disponibile

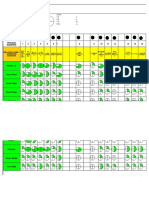

Essar Refinery Integrated Management System

MASTER CHECK LIST FOR APR 2012- MAR 2013

Plant: S & D Dept. /Section: S & D (Tank Farm)

Sr. Doc. No. Description Frequency Remark Responsibility

No.

1 Inspection of Locked Open/Closed Valves Half Yearly To be start from 1st Alpesh Patel

week of Sept 2012

2 Inspection of Guards Moving Machinery Half yearly To be start from 1st Abhishek Tiwari

week of Sept 2012

3 CHECKLIST FOR SAFTEY HARDWARE Monthly To be start from 1st Sandip Patel

week of Sept 2012

4 Inspection of Stairs/Fixed Ladders Half Yearly To be start from 1st Saurabh Gawali

week of Sept 2012

5 TOOL BOX TALK REPORT Weekly To be start from 1st Bhavik Mehta

week of Sept 2012

6 IN SERVICE INSPECTION CHECK LIST FOR Monthly To be start from 1st All field Officers

TANKS week of Sept 2012 of Tank farm

7 INSPECTION OF SAFETY SHOWER Monthly To be start from 1st Indu Mishra

week of Sept 2012

8 HOUSE KEEPING CHECKLIST Monthly To be start from 1st All Field Officers

week of Sept 2012 of Tank Farm

9 Inspection of BA/Escape Sets Quarterly To be start from 1st Krunal Jagani

week of Sept 2012

10 INSPECTION OF MCP (MANUAL CALL POINT) Quarterly To be start from 1st Nirav Vyas

week of Sept 2012

11 CHECKLIST FOR FIRE HYDRANT INSPECTION Quarterly To be start from 1st Laxman

week of Sept 2012 BhanuShali

12 WATER & FOAM TOWER MONITOR Quarterly To be start from 1st Laxman

week of Sept 2012 BhanuShali

Maintained By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

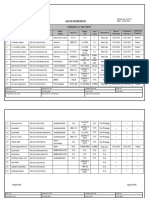

Essar Refinery Integrated Management System

Inspection of Locked Open/Closed Valves

Plant: S & D Dept. /Section: S & D (Tank Farm)

Frequency: Half Yearly Date:-

SN Location/Area Description /Identification of Normal Position Actual Position Seal is Intact Remarks

Valve

Locked Locked Open Close Yes No

open closed

1

2

3

4

5

6

7

8

9

10

11

12

Maintained By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

Inspection of Guards Moving Machinery

(Coupling, Belt Pulley, Roller etc.).

Plant: S & D Dept. /Section: S & D/ Tank farm

Frequency: Half yearly Date: ________________

SN Check Points/ Details of Moving Machinery with Deficiency Deficiency No. Corrective

Deficiency SN Moving Area/ Description Action Taken

Machinery Location

Tag No.

1. No Identification Nos. & 1

Description/not clearly painted/ 2

needs repainting.

3

2. Not fixed Properly.(Tied with

metallic wire, No/with Less bolts 4

etc.) 5

3. Guard 6

4. broken/deformed/corroded.

7

Incomplete Guard. (Excess

opening/ gap to normal reach to 8

moving parts) 9

5. No /missing guard. 10

6. Any other (please specify).

Inspected By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

CHECKLIST FOR SAFTEY HARDWARE

Plant: S & D Dept. /Section: S & D/ Tank farm

Frequency: Monthly Date: _______________ _

Deficiency List List of fire hydrant with Deficiency

Sr. Equipment Location Deficiency Corrective Action Taken

No No. No.

.

A WIND SOCK

1. Wind sock cage NOT moving freely

2. Wind sock NOT showing right direction

3. Wind sock cloth found damaged / open

stitched / colour faded

4. Wind sock base loose bolts / open

5. bolts

6. Wind sock visibility in night hours

7. NOT clear

Telescopic stand bent position

Any other, specify ( )

B EMERGENCY ASSEMBLY POINT

1. Condition of Emergency assembly

point easily visible from all sides, in

sound condition, without dull paint /

2 picture

Surrounding area - easily accessible

3. and unobstructed from all sides

Ways to Emergency Assembly point

identified and displayed / paint with in

plant?

C PORTABLE GAS DETECTOR

1. Is the gas detector not working

2. properly?

Are all attachments to the gas detector

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

viz. pump and tubing handy and in non

3. working condition?

4. Battery charging not working.

5. Display screen not clear and intact

6. Function of any button not working

7. properly

8. Sampling Pump body damage /

defect

Sampling pump not working

satisfactory

Any other, specify ( )

Inspected By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

Inspection of Stairs/Fixed Ladders

Plant: S & D Dept. /Section: S & D/Tank Farm

Frequency: Half Yearly Date: -

Deficiency List Details of Stairs/Fixed Ladders with Deficiency

Sr Area Stairs/ Location/ Deficienc Corrective Action

No. Ladder Description y Taken

Sr. No. No.

1. Cracked/Damaged steps.

2. Rusted or corroded spots

3. Loose, worn or damaged rungs

or side rails

4. Damaged or corroded part of

cage.

5. Corroded bolts & rivet heads

on inside of metal stack.

6. Damaged or corroded hand

rails or brackets on platforms.

7. Weekend or damaged run on

brick or concrete slab

8. Base of ladder obstructed.

9. Loose, corroded or damaged

support

Inspected By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

TOOL BOX TALK REPORT

Plant: S & D Dept. /Section: S & D/Tank Farm

Frequency: Weekly Date: -

SN Main Points Explained Names of the persons present Remarks

1 Importance of PPES

2 Emergency Numbers

3 Fire Fighting System (Hydrant , Monitor)

4 Usage of Safety Shower

5 House Keeping in Area

6 Importance of Safety during Hot & Cold

work

7 Fire and Gas Detection (MCP)

8 Spillage

9 Assembly Point Importance

Tool Box talk given by: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

IN SERVICE INSPECTION CHECK LIST FOR TANKS

Plant: S & D Dept. /Section: S & D/Tank Farm

Frequency: Monthly Date: -

Capacity (KL): Dia (Mt): Height (Mt): Type of Tank:

SN Particulars Observation

1.0 Foundation. Check levelness.

1.1 Concrete Ring -check for broken concrete, crakes, drain opening for

bottom leak

1.2 Asphalt-check for tank settling, look for areas where leaching of oil left rock

filler exposed.

1.3 Site drainage check operating condition of drains.

1.4 Housekeeping- inspects area for vegetation, flammable material build up.

2.0 Shell- inspect for paint failure ,pitting corrosion

Sealing between bottoms to foundation.

2.1 Shell internal-inspect for Grooving, corrosion, pitting and coating failure.

2.2 Wind girder-Inspect for corrosion at, tack welded junction, support to shell.

3.0 Man ways Nozzle-inspect for cracks, dimpling of shell plate around nozzle,

flange leak.

3.1 Tank piping and manifold-Inspect piping, flange for, leak, anchored

piping, sample connections, check weld on shell mounted davit clips above

6 dia pipe.

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

3.2 Mixer Inspect for proper mounting, leak and power cable.

4.0 Roofs Deck plate external corrosion-inspect for paint failure, pitting, hole

product on roof.

4.1 Roof deck- inspect for standing water, sagging etc.

4.2 Roof insulation-inspect for crack & leak.

4.3 Primary seal fabric inspect for deterioration, opening in seals, inspect

secondary seal for buckling,

5.0 Sample hatch- inspect sample hatch cover, its sealing, check marking of

reference height & reinforcing pad,

5.1 Gauge well-inspect size of slots, thinning, &Roof guide.

5.2 ATG-Check the hatch for corrosion and missing bolts.

5.3 Roof mounted vents in IFR Tank- check condition of screen, locking and

pivots pin.

5.4 Emergency Roof Drain- check for water level.

5.5 Roof leg-Check for their position, condition of neoprene cover.

5.6 Vacuum breaker Report type, check cleanliness of mesh.

5.7 Rim Vent- Check condition of screen on Rim Vent cover.

5.8 Pontoon inspection hatch-Check pontoon for leakage by opening hatch

cover, check for LEL, Inspect lock down device.

6.0 Handrails Inspect for pitting, hole, paint failure, attachment welds, inspect

handrail between rolling ladder and gauging platform.

6.1 Platform Frame-inspect frame for corrosion and paint failure, inspect

attachment of frame to support and supports to tank for corrosion and weld

failure.

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

6.2 Deck plate and grating Inspect deck plate for corrosion, Paint failure,

inspect grating for corrosion and tie down clip.

6.3 Stairway stringer-inspect spiral stair way stringer for corrosion paint

failure, weld failure, attachment of stairway treads to stringer, stairway

support to shell weld and reinforcing pad.

6.4 Rolling ladder-inspect rolling ladder stringer for corrosion, check condition

of ladder fixing rungs, check for wear and corrosion where rolling ladder

attached to gauging platform, inspect moving parts, inspect rolling ladder

wheel for freedom of movements, ensure 18 of unworn track & inspect

alignment of rolling ladder with roof track.

7.0 Piping Inspect piping for shoes off support, bottom out springs, support

corrosion, loose brackets & side plates and rollers.

7.1 Insulation check for damage, penetration, missing jacketing, bulging &

banding broken and missing.

8.0 Dyke check for vegetation build up, trash, inspect for cracks, inspect for

settlements, and ensure all out going pipes are properly sealed.

Abbreviation 1. Leaching - Permeate or penetrate gradually 2. Dimpling A slight depression 3.Davit clip structure

used to lower things. 4, Tread step, 5 Stringer long beam. 6, Rung one step of ladder 7.Bracket projected support.

Inspected By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

INSPECTION OF SAFETY SHOWER

Plant: S & D Dept. /Section: S & D/Tank Farm

Frequency: Monthly Date: -

Sr Description location Observation Action

No

1 Water pressure

2 Shower head.

3 Eye wash fountain ball

4 Pedal valve

5 Pull Rod

6 Housekeeping in surrounding area

7 Other if any specify

Inspected By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

HOUSE KEEPING CHECKLIST

Plant: S & D Dept. /Section: S & D/Tank Farm

Frequency: Monthly Date: -

S.No Check Points Observations Corrective Action

. Taken

Plant operations area :

1 Floor clean, no pools/spillage of condensate/ oil/chemicals/water etc.

2 Platform/Grating ok

3 Tag Nos. painted as per standard on equip./machines

4 Plant area free of superfluous material

5 Escape routes marked

6 Access to fire extinguishers/MCP/Emergency exit etc. unobstructed

7 Scrape and refuse bins provided & cleaned.

8 Temporary floor opening without barricading caution/sign boards "Do

not enter without permit".

9 Drains and vents are plugged/capped/blinded

10 Is insulation in good condition

11 Guards- Machine/Railing/Ladders/platforms ok

12 Colour Coding and Sign Boards

13 Colour coding of pipelines done & displayed conspicuously

14 Adequate Nos. of caution /hazard boards & displayed conspicuously

-appropriateness of display locations

15 Tanks identification as per standards

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

16 Road

17 Swept , No dust , No debris ,Road in good condition

18 Drains :

19 Plant drains having proper cover and surrounding area of OWS pit

clean. Pits not over flowing

20 Storm water channels -free from hydrocarbon and debris. No

vegetation growth. Pass ways over channels.

21 Fire Equipments(FH/FM/Hose Boxes/Deluge/ Extinguishers)

22 Identification Nos. painted properly & in good condition

23 Extinguishers & hose boxes at their proper location

24 Route Not obstructed

25 Hydrants/Monitors/Deluge not leaking

26 Dyke/tanks

27 Water logging/ spillage

28 Material stored/lying inside the dyke

29 Damaged dyke wall/gap at the entry point of pipes or at joints

30 Loose material lying on tank top

31 Growth of wild vegetation

Inspected By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

Inspection of BA/Escape Sets

Plant: S & D Dept. /Section: S & D/Tank Farm

Frequency: Quarterly Date: -

Deficiency List S. No. Equipment Location Deficiency No. Corrective

No. Action Taken

1. Cylinders empty or pressure < 150 bars.

2. Set is not clean.

3. Facemask is dirty.

4. Hose pipe is leaking.

5. Hose pipe is deteriorated.

6. Hose connection/fittings are leaking.

7. Neck strap is in bad condition/damaged

8. Cylinder bag is in bad condition/damaged

9. Valve pin is missing.

10. No/damaged box for set.

11. Pressure gauge condition.

12. Working of whistle.

13. Condition of body harness and buckle.

14. Any other (please specify)

Inspected By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

INSPECTION OF MCP (MANUAL CALL POINT)

Plant: S & D Dept. /Section: S & D/Tank Farm

Frequency: Quarterly Date: -

Deficiency List Details of MCPs with Deficiency

Sr. Equipme Type Location Deficien Corrective Action Taken

No nt cy

. No. No.

1. Sign board/painting faded.

2. Broken glass

3. Cable condition (not

clamped/deteriorated

4. Alarm indication at Control Room.

5. Alarm indication at Fire Station.

6. Siren status in field (if provided)

7. Sounding of siren (Not OK)

8. No accessible (obstructed)

9. Any other, specify ( )

Inspected By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

CHECKLIST FOR FIRE HYDRANT INSPECTION

Plant: S & D Dept. /Section: S & D/Tank Farm

Frequency: Quarterly ` Date: -

Deficiency List List of fire hydrant with Deficiency

Sr. Equipment Location Deficiency Corrective Action Taken

No No. No.

.

1. Painting

2. Hydrant number not

legible/painted

3. Isolation Valve condition

4. Any part broken/damaged

5. Leaking valve

6. Manual Operation not

satisfactory Condition

(damaged/jammed).

7. Operating valve is obstructed

(not easily accessible).

8. Lugs damage

9. Rubber washer damage

10. Spindale/wheel damage

11. Coupling not proper

12. Blank cap missing

13. Any other, specify ( )

Inspected By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

Essar Refinery Integrated Management System

WATER & FOAM TOWER MONITOR

Plant: S & D Dept. /Section: S & D/Tank Farm

Frequency: Quarterly ` Date: -

Sr. No. Location Tag No. Deficiency no Corrective Action Taken

Deficiency List

1 Physical condition

2 Approach to Foam

Inlet Breeching

Connection

3 Appearance/paint

condition

4 Local Operation of

valves

5 Foam/Water line

condition

6 Foam accessories

condition

7 Remarks if any or

any other deficiency

Inspected By: - Name: - Designation: - Sign: - Date:-

Reviewed By: - Name: - Designation: - Sign: - Date:-

DOC No.: - Revision No.:- 00 Page No. :-

S-ar putea să vă placă și

- Test Report of Bricks (Fly Ash)Document1 paginăTest Report of Bricks (Fly Ash)Kumar AbhishekÎncă nu există evaluări

- Vepl 2Document15 paginiVepl 2Manas Ranjan NayakÎncă nu există evaluări

- PLTU Tj. Awar-Awar Rev 1Document49 paginiPLTU Tj. Awar-Awar Rev 1DangolÎncă nu există evaluări

- IR-011-27 Excavator Daily Inspection Check ListDocument1 paginăIR-011-27 Excavator Daily Inspection Check Listprasanth kutyÎncă nu există evaluări

- Laziz Pizza Micro 31102023 JOB ORDER SLIPDocument1 paginăLaziz Pizza Micro 31102023 JOB ORDER SLIPrahulyadav.hbtiÎncă nu există evaluări

- Smoke DetectorDocument1 paginăSmoke DetectorDelta akathehuskyÎncă nu există evaluări

- Ryk FormDocument23 paginiRyk Formtejaaeie053Încă nu există evaluări

- Swivel 11 TDocument8 paginiSwivel 11 TGuruh SuprayitnoÎncă nu există evaluări

- Portable Eyewash Inspection ChecklistDocument1 paginăPortable Eyewash Inspection Checklistarunjith r100% (1)

- SKILL MATRIX 2006 07: Dpett./Section: Qc/Lab Score Critical Process - Safety Special Process-Quality General Process 1Document9 paginiSKILL MATRIX 2006 07: Dpett./Section: Qc/Lab Score Critical Process - Safety Special Process-Quality General Process 1lalit kumarÎncă nu există evaluări

- PM F 11 HydDoz PumpsDocument1 paginăPM F 11 HydDoz Pumpsjp mishraÎncă nu există evaluări

- Progress and Audit Report of SKMS Reach-II Oct-2022Document13 paginiProgress and Audit Report of SKMS Reach-II Oct-2022Mahendar ErramÎncă nu există evaluări

- Form-HSE-TMR-012 Bar Bender InspectionDocument1 paginăForm-HSE-TMR-012 Bar Bender Inspectionkenia infoÎncă nu există evaluări

- BASKARDocument5 paginiBASKARGodwin GodwinÎncă nu există evaluări

- DATA SHEET Eye Wash Saftey ShowerDocument7 paginiDATA SHEET Eye Wash Saftey ShowerLAKHTIRIÎncă nu există evaluări

- PM F 10 AmmDoz PumpsDocument1 paginăPM F 10 AmmDoz Pumpsjp mishraÎncă nu există evaluări

- 8001-WI - 01-05-52 Towing OperationDocument7 pagini8001-WI - 01-05-52 Towing OperationAgung Tri SugihartoÎncă nu există evaluări

- SWMS-09 Pipe Freezing For B1 Level 1 Mechanical Room (27-July-2021) Final (Alstern)Document24 paginiSWMS-09 Pipe Freezing For B1 Level 1 Mechanical Room (27-July-2021) Final (Alstern)Jose Manuel LimÎncă nu există evaluări

- Compliance RegisterDocument2 paginiCompliance RegisterDipjyoti SenÎncă nu există evaluări

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Dirty / Leakage / Clean Oil PumpDocument1 paginăChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Dirty / Leakage / Clean Oil Pumpjp mishraÎncă nu există evaluări

- Handbuch Luscombe LSADocument72 paginiHandbuch Luscombe LSARodol MarskeÎncă nu există evaluări

- Final MPR-Reach II - June-2021 DT 3-7-21Document13 paginiFinal MPR-Reach II - June-2021 DT 3-7-21Mahendar ErramÎncă nu există evaluări

- 2.9a Plant Equipment - Bulldozer ChecklistDocument2 pagini2.9a Plant Equipment - Bulldozer ChecklistNoel OlivarÎncă nu există evaluări

- List of InstrumentsDocument2 paginiList of InstrumentsKushal SharmaÎncă nu există evaluări

- Eni Commissioning StandardDocument204 paginiEni Commissioning Standardkumar100% (2)

- Form-HSE-TMR-005 Welding InspectionDocument1 paginăForm-HSE-TMR-005 Welding Inspectionkenia info100% (1)

- 27964E00Document14 pagini27964E00Ua AnyanhunÎncă nu există evaluări

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Main Centrifuging UnitDocument1 paginăChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Main Centrifuging Unitjp mishraÎncă nu există evaluări

- Overhaul Report - 2p764aDocument12 paginiOverhaul Report - 2p764aadamnassir91Încă nu există evaluări

- Technical Report On Soil Resistivity TestDocument7 paginiTechnical Report On Soil Resistivity TestIkhuosho AbodeÎncă nu există evaluări

- L.P.T Reports.Document12 paginiL.P.T Reports.Shaikh AdilÎncă nu există evaluări

- Examination Procedures For Ultrasonic Thickness MeasurementDocument13 paginiExamination Procedures For Ultrasonic Thickness MeasurementOsilonya HenryÎncă nu există evaluări

- Vendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitleDocument6 paginiVendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitlenisargkedarÎncă nu există evaluări

- Checklist Mini RollerDocument9 paginiChecklist Mini Rollershamshad ahamedÎncă nu există evaluări

- Tomini Infinity 12th Nov 2021 PSC Closure ReportDocument4 paginiTomini Infinity 12th Nov 2021 PSC Closure ReportManoj TyagiÎncă nu există evaluări

- 15 Leakage DetectionDocument37 pagini15 Leakage DetectionpeccÎncă nu există evaluări

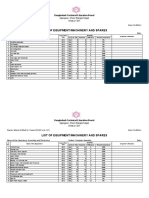

- List of Equipment/Machinery and Spares: Bangladesh Technical Education BoardDocument13 paginiList of Equipment/Machinery and Spares: Bangladesh Technical Education BoardSumyaÎncă nu există evaluări

- Meenakshi Polymers Pvt. LTD.: Poison Test SheetDocument2 paginiMeenakshi Polymers Pvt. LTD.: Poison Test SheetKaran Malhi100% (2)

- 2.9e Plant Equipment - Mobile Crane ChecklistDocument2 pagini2.9e Plant Equipment - Mobile Crane ChecklistNoel OlivarÎncă nu există evaluări

- Boiler Performance Test Report Rev0Document73 paginiBoiler Performance Test Report Rev0mvrk19650% (1)

- PM F 13 OvefDocument1 paginăPM F 13 Ovefjp mishraÎncă nu există evaluări

- Soil CBR - Gandhinagar-KalolDocument6 paginiSoil CBR - Gandhinagar-KalolAlok Bhatt 'avi'Încă nu există evaluări

- Permit To Work Application: Vistamarine Shipbuilding and Shiprepair IncDocument2 paginiPermit To Work Application: Vistamarine Shipbuilding and Shiprepair IncJezreel TolentinoÎncă nu există evaluări

- 2 Mei BalamDocument1 pagină2 Mei BalamARTHAGINAÎncă nu există evaluări

- Process Paramater 0.5ML MC-06Document1 paginăProcess Paramater 0.5ML MC-06Musyoka UrbanusÎncă nu există evaluări

- Jadwal Kerja Ice BSDDocument1 paginăJadwal Kerja Ice BSDAdmin Trisula PestÎncă nu există evaluări

- Dasarathi Naik and Engineers Pvt. Ltd. Concrete Pour Card: ClientDocument1 paginăDasarathi Naik and Engineers Pvt. Ltd. Concrete Pour Card: ClientTusarranjan BhuyanÎncă nu există evaluări

- K-003ab C&e 2012-05-09Document5 paginiK-003ab C&e 2012-05-09rcpuram01Încă nu există evaluări

- Maintain Training FacilitiesDocument8 paginiMaintain Training FacilitiesCatherine ReyesÎncă nu există evaluări

- Formates - Model Machinekaizen Regrsuggestion Formatkaizen Sheetsuggn Regzone Check - Oplmachine LayoutTPM BoardDocument25 paginiFormates - Model Machinekaizen Regrsuggestion Formatkaizen Sheetsuggn Regzone Check - Oplmachine LayoutTPM BoardVinod SaleÎncă nu există evaluări

- Ohs-Pr-09-10-F20 (A) Fuel Driven Equipment InspectionDocument2 paginiOhs-Pr-09-10-F20 (A) Fuel Driven Equipment InspectionBalaÎncă nu există evaluări

- Valve Testing ProcedureDocument10 paginiValve Testing Proceduremoytabura96100% (5)

- Boiler Daily Check ListDocument3 paginiBoiler Daily Check Listmr.coc.lol.bdÎncă nu există evaluări

- 00-Division 15-Section 15001 General M&E Requirements-Version 2.0Document69 pagini00-Division 15-Section 15001 General M&E Requirements-Version 2.0skzubsÎncă nu există evaluări

- Ops ManualDocument426 paginiOps ManualAmal100% (1)

- Spesification For Earth Work (IFD Rev 1) SWS BalonganDocument11 paginiSpesification For Earth Work (IFD Rev 1) SWS BalonganEndiarto Budi RaharjoÎncă nu există evaluări

- EME Lab Planning - RefDocument1 paginăEME Lab Planning - Refparth bhardwajÎncă nu există evaluări

- Unit Test Plan - Template: Document Change HistoryDocument2 paginiUnit Test Plan - Template: Document Change HistoryPrince PrasannaÎncă nu există evaluări

- Project 1 BriefDocument3 paginiProject 1 Briefapi-289083087100% (1)

- S 123 Sept 17060917Document41 paginiS 123 Sept 17060917rockmanqhÎncă nu există evaluări

- NSA2400MXDocument48 paginiNSA2400MXKishor.BhagatÎncă nu există evaluări

- Synopsis: Museum Architecture: by Gopika Thaplyal 4 Year B.ArchDocument5 paginiSynopsis: Museum Architecture: by Gopika Thaplyal 4 Year B.ArchPrafull Raut100% (1)

- Transgrid Sydney West 330Kv Substation 132kV SSB'S: Structural Design ReportDocument5 paginiTransgrid Sydney West 330Kv Substation 132kV SSB'S: Structural Design ReportThaiNguyenÎncă nu există evaluări

- Design of Seismic ArresterDocument3 paginiDesign of Seismic ArresterChandan vatsÎncă nu există evaluări

- PWC Design Guidelines For Sub-Development Rev3Document32 paginiPWC Design Guidelines For Sub-Development Rev3Dinesh GuptaÎncă nu există evaluări

- Membranes' in Lightweight Membrane StructureDocument9 paginiMembranes' in Lightweight Membrane StructureSuvarna456Încă nu există evaluări

- 1997jan StruclDocument7 pagini1997jan StruclEdzon LacayÎncă nu există evaluări

- Me, Unpacked.Document60 paginiMe, Unpacked.Slobodan MaldiniÎncă nu există evaluări

- Fortinet Fortigate Workspot Configuration Guide 1.0Document13 paginiFortinet Fortigate Workspot Configuration Guide 1.0Abdelilah CharboubÎncă nu există evaluări

- Pre Cast ConstructionDocument55 paginiPre Cast ConstructionAmalaÎncă nu există evaluări

- Tailoring Autocad P&Id and Autocad Plant 3DDocument194 paginiTailoring Autocad P&Id and Autocad Plant 3DjaimeÎncă nu există evaluări

- CE PROJECT 1 - 1st Semester SY 2019-2020Document1 paginăCE PROJECT 1 - 1st Semester SY 2019-2020Jose Mari RoldanÎncă nu există evaluări

- Project Proposal: Office of The Municipal Planning and Development Officer EmailDocument5 paginiProject Proposal: Office of The Municipal Planning and Development Officer EmailMary John Paul BetontaÎncă nu există evaluări

- Bitumen Mastic Laying MethodologyDocument3 paginiBitumen Mastic Laying Methodologyvenkateswara rao PothinaÎncă nu există evaluări

- Test Report: Hit Hy20 With 3/8 and 1/2 Inch Diameter Hit-A Rods in Elematic Hollowcore PlankDocument4 paginiTest Report: Hit Hy20 With 3/8 and 1/2 Inch Diameter Hit-A Rods in Elematic Hollowcore PlankSivadol VongmongkolÎncă nu există evaluări

- Rizal As A Inventor, Discover and An ArchitectDocument11 paginiRizal As A Inventor, Discover and An ArchitectCarlo CanalesÎncă nu există evaluări

- Sustainable Design Requirements-ADDDocument16 paginiSustainable Design Requirements-ADDsreedeviÎncă nu există evaluări

- Java Lab Manual Handbook of LabDocument39 paginiJava Lab Manual Handbook of Labsanjaliya meetÎncă nu există evaluări

- Green Star Rating System PresentationDocument77 paginiGreen Star Rating System PresentationJMÎncă nu există evaluări

- Cdot AnraxDocument8 paginiCdot AnraxJatin ChaudhariÎncă nu există evaluări

- Detonado Dragon Quest VIII PDF: Mirror Link #1Document4 paginiDetonado Dragon Quest VIII PDF: Mirror Link #1AllysonWaine0% (1)

- Government of Andhra Pradesh Higher Education Department - Admission of Students Into UnderDocument37 paginiGovernment of Andhra Pradesh Higher Education Department - Admission of Students Into UnderSwamynathan AbinayaÎncă nu există evaluări

- Technical Drafting 10Document20 paginiTechnical Drafting 10obiedoshaldan23Încă nu există evaluări

- IEC 60598 - LuminairesDocument3 paginiIEC 60598 - Luminairessaniljit100% (4)

- NTCC REPORT Final Ka Bhi FinalDocument14 paginiNTCC REPORT Final Ka Bhi Finalbhawna JyotiÎncă nu există evaluări

- P40U USB Adaptor Brochure enDocument2 paginiP40U USB Adaptor Brochure enMouguelisYoussefÎncă nu există evaluări

- Arx - TVM Lte App Note 0614Document5 paginiArx - TVM Lte App Note 0614Yiğit FarukÎncă nu există evaluări

- Use Rational Functional Tester Script Assure Technology To Build Test Scripts That Run When Code ChangesDocument9 paginiUse Rational Functional Tester Script Assure Technology To Build Test Scripts That Run When Code ChangesNaveen Kumar BysaniÎncă nu există evaluări