Documente Academic

Documente Profesional

Documente Cultură

0.3 Pakalnis

Încărcat de

Eugenio Salinas IbarraTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

0.3 Pakalnis

Încărcat de

Eugenio Salinas IbarraDrepturi de autor:

Formate disponibile

Underground Design Methods 2015 Y Potvin (ed.

)

2015 Australian Centre for Geomechanics, Perth, ISBN 978-0-9924810-3-2

https://papers.acg.uwa.edu.au/p/1511_0.3_Pakalnis/

Empirical design methods in practice

RPakalnisPakalnis&AssociatesandtheUniversityofBritishColumbia,Canada

Abstract

Empiricalmethodsarethemostwidelyuseddesigntechniquesemployedwithintheminingindustrylargely

due to their success in the design of mine structures. This paper summarises the applications/

implementationofempiricaldesignmethodsthattheauthorhascompiled/coordinatedoverthepastthirty

years with over 150 underground mining operations contributing either through consulting, research,

assessment,database,verificationand/orimplementation.Thesedesignguidelineshavebeenimplemented

throughouttheworldinassociationwithresearchers,mineengineers,operatorsandlegislatorstoarriveat

design methodologies based upon past practice and future implementation and assessment in order to

ensure a safe and costeffective mining operation. This paper summarises design curves that have been

developedattheUniversityofBritishColumbiaoverthepastthirtyyearswiththemethodologyfordesign

beingacommonthreadforallthetoolspresentedwhichrequirestheoperatortoaddressstress,structure

andtherockmass.

1 Introduction

Mining is a dynamic process, which requires in excess of thousands of cubic metres of openings to be

developed daily over the life of a mining operation. Those openings may be for development and/or

productionpurposes;however,allcasesmustbedesignedsoastoensuretherequiredbehaviour.Thesite

engineer,therefore,mustdesignopeningsorpillarsafteraddressingallissuesrelevanttothedesignand

assessmentoftheoverallbehaviour.

Aminestructure,whetheritisaminepillaroranopening,isgenerallyinfluencedbynumerousblocksof

intact rock. Individually their properties and behaviour can be readily assessed on a laboratory scale;

however, when analysed on a mine wide scale, the interaction of the rock block and the rock mass

behaviourisdifficultifnotimpossibletopredictemployingsolelyadeterministicapproach.

Designcanbecategorisedintothreedomains:

Analyticalmethodsintheformofnumericalcodes,closedformsolutions,classicalphysicaland

strengthmodels.

Observationalmethodswhichrelyonmonitoringoftherockmassandverificationofbehaviour.

Empiricalmethodswhichassessthestabilitybaseduponpastpracticecoupledwithexistingmine

behaviourforfutureprediction.

Empirical derivations have gained acceptance over the last thirty years largely due to their predictive

capabilitysinceconventionalmethodsofassessmenthavethedifficultyofidentifyingthejointednatureof

therockmaterial,assigningpropertiestheretoandestablishinginputparametersforsubsequentnumerical

evaluation. The process that the author has found to be of greatest value is to employ numerical codes,

analyticaltoolsandobservationalapproachesastoolstotheoveralldesignprocesswhichwillincorporate

anempiricalcomponenttowardsthedesign.Individuallyeachisonlyatoolthatrequiresthedesignerto

addressthefactorsmostcriticaltothestabilityoftheoverallundergroundstructurewhichincludesstress,

structureandtherockmassas(Figure1).Thefieldofempiricalminedesigncanbebrokenintothebroad

categories of pillar design and opening design. Opening design has evolved from the tunnel span design

methods of the 1960s and 1970s (Bieniawski 1976). Underground openings have more complex

geometries than found in tunnels, which has required different design approaches. Some of the first

Underground Design Methods 2015, Perth, Australia 37

Empirical design methods in practice R Pakalnis

appliedempiricalminedesignmethodsforopeningsoriginatedwiththeworkofMathewsetal.(1980)and

Laubscher(1977). Applied pillar design work has developed from early coal mining with applied design

curves developed by Lunder (1994) and used internationally. Extensive work in areas of drift and stope

openings and pillar design have been conducted in Australia and Canada with some of the most widely

applied methods originating at the University of British Columbia, Canada (Mathewsetal.1980;

Lang 1994; Potvin1988; Nickson 1992). The more widespread use of empirical methods inherently made

these systems more reliable since they are developed and refined only through use and experience with

verification through measurement with inputs from analytical sources coupled with stress, structure and

the rock mass as inputs. Empirical design methods are evolving and the application of some of these

methodsisbecomingconfusing.Themethodsarebeingmodifiedandusedwithinnewgroundconditions

and mining environments, sometimes without regard to the original conditions that the design methods

weredevelopedfor.Itiscriticaltoknowthydatabaseasempiricaldesignmustinterpolatebetweenknown

conditions and not extrapolate beyond the database. In addition, researchers potentially add levels of

complexitytotheempiricaldesignmethodsthataresometimesunwarrantedandunnecessarilyconfusing.

STRESS ANALYSIS

FABRIC ANALYSIS

ROCK MASS CLASSIFICATION

INDUCED STRESS > ROCK MASS STRENGTH

YES YES

NO

BURST

YIELD

MODIFY GEOMETRY IS STRUCTURE CONTROLLING STABILITY

MODIFY MINING METHOD

SUPPORT

YES

DESTRESS NO

SEISMIC

MONITORING

OTHER

NUMERICAL MODELLING

ANALYTICAL DESIGN EMPIRICAL DESIGN SOLUTION

STRESS EFFECT

LIMIT SPAN

SUPPORT WEDGE

SEQUENCE

OTHER

EXCAVATION AND MONITORING

RE-EVALUATE MINE PLAN

STRESS

ROCK MASS

STRUCTURE

Figure 1 Design methodology incorporating stress, structure and the rock mass

38 Underground Design Methods 2015, Perth, Australia

Keynote addresses

Thedesignmethodssummarisedinthispaperarebaseduponastronganalyticalfoundationcoupledwith

extensive field observation to arrive at a calibrated empirical approach towards the solution to a given

problem.Themethodspresentedinthispaperarecompiledfromextensiveminevisits,literaturereviews,

discussions among researchers and practitioners coupled with analytical and numerical assessments with

thesuccessfulimplementationatmineoperations.Twoprimeobjectivesinherentwiththedesignprocess

arethattheminemustbesafeandoperateaseconomicallyaspossible.Thispaperreviews updatestothe

designcurvespresentedinPakalnis(2002)withsubsequentimplementationandobservationwithrespect

totheiruseasdesigntoolsfortheminingindustry.

2 Design relationships

The reader is referred to an earlier paper (Pakalnis 2002) on the details of the individual design curves

presented in this paper as the focus here is on the modifications and subsequent use of the proposed

relationshipsoverthepastthirtyyears.

2.1 Stability graph method ELOS

The stability graph method for open stope design was initially proposed by Mathews et al. (1980) and

subsequently modified by Potvin (1988) and Nickson (1992) to arrive at the modified stability graph.

Stability was qualitatively assessed as either being stable, potentially unstable or caved. Research at the

UniversityofBritishColumbiaquantifiedthedegreeofsloughbytheintroductionofthetermequivalent

linearoverbreak/slough(ELOS)byClark(1998).Thishasresultedintheempiricalestimationofwallslough

employingthestabilitynumberN,asshowninFigure2,withrespecttothehydraulicradius.

Figure 2 Empirical estimation of wall slough (ELOS) after Clark (1988)

Underground Design Methods 2015, Perth, Australia 39

Empirical design methods in practice R Pakalnis

2.2 Span design entry methods

Thecriticalspancurve(Lang1994)hasbeenaugmentedtoinclude292casehistoriesofstableandunstable

entrytypestopebacksfromsixdifferentminesbyWangetal.(2000).Itexpandsontheoriginaldatabase

toincorporatelowerrockmassratings(RMRs)(Figure3).Thecriticalspanisdefinedasthediameterofthe

largestcirclethatcanbedrawnwithintheboundariesoftheexposedback,asviewedinplanandshownin

Figure3.Thisexposedspanisthenrelatedtotheprevailingrockmassoftheimmediatebacktoarriveata

stability condition. The design span refers to spans which have used no support and/or spans which

include pattern bolting (1.8m long bolts on 1.21.2m) for local support. The RMR, as proposed by

Bieniawski(1976),isemployedwithcorrectionsforthepresenceofshallowjoints(under30)byreducing

theRMRby10.Thestabilityoftheexcavationisclassifiedintothreecategories:

Stableexcavation

Nouncontrolledfallsofground.

Nomovementofbackobserved.

Noextraordinarysupportmeasureshavebeenimplemented.

Potentiallyunstableexcavation

Extragroundsupportmayhavebeeninstalledtopreventpotentialfallsofground.

Movementwithinback.

Increasedfrequencyofgroundworking.

Unstableexcavation

Theareahascollapsed.

Failureabovethebackisapproximately0.5timesspanintheabsenceofmajorstructure.

Supportwasnoteffectivetomaintainstability.

Figure 3 Critical span curve for mine entry methods employing local support only

40 Underground Design Methods 2015, Perth, Australia

Keynote addresses

Theaboveapproachisbaseduponrockmassinstability.Wherediscretewedgeshavebeenidentified,they

mustbesupportedpriortoassessmentemployingthecriticalspancurve.Stabilityisgenerallyidentifiedin

terms of short term stability (excess of three months) as the database is largely based upon stoping

methods that are of short duration. Where back movement has been identified, critical magnitudes in

excessof1mmwithinatwentyfourhourperioddictatethatthestopewillnotbeaccessedforafurther

twentyfourhourperiod.Thisisbaseduponobservationsfromthesixminescomprisingthedatabase.

2.3 Pillar design graph

Acomprehensivepillardatabasethatrelatesgeometry,loadingconditions,insiturockstrengthand

stabilityconditionhasbeendeveloped.Analysisofthisdatabasehasledtothedevelopmentofthepillar

stabilitygraph(Figure4).

Figure 4 Pillar stability graph

A total of 178 stability cases have been included where each case example represents a failed pillar, an

unstable pillar or a stable pillar, as compiled by Lunder (1994). The pillar data used to develop this

methodology is a compilation of seven individual pillar stability databases that have been published

worldwide. The information available is the pillar stability assessment, the predicted pillar load and the

pillar geometry. Five of the seven databases originate from massive sulphide deposits and all of the

databases have reported RMRs in excess of 65%, representing good to very good quality rock mass

conditions.Figure4showstheobservedconditionsthatwouldbeencounteredforeachstabilitylevel.This

isbasedupondetailedresearchworkshowingthatpillarstabilitylevelscouldbeassessedonafivelevel

scale.Thiswassimplifiedinordertoassimilatethedatawiththeadditionaldatabasesthatwerecollected

from the literature. Two primary factors are used in this design methodology: a geometric term that

representspillarshapeandastrengthtermthatincludestheintactrockstrengthandthepredictedpillar

load.Rockmassstrengthisdependentupontheamountofconfiningstressappliedtoasample.Inthecase

of mine pillars, the more slender a pillar, the less confining stress will be available resulting in a lower

strengthforagivenrocktype.Thepillarwidth(Wp)isdefinedasthedimensionnormaltothedirectionof

the induced stress, whereas the pillar height (Hp) is measured parallel to the induced stress. The pillar

strengthgraphwasdevelopedbyplottingtheratioofpillarload/unconfinedcompressivestrength(UCS),as

Underground Design Methods 2015, Perth, Australia 41

Empirical design methods in practice R Pakalnis

showninFigure4totheWp/Hp.The pillarloadismeasuredat thecoreofthepillarwhereastheUCSis

that recorded for the intact rock comprising the pillar. The pillar stability graph presented here is a

collectionofawiderangeandtypeofminepillar.

3 Support design

The reader is referred to an earlier paper by Pakalnis (2008) on the details of the methodology towards

support that has been derived from over twenty mining operations that incorporate analytical and

empirical approaches towards assessing the Factor of Safety (FS) for a mine opening. The approach is to

assess the potential for an adverse structure employing an analytical approach, such as provided by the

softwareprogramUnwedge(Rocscience2008).Theinitialassessmentaspractisedatthefaceistodefineif

adeadweightwedgeispossibleandthisemploysasimplestereoanalysispoleplot(Figure5).Thisfigure

showsconditionsforgravityfallsandhowitispresentedontoastereographicprojection.Theplotofgreat

circles representing the individual planes must encompass the centre in order for a gravity fall to occur,

whereas for a sliding wedge, this does not occur. Similarly, the pole plot shows that a triangle drawn

betweenthethreepolesmustencompassthecentreinordertohaveagravityfall.

Figure 5 Conditions for (a) gravity fall and (b) sliding instability for wedge within back of tunnel

3.1 Dead weight

Deadweightconditionsifidentifiedstructurallybytheabovetest(Figure5)wouldconservativelyestimate

thatthemaximumdepthoffailurewouldbe0.5timesthespan.Typically,adepthoffailureequivalentto

either0.5to0.3timesspanisemployedinpractise(Beauchamp2006);however,baseduponpastobserved

back failures and modelling (MacLaughlin et al. 2005), one largely observed an arched back, as shown in

Figure6. It must be noted that the depth of failure is assumed to be 0.5 span; however, with adverse

structurepresentonemustassessanalytically(i.e.Unwedge)thevolumeofthewedgetoarriveatthetrue

volumewhichwill generallybelessthan0.5times span.Thepotentialfailurezoneis thenapproximated

(Figure6) with the bolt capacity, as defined by the breaking strength of the bolt as well as the bond

strengthoftheboltpassingthoughthefailuresurface(Tables13).Theaboveapproachassumesallbolts

are plated with the support capacity defined by the value of the sum of the individual bolts, which are

defined by either the breaking strength or the bond strength of the bolts passing through the failure

surfacewhicheveristhelowerofthetwo.Theaboveisaconservativeapproach,astheanalysisassumes

acentreboltatmidspan.Thepotentialforstructuralinstabilitywasidentifiedasdeadweight;however,a

42 Underground Design Methods 2015, Perth, Australia

Keynote addresses

detailed analytical assessment such as provided by Unwedge will result in a more realistic and less

conservativeassessment,asthedepthoffailureismostlikelymuchlessthan0.5timesspanbuthastobe

identified in the field as having this potential. A further constraint is that the corner bolt should be in

excess of 0.5times bolt spacing from the adjacent wall in order to ensure effectiveness unless

strapped/shotcreted.

Figure 6 Factor of Safety analysis dead weight

3.2 Rock mass assessment

Thepotentialforrockmassinstabilityisdefinedbythespandesigncurve,whichemployslocal/nosupport,

asshowninFigure3anddetailedbyPakalnisetal.(2007).Thedepthoffailurehasbeenobservedinthe

absenceofstructuralinstabilitytobeequalto0.5timesspanfortheunstablezoneandapproachingfrom

00.5timesthespanwithinthepotentiallyunstablezone.

3.3 Surface support

This is detailed in Pakalnis et al. (2010) and summarised in this paper where the use of shotcrete as

confiningtherockmassfabricintoasinglesupportunitisassessed(Figure8).Itmustberecognisedthata

weakrockmasswilllikelyresultintheindividualrockblocksfallingbetweenthebolts;therefore,surface

supportisrequiredtoconfinetherockmassasasinglesupportunit.Itisalsocriticaltoboltthroughthe

shotcretemembranewithinaweakrockmass(RMR76<45%)toensurethattheboltsandsurfacesupport

areconfinedanddonotactindependentlyofeachother.Surfacesupportrequirementsfortemporaryand

permanent (storage rooms, crusher chambers and maintenance shops) support correspond to an

excavationsupportratio(ESR)of3and1.3,respectively(Grimstad&Barton1993).ThisisshowninFigure8

withtherangeofweakrockmassesobservedwithinNevadaoperations(2045%)andassociatedspansof

6m(20ft) and summarised in Table 4. It must be recognised that the shotcrete is reinforced with bolts

whichconfinethepotentialblock.

Underground Design Methods 2015, Perth, Australia 43

Empirical design methods in practice R Pakalnis

Figure 7 Shotcrete as confining the rock mass into a single unit

Figure 8 Surface support (after Grimstad & Barton 1993)

44 Underground Design Methods 2015, Perth, Australia

Keynote addresses

3.4 Intersection support

Intersection support as shown in Figure 9 employs the methodology outlined in this section in terms of

deadweightsupportandsurfacesupport(Figure9).Thevolumeoffailureisapproximatedbyarightangle

conehavingaheightequalto0.5timesdiameterwithsupportcapacitydefinedbythevalueofthesumof

the individual bolts which are defined by either the breaking strength or the bond strength of the bolts

passing through the failure surface whichever is the lower of the two. The above is a conservative

approach as the analysis assumes a centre bolt at mid span. The potential for structural instability was

identified as dead weight; however, a detailed analytical assessment such as provided by Unwedge will

resultinamorerealisticandlessconservativeassessmentasthedepthoffailureismostlikelymuchless

than0.5timesspanbuthastobeidentifiedinthefieldastothispotential.Afurtherconstraintisthatthe

bolt past the cone boundary must be greater than 0.5 bolt spacing since one would largely negate the

supportcapabilitywithhavingacornerboltunlessconfinedbystraps/shotcrete.

Figure 9 Intersection support dead weight

Underground Design Methods 2015, Perth, Australia 45

Empirical design methods in practice R Pakalnis

Table 1 Support properties rockbolt properties

Bolttype Yieldstrength(tonnes) Breakingstrength(tonnes)

15.9mm(5/8)mechanical 6.1 10.2(grade690MPa)

Splitset(SS33) 8.5 10.6

Splitset(SS39) 12.7 14

StandardSwellex n/a 11

YieldingSwellex n/a 9.5

SuperSwellex n/a 22

20mmrebar(#6) 12.4 18.5

22mmrebar(#7) 16 23

25mmrebar(#8) 20.5 30.8

#6DYWIDAG 11.9 18

#7DYWIDAG 16.3 24.5

#8DYWIDAG 21.5 32.3

#9DYWIDAG 27.2 40.9

#10DYWIDAG 34.6 52

12.7mm(1/2)cablebolt 15.9 18.8

15.9mm(5/8)cablebolt 21.6 25.5

6.35102mm(1/44)strap(MS) 25 39

#6refersto6/8;#7refersto7/8diameteretc.

Table 2 Support properties Screen-bag strength 1.22 1.22 m (4 4 ft) pattern

102x102mm(44)wieldedwiremesh(4gauge) Bagstrength=3.6tonnes

102x102mm(44)wieldedwiremesh(6gauge) Bagstrength=3.3tonnes

102x102mm(44)wieldedwiremesh(9gauge) Bagstrength=1.9tonnes

102x50.8mm(42)wieldedwiremesh(12gauge) Bagstrength=1.4tonnes

50.8mm(2)chainlink(11gaugebaremetal) Bagstrength=2.9tonnes

50.8mm(2)chainlink(11gaugegalvanised) Bagstrength=1.7tonnes

50.8mm(2)chainlink(9gaugebaremetal) Bagstrength=3.7tonnes

50.8mm(2)chainlink(9gaugegalvanised) Bagstrength=3.2tonnes

4gauge=584mm(23)diameter;6gauge=5.08mm(0.20);9gauge=4.06mm(0.16)diameter;11gauge=3.18mm(0.125);

12gauge=2.79mm(0.11)diameter.

Shotcreteshearstrength=2MPa=200tonnes/m2.

46 Underground Design Methods 2015, Perth, Australia

Keynote addresses

Table 3 Support properties bond strength

Bolttype Bondstrength(tonnes/m)

39mmsplitsetweakground(<45%RMR) 0.753.6

39mmsplitsethardground(>55%RMR) 2.55

StandardSwellexweakground(<45%RMR) 8.113.8

StandardSwellexhardground(>55%RMR) 915

Cableboltweakground(<45%RMR) 24

Cablebolthardground(>55%RMR) 28

#6rebarweakground(<45%RMR) 1214

#6rebarhardground(>55%RMR) 59

Table 4 Fabric support requirements (after Grimstad & Barton 1993) for 6 m span

Q RMR Permanentsupport Temporarysupport

ESR=1.3 ESR=3

0.07 <20% Spiling+(actual) Spiling+(actual)

0.070.4 2035% 912cm(35) 59cm(24)

fibrereinforcedshotcrete fibrereinforcedshotcrete

0.41.1 3545% 59cm(24) 410cm(24)

fibrereinforcedshotcrete fibrereinforcedshotcrete

4 Weak rock mass design

AmajorstudywasundertakenbytheUSNationalInstituteforOccupationalSafetyandHealth(NIOSH)and

detailedinBradyetal.(2005)toaddressthehighfrequencyofrooffallinjuriesbeingrecordedinNevada

mines. The Spokane Research Laboratory and the University of British Columbia Geomechanics group

focused on the development of safe and costeffective underground design guidelines for weak rock

masseshavinganRMRintherangeof15to45%.Figure10showstheexistingempiricaldatabasepriorto

thestudywheretherockmasseswerelargelyclassifiedinexcessof65%(RMR76). Aweakrockmassupon

reviewofsiteconditionsobservedwaspresentedasthathavinganRMR76oflessthan45%and/orarock

mass quality (Q) of under 1.0. This is based upon a database in excess of twenty mining operations, as

detailed in Pakalnisetal. (2007). Weak ground conditions, ground support, and mining methods used in

severalNevadaundergroundmineswereobserved.TheRMRvalueswerecalculatedtoupdatebothspan

designcalculationsandstabilitygraphs,andadatabaseonunderhandminingmethodswasdevelopedto

reflectexistingNevadaminingconditions.Theimmediaterockmasswasalsocharacterisedandanalysedin

terms of prevailing type of ground support, potential failure mechanisms, and rock behaviour which

resultedin modifications/augmentationtothedesigncurves,asshowninFigure11,forthewallstability

graphforweakrockmasses.AninitialobservationfromFigure11isthattheclassicaldesigncurves(ELOS),

as shown in Figure 2, are inaccurate at low N' and hydraulic radius values. If the hydraulic radius is kept

below3.5mwithinaweakrockmass,theELOSvaluewasrecordedtobelessthan1m.

Underground Design Methods 2015, Perth, Australia 47

Empirical design methods in practice R Pakalnis

Figure 10 Schematic showing transition of weak rock mass to stronger along with existing database

Figure 11 Wall stability graph as developed for weak rock masses (Pakalnis et al. 2007)

4.1 Operations guidelines

Withweakrockmasses,blastcontroliscriticaltoensurethattherockmassisnotfurtherdisturbedfrom

overblasting.BothQueenstakesSSXMineandBarricksGoldstrikeoperationguidelinesforblastingbased

onRMRvalueshavebeensummarisedinFigure12.Inaddition,thelengthofroundpulledisrelatedtothe

RMRfora5msupportedbackspan(Figure12).AnexampleiswheretheRMRis1520%.Thiswoulddictate

that only a 1.2m advance is possible otherwise failure of the unsupported back will result. Spiling is

recommendedattheseRMRthresholds.Figure12showsthedegreeofloadingofadevelopmentroundat

BarricksGoldstrikeMinefora55mheadingwithrespecttotheRMR.

48 Underground Design Methods 2015, Perth, Australia

Keynote addresses

Figure 12 RMR versus influence on blasting in weak ground (Pakalnis et al. 2007)

TheeffectofblastingonweakrockmasseswasfurtherassessedthroughaNIOSHsponsoredinitiativeand

detailed by Caceres (2011) in his PhD dissertation: Quantifying the Effect of rock mass quality on peak

particlevelocity(PPV)forundergrounddriftdevelopment.Figure13showsarelationshipderivedfromthe

PPV and scaled distance (SD) as a function of rock mass quality obtained from multiple records and

operationstoarriveatcriticalthresholdsforblastdesign.

Underground Design Methods 2015, Perth, Australia 49

Empirical design methods in practice R Pakalnis

Figure 13 PPV versus scaled distance for varying rock qualities

A further observation amongst weak rock mass mines was the success achieved through arching of the

back. It was found that for weak rock masses that arching the back dramatically increased the overall

stabilityforagivenspan.ThisisschematicallyshowninFigure14wherebythepotentialwedgevolumeis

significantlydecreasedemployinganarchedbackandtheeffectivenessoftheappliedsupportincreasedas

agreaterlengthofboltpassesbeyondthefailureplane.Thishasbeenshowntobeamajorcontributing

factortotheoverallstabilityforminesoperatingwithinweakrockmasses.

Figure 14 Effect of arching on back of tunnel

5 Other observations

This section refers to empirical approaches developed with UBC researchers and industry sponsors to

addressproblemsthatassistedinunderstandingtheoverallconcernsandsubsequentmodificationthereof

inordertoarriveatasafeandcosteffectiveoperation.

5.1 Rock mass assessment

AconcernistheevaluationofRQDforweakrockmasseswhichrequiresadefinitionandinterpretationfor

sound core. The International Society for Rock Mechanics (1978) definition: Pieces of sound core over

50 Underground Design Methods 2015, Perth, Australia

Keynote addresses

10cmlongthatareexpressedasapercentageofthelengthdrilled.ThisisfurtherdefinedbyDeereand

Deere(1988):toonlyincorporategoodrockrecoveredfromanintervalofaboreholeandnottoinclude

problematic rock that is highly weathered, soft, fractured, sheared and jointed and counted against the

rock mass. The International Society for Rock Mechanics further identifies material that is obviously

weakerthanthesurroundingrock,suchasoverconsolidatedgougeisdiscounted,asitisonlyabletobe

recovered by advanced drilling techniques. The author incorporates the above augmented by weak rock

massoperationswithinthisdatabasetoarriveatthefollowing,asdetailedinMilneetal.1998.Inpractice,

a high RQD value does not always translate to high quality rock. It is possible to log 1.5m of intact clay

gougeanddescribeitashaving100%RQD.ThismaybetruebasedontheoriginaldefinitionofRQDbutis

verymisleadingandgivestheimpressionofcompetentrock.AparametercalledhandledRQD(HRQD)was

introduced (Robertson 1988). HRQD (Figure 15) is measured in the same way as RQD, after the core has

beenfirmly handledinan attempttobreakthe coreintosmallerfragments.Duringhandling,thecoreis

firmly twisted and bent but without substantial force or the use of any tools. This attempts to quantify

soundcore.

Figure 15 Handled RQD

5.2 Underhand cut-and-fill

AmajorfocusofstudyatUBCisthedevelopmentofdesignguidelinesforminingunderfill.Itincorporates

empirical data along with analytical assessments to arrive at design relationships that enable one to

understand the overall failure mechanism and extend upon the existing state of knowledge in sill mat

design(Pakalnisetal.2006).Figure16andTable5relatesthedatabaseofunderhandminingoperations

with vertical sidewalls with a FS of 2.0. The chart is based on flexural instability employing fixed beam

analysiswithsurchargeloading.Thestrengthsinpracticeweregenerallylowerthanstrengthsdictatedby

theanalyticalmethodandthiscouldbeduetoQA/QC,confinement/other.Therelationshipfoundbetween

tensileandUCSforconsolidatedpastewaswellinexcessof0.1UCSwhichhasbeenemployedhistorically

Underground Design Methods 2015, Perth, Australia 51

Empirical design methods in practice R Pakalnis

in the literature which indicates that the sill mat is much stronger than assumed (Hughes 2014). This is

showninFigure17wherebytensiletestingatStillwaterMinecementedpastecylindersindicatedatensile

strength~0.22oftheUCSandwheremeasuredstablespanswereplottedagainstUCSandrelatedtothe

bestfitUCSderivedbeamedtheoryestimate.Itshowedthatthe0.1UCSderivedtensilestrengthgreatly

underestimatedthebeamstability.

Figure 16 Stability chart for the design of undercut sills with vertical sidewalls with a FS of 2. Chart is

based upon fixed beam bending failure with surcharge

52 Underground Design Methods 2015, Perth, Australia

Keynote addresses

Table5Underhandcutandfilldatabase

MINE %CEMENT SPAN SILL THICKNESS UCS COMMENTS REASON

(m) (m) (MPa) UNDER FILL

PASTE

1 RED LAKE MINE 10 6.1 3 1.5 DESIGN STRENGTHS GOVERN TIME STRESS ~2000m DEPTH

(~0.6m gap) TO MINE UNDER(14D-28D)

2a ANGLOGOLD(1999 VISIT) 6.5 7.6 4.6 5.5 CRF WEAK RMR ~25%+

2b MURRAY MINE 8% 9.1 4.6 6.9 CRF DESIGN

2c (QUEENSTAKE-2004) 8% 21 4.6 6.9 MINED REMOTE - NO CAVE

2" MINUS AGG

GO UNDER A MIN OF 14D,

WALL CRF 5-6% BINDER

JAM TIGHT TO BACK/STEEP

3 ESKAY 7 3 3 4 - 12 CRF(4MPa Design) WEAK RMR ~25%+

UCS is 11MPa(28Day)

4a TURQUOISE RIDGE 9 13.7 4 8.3 CRF TEST PANEL

4b 9 3.7 3 8.3 CRF DRIFT & FILL WEAK RMR ~25%+

4c 9 7.3 3 8.3 CRF PANEL

5 MIDAS 7 2.7 3 3.4 CRF WEAK RMR ~25%+

6 DEEP POST 6.75 4.9 4.3 4.8 CRF WEAK RMR ~25%+

GO UNDER IN 28DAYS

0.7 PASTE (FS=1.5)

7a STILLWATER - NYE 10 1.8 2.7 0.3 GO UNDER IN 7DAYS-28DAYS)

7b 2.4 2.7 0.5 (5% BINDER-0.5MPa UCS 28D)

7c 3 2.7 0.7 (7% BINDER-0.7MPa UCS 28D) STRESS~ 800m

7d 3.7 2.7 1 (10% BINDER-1MPa UCS 28D)

7e 4.3 2.7 1.4 (12% BINDER-1.2MPa UCS 28D)

7f 4.9 2.7 1.8

7g 5.5 2.7 2.3

7h 6.1 2.7 2.9

8 MIEKLE STH 7 4.6-6.1 4.6 5.5 CRF WEAK RMR ~25%+

BARRICK

9 Gold Fields - AU 10 5 5 4.45 CRF WEAK RMR ~25%+

10 Stratoni Mine 12.8 6-9 6 2 High Density Slurry WEAK RMR ~25%+

TVX (78% WT SOLIDS)

10% Cemented Hydraulic Fill

11 Galena - Coeur de Alene 10 3 3 2.5 (73-75% Wt Solids) STRESS ~1000m DEPTH

(includes 0.9m air gap) (UCS after 7 days)

GO UNDER IN 3 DAYS(2.4MPa UCS)

12 Lucky Friday - Hecla 8 2.4-4.6 3 4.8 8% Paste(COARSE TAILS) STRESS ~2000m DEPTH

(Gold Hunter) (includes 0.6m air gap) (no free water)

1.2MPa IN BACK AND 0.5MPa IN WALLS

13 Newcrest 12-24 6-8 5 1.2-1.5 DESIGN STRENGTHS GOVERN TIME WEAK RMR ~25%+

(Kencana Mine vs dry tuff TO GO UNDER PASTE 7D-28D

SPAN 6m UNDER PASTE

14 Lanfranchi Nickel Mines 4-8 6-12* 5 1.2-2 SPAN 12m INTERSECTIONS CABLED(6m) STRESS ~850m DEPTH

(Helmuth South) *inters TO GO UNDER PASTE 14D

GO UNDER IN 28 DAYS

15 Cortez Hills 7.8 6-11* 4.6 6 SPAN IS 6m WITH 11m AT INTERSECTIONS WEAK RMR ~15%+

(Barrick) *inters MAXIMUM TOP SIZE 5cm(2")

CEMENTED AGGREGATE FILL

16 Andaychagua Mine 14 5-15 3.5 16+ SPAN IS 15m WEAK RMR ~15%+

(Volcan) AGGREGATE FILL -3/4"

Underground Design Methods 2015, Perth, Australia 53

Empirical design methods in practice R Pakalnis

Figure 17 Stillwater Mine stable undercut paste spans versus recorded UCS with beam formulae design

curves for 3 m thick mat

5.3 Effect of freezing on RMR

TheCamecooperations,amongotherssuchastheKupolMineofKinross,relyonfrozengroundinpartfor

stabilityand/orwatercontrol.ACamecosponsoredinitiativeanddetailedbyRoworth(2013)inherMSc

dissertation, Understanding the effect of freezing on rock mass behaviour as applied to the Cigar Lake

miningmethod,isdetailedinthispaper.Figure18showsarelationshipwherebyfrozenversusunfrozen

groundwasrecordedintermsofRMR76andrelatedtoexposedspan.Theinfluenceoffreezingontherock

massqualitywasfoundtobesignificantforveryweakrocksanddecreasesexponentiallywithincreasing

rockmassstrength.TheunfrozenRMR76forRMRunder50%uponfreezinghadagainofupto40points,

whereasunfrozenRMRgreaterthan50%hadafrozenRMRoflessthan10pointgain.Conservatively,an

increaseof20occurs,i.e.30%unfrozenRMRis50%frozen.

54 Underground Design Methods 2015, Perth, Australia

Keynote addresses

Figure 18 Effect of freezing on RMR76 (Roworth 2013)

6 Conclusion

The approach towards design summarised in this paper is one whereby existing databases have been

calibratedtoanalyticalandempiricalapproachesandmodifiedaccordingtoobservedminebehaviour.The

tools have been used successfully to predict levels of dilution, pillar stability, opening stability, support

requirements among factors that have been trialled in the field. The methodology towards design must

identifythe potentialforstress,structuralandrockmassinstability;therefore,thedesigncurvespresent

only one part of the overall design process. It is critical that empirical tools be employed to predict rock

responsebyinterpolatingandnotextrapolatingwhereminimaldataisavailable.Theapproachespresented

in this paper are to be employed as a tool for the practitioner and to augment the methodology with

his/her own database and decisionmaking process in order to arrive at a workable solution. The

relationships developed here assist the operator/engineer to identify potential concerns thereby

developing a safer work environment. These design guidelines have been implemented throughout the

world in association with researchers, mine engineers, operators and legislators to arrive at design

methodologiesbaseduponpastpractice,futureimplementationandassessmentinordertoensureasafe

and costeffective mining operation. This seminar on empirical design is the first of many to come and

allowsonetodefineconcerns,findsolutionsanddiscusssimilarproblems.

Acknowledgement

Thestudents,theminesandcolleagueswhohavecontributedtotheknowledgebase.

References

Beauchamp,L2006,Groundsupportmanual,MinesandAggregatesSafetyandHealthAssociation,NorthBay,ON.

Bieniawski, ZT 1976, Rock mass classification in rock engineering, in ZT Bieniawski (ed.), Exploration for Rock Engineering:

ProceedingsoftheSymposiumonExplorationforRockEngineering,A.A.Balkema,Lisse,pp.97106.

Brady,T,Martin,L&Pakalnis,R2005,Empiricalapproachesforopeningdesigninweakrockmasses,MiningTechnology,vol.114,

no.2,pp.1320.

Caceres, C 2011, Quantifying the effect of rock mass quality on peak particle velocity for underground drift development PhD

thesis,UniversityofBritishColumbia.

Underground Design Methods 2015, Perth, Australia 55

Empirical design methods in practice R Pakalnis

Clark,L1998,MinimizingdilutioninopenstopeminingwithfocusonstopedesignandnarrowveinlongholeblastingMasterof

Sciencethesis,UniversityofBritishColumbia.

Deere,DU&Deere,DW1988,Therockqualitydesignation(RQD)indexinpractice,inIKirkaldie(ed.),Rockclassificationsystems

forengineeringpurposes,AmericanSocietyforTestingandMaterials,AnnArbor,MI,pp.91101.

Grimstad, E & Barton, N 1993, Updating the Qsystem for NMT, in C Kompen, SL Opsahl & SL Berg (eds), Proceedings of the

InternationalSymposiumonSprayedConcrete,NorwegianConcreteAssociation,21p.

Hughes,P2014,UnderhandcutandfillcementedpastebackfillsillbeamsPhDthesis,UniversityofBritishColumbia.

InternationalSocietyforRockMechanics1978,Commissiononstandardizationoflaboratoryandfieldtests:suggestedmethods

for the quantitative description of discontinuities in rock masses, International Journal of Rock Mechanics and Mining

SciencesandGeomechanicsAbstracts,vol.15,pp.319368.

Lang,B1994,SpandesignforentrytypeexcavationsMasterofSciencethesis,UniversityofBritishColumbia.

Laubscher, DH 1977, Geomechanics classification of jointed rock masses mining applications, Transactions of the Institute of

MiningandMetallurgy,vol.86,pp.18.

Lunder,P1994,Hardrockpillarstrengthestimation:anappliedempiricalapproachMasterofSciencethesis,UniversityofBritish

Columbia.

MacLaughlin,MM, Pakalnis,R &Brady,TM2005,Adistinctelementparametricstudyoffailuremodesaroundanunderground

opening in rock masses of varying quality, Proceedings of the 40th US Symposium on Rock Mechanics, American Rock

MechanicsAssociation,Minneapolis,10p.

Mathews,KE,Hoek,E,Wyllie,DC&Stewart,S1981,Predictionofstableexcavationspansforminingatdepthsbelow1,000metres

inhardrock/GolderAssociates,CANMETLibrary&DocumentationServicesDivision,Vancouver.

Nickson, S 1992, Cable support guidelines for underground hard rock mine operations Master of Science thesis, University of

BritishColumbia.

Pakalnis,R2002,EmpiricaldesignmethodsUBCGeomechanicsupdate,inRHammah,WBawden,JCurran&MTelesnicki(eds),

Proceedings of the 5th North American Rock Mechanics Symposium and the 17th Tunnelling Association of Canada

Conference(NARMSTAC2002),Miningandtunnelinginnovationandopportunity,UniversityofToronto,Toronto,Canada,

12p.

Pakalnis, R 2008, Methodology towards ground support, Strategic versus tactical approaches in mining, Quebec, Canada,

UniversityofLaval,ACG,UniversityofWitwatersrand,12p.

Pakalnis,R,Brady,T,Blake,W&MacLaughlin,M2006,Designspansunderhandcutandfillmining,BulletinoftheCanadian

InstituteofMiningandMetallurgy,vol.99,no.1094,7p.

Pakalnis,R,Brady,T,Hughes,P&McLaughlin,M2007,Designguidelinesforundergroundminingoperationsinweakrockmasses,

Proceedings of the 1st CanadaUS Rock Mechanics Symposium International Workshop on Rock Mass Classification in

UndergroundMining,NationalInstituteforOccupationalSafetyandHealth,Atlanta,GA,12p.

Pakalnis,R,Roworth,M,Caceres,C,Martin,L,Seymour,B&Lourence,P2010,Groundsupportmethodologyemployingshotcrete

forundergroundmines,ProceedingsoftheSMEAnnualMeetingandExhibit,SocietyforMining,Metallurgy&Exploration,

Englewood,CO,preprintno.10013,pp.5558.

Potvin,Y1988,EmpiricalopenstopedesigninCanadaPhDthesis,UniversityofBritishColumbia.

Robertson,AM1988,Estimatingweakrockstrength,ProceedingsoftheSMEAnnualMeeting,SocietyforMining,Metallurgy&

Exploration,Englewood,CO,preprintno.88145,5p.

Rocscience2008,Unwedgesoftwarepackage,https://www.rocscience.com/rocscience/products/unwedge

Roworth,M2013,UnderstandingtheeffectoffreezingonrockmassbehaviourasappliedtothecigarlakeminingmethodMaster

ofSciencethesis,UniversityofBritishColumbia.

Wang,J,Pakalnis,R,Milne,D&Lang,B2000,Empiricalundergroundentrytypeexcavationspandesignmodification,Proceedings

ofthe53rdAnnualConferenceoftheCanadianGeotechnicalSociety,TheCanadianGeotechnicalSociety,Richmond,BC.

56 Underground Design Methods 2015, Perth, Australia

S-ar putea să vă placă și

- Grupo 5 Empirical Design Methods Update 2014 PDFDocument10 paginiGrupo 5 Empirical Design Methods Update 2014 PDFAshanti UtahelÎncă nu există evaluări

- Empirical Design MethodsDocument16 paginiEmpirical Design MethodsyoniÎncă nu există evaluări

- Empirical Deign Methods in UG Mine - RpakalnisDocument49 paginiEmpirical Deign Methods in UG Mine - RpakalnisCarlos A. Espinoza M100% (1)

- Grupo 5 Empirical Design Methods - Update (2014)Document10 paginiGrupo 5 Empirical Design Methods - Update (2014)Fidel Angel CercedoÎncă nu există evaluări

- Rock Mass Grouting For Dams, An Observational Design ApproachDocument13 paginiRock Mass Grouting For Dams, An Observational Design Approachmevice63Încă nu există evaluări

- TunellingUndergrSpacTechn-V12n4-1997-Lesson Learned From Field Meassurements in Tunneling-SakuraiDocument8 paginiTunellingUndergrSpacTechn-V12n4-1997-Lesson Learned From Field Meassurements in Tunneling-SakuraiClovis GonzattiÎncă nu există evaluări

- Sakurai 1997 PDFDocument8 paginiSakurai 1997 PDFMatiasNavarroQuilodránÎncă nu există evaluări

- Excavation Engineering - DesbloqueadoDocument9 paginiExcavation Engineering - DesbloqueadoChristopher Manuel Fabrega CastilloÎncă nu există evaluări

- A Damage-Controlled Force-Based Seismic Design Method For RC FramesDocument22 paginiA Damage-Controlled Force-Based Seismic Design Method For RC FramesTinh T. LeÎncă nu există evaluări

- 01 SainsburyDocument16 pagini01 SainsburyAlagu RamÎncă nu există evaluări

- Planning Analysis Design of Hospital Building Using Staad Prov8iDocument5 paginiPlanning Analysis Design of Hospital Building Using Staad Prov8ikbkwebsÎncă nu există evaluări

- EN - Bridge Insight - Civil - Ebook - Vol 04Document12 paginiEN - Bridge Insight - Civil - Ebook - Vol 04mostofa33Încă nu există evaluări

- Design MethodologyDocument32 paginiDesign MethodologyAnonymous WzAaGNihÎncă nu există evaluări

- MDunn UncertaintyInGroundSupportDesign 2013Document13 paginiMDunn UncertaintyInGroundSupportDesign 2013Saurabh MishraÎncă nu există evaluări

- Review Paper On Seismic Retrofitting ofDocument5 paginiReview Paper On Seismic Retrofitting ofbenedict110903Încă nu există evaluări

- Geotechnioue: ParisDocument14 paginiGeotechnioue: ParisAMOUZOUN ChristopheÎncă nu există evaluări

- AADE-05-NTCE-61 - Calhoun PDFDocument12 paginiAADE-05-NTCE-61 - Calhoun PDFAndrianus BimoÎncă nu există evaluări

- Perancangan Lereng (Slope Design)Document9 paginiPerancangan Lereng (Slope Design)@@)&()Încă nu există evaluări

- Explicit Reinforcement Models For Fully-Grouted Rebar Rock BoltsDocument14 paginiExplicit Reinforcement Models For Fully-Grouted Rebar Rock BoltsSajjad AnwarÎncă nu există evaluări

- Taormina Ixa Loli Gelagoti Kourkoulis 2012rockanalDocument13 paginiTaormina Ixa Loli Gelagoti Kourkoulis 2012rockanalorazio casablancaÎncă nu există evaluări

- Misko CUBRINOVSKI 2011Document24 paginiMisko CUBRINOVSKI 2011zomungÎncă nu există evaluări

- Matasovicetal.2011 CH6 InSituMeasurementsDocument45 paginiMatasovicetal.2011 CH6 InSituMeasurementsKelly Camarena CamposÎncă nu există evaluări

- [doi 10.1115_PVP2013-97435] Wieschollek, Matthias; Diamanti, Kalliopi; Pinkawa, Marius; Hoff -- [ASME ASME 2013 Pressure Vessels and Piping Conference - Paris, France (Sunday 14 July 2013)] Volume 8.pdfDocument10 pagini[doi 10.1115_PVP2013-97435] Wieschollek, Matthias; Diamanti, Kalliopi; Pinkawa, Marius; Hoff -- [ASME ASME 2013 Pressure Vessels and Piping Conference - Paris, France (Sunday 14 July 2013)] Volume 8.pdfMohamad Al MellÎncă nu există evaluări

- 0.1 BawdenDocument18 pagini0.1 BawdenedwinsÎncă nu există evaluări

- UntitledDocument19 paginiUntitledAgungRizkyÎncă nu există evaluări

- Methodology For Performance Based EartDocument14 paginiMethodology For Performance Based EartMarjorie BlossiersÎncă nu există evaluări

- 1129634884isrm SM Rock Stress Part 4 2003 PDFDocument5 pagini1129634884isrm SM Rock Stress Part 4 2003 PDFDavid Almanza PerezÎncă nu există evaluări

- Effect of Lateral Load Patterns in Pushover Analysis: November 2009Document6 paginiEffect of Lateral Load Patterns in Pushover Analysis: November 2009mohamedÎncă nu există evaluări

- Chapter 7 Structural Analysis of Sedimentary Basins: 7.2 ApproachDocument2 paginiChapter 7 Structural Analysis of Sedimentary Basins: 7.2 ApproachFolla ZahraÎncă nu există evaluări

- Factor de Daño DDocument12 paginiFactor de Daño Doscar2302Încă nu există evaluări

- Stláčanie Tunela - Všetky MetódyDocument18 paginiStláčanie Tunela - Všetky MetódyDaniel MoravanskýÎncă nu există evaluări

- Seismic Behaviour of R.C. Structures Including Soil-Stcrutures Interaction and Soil Variability EffectsDocument12 paginiSeismic Behaviour of R.C. Structures Including Soil-Stcrutures Interaction and Soil Variability EffectsHoney VermaÎncă nu există evaluări

- Stbu 11 00022Document16 paginiStbu 11 00022Elena MiceliÎncă nu există evaluări

- Case Study: Performance-Based Seismic Design of Reinforced Concrete Dual System BuildingDocument9 paginiCase Study: Performance-Based Seismic Design of Reinforced Concrete Dual System BuildingQorry OktaliaÎncă nu există evaluări

- EE SlopeStabilityAnalysis SPDocument41 paginiEE SlopeStabilityAnalysis SPAlexis MaronÎncă nu există evaluări

- IV Design Procedures Mechanistic-EmpiricalDocument10 paginiIV Design Procedures Mechanistic-EmpiricalSara BenavidesÎncă nu există evaluări

- ArchivesofMiningSciences 1070 2105 1 SMDocument18 paginiArchivesofMiningSciences 1070 2105 1 SMLAURENT JIBUNGEÎncă nu există evaluări

- Preprint 10-010: Geotechnical Instrumentation Research Leads Into Development of Improved Mine DesignsDocument7 paginiPreprint 10-010: Geotechnical Instrumentation Research Leads Into Development of Improved Mine DesignsEduardo MenaÎncă nu există evaluări

- 75 Stille&Palmstrom On Class As A ToolDocument23 pagini75 Stille&Palmstrom On Class As A ToolBlackcat FreeManÎncă nu există evaluări

- Measurement-While-Drilling Technique PDFDocument9 paginiMeasurement-While-Drilling Technique PDFWilkhen ChuraÎncă nu există evaluări

- Slope Design Process1Document5 paginiSlope Design Process1@@)&()Încă nu există evaluări

- 10ncee 001676 PDFDocument12 pagini10ncee 001676 PDFChetan PatilÎncă nu există evaluări

- Stress Measurement in Rock Mass: IGC 2009, Guntur, INDIADocument5 paginiStress Measurement in Rock Mass: IGC 2009, Guntur, INDIAShivendra KumarÎncă nu există evaluări

- Suggested Improvements To Performance-Based Seismic GuidelinesDocument8 paginiSuggested Improvements To Performance-Based Seismic GuidelinesshaimenneÎncă nu există evaluări

- 2022 - Predicting Tunnel Squeezing Using Support Vector Machine Optimized by Whale Optimization AlgorithmDocument24 pagini2022 - Predicting Tunnel Squeezing Using Support Vector Machine Optimized by Whale Optimization Algorithm周牮Încă nu există evaluări

- Chapter 1 - Philosophy of Engineering Clas - 2011 - Engineering Rock Mass ClassiDocument5 paginiChapter 1 - Philosophy of Engineering Clas - 2011 - Engineering Rock Mass ClassiAna MariaÎncă nu există evaluări

- Pushover Analysis of A Multi Storey BuildingDocument33 paginiPushover Analysis of A Multi Storey BuildingPrakhar VarshneyÎncă nu există evaluări

- Rovnice Pre Výpočet SRF - Mega DôležitéDocument23 paginiRovnice Pre Výpočet SRF - Mega DôležitéDaniel MoravanskýÎncă nu există evaluări

- Measurement While Drilling TechniqueDocument9 paginiMeasurement While Drilling TechniqueDavid Umiña YanaÎncă nu există evaluări

- Poryecto Pi 2019Document17 paginiPoryecto Pi 2019Joseph AlexandreÎncă nu există evaluări

- Computers and Geotechnics: G.S.P. Singh, U.K. SinghDocument15 paginiComputers and Geotechnics: G.S.P. Singh, U.K. Singhkatta_sridharÎncă nu există evaluări

- Uncertainty in Ground Support Design and Implementation in Underground MiningDocument14 paginiUncertainty in Ground Support Design and Implementation in Underground MiningHar AhmadÎncă nu există evaluări

- Engineering Structures: J. Ramon Gaxiola-Camacho, Hamoon Azizsoltani, Francisco J. Villegas-Mercado, Achintya HaldarDocument11 paginiEngineering Structures: J. Ramon Gaxiola-Camacho, Hamoon Azizsoltani, Francisco J. Villegas-Mercado, Achintya Haldarsriram narendranÎncă nu există evaluări

- OMAE2017-62059: Guidelines For Estimating Remaining Fatigue Life of Ageing Offshore Jacket StructuresDocument9 paginiOMAE2017-62059: Guidelines For Estimating Remaining Fatigue Life of Ageing Offshore Jacket Structuresklop disposableÎncă nu există evaluări

- Soil Dynamics and Earthquake Engineering: Massimiliano Bocciarelli, Gaia BarbieriDocument10 paginiSoil Dynamics and Earthquake Engineering: Massimiliano Bocciarelli, Gaia BarbieriAli HassenÎncă nu există evaluări

- Fyp Final Defense Presentation-Swat MotorwayDocument47 paginiFyp Final Defense Presentation-Swat MotorwayUsama ShahidÎncă nu există evaluări

- Valley Edifice Residential Building: Cristian Sanchez Anwar Salomon Christian DiazDocument17 paginiValley Edifice Residential Building: Cristian Sanchez Anwar Salomon Christian DiazANDRES FELIPE RODRIGUEZÎncă nu există evaluări

- In Situ Stress Measurement FEB2023Document75 paginiIn Situ Stress Measurement FEB2023charodt cruzÎncă nu există evaluări

- Numerical Back-Analysis of Highwall Instability in An Open Pit: A Case StudyDocument16 paginiNumerical Back-Analysis of Highwall Instability in An Open Pit: A Case StudyAlcantara MarielaÎncă nu există evaluări

- HPTO12 Installation & MaintenanceDocument23 paginiHPTO12 Installation & MaintenanceHeider Marin Solarte100% (1)

- Mini Swesite Broschyr - Web PDFDocument9 paginiMini Swesite Broschyr - Web PDFcokiaaÎncă nu există evaluări

- Is 5563 1985Document16 paginiIs 5563 1985Kamal RajuÎncă nu există evaluări

- Eging Installation ManualDocument18 paginiEging Installation ManualJavad NaserbakhtÎncă nu există evaluări

- Manual de Partes LS600NPDocument34 paginiManual de Partes LS600NPJosette Fallas ArayaÎncă nu există evaluări

- FirestoneDocument108 paginiFirestoneEduardoÎncă nu există evaluări

- Weber ManualDocument32 paginiWeber Manualjoe_b_32607Încă nu există evaluări

- NRG 200M Wind Vane InstructionsDocument14 paginiNRG 200M Wind Vane InstructionsBruno KaiqueÎncă nu există evaluări

- CBZ 160 StarDocument90 paginiCBZ 160 StarAlexander OlivosÎncă nu există evaluări

- Intelligent Plus: Installation ManualDocument54 paginiIntelligent Plus: Installation ManualAle LatroÎncă nu există evaluări

- 240-56063843 Analogue Oil and Winding Temperature GuagesDocument8 pagini240-56063843 Analogue Oil and Winding Temperature GuagesKhashane Willy MohaleÎncă nu există evaluări

- Tightening TorquesDocument4 paginiTightening Torquesflanker76Încă nu există evaluări

- Cts Spare Stock - Kasi Sales - 31!12!19.Document7 paginiCts Spare Stock - Kasi Sales - 31!12!19.saptarshi halderÎncă nu există evaluări

- Metric DIN 93 SpecDocument5 paginiMetric DIN 93 SpecJhon Edison Posada MuñozÎncă nu există evaluări

- CM470 Yedek Parça 2004Document458 paginiCM470 Yedek Parça 2004Sales Aydinkaya100% (2)

- Saej2244 1v001Document9 paginiSaej2244 1v001bigtone2001Încă nu există evaluări

- Spare Parts.Document66 paginiSpare Parts.Ronald Bienemi PaezÎncă nu există evaluări

- Tru-Tension Fasteners: TDS-006A 2-1-01Document6 paginiTru-Tension Fasteners: TDS-006A 2-1-01SOLRAKÎncă nu există evaluări

- ETA 07 0260 HIT-RE 500-SD Injection Mortar For Anchoring Application ETAG 001-05 Option 1 Approval Document ASSET DOC APPROVAL 0152Document52 paginiETA 07 0260 HIT-RE 500-SD Injection Mortar For Anchoring Application ETAG 001-05 Option 1 Approval Document ASSET DOC APPROVAL 0152Marcelo San MartinÎncă nu există evaluări

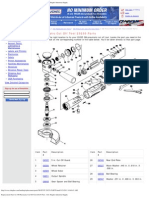

- Replacement Parts For 3M Pneumatic Cut Off Tool 20235 PartsDocument2 paginiReplacement Parts For 3M Pneumatic Cut Off Tool 20235 Partsskyler summersÎncă nu există evaluări

- Despiece TXT Rokie 2005-18!10!2009Document58 paginiDespiece TXT Rokie 2005-18!10!2009Jean-François ThorainÎncă nu există evaluări

- X-Arm ManualDocument24 paginiX-Arm ManuallearningboxÎncă nu există evaluări

- Arauca Caja QR513 PDFDocument36 paginiArauca Caja QR513 PDFCarlos LimadaÎncă nu există evaluări

- Defence Untouched Data 222Document48 paginiDefence Untouched Data 222kam6Încă nu există evaluări

- Metal Jacketed Gasket Instruction ManualDocument6 paginiMetal Jacketed Gasket Instruction ManualCalvin WongÎncă nu există evaluări

- 54+slide Tilt+Sunroof+and+Soft+TopDocument55 pagini54+slide Tilt+Sunroof+and+Soft+TopaterrohotmailÎncă nu există evaluări

- Dana-Spicer Ford Light Axle Applications Catalog Parts - D44 IFSDocument3 paginiDana-Spicer Ford Light Axle Applications Catalog Parts - D44 IFSAndres BM0% (1)

- Structural Calculation Report (SCR-0146 - A) : Wind-LoadDocument36 paginiStructural Calculation Report (SCR-0146 - A) : Wind-LoadAlem LoajnerÎncă nu există evaluări

- Technical Specifications: Duct Work and Outlets GeneralDocument16 paginiTechnical Specifications: Duct Work and Outlets GeneralNedunuri.Madhav MurthyÎncă nu există evaluări

- JD Implant Retreatment ToolsDocument2 paginiJD Implant Retreatment Toolsyounisismail935Încă nu există evaluări

![[doi 10.1115_PVP2013-97435] Wieschollek, Matthias; Diamanti, Kalliopi; Pinkawa, Marius; Hoff -- [ASME ASME 2013 Pressure Vessels and Piping Conference - Paris, France (Sunday 14 July 2013)] Volume 8.pdf](https://imgv2-2-f.scribdassets.com/img/document/448256677/149x198/d101cc149a/1582298254?v=1)