Documente Academic

Documente Profesional

Documente Cultură

RP2016 Wurzbach GreaseCompatibility Rev3

Încărcat de

dhowardjDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RP2016 Wurzbach GreaseCompatibility Rev3

Încărcat de

dhowardjDrepturi de autor:

Formate disponibile

How to Determine Grease Compatibility and Why Its

Important

The risks of mixing lubricants and new methods for determining long-term

compatibility impacts

Richard N. Wurzbach, Gretchen Kowalik, MRG Labs York, Pennsylvania, USA

Abstract

Grease compatibility charts have been developed and circulated since the 1980s without much

alteration. However, grease technology has changed significantly over the years, and there are many

proven examples of performance that contradict several widely used compatibility charts. Recent

research shows grease compatibility charts to be contradictory and dated. Changing formulations and

complexity in application have rendered grease compatibility charts unreliable. This paper describes the

most common examples of incompatible mixing and how to determine if two greases are compatible.

Background

Many organizations rely on compatibility charts to make important maintenance decisions that can have

a significant economic impact. Such charts are readily available in some published papers, periodicals,

and webpages. However, very few such chart given any reference for the origin of the data or any

research utilized to establish the compatibility relationships described.

Working as a lubrication engineer for multiple companies and industries, the author has frequently

encountered lubrication program decisions that have been based on these charts. While working in a

lab environment to objectively evaluate the compatibility of specific products using laboratory analysis

data, significant concerns have been raised about some charts after seeing that greases presented as

Compatible have proven to be quite incompatible.

Researching Compatibility Charts

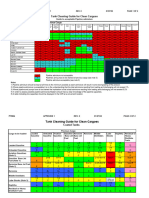

As a starting point for this research, a selection of 17 different compatibility charts were found and

evaluated for formats and differences. The chart below shows the labels used in these charts, and how

many times these descriptions show up in the charts. 17 occurrences would indicate that a grease

category was present in each of the charts found, and there were only three such products.

Reliable Plant 2016 Conference Proceedings |

Tribology Transit Eastern Ultra Accurate PriestOil PriestOil Thixo

Prolab .com Amsoil Lubritene NSK Lube Marine Lube Lubricants Chart1 Chart2 Grease ExxonMobil Hipertech Amsoil Cenex LubeTalkWeb Totals

Aluminum Complex 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 17

Barium 1 1 1 1 1 5

Barium Complex 1 1 1 1 1 1 1 1 1 1 10

Calcium 1 1 1 1 1 1 1 7

Calcium Stearate 1 1 1 1 1 1 1 1 8

Calcium 12-Hydroxy 1 1 1 1 1 1 1 1 1 1 1 1 1 13

Calcium 12-Hydroxystearate 1 1 2

Calcium Complex 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 17

Bentonite Clay 1 1 1 1 1 1 6

Clay 1 1 1 1 1 1 1 1 1 1 1 11

Lithium 1 1 1 1 1 1 1 7

Lithium 12-Hydroxy 1 1 1 1 1 1 1 1 1 1 1 1 12

Lithium 12-Hydroxystearate 1 1 2

Lithium Complex 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 17

Sodium 1 1 1 1 1 1 6

Polyurea 1 1 1 1 1 1 1 1 8

Polyurea (Conventional) 1 1 1 1 1 1 1 7

Polyurea (modified) 1 1

Polyurea Shear Stable 1 1 1 1 1 1 1 7

Polyurea (LUB-LM type) 1 1

Calcium Sulfonate 1 1 1 1 1 1 1 1 1 9

Silica Gel 1 1

Silica 1 1

Polyurea (Lubrilife) 1 1

Lithium Stearate 1 1 1 3

Figure 1: Compilation of 17 grease compatibility charts from the internet

The three products that appeared in each of the tables were Aluminum Complex, Lithium Complex, and

Calcium Complex. However, the commonality ends there. A total of 25 different product descriptions

were found in the 17 tables. Some may have been referring to the same product categories, but failed

to use common nomenclature, so it is difficult to determine where there might be overlap.

Contradictions

Several contradictions were found among the various charts. For example, the chart found at

Tribology.com indicated that Barium Complex grease is COMPATIBLE with Clay thickened grease.

However, charts from Amsoil, Transit Lubricants Ltd., UltraLube, and others indicate that this mixture is

INCOMPATIBLE. Charts from Lubritene and Transit Lubricants indicate that Polyurea grease is

BORDERLINE COMPATIBLE with Calcium Complex. A chart provided by Amsoil shows both Polyurea

(shear stable) and Polyurea (conventional) are COMPATIBLE with Calcium Complex. And a chart from

Thixogrease shows Calcium Complex to be INCOMPATIBLE with both Polyurea (conventional) and

Polyurea (Lubrilife).

Perhaps one of the most common inadvertent mixing of greases occurs when a Lithium Complex grease,

commonly specified or used as a factory fill in bearings in fans and pumps, meets up with a Polyurea

grease, often used in electric motors. It is quite easy for a plant where strict guidance is not given or

adhered to, for these two products being used side-by-side (in the pillow block bearings and motor of a

fan, for instance) to be mixed. Upon consulting charts for this important mixing condition, a chart from

NSK bearings calls Polyurea and Lithium Complex INCOMPATIBLE. Charts from Lubritene, Priest Motor

Repair, and Transit Lubricants show them to be BORDERLINE COMPATIBLE. And the most commonly

seen charts, including Tribology.com, Cenex, and those published in ReliablePlant magazine show

Polyurea (conventional) to be INCOMPATIBLE, and Polyurea (Shear Stable) to be COMPATIBLE.

However, there is no definition given for Compatible Polyurea. Certainly no Product Data Sheets

describe Polyurea greases as conventional. If this term is thought of as being a differentiation from

| Reliable Plant 2016 Conference Proceedings

Shear Stable Polyureas, there is likewise no definition to describe what would be considered Non-

Shear Stable greases.

Shear stability, in fact, is determined by the ASTM methods using a grease worker for extended number

of strokes, and measurement of changes in the penetration value relative to the standard 60 double-

stroke result. Meaning, that shear stability is actually a scale, where greases can be described as having

Excellent shear stability (<5% reduction in penetration after extended working), Very Good, Good

and Poor. So which of these would be labelled Shear Stable and which would be labeled

conventional? In order to rely on a chart for the correct course of action regarding mixing

compatibility, it would mean the difference between tearing down a machine to remove all traces of

grease, versus taking no action because the chart says Compatible.

Chart Origins

If it can be said that there are significant disagreements between the various charts, it is true that they

all have one thing in common. Few of the 17 charts that were researched provided any link or reference

to research that was conducted to develop them. That is to say, that charts being used to make

significant engineering and design decisions are contradictory, and do not indicate the source of

information or research used to compile them.

Upon observation, it becomes obvious that several of the charts are derivative from others. The various

descriptions used lead to a certain differentiation that implies that some may have been copied from

others. Many charts include a disclaimer, usually stating that it would be preferable to either clean out

all old grease and avoid any mixing, or stating that the charts are believed to be accurate at the time of

publication, but the publisher takes no responsibility for the guidance included in the chart. Some

charts that are obviously derived from these with such a disclaimer are stripped away from the

disclaimer in the re-publication. One that did supply information regarding the source for chart

development was the Acculube chart, which states, There are libraries full of good compatibility charts,

but many contradict each other. The critical consideration for the compatibility of greases is the type of

thickener used in the formula- and also the type of base fluid used. Here's what Acculube believes is a

good basic compatibility guideline, based on its 25+ years of experience working hands-on with users of

commercial greases. We've assigned each "combination" a rating:

C when the mixture is compatible

N for when it is not compatible, and

? when the combination is questionable. (This means it might be compatible, but needs to be

tested.)

Certainly an honest assessment of the available compatibility charts, but basing their recommendations

on extensive experience. It is not known, however, if this experience is anecdotal, or part of a carefully

conducted compatibility study between groups of greases with different thickeners under carefully

controlled and repeatable testing.

Reliable Plant 2016 Conference Proceedings |

Another well documented chart was featured in a Machinery Lubrication magazine article. i This chart,

originally in an article in Plant Services magazine, dated from 1997, and was based on research of 10

greases conducted by NSK bearing company. Perhaps the most detailed backing information provided,

the results were based on two greases which were first tested separately and then blended at three

different ratios. The worked penetration test was used on the greases after being blended at room

temperature and again after storage at 250F. This result produced the following chart (Figure 2), as it

appeared in Machinery Lubrication magazine:

Figure 3: Unreferenced chart:

Figure 2: Gebarin, Sabrin, Recommendations for Mixing

http://www.machinerylubrication.com/Read/29337/understanding

Greases, Machinery Lubrication, June 2006

-grease-compatibility

Figure 4: Turner, David, The Skinny on Grease Lubrication,

Machinery Lubrication, Jan 2007

Two other charts that have been published by Noria are included here as well. The chart in Figure 3

contains the following: A note of caution: not all polyurea thickeners are compatible. Be thorough in

reviewing the compatibility of the greases used at the motor rebuild shop and at the site. Ideally use

| Reliable Plant 2016 Conference Proceedings

the same grease for both. So if nearly every chart we have seen shows that all Polyurea thickened

greases are C-compatible with Polyurea thickened greases, how can we reliably use these charts?

While they were published at different times, and therefore we do not necessarily expect these to be

identical, it does underscore the challenge of finding a single, authoritative chart to be used with

confidence when making decisions regarding grease mixing.

Basis for Grease Compatibility

It is interesting to note, that all such charts that can be found on grease compatibility focus only on the

family of thickener involved. There are, in effect, three components to any formulated grease: the base

oil, the additives and the thickener. When dealing with mixing of oils, the key considerations are the

viscosity of each product, the base oil type, and the thickener. Somehow, though, these critical

parameters are overlooked when utilizing grease compatibility charts. This is somewhat understood,

since the most common reason for grease mixing problems is related to differences in grease thickener.

However, that is not the only issue.

Base oil compatibility

Greases are manufactured from both mineral oil and synthetic oil bases. Some synthetic base oils are

incompatible with mineral oils and other types of synthetics, just as in mixing of lubricating oils.

Therefore, it is important to consider the type of base oil in the grease when determining compatibility.

If the grease thickeners are compatible, but the base oils are not, the resulting mixture can be

problematic and a poor performer. Viscosity is critical when selecting any lubricant. Likewise, when

greases are mixed where the base oil viscosities are significantly different, the resulting mixture will not

be optimized for the application.

Additive compatibility

It is well understood that when oils are mixed, any incompatibility in the additive packages will result in

poor performance, and often additive reactions creating deposits. While reacting additives will not

settle to the bottom in grease, as is the concern in oil, the changes can be problematic, impacting

additive effectiveness, and in some cases creating corrosive conditions in the grease. Additive

compatibilities with metallurgy of the lubricated component must also be considered.

Thickener compatibility

Mixing of greases with incompatible thickeners can cause the most immediate and obvious changes

which interfere with effective lubrication. Many mixtures will initially soften, often to the point of

migration through seals or away from lubricated surfaces. Some mixtures will cause the thickener to

release the oil, and the separated phase will run freely from the bearing, gear or housing. Other

mixtures harden initially, and cause component load issues, and poor grease motility. This potential

effect is not easily determined. Simply mixing two greases together to observe changes may not provide

any obvious difference. But carefully mixing the greases in different ratios, and subjecting them to

Reliable Plant 2016 Conference Proceedings |

mixing, working, and heating cycles can result in measureable changes in properties to predict their

performance in a machine.

Testing for Grease Compatibility

So if this research has demonstrated the unreliability of the many different and contradictory grease

compatibility charts found in publications and accessible on the internet, it is important to discuss what

additional steps can be taken to evaluate compatibility of greases. ASTM D6185 is the Standard

Practice for Evaluating Compatibility of Binary Mixtures of Lubricating Greases. This method involves

the mixing of the intended greases is ratios of 25:75, 50:50, and 75:25. The resulting mixtures are

evaluated for changes in dropping point, shear stability and storage stability. The second two of these

involve measuring changes in the cone penetration value.

While this 2011 standard has greatly improved the uniformity to which greases can be tested for

compatibility, it should be noted that the three evaluation tests are static in nature. While there is some

mechanical working of the grease prior to testing, this is minimal mechanical perturbation. When a

grease mixture is introduced into a machine, such as a motor bearing, it will undergo significant mixing

and working in a relatively short period of time. This compares to the 60 double strokes utilized to mix

and work the binary mixture evaluated in the standard. A mixture of greases introduced in a common

ball-bearing operating at 1750 rpm will see nearly 30 million mixing and working events in just 3 days of

operation. This mixture will be subjected to continuous dynamic forces, and its performance and

possible degradation will be influenced by this more than the static response seen in cone penetration

or dropping point measurements. The ability of this testing to adequately predict inservice mixtures

may be reasonably questioned.

Working in a Bearing Simulator

Some studies have been performed to improve the mixing and

working of the greases to better simulate machine conditions.

Included is an electric motor test stand developed for the

Electric Power Research Institutes Effective Grease Practices

guideline. This test stand consists of the end bell from a 60 hp

electric motor, mounted with a ball bearing in a stub shaft. The

shaft is turned by a fractional horsepower motor, coupled to a

turned-down shaft. The housing of the end bell is removed and

replaced by a Plexiglas window to observe the condition of the

grease under dynamic conditions. For the purpose of testing

grease mixtures, the 25:75, 50:50, and 75:25 ratios are placed

sequentially into the bearing by hand packing, and packing the

adjacent housing area to full. This is then run for 72 hours, to

achieve the 30 million plus perturbations of the grease. The

conditions observed are noted, and the grease is removed from

Figure 5: Grease Mixing Test Stand

| Reliable Plant 2016 Conference Proceedings

the bearing from the load zone area.

Dynamic Analysis

The resulting mixture is analyzed by Fourier Transform Infrared Spectroscopy (FTIR) to note any reaction

or unexpected oxidation of the components in the grease. The grease is also evaluated by elemental

spectroscopy to likewise evaluate for unexpected final ratios of additives, as compared to the

anticipated averaging of values seen in the original products, adjusting for mixing ratios. Finally, the

grease is tested in a controlled stress rheometer to evaluate changes in flow and shear properties as

compared to the original products. The values that are measured include the yield stress, which can

predict the hardening or softening the grease may undergo; the oscillation stress, which can give insight

into the likelihood of oil separation and other effects; and recoverable compliance, which can help to

identify those mixtures that might experience channeling or tunneling in the equipment housing.

Taken together, these tests may provide a more comprehensive picture of the potential effects of

mixing two grease products together, and help a user avoid reliability issues from grease mixing, even of

products that might otherwise appear to be Compatible on charts.

Examples of Grease Compatibility Testing

The following are results of testing of binary mixtures of greases using the methods described in this

paper and using the grease mixing test stand to mix and work the samples. The first example is of two

commonly used Polyurea thickened greases. This mixture was chosen for a company looking to

consolidate the number of greases being used in their facility. One area of the facility utilized Chevron

SRI in all electric motors, while the remainder utilized Mobil Polyrex EM. The goal was to consolidate to

one product for all motors. However, it would not be possible to completely clean all of the grease out

of the motors of the grease being replaced, and thus it became necessary to verify that one polyurea

grease could be directly added to a motor containing the other. According to most grease compatibility

charts, Polyurea greases are compatible with each other, and such a transition would be allowed.

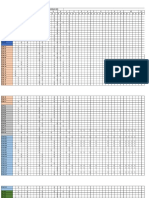

Table 1 shows the product Information for Chevron SRI-2 and Mobil Polyrex EM Grease

Test Chevron SRI Grease 2 [1] Mobil Polyrex EM [2]

NLGI Grade 2 2

Thickener Type Polyurea Polyurea

Penetration, Worked, ASTM

280 285

D217

Viscosity of Oil, ASTM D445 cSt

116 115

@ 40 C

These greases are very comparable based on their consistency and viscosity of the base oils.

Reliable Plant 2016 Conference Proceedings |

Table 2 shows differences between elemental spectroscopy (RDE) values for the reference greases and

the 50:50 mixture of Chevron SRI Grease 2 and Mobil Polyrex EM. The area highlighted in yellow is

where there is contrast between the products and evidence of mixing is observable.

Fe Cr Pb Cu Sn Al Ni Ag Si B Na Mg Ca Ba P Zn Mo Ti V

Polyrex EM 1.1 0.5 0.0 0.6 0.0 3.5 0.6 0.1 2.0 0.1 0.5 0.2 1.2 8.2 123.6 2.3 1.4 0.0 1.3

SRI 4.9 1.0 0.2 0.3 0.0 1.4 1.7 0.1 1.6 0.2 1.0 21.5 3.4 15.6 0.0 576.8 1.9 0.0 2.2

50:50

SRI2/Poly EM 0.8 0.4 0.0 0.3 0.0 0.0 0.3 0.1 1.7 0.6 0.8 10.2 5.1 4.6 31.8 301.7 1.1 0.0 0.5

These differences show an obvious formulation difference between these products with regard to (most

likely) anti-wear additives, but that alone would not be sufficient to disqualify the mixture for

compatibility, if the resulting product still functioned effectively with regard to wear resistance.

Table 3 shows rheological values for the two worked reference samples and the 50:50 worked mixture.

Areas highlighted in red indicate values of concern.

Expected Yield Stress Expected Recoverable Expected

Trial G (Pa)

G (Pa) Yield Stress Compliance (%) R-C %

Chevron SRI2

31690 -- 872 -- 34% --

Worked

Polyrex EM Worked 12480 -- 386.6 -- 29%

50:50 SRI2:Polyrex

8605 22085 354.1 629 59% 31%

Worked

G'

35000 31690

30000

25000 22085

Yield Stress (Pa)

20000

15000 12480

10000 8605

5000

0 0

0

Chevron SRI2 Worked Polyrex EM Worked 50:50 SRI2:Polyrex Worked

G (Pa) Expected G G (Pa) - Outlier

Figure 6 shows the expected G values and the actual G values for the 50:50 mixture of Chevron SRI Grease 2 to Mobil Polyrex EM and the

reference greases.

| Reliable Plant 2016 Conference Proceedings

Yield Stress

1000

872

900

800

700 629

600

G' (Pa)

500

386.6

400 354.1

300

200

100

0 0

0

Chevron SRI2 Worked Polyrex EM Worked 50:50 SRI2:Polyrex Worked

Yield Stress (Pa) Expected Yield Stress Yield Stress (Pa) - Outlier

Figure 7 shows the expected yield stress values and the actual yield stress values for the 50:50 mixture of Chevron SRI Grease 2 to Mobil Polyrex

EM and the reference greases.

Recoverable Compliance

70%

59%

60%

Recoverable Compliance

50%

40% 34%

31%

29%

30%

20%

10%

0

0%

Chevron SRI2 Worked Polyrex EM Worked 50:50 SRI2:Polyrex Worked

Recoverable Compliance (%) Expected R-C % R-C% - Outlier

Figure 8 shows the expected recoverable compliance values and the actual recoverable compliance values for the 50:50 mixture of Chevron SRI

Grease 2 to Mobil Polyrex EM and the reference greases.

In this case, each of the values of the 50-50 mixture is significantly different than the expected

numerical average of the unmixed products. This demonstrates a change in properties due to mixing,

and raises a concern about this mixtures performance in the long-term. It could be expected that this

mixture could be subject to softening, some oil separation, and a tendency to channel when allowed to

Reliable Plant 2016 Conference Proceedings |

persist in a mixed state in the motor housing. For this reason, this mixture was not permitted for this

customer site, and the decision was made to keep two greases in place at the facility, until a future time

when the motors could be removed and thoroughly cleaned of the existing product.

Strategies to Minimize Mixing Effects

It can be difficult to avoid mixing of greases altogether in a plant environment, but there are several

steps that can be taken to minimize the impact and likelihood of mixing of incompatible greases.

Step 1: Provide clear guidance

All personnel involved in applying greases to equipment should be trained and receive instructions on

the proper product to use on each piece of equipment and location. This includes employees and

contractors that may be working in the facility. Provide labels and color codes where possible to

minimize confusion.

Step 2: Involve purchasing in grease specification

A common area for grease mixing is in new and rebuilt equipment. Even when all plant personnel are

given clear guidance and adhere to the correct products, equipment can be returned to the facility with

a grease that is different than what will be added while in service. And new bearings, gears, motors,

etc., often come supplied with a product incompatible with the grease being used to relubricate.

Step 3: Consolidate lubricants

Identify the minimum number of products required to meet the design of equipment in use in the

facility, and consolidate to that number. Do not stock additional products for convenience or brand

loyalty. This increases likelihood of mixing.

Step 4: Test potential mixtures

If the wrong grease has been inadvertently added to a machine, or a consolidation is required that will

transition the use of a product in a machine, perform simulated mixing and working of the mixtures, and

dynamic properties testing to evaluate the mixtures performance. For those mixtures which prove to

be incompatible, the extra effort must be taken to thoroughly clean all traces of grease from the

housing, supply lines, and bearings/gears to ensure long life and reliable operation of the machinery.

Grease compatibility charts may seem a convenient and easy way to make decisions based on actual or

potential grease mixing. However the unreliability of these charts, and the complex interaction of base

oils, additives and grease thickeners require that a more certain approach is taken to ensure optimal

equipment performance. The effort taken to avoid mixtures where possible, and to test mixtures for

compatibility issues and take appropriate action, is an investment in reliability that will pay dividends.

i

Gebarin, Sabrin, Recommendations for Mixing Greases, Machinery Lubrication, June 2006.

| Reliable Plant 2016 Conference Proceedings

S-ar putea să vă placă și

- Trio CT 1040 Jaw Crusher Manual (SN. 225) PDFDocument41 paginiTrio CT 1040 Jaw Crusher Manual (SN. 225) PDFkenoy100% (2)

- Dragline Dictionary Apr14Document578 paginiDragline Dictionary Apr14dhowardj100% (1)

- S151929 - 20210127.indd KAO SURFACTANTESDocument12 paginiS151929 - 20210127.indd KAO SURFACTANTESAlfredo Méndez100% (1)

- Belex Wireline LubricantDocument2 paginiBelex Wireline LubricantdhowardjÎncă nu există evaluări

- Belex Wireline LubricantDocument2 paginiBelex Wireline LubricantdhowardjÎncă nu există evaluări

- G1 Gravity Thickener EquipmentDocument136 paginiG1 Gravity Thickener EquipmentLUIS ALONSO TARAMUEL TAPIEÎncă nu există evaluări

- Elastomer, Fluid Compatibility Chart (Fluids Beginning With M)Document3 paginiElastomer, Fluid Compatibility Chart (Fluids Beginning With M)NovancyÎncă nu există evaluări

- Epoxy Coating Chemical Resistance 2015Document2 paginiEpoxy Coating Chemical Resistance 2015Mohamed AbdelrahmanÎncă nu există evaluări

- Form Frekuensi BackwashDocument18 paginiForm Frekuensi Backwashyahya.pmkepÎncă nu există evaluări

- 2010 Safety Training PGMDocument12 pagini2010 Safety Training PGMJames Mathai100% (1)

- Insurance and Reinsurance 2008Document19 paginiInsurance and Reinsurance 2008abhishekÎncă nu există evaluări

- Rekapan Survey Kebutuhan Dan Harapan Kesh O.RDocument70 paginiRekapan Survey Kebutuhan Dan Harapan Kesh O.Rsabita dwiratnaÎncă nu există evaluări

- Manpower Deployment Plan Ot2499Document1 paginăManpower Deployment Plan Ot2499becemÎncă nu există evaluări

- Schedule AlatDocument1 paginăSchedule AlatKanekiÎncă nu există evaluări

- GE ProbesDocument1 paginăGE Probesmahmoud kassemÎncă nu există evaluări

- Hongzhen He 4336708: Mole Fraction Molar Flows Mole Fraction Molar Flows Mole Fraction Molar Flows Kmol/h Kmol/h Kmol/hDocument3 paginiHongzhen He 4336708: Mole Fraction Molar Flows Mole Fraction Molar Flows Mole Fraction Molar Flows Kmol/h Kmol/h Kmol/hbellepimmanaÎncă nu există evaluări

- 100 & 200 Series - Chemical Resistance ChartDocument5 pagini100 & 200 Series - Chemical Resistance ChartdulioÎncă nu există evaluări

- Slab CycleDocument2 paginiSlab CycleSudarshan ManeÎncă nu există evaluări

- Chemistry and Technology of The Cosmetics and Toiletries Industry (PDFDrive)Document411 paginiChemistry and Technology of The Cosmetics and Toiletries Industry (PDFDrive)Audrey Ann100% (1)

- Data Sanitasi Dasar Puskesmas Tanjung BingkungDocument9 paginiData Sanitasi Dasar Puskesmas Tanjung BingkungEVA YANTIÎncă nu există evaluări

- Cool Drinks Daily Report 2020Document12 paginiCool Drinks Daily Report 2020vrnagencyÎncă nu există evaluări

- By Language 141027 ExcelDocument362 paginiBy Language 141027 ExcelrivasÎncă nu există evaluări

- Daftar Makan Security Kawasan 328: Bulan: Agustus 2017Document13 paginiDaftar Makan Security Kawasan 328: Bulan: Agustus 2017Insan KamalÎncă nu există evaluări

- NEA - Allowable Limits For Trade Effluent Discharge To Watercourse or Controlled WatercourseDocument2 paginiNEA - Allowable Limits For Trade Effluent Discharge To Watercourse or Controlled WatercourseleeÎncă nu există evaluări

- Rubber Chemical Resistance, Rubber Chemical Compatibility, Page 4Document14 paginiRubber Chemical Resistance, Rubber Chemical Compatibility, Page 4Quality ControlÎncă nu există evaluări

- Teacher's Form Filipino PothosDocument11 paginiTeacher's Form Filipino Pothoschristine rose maghariÎncă nu există evaluări

- Schedule Manpower & Equipment Outside - InsideDocument2 paginiSchedule Manpower & Equipment Outside - InsideDeary Nanda Aprillio100% (1)

- Sign Category TambahanDocument3 paginiSign Category TambahantediÎncă nu există evaluări

- PORON Polyurethanes Chemical Resistance Data SheetDocument2 paginiPORON Polyurethanes Chemical Resistance Data SheetSteve FransiscusÎncă nu există evaluări

- Supplemental Digital Content-Table 1. Quality Assessment of Included Case-Control StudiesDocument5 paginiSupplemental Digital Content-Table 1. Quality Assessment of Included Case-Control StudiesmelianyÎncă nu există evaluări

- Speed Control System With Safety Break. Actuation Table For Selenoid and ClutchDocument7 paginiSpeed Control System With Safety Break. Actuation Table For Selenoid and ClutchEka SukandaÎncă nu există evaluări

- Adsorpsi, OilDocument35 paginiAdsorpsi, OilSyarifahÎncă nu există evaluări

- JATRABARI Sample Shop + Sample ProductDocument4 paginiJATRABARI Sample Shop + Sample ProductNahid HossenÎncă nu există evaluări

- Schedule Alat Dan Man PowerDocument3 paginiSchedule Alat Dan Man PowerBagas Lesta CoratiesÎncă nu există evaluări

- Contoh Format Daftar Brand Activation Unit Bisnis Batam TAHUN 2018Document5 paginiContoh Format Daftar Brand Activation Unit Bisnis Batam TAHUN 2018Ye O EsÎncă nu există evaluări

- Survey TallyDocument312 paginiSurvey TallyJohn Patrick SalongaÎncă nu există evaluări

- Manpower - Equipment ScheduleDocument2 paginiManpower - Equipment ScheduleSasha Braus0% (1)

- PTM04 App1 - Tank Cleaning Guide For Clean CargoesDocument2 paginiPTM04 App1 - Tank Cleaning Guide For Clean CargoesАлександр СанинÎncă nu există evaluări

- Why Does An Apple Turn Brown?: Name: Kellen Campbell School: Centerville Junior High Teacher: Mr. TranDocument23 paginiWhy Does An Apple Turn Brown?: Name: Kellen Campbell School: Centerville Junior High Teacher: Mr. TranKellen CampbellÎncă nu există evaluări

- Evac Product Catalogue 2010 2011Document727 paginiEvac Product Catalogue 2010 2011Branko Grbcic100% (2)

- Indirect Manpower Deployment ScheduleDocument1 paginăIndirect Manpower Deployment ScheduleMDhana SekarÎncă nu există evaluări

- Measurements On Loaded Building-Board Panel Sound AbsorbersDocument11 paginiMeasurements On Loaded Building-Board Panel Sound AbsorbersAntonioPalloneÎncă nu există evaluări

- Relevet 2010Document6 paginiRelevet 2010ald-mÎncă nu există evaluări

- List SpilkitDocument1 paginăList Spilkitppi.rskalideresÎncă nu există evaluări

- TH B07 Alkali and Surfactant Consumption in Sandstone Outcrop RocksDocument11 paginiTH B07 Alkali and Surfactant Consumption in Sandstone Outcrop Rocks56962645Încă nu există evaluări

- CSM Design Guidelines: Feed Flowrate, m3/hr (Maximun Per Vessel)Document1 paginăCSM Design Guidelines: Feed Flowrate, m3/hr (Maximun Per Vessel)arranguezjr5991Încă nu există evaluări

- CSM Design GuidelineDocument1 paginăCSM Design GuidelineWalter BastidasÎncă nu există evaluări

- Instrumen SMD 2018 BaruDocument45 paginiInstrumen SMD 2018 BaruAnonymous T5wq376YnÎncă nu există evaluări

- Rubber Chemical Resistance, Rubber Chemical Compatibility, Page 2Document12 paginiRubber Chemical Resistance, Rubber Chemical Compatibility, Page 2Quality ControlÎncă nu există evaluări

- Angket Survey Masyarakat Tahap 3Document25 paginiAngket Survey Masyarakat Tahap 3RAFY GAMINGÎncă nu există evaluări

- Chemical Resistance Chart (Trelleborg)Document8 paginiChemical Resistance Chart (Trelleborg)윤병택Încă nu există evaluări

- Rekap Pengambilan ApdDocument29 paginiRekap Pengambilan Apdkembarjayakaryagkt2023Încă nu există evaluări

- Monas Del AlbumDocument3 paginiMonas Del AlbumCamilo Andrés Melo PinzónÎncă nu există evaluări

- Matriz de Sustancias Por SectorDocument3 paginiMatriz de Sustancias Por SectorMarianela Angel VillagranÎncă nu există evaluări

- IO ListDocument5 paginiIO ListkhirodbarikÎncă nu există evaluări

- Materi Presentasi Insinyur TerryDocument19 paginiMateri Presentasi Insinyur TerryRizqi SBSÎncă nu există evaluări

- Schedule AlatDocument1 paginăSchedule AlatdiangitayaÎncă nu există evaluări

- Lesueur Special 2011Document7 paginiLesueur Special 2011Iwan TirtaÎncă nu există evaluări

- Inv Global Garden PDFDocument1 paginăInv Global Garden PDFaaaÎncă nu există evaluări

- Jadwal WFO Biro Hukum 2022 AprilDocument1 paginăJadwal WFO Biro Hukum 2022 AprilBiro Hukum KKPÎncă nu există evaluări

- April Attandance Record Date DAY ABC ABC: 1 Weakly OffDocument14 paginiApril Attandance Record Date DAY ABC ABC: 1 Weakly OffsatiaakÎncă nu există evaluări

- HPP Shoes LaundryDocument36 paginiHPP Shoes LaundryAgungPratamaÎncă nu există evaluări

- Invent Ar IsDocument130 paginiInvent Ar IswidiÎncă nu există evaluări

- Simpson 2007Document12 paginiSimpson 2007Sâu HeoÎncă nu există evaluări

- Advanced Technique For Grease Oxidation MeasurementDocument11 paginiAdvanced Technique For Grease Oxidation MeasurementdhowardjÎncă nu există evaluări

- Mobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic GreaseDocument3 paginiMobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic Grease Mobil 1™ Synthetic GreasedhowardjÎncă nu există evaluări

- Spedie TheDocument40 paginiSpedie ThedhowardjÎncă nu există evaluări

- Flir TI Guidebook For Facilities MaintenanceDocument26 paginiFlir TI Guidebook For Facilities MaintenancedhowardjÎncă nu există evaluări

- Friction Lubrication and Wear of Gears ADocument17 paginiFriction Lubrication and Wear of Gears AdhowardjÎncă nu există evaluări

- Buc Will: Document Identifier NND Heading Has Lncn-Poijndi !iIL-PRF-16173EDocument40 paginiBuc Will: Document Identifier NND Heading Has Lncn-Poijndi !iIL-PRF-16173EJustformedia JustformediaÎncă nu există evaluări

- Caliber M TDS 2051Document1 paginăCaliber M TDS 2051dhowardjÎncă nu există evaluări

- ARMY 702-19 Reliability - Availability and Maintainability PDFDocument32 paginiARMY 702-19 Reliability - Availability and Maintainability PDFdhowardj100% (1)

- 111AAA Worlds Largest GearsDocument5 pagini111AAA Worlds Largest GearsdhowardjÎncă nu există evaluări

- No-Tox BioFR Hydraulic 46Document2 paginiNo-Tox BioFR Hydraulic 46dhowardjÎncă nu există evaluări

- EHL Military PaperDocument355 paginiEHL Military PaperdhowardjÎncă nu există evaluări

- Quantum TS Global Synthetic ATFDocument2 paginiQuantum TS Global Synthetic ATFdhowardjÎncă nu există evaluări

- Molylube Cam Compound L56Document2 paginiMolylube Cam Compound L56dhowardjÎncă nu există evaluări

- ARMY 702-19 Reliability - Availability and Maintainability PDFDocument32 paginiARMY 702-19 Reliability - Availability and Maintainability PDFdhowardj100% (1)

- Biodegradable Wire Rope Coating GreaseDocument2 paginiBiodegradable Wire Rope Coating GreasedhowardjÎncă nu există evaluări

- Bel-Ray Rust Preventative CoatingDocument3 paginiBel-Ray Rust Preventative CoatingdhowardjÎncă nu există evaluări

- Synthetic Diesel Hammer LubricantDocument2 paginiSynthetic Diesel Hammer LubricantdhowardjÎncă nu există evaluări

- Belex Wireline LubricantDocument2 paginiBelex Wireline LubricantdhowardjÎncă nu există evaluări

- Lubricants and Lubrication of Plastic GearsDocument3 paginiLubricants and Lubrication of Plastic GearsdhowardjÎncă nu există evaluări

- Bel-Ray 6 in 1 Multipurpose LubricantDocument2 paginiBel-Ray 6 in 1 Multipurpose LubricantdhowardjÎncă nu există evaluări

- Freudenberg - en - Technical Elastomers-Web PDFDocument37 paginiFreudenberg - en - Technical Elastomers-Web PDFdhowardjÎncă nu există evaluări

- OxidationDocument1 paginăOxidationdhowardjÎncă nu există evaluări

- Molylube Open Gear & Rope LubricantDocument2 paginiMolylube Open Gear & Rope LubricantdhowardjÎncă nu există evaluări

- Needle BearingsDocument184 paginiNeedle Bearingsmanoj983@gmail.com100% (1)

- FAG Bearing DamageDocument91 paginiFAG Bearing Damagesamir8albinoÎncă nu există evaluări

- Boundary LubricationDocument8 paginiBoundary Lubricationadityanarang147Încă nu există evaluări

- Guidelines For Bearing Design Using Nylon MaterialDocument3 paginiGuidelines For Bearing Design Using Nylon MaterialDiego ReggianiniÎncă nu există evaluări

- Synthetic Hi-Temp GreaseDocument1 paginăSynthetic Hi-Temp GreasetariÎncă nu există evaluări

- Petron MV Ep 1 Moly Grease Pds 6-11Document2 paginiPetron MV Ep 1 Moly Grease Pds 6-11Justin HernandezÎncă nu există evaluări

- Rammer 1655 Operators Manual 2015Document76 paginiRammer 1655 Operators Manual 2015SerkanAlÎncă nu există evaluări

- TDTG Bucket ElevatorDocument20 paginiTDTG Bucket ElevatorVictor Julio Torres Daza0% (1)

- GEK - 30375M Lubrication SpecificationsDocument34 paginiGEK - 30375M Lubrication SpecificationsMARITZA GABRIELA ARIZABAL MEDINAÎncă nu există evaluări

- Marmon-Herrington: Operators ManualDocument43 paginiMarmon-Herrington: Operators Manualgabri1992Încă nu există evaluări

- Mining Raasm USA - Brochure PDFDocument10 paginiMining Raasm USA - Brochure PDFHector Robinson Prieto WilchesÎncă nu există evaluări

- BDF 35S Freefall Davit Manual (RV.1)Document46 paginiBDF 35S Freefall Davit Manual (RV.1)Cleverson Schmidt100% (4)

- MAM200Document20 paginiMAM200arielenryÎncă nu există evaluări

- Staburags Nbu 12/300 KP: Long-Term Grease For Rolling and Plain BearingsDocument1 paginăStaburags Nbu 12/300 KP: Long-Term Grease For Rolling and Plain BearingsJa AkÎncă nu există evaluări

- Grease04Interchange Proof 1Document1 paginăGrease04Interchange Proof 1smhea123Încă nu există evaluări

- Loctite Solution Guide Issue 6Document56 paginiLoctite Solution Guide Issue 6José María GarcíaÎncă nu există evaluări

- Rehs1501-00 Installation & Replacement Procedure For Greased Link Pin Joints 992G 25-03-2003Document18 paginiRehs1501-00 Installation & Replacement Procedure For Greased Link Pin Joints 992G 25-03-2003Jean-Jacques OuandaogoÎncă nu există evaluări

- Recent Technical Trends in Ball ScrewsDocument12 paginiRecent Technical Trends in Ball ScrewsjoseingtecindÎncă nu există evaluări

- Instruction Manual Unique Sanitary Mixproof Valve Including Us Version Ese00923enDocument120 paginiInstruction Manual Unique Sanitary Mixproof Valve Including Us Version Ese00923enAnonymous KdnOsd9Încă nu există evaluări

- Ugo Basile 7025/7125 Rodent VentilatorDocument38 paginiUgo Basile 7025/7125 Rodent VentilatorNikos Psihalakis100% (1)

- wrcc30 2015 GB - 3Document52 paginiwrcc30 2015 GB - 3Daniela RossiÎncă nu există evaluări

- MHC Checklist05Document4 paginiMHC Checklist05Tawfiq ZidanÎncă nu există evaluări

- Business Class M2 Workshop Manual-3-1Document150 paginiBusiness Class M2 Workshop Manual-3-1Dinator CortésÎncă nu există evaluări

- 44SP ManualDocument13 pagini44SP ManualHamzeh M. Abu HawashÎncă nu există evaluări

- Mobilith AW SeriesDocument3 paginiMobilith AW SeriesDavid SalgueroÎncă nu există evaluări

- RP2016 Wurzbach GreaseCompatibility Rev3Document10 paginiRP2016 Wurzbach GreaseCompatibility Rev3dhowardjÎncă nu există evaluări

- SKF BearingsDocument108 paginiSKF BearingsAgg GlezÎncă nu există evaluări

- Sistemas de Lubrican ProgresivaDocument132 paginiSistemas de Lubrican ProgresivaAlvaroÎncă nu există evaluări

- GPCDOC GTDS Shell Gadus S4 OG Clear Oil 20000 (En) TDSDocument2 paginiGPCDOC GTDS Shell Gadus S4 OG Clear Oil 20000 (En) TDSArdi Sepdiniyoko01Încă nu există evaluări

- PC1250-8 Gen00055-04 PDFDocument137 paginiPC1250-8 Gen00055-04 PDFWill Front100% (1)

- 大型蓄能器Document39 pagini大型蓄能器HayLenLeeÎncă nu există evaluări