Documente Academic

Documente Profesional

Documente Cultură

Interlocking & Curb Stone Rev.1

Încărcat de

Shaddy Joseph Endrawes100%(1)100% au considerat acest document util (1 vot)

91 vizualizări3 paginiinterlocking mS

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOC, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentinterlocking mS

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

91 vizualizări3 paginiInterlocking & Curb Stone Rev.1

Încărcat de

Shaddy Joseph Endrawesinterlocking mS

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

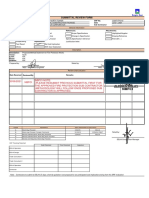

METHOD OF STATEMENT

FOR

INTERLOCKING BLOCK AND CURB

STONE

METHOD OF STATEMENT FOR

INTERLOCKING BLOCK AND CURB

STONE

Summary: This Method of Statement applies to the following;

Materials for Application;

1. Pre-Cast Curb Stone Transmittal #C-0051Rev.1

2. Interlocking Block, Transmittal # C-0052

3. Aggregate Sub-base & Base Coarse

4. Geotextile, Separation Layer-Geotextile Fabric 140

Transmittal # C-0047Rev.1

5. Mortar

6. Soil Sterilizer

1. Delivery, Storage and Handling:

MOS for Interlocking Block and curve Stone Rev.1

Page 1 of 3

A. After the material samples have been approved, all materials

shall be delivered to site in the manufacturers original

unopened containers and packages with seals unbroken and

labels intact and shall be stored in a dry place. Materials such as

cements, which are partially caked, the containers for which

show water stain or which are damaged or unsuitable for use

shall be removed from site.

B. Damaged curbs shall not be allowed to be used so that

precautionary measures shall be undertaken to prevent racking,

chipping or other damage during unloading and storage at the

site. Any damage curb installed shall be immediately removed

from the site and replaced with a new material.

C. The work shall be coordinated with other sections of work

which adjoins other materials before installation of the material

herein.

2. Installation:

Curb:

A. Set lay-out for curb stone according to plan with reference to

lines and grades.

B. The base coarse shall be compacted to attain sufficient

compaction prior to its final placement.

C. Set curbs in full bed of mortar that it will be stable and can

resist lateral force exerted by the adjoining elevated

interlocking blocks.

D. The joint of the curb stone shall be spaced for at least 10 mm

and the same will be filled with mortar so that there will be no

lack of bond between adjoining curb.

Interlocking Blocks

A. Prepare sub grade for the installation of the interlocking blocks.

Any soft soils shall be removed so that it will not create

unstable foundation.

B. Place aggregate sub base and base as indicated in the plan.

MOS for Interlocking Block and curve Stone Rev.1

Page 2 of 3

Compact by tamping with rubber mallet and screed to depth

required to allow setting of pavers.

C. Place geotextile over compacted base course, overlapping ends

and edges at least 300 mm.

D. Place leveling course and screed to a thickness of 25-38 mm,

taking care that moisture content remains constant and density

is loose and constant unit pavers are set and compacted.

E. Treat leveling base with soil sterilizer to inhibit growth of grass

and weeds.

F. Set pavers with minimum joint width of 1.6 mm and maximum

of 3 mm, being careful not to disturb leveling base. If pavers

have spacer bars, place pavers hand tight against spacer bars.

Using string lines to keep straight lines. Fill gaps between units

not to exceed 10 mm with pieces cut from full size unit pavers.

G. Spread dry sand and fill joints pavers, vibrate pavers and add

sand until joints are completely filled, remove excess sand.

H. Do not allow traffic on installed pavers until sand has been

vibrated into joints.

3. Cleaning and Protection:

A. Remove and replace unit pavers that are loose, chipped, broken,

stained or otherwise damaged or that do not match adjoining

units as intended.

B. Protect the finished work from damage until substantial

completion.

C. At the end of each day of work, remove from the site rubbish

and debris resulting from this work.

MOS for Interlocking Block and curve Stone Rev.1

Page 3 of 3

S-ar putea să vă placă și

- Method Statement For Cement Board Dry Wall PartitionsDocument10 paginiMethod Statement For Cement Board Dry Wall PartitionsComet GroupÎncă nu există evaluări

- Method Statement For Sign Board InstallationDocument45 paginiMethod Statement For Sign Board InstallationEngr Primus ChinonyeÎncă nu există evaluări

- Epoxy Painting Method GuideDocument3 paginiEpoxy Painting Method GuideKaram MoatasemÎncă nu există evaluări

- BCB Solutions Business ProfileDocument9 paginiBCB Solutions Business ProfileJacaranda FM NewsÎncă nu există evaluări

- MS For Ceramic Tile InstallationDocument8 paginiMS For Ceramic Tile InstallationNikita KasyanovÎncă nu există evaluări

- Method Statement For Road Construction Over WetlandsDocument4 paginiMethod Statement For Road Construction Over WetlandsYibeltal ChaneÎncă nu există evaluări

- Excavation Method StatementDocument6 paginiExcavation Method StatementWaleed SalihÎncă nu există evaluări

- 007 MS - Kerb & Interlocking Tiles InstallationDocument3 pagini007 MS - Kerb & Interlocking Tiles InstallationAnonymous iI88LtÎncă nu există evaluări

- P028 Aso 090000 Mat 000024 - 02 BHC AjnDocument101 paginiP028 Aso 090000 Mat 000024 - 02 BHC AjnnagarajankumaranÎncă nu există evaluări

- Water RecDocument9 paginiWater RecToyEn MEgatÎncă nu există evaluări

- Nawaz Khan - Civil InspectorDocument4 paginiNawaz Khan - Civil InspectormlÎncă nu există evaluări

- METHOD OF STATEMENT - ALKHOMRA PROJECT - CarbstoneDocument7 paginiMETHOD OF STATEMENT - ALKHOMRA PROJECT - Carbstoneahmed samirÎncă nu există evaluări

- Construction Method Statement PDFDocument22 paginiConstruction Method Statement PDFFaruk AtalarÎncă nu există evaluări

- Standard Construction Specs for Roads and Pavement MarkingsDocument3 paginiStandard Construction Specs for Roads and Pavement MarkingsRolando de GuzmanÎncă nu există evaluări

- 06 3 EarthworksDocument25 pagini06 3 EarthworksAbderrahmaneTemhachetÎncă nu există evaluări

- Logo of Client Logo of EngineerDocument3 paginiLogo of Client Logo of EngineerDawood Shaik Abdul CadarÎncă nu există evaluări

- Method Statement Repairing Honey OmbDocument3 paginiMethod Statement Repairing Honey Ombmamat hamzahÎncă nu există evaluări

- Kerbstones Installation GuidelinesDocument4 paginiKerbstones Installation Guidelinespartha_svnitÎncă nu există evaluări

- Mobilization Plan PreparationDocument5 paginiMobilization Plan PreparationAhmed AdelÎncă nu există evaluări

- P 2014 00693 Construction Method StatementDocument9 paginiP 2014 00693 Construction Method StatementTATATAHER0% (1)

- S16 MobilizationDocument4 paginiS16 MobilizationsurenderÎncă nu există evaluări

- Method Statement For Cmu Block WorkDocument8 paginiMethod Statement For Cmu Block WorkAnwar MohiuddinÎncă nu există evaluări

- Earthwork Excavation-Method StatementDocument4 paginiEarthwork Excavation-Method StatementKhaled AbdelbakiÎncă nu există evaluări

- Demolition Work Audit Checklist: Los Angeles Community College DistrictDocument6 paginiDemolition Work Audit Checklist: Los Angeles Community College DistrictJaycee PagadorÎncă nu există evaluări

- Quality Systems Manual Method Statement: Tiling Work (Floors and Walls)Document8 paginiQuality Systems Manual Method Statement: Tiling Work (Floors and Walls)Lloyd MariÎncă nu există evaluări

- QA/QC Plan Ensures Project ComplianceDocument18 paginiQA/QC Plan Ensures Project ComplianceSen IMO67% (3)

- NMS 2-MS-Rectification of Excess Gap Between The Door Frame and WallDocument8 paginiNMS 2-MS-Rectification of Excess Gap Between The Door Frame and WallsathiyaprasathÎncă nu există evaluări

- Construction Method StatementDocument18 paginiConstruction Method StatementAziz RahmanÎncă nu există evaluări

- Method Statement and SpecificationDocument17 paginiMethod Statement and SpecificationApai MfarÎncă nu există evaluări

- Sika Skim Coat Pds enDocument2 paginiSika Skim Coat Pds enizzatazwanzailanÎncă nu există evaluări

- Concrete Placement (Spec)Document18 paginiConcrete Placement (Spec)Vetrivel MuruganÎncă nu există evaluări

- Health, Safety & EnvironmentDocument7 paginiHealth, Safety & EnvironmentAhsan AfzaalÎncă nu există evaluări

- Renovation Works at Al Forsan Sports ResortDocument7 paginiRenovation Works at Al Forsan Sports ResortAshimolowo BabatundeÎncă nu există evaluări

- Method Statement and Risk Assessment For General Stone Masonry Including Dry Stone WallingDocument8 paginiMethod Statement and Risk Assessment For General Stone Masonry Including Dry Stone WallingMatin Hamid FaqiriÎncă nu există evaluări

- Method Statement For Brickworks: Pembinaan Infra E&J SDN BHDDocument5 paginiMethod Statement For Brickworks: Pembinaan Infra E&J SDN BHDChezy629Încă nu există evaluări

- 01-ABC Subcontract Plan.-Rev.01Document6 pagini01-ABC Subcontract Plan.-Rev.01Shahid BhattiÎncă nu există evaluări

- Asphalt RestorationDocument24 paginiAsphalt Restorationshoaib akhtar100% (1)

- National Water CompanyDocument11 paginiNational Water CompanyHassan MokhtarÎncă nu există evaluări

- Method Statement of Mass Concrete Block Precast WorksDocument41 paginiMethod Statement of Mass Concrete Block Precast WorksShams JogÎncă nu există evaluări

- QLASSIC CERTIFICATION SCHEME INTRODUCTIONDocument34 paginiQLASSIC CERTIFICATION SCHEME INTRODUCTIONMsh SabriÎncă nu există evaluări

- PMPT Itp 010Document3 paginiPMPT Itp 010hz135874Încă nu există evaluări

- Waterproofing Screed Installation GuideDocument5 paginiWaterproofing Screed Installation Guideramtsan100% (2)

- Football Field Construction GuideDocument29 paginiFootball Field Construction GuideNicklaus TanÎncă nu există evaluări

- Large Wall Tile Installation MethodDocument35 paginiLarge Wall Tile Installation Methodlokesh.kukadiyaÎncă nu există evaluări

- Repairing of Plaster WallsDocument4 paginiRepairing of Plaster WallsSayan GharÎncă nu există evaluări

- Vetonit Spatter Dash-MC SDM212Document2 paginiVetonit Spatter Dash-MC SDM212toni mujiyonoÎncă nu există evaluări

- Inspection Checklist Masonry WallDocument3 paginiInspection Checklist Masonry WallJonatan LopezÎncă nu există evaluări

- Method Statement For Sign Board Excavation & Installation - Safe Work Method of StatementDocument2 paginiMethod Statement For Sign Board Excavation & Installation - Safe Work Method of StatementUmair AslamÎncă nu există evaluări

- Unops Daily ReportDocument2 paginiUnops Daily ReportFeraydoon NasratzadaÎncă nu există evaluări

- Hollow Core Slab PDFDocument4 paginiHollow Core Slab PDFStraus WaseemÎncă nu există evaluări

- METHOD - STATEMENTf New ForDocument48 paginiMETHOD - STATEMENTf New Forhysh89Încă nu există evaluări

- Method Statement FOR Embedded Conduits, Boxes and Fittings InstallationDocument6 paginiMethod Statement FOR Embedded Conduits, Boxes and Fittings InstallationWalidÎncă nu există evaluări

- Method Statement For ScaffoldingDocument3 paginiMethod Statement For ScaffoldingDouglas JambaÎncă nu există evaluări

- Method Statement For Earthwork Cutting and FillingDocument8 paginiMethod Statement For Earthwork Cutting and FillingABDO ALLIAÎncă nu există evaluări

- Ms Block WorksDocument3 paginiMs Block WorksjaladeepÎncă nu există evaluări

- Surface GI Conduit Installation Method StatementDocument4 paginiSurface GI Conduit Installation Method StatementJaneÎncă nu există evaluări

- Method Statement For Installation For Curtain Wall Unitized PDFDocument38 paginiMethod Statement For Installation For Curtain Wall Unitized PDFAshimolowo BabatundeÎncă nu există evaluări

- CV-0013-005 - Method Statement For Concrete Work (Revised)Document13 paginiCV-0013-005 - Method Statement For Concrete Work (Revised)한상호Încă nu există evaluări

- Method of Statement For Interlocking Block and Curb StoneDocument4 paginiMethod of Statement For Interlocking Block and Curb StoneTAHER AMMAR100% (1)

- Technical Specfications - Elsa AbenojaDocument7 paginiTechnical Specfications - Elsa AbenojaCattleya PenalosaÎncă nu există evaluări

- Decision TreeDocument2 paginiDecision TreeShaddy Joseph EndrawesÎncă nu există evaluări

- Doors Method StatementDocument5 paginiDoors Method StatementTAHER AMMAR100% (2)

- 121 - PMP Study Notes PrintDocument11 pagini121 - PMP Study Notes PrintHrishikesh KausthubanÎncă nu există evaluări

- 4 4 1 D Doc14 Ing Def - VPDFDocument8 pagini4 4 1 D Doc14 Ing Def - VPDFShaddy Joseph EndrawesÎncă nu există evaluări

- PMINotesv 6Document30 paginiPMINotesv 6Shaddy Joseph EndrawesÎncă nu există evaluări

- PMP Project Communication ManagementDocument27 paginiPMP Project Communication ManagementkittyceoÎncă nu există evaluări

- My PMBOK Notes PDFDocument5 paginiMy PMBOK Notes PDFShaddy Joseph Endrawes100% (1)

- PMP Exam Preparation Course OverviewDocument114 paginiPMP Exam Preparation Course OverviewShaddy Joseph Endrawes100% (1)

- PMP Revision NotesDocument50 paginiPMP Revision NotesShaddy Joseph EndrawesÎncă nu există evaluări

- 03hussam Executing & Monitoring and Controlling & ClosingDocument164 pagini03hussam Executing & Monitoring and Controlling & ClosingShaddy Joseph EndrawesÎncă nu există evaluări

- Pmi Cost Management ProcessesDocument1 paginăPmi Cost Management ProcessesShaddy Joseph EndrawesÎncă nu există evaluări

- Project Risk Management PMP Prep - Quick Review Statements For ReviewDocument7 paginiProject Risk Management PMP Prep - Quick Review Statements For ReviewShaddy Joseph EndrawesÎncă nu există evaluări

- LEED GA Additional Study Resources PDFDocument2 paginiLEED GA Additional Study Resources PDFShaddy Joseph EndrawesÎncă nu există evaluări

- Box Sync ReadMeDocument1 paginăBox Sync ReadMeDaniel AmbrosioÎncă nu există evaluări

- 223Document12 pagini223Shaddy Joseph EndrawesÎncă nu există evaluări

- Control JointsDocument6 paginiControl JointsShaddy Joseph EndrawesÎncă nu există evaluări

- Air Pollution1Document20 paginiAir Pollution1Shaddy Joseph EndrawesÎncă nu există evaluări

- Letter To ItccDocument1 paginăLetter To ItccShaddy Joseph EndrawesÎncă nu există evaluări

- 1119Document51 pagini1119premlaraÎncă nu există evaluări

- LEED GA Study ScheduleDocument3 paginiLEED GA Study ScheduleShaddy Joseph EndrawesÎncă nu există evaluări

- Plastering Work Method StatementDocument1 paginăPlastering Work Method StatementShaddy Joseph EndrawesÎncă nu există evaluări

- Air Pollution1Document20 paginiAir Pollution1Shaddy Joseph EndrawesÎncă nu există evaluări

- ENL2100 Calender W15.Doc Jan12.15Document3 paginiENL2100 Calender W15.Doc Jan12.15Shaddy Joseph EndrawesÎncă nu există evaluări

- UAE Labour LawDocument44 paginiUAE Labour Lawkumar dubai100% (1)

- SpiderDocument16 paginiSpiderShaddy Joseph EndrawesÎncă nu există evaluări

- Best Practice Enviromental ManagementDocument44 paginiBest Practice Enviromental ManagementLuis ItoÎncă nu există evaluări

- Standard Tube MapDocument1 paginăStandard Tube MapRodolfo InsaurraldeÎncă nu există evaluări

- The History of Lego Reading ComprehensionDocument3 paginiThe History of Lego Reading Comprehensionkadriye kayaliÎncă nu există evaluări

- Basic Mechanical Engineering ConceptDocument2 paginiBasic Mechanical Engineering Conceptgyanimahato.4345Încă nu există evaluări

- Geo Strap Testing Method StatementDocument7 paginiGeo Strap Testing Method StatementUmesh MishraÎncă nu există evaluări

- Long Span Structures For Stadium RoofingDocument18 paginiLong Span Structures For Stadium RoofingMatala Hari ChandanaÎncă nu există evaluări

- Applicable Design Codes: Www.s3design - in Mail@s3design - inDocument4 paginiApplicable Design Codes: Www.s3design - in Mail@s3design - insonofalexanderÎncă nu există evaluări

- Warm Humid Climate Book 3rd SEMDocument34 paginiWarm Humid Climate Book 3rd SEMflower lilyÎncă nu există evaluări

- Methods of Construction of Prestressed MembersDocument20 paginiMethods of Construction of Prestressed Membersofreneo_joshua4437Încă nu există evaluări

- RC BeamDocument5 paginiRC BeamvikasÎncă nu există evaluări

- Chapter 1 BEAMDocument25 paginiChapter 1 BEAMDawit TesfayÎncă nu există evaluări

- Valv Diluvio Claval Diafragma TubularDocument29 paginiValv Diluvio Claval Diafragma TubularDaniel ReyÎncă nu există evaluări

- Cracker Technical ManualDocument19 paginiCracker Technical Manualj3hdzÎncă nu există evaluări

- Architecture American PeriodDocument11 paginiArchitecture American PeriodmarieleÎncă nu există evaluări

- MetStructures Technical ManualDocument76 paginiMetStructures Technical ManualananditÎncă nu există evaluări

- SRF - FP - 010-Merged - 4Document17 paginiSRF - FP - 010-Merged - 4Jhomz MartinezÎncă nu există evaluări

- Manufacturing of Bricks in The Past, in The Present and in The Future: A State of The Art ReviewDocument13 paginiManufacturing of Bricks in The Past, in The Present and in The Future: A State of The Art ReviewpvkarthickÎncă nu există evaluări

- 2 - Types of Stone, Brick and Block Masonry-2000Document70 pagini2 - Types of Stone, Brick and Block Masonry-2000asadÎncă nu există evaluări

- Area Drain For Outdoor Eye WashDocument4 paginiArea Drain For Outdoor Eye WashswapnilupgadeÎncă nu există evaluări

- Affordable Dreams: Realize Your Kitchen DreamsDocument30 paginiAffordable Dreams: Realize Your Kitchen DreamsCorner Ửiter'sÎncă nu există evaluări

- Bill of Materials Northgate TownhouseDocument4 paginiBill of Materials Northgate TownhouseJohnÎncă nu există evaluări

- Constitutive Equation and Normalized Carpet Plots of Symmetrical Fiber Reinforced LaminatesDocument90 paginiConstitutive Equation and Normalized Carpet Plots of Symmetrical Fiber Reinforced LaminatesjoereisÎncă nu există evaluări

- Materials and Their Properties and StructureDocument29 paginiMaterials and Their Properties and StructureIncrediBlockÎncă nu există evaluări

- Advantages of Using The Following Floor and Roof Slab SystemDocument1 paginăAdvantages of Using The Following Floor and Roof Slab SystemMarlo LucesÎncă nu există evaluări

- Pip Stf05521Document16 paginiPip Stf05521joelgir32100% (5)

- NPD High Level Status: Concept Development FeasibilityDocument22 paginiNPD High Level Status: Concept Development FeasibilityRaviÎncă nu există evaluări

- 4clicks Introduction To Rsmeans Estimating: 4clicks Online Virtual TrainingDocument76 pagini4clicks Introduction To Rsmeans Estimating: 4clicks Online Virtual TrainingRey Eduard Q. UmelÎncă nu există evaluări

- Ahrs GRS 77Document98 paginiAhrs GRS 77franjov22Încă nu există evaluări

- Concrete Pouring RAMSDocument19 paginiConcrete Pouring RAMSKaren OlivierÎncă nu există evaluări

- Exterior Wall Finish Scratch TextureDocument2 paginiExterior Wall Finish Scratch TextureRavi Ranjan KumarÎncă nu există evaluări

- Metal and Wood Shop Tools and Equipment GuideDocument38 paginiMetal and Wood Shop Tools and Equipment Guideメルヴリッ クズルエタÎncă nu există evaluări

- Hatchery Kasolwe Phase 2Document53 paginiHatchery Kasolwe Phase 2Mwesigwa DaniÎncă nu există evaluări