Documente Academic

Documente Profesional

Documente Cultură

Gearbox Bearing Fitting PDF

Încărcat de

mxckcxzlm.c,Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Gearbox Bearing Fitting PDF

Încărcat de

mxckcxzlm.c,Drepturi de autor:

Formate disponibile

-

Gearbox bearing fitting

Gearbox bearing shimming

Bearing shimming is carried out to guarantee the required axial clearance of the gearbox main and

secondary shafts.

Shim washers are inserted into the seat before fitting the bearings, only on the gearbox cover.

Start shimming the gearbox cover using 0.20 0.30 mm shim washers either under the main shaft or

the secondary shaft bearing.

The shim washers for the secondary shaft available in the spare parts list are:

0.10 mm; 0.15 mm; 0.20 mm;

0.30 mm; 0.50 mm; 1mm

The shim washers for the main shaft available in the list are: 0.10 mm; 0.30 mm; 0.50 mm

Bearings fitting.

Make sure the bearing seats are clean and free of grease. Afterwards, warm the engine crankcase and

the gearbox cover at 160C for at least 30 minutes.

IMPORTANT: Not warming up the engine crankcase adequately

results in bearing seat damage.

Fig. 1

The main shaft bearing on the engine crankcase side is

shielded on one side (only gearbox bearing to be

shielded besides the gear selector drum bearing).

Therefore, when fitting the bearing, the shielding

should be facing down and so

not be visible. Fig. 2

Shielded side

Fig. 2

Before fitting, make sure that the bearings are

clean and that the outer ring is free of grease.

When fitting the bearings, the balls should be facing up

and visible to facilitate lubrication. Fig. 1

Balls facing up and visible

Shielding not visible

-

After fitting the bearings and letting the crankcase cool off, hit the bearings with an adequate stopper

to make sure they totally rest on the housing base. (It is also possible to rest a stopper on the fitted

bearing and place some weight on the stopper. This is to prevent bearing from moving while the

crankcase is cooling.)

IMPORTANT: The stoppers used to insert these bearings must only press the outer ring

and never any other bearing part.

Checking the gear shaft axial clearance.

This checking must be carried out with the engine crankcase closed and the gear and gearbox cover

assembled.

Place a dial gauge on the main shaft end, push the shaft axially and check the axial clearance. Fig. 3

Then carry out a similar operation for the secondary shaft. Fig. 4

Fig. 3 Fig. 4

Axial Axial

movement movement

The required gear shaft axial clearance is: 0.20 0.30 mm

To modify the gear shaft axial clearance, replace the shim washers under the gearbox cover bearings.

To fit as well as to remove bearings from their seat,

the engine crankcase and the gearbox cover must be warmed up at 160C for 30 minutes.

IMPORTANT: Not warming up the engine crankcase adequately results

in bearing seat damage.

IMPORTANT: Before closing the engine crankcase permanently,

thoroughly lubricate the bearings with gearbox oil.

S-ar putea să vă placă și

- FArrius2F 05Document2 paginiFArrius2F 05starsalingsoul8000100% (1)

- Section 13F - Engine Electrical System PDFDocument14 paginiSection 13F - Engine Electrical System PDFrobbertmdÎncă nu există evaluări

- Chapter 76 - Engine Controls: BHT-206L4-MM-9Document22 paginiChapter 76 - Engine Controls: BHT-206L4-MM-9Raisa RabeyaÎncă nu există evaluări

- Turboshaft Engine Air Particle Separation: Progress in Aerospace Sciences July 2010Document88 paginiTurboshaft Engine Air Particle Separation: Progress in Aerospace Sciences July 2010abuzaidÎncă nu există evaluări

- The Giza Power PlantDocument10 paginiThe Giza Power Plantinterstar100% (1)

- M00006-1-1520-280-PMD Main Rotor Pylon SectionDocument6 paginiM00006-1-1520-280-PMD Main Rotor Pylon SectionabuzaidÎncă nu există evaluări

- Balancing Pylontech BatteriesDocument1 paginăBalancing Pylontech BatteriesfrancisÎncă nu există evaluări

- Unit 4.agb-Rgb 16112019Document32 paginiUnit 4.agb-Rgb 16112019motores4297Încă nu există evaluări

- Turboshaft Engines: 1,700-2,000 SHP ClassDocument2 paginiTurboshaft Engines: 1,700-2,000 SHP Class唐波Încă nu există evaluări

- Manual SBIndexDocument122 paginiManual SBIndexRS BAÎncă nu există evaluări

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 4Document24 paginiRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 4anony8103Încă nu există evaluări

- Component Symbols: Pressure TransmitterDocument21 paginiComponent Symbols: Pressure TransmitterItgeltbayarÎncă nu există evaluări

- CA1550Manual Cargador Bateria PDFDocument41 paginiCA1550Manual Cargador Bateria PDFmonoramirexÎncă nu există evaluări

- NOR10 763-1 P68 AP68 Tech-Pub Index 5Document13 paginiNOR10 763-1 P68 AP68 Tech-Pub Index 5riversgardenÎncă nu există evaluări

- S-76 Barrier Filter PamphletDocument20 paginiS-76 Barrier Filter PamphletJoness9Încă nu există evaluări

- M250-C30R3M Inspection Check SheetsDocument15 paginiM250-C30R3M Inspection Check SheetsturboshaftÎncă nu există evaluări

- Section 13A - Engine Introduction PDFDocument8 paginiSection 13A - Engine Introduction PDFrobbertmdÎncă nu există evaluări

- Black Hawk HelicopterDocument34 paginiBlack Hawk HelicopterJohnny ParradoÎncă nu există evaluări

- Search Light WDMDocument52 paginiSearch Light WDMAbdallah MhairatÎncă nu există evaluări

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document13 paginiTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robinyÎncă nu există evaluări

- Questionarie-Arriel 2B&2B1Document13 paginiQuestionarie-Arriel 2B&2B1AbelSinglei100% (2)

- UH-60 Fuel SystemDocument15 paginiUH-60 Fuel SystemYung Chun LinÎncă nu există evaluări

- Aircraft Engine Test StandsDocument2 paginiAircraft Engine Test StandsVinod KumarÎncă nu există evaluări

- Temperature Measurement Problems in An Aero Gas Turbine EngineDocument5 paginiTemperature Measurement Problems in An Aero Gas Turbine EnginesenthilÎncă nu există evaluări

- FS - M - Sikorsky S 70A L UH 60 A L Maintenance PracticalDocument1 paginăFS - M - Sikorsky S 70A L UH 60 A L Maintenance PracticalAustin BanttariÎncă nu există evaluări

- 412-MD-04-S02 Handling and ServicingDocument18 pagini412-MD-04-S02 Handling and ServicingJhoann Miguel Galvan SarabiaÎncă nu există evaluări

- AS350 Spray Gear 210B - 2002Document1 paginăAS350 Spray Gear 210B - 2002Russell GouldenÎncă nu există evaluări

- ND Bk117 FSX ManualDocument22 paginiND Bk117 FSX ManualAnonymous n605TvNbÎncă nu există evaluări

- EC 130 B4-02 Intro To FM and LimitsDocument39 paginiEC 130 B4-02 Intro To FM and LimitsMZJ100% (1)

- 412 Ipb CH64Document12 pagini412 Ipb CH64dellaadlinaÎncă nu există evaluări

- MML 912 Series Ed3 r2 eDocument174 paginiMML 912 Series Ed3 r2 eHenrique Boaventura MedeirosÎncă nu există evaluări

- Section 13C - Engine Oil System PDFDocument4 paginiSection 13C - Engine Oil System PDFrobbertmdÎncă nu există evaluări

- TM 1-1500-204-23-1, Change 5Document448 paginiTM 1-1500-204-23-1, Change 5"Rufus"Încă nu există evaluări

- Type Certificate Data Sheet: No. EASA.R.002Document26 paginiType Certificate Data Sheet: No. EASA.R.002tony cheungÎncă nu există evaluări

- FM 55-450-2 Army Helicopter Internal Load Operations - CHPTR 6 Load Preparation, Loading, and Tie-DDocument26 paginiFM 55-450-2 Army Helicopter Internal Load Operations - CHPTR 6 Load Preparation, Loading, and Tie-DSebastian ZarzyckiÎncă nu există evaluări

- Cessna 185 Familiarisation CourseDocument5 paginiCessna 185 Familiarisation CourseAmmar A. AlliÎncă nu există evaluări

- BHT 412 SPM Chapter 02 Torque PDFDocument30 paginiBHT 412 SPM Chapter 02 Torque PDFMARKPÎncă nu există evaluări

- 412 MM CH06Document8 pagini412 MM CH06Sebastian GarciaÎncă nu există evaluări

- Maintenance Manual Main Rotor/Main Rotor Drive System: BHT-206A/B-SERIES-MM-6Document112 paginiMaintenance Manual Main Rotor/Main Rotor Drive System: BHT-206A/B-SERIES-MM-6Benito PalmaÎncă nu există evaluări

- 05 10 03 PDFDocument2 pagini05 10 03 PDFAnonymous 298xlo3uUÎncă nu există evaluări

- Continued Aiirworthiness - Model 200 SériesDocument129 paginiContinued Aiirworthiness - Model 200 SériesGabriel vieiraÎncă nu există evaluări

- Section 9: Pitot Static SystemDocument6 paginiSection 9: Pitot Static SystemrobbertmdÎncă nu există evaluări

- Cabri G2 Question Rev Sep 2017Document33 paginiCabri G2 Question Rev Sep 2017Hanh Trung Nguyen Duc100% (1)

- O-320 (76 Series) Operator Manual 60297-22Document68 paginiO-320 (76 Series) Operator Manual 60297-22SammÎncă nu există evaluări

- Section 12 - Lighting PDFDocument10 paginiSection 12 - Lighting PDFrobbertmdÎncă nu există evaluări

- TR EC120 13-14-16 r.01Document89 paginiTR EC120 13-14-16 r.01Zmaj TelovajÎncă nu există evaluări

- Aerospatiale A350Document8 paginiAerospatiale A350Bruno Alonso PachecoÎncă nu există evaluări

- Unit 3.hot Section 16112019Document65 paginiUnit 3.hot Section 16112019motores4297Încă nu există evaluări

- TM 9-1725 Ordnance Engine Model R975-C4 (Continental) 1944Document272 paginiTM 9-1725 Ordnance Engine Model R975-C4 (Continental) 1944beppefranzÎncă nu există evaluări

- Arriel 1Document60 paginiArriel 1Santoyo EdgarÎncă nu există evaluări

- C47B OmmDocument12 paginiC47B OmmturboshaftÎncă nu există evaluări

- Chapter 32 - Landing Gear: Contents - Illustrated Parts BreakdownDocument50 paginiChapter 32 - Landing Gear: Contents - Illustrated Parts BreakdownWilson BarbosaÎncă nu există evaluări

- Brantly Helicopter ReportDocument4 paginiBrantly Helicopter Reportjorge paezÎncă nu există evaluări

- Practical Training For WALTER M601 EngineDocument5 paginiPractical Training For WALTER M601 EngineКонстантинÎncă nu există evaluări

- SB Ibis 004 (English)Document3 paginiSB Ibis 004 (English)wibisairÎncă nu există evaluări

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 74-20-03Document2 paginiRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 74-20-03anony8103Încă nu există evaluări

- Rolls - Royce: 250 - C47B Operation and MaintenanceDocument23 paginiRolls - Royce: 250 - C47B Operation and MaintenanceSerafin MoralesÎncă nu există evaluări

- Aerospace Actuators 2: Signal-by-Wire and Power-by-WireDe la EverandAerospace Actuators 2: Signal-by-Wire and Power-by-WireÎncă nu există evaluări

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsDe la EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsÎncă nu există evaluări

- v888 Request by An Individual For Information About A Vehicle PDFDocument2 paginiv888 Request by An Individual For Information About A Vehicle PDFmxckcxzlm.c,0% (1)

- E3160 PDFDocument2 paginiE3160 PDFmxckcxzlm.c,Încă nu există evaluări

- E3155 PDFDocument2 paginiE3155 PDFmxckcxzlm.c,Încă nu există evaluări

- Fork Rebuilding PDFDocument2 paginiFork Rebuilding PDFmxckcxzlm.c,Încă nu există evaluări

- Leadership Culture and Management Practices A Comparative Study Between Denmark and Japan PDFDocument70 paginiLeadership Culture and Management Practices A Comparative Study Between Denmark and Japan PDFMichelle Samillano PasaheÎncă nu există evaluări

- Soichiro HondaDocument5 paginiSoichiro HondaVeronika YsÎncă nu există evaluări

- Complete Tank FabricationDocument8 paginiComplete Tank Fabricationnike_y2kÎncă nu există evaluări

- Carbonate PetrophysicsDocument6 paginiCarbonate PetrophysicsRovshan1988Încă nu există evaluări

- Ultimate Holding Capacity Drag mx5Document1 paginăUltimate Holding Capacity Drag mx5Luana MarchioriÎncă nu există evaluări

- Team Building & Team WorkDocument39 paginiTeam Building & Team WorkAmrita DasÎncă nu există evaluări

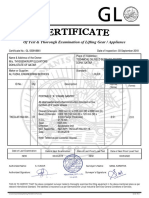

- Of Test & Thorough Examination of Lifting Gear / Appliance: - QatarDocument12 paginiOf Test & Thorough Examination of Lifting Gear / Appliance: - QatarChaimaÎncă nu există evaluări

- Oyo Busines ModelDocument1 paginăOyo Busines ModelVikash KumarÎncă nu există evaluări

- The Economic Essentials of Digital StrategyDocument13 paginiThe Economic Essentials of Digital StrategydhietakloseÎncă nu există evaluări

- Bus & Cycle Signs & MarkingsDocument5 paginiBus & Cycle Signs & MarkingsDaniel YitbarekÎncă nu există evaluări

- HS 30 eDocument9 paginiHS 30 eJayakrishnaÎncă nu există evaluări

- Amces 2020Document1 paginăAmces 2020Karthik GootyÎncă nu există evaluări

- ATB Riva Calzoni Gianluca RaseniDocument35 paginiATB Riva Calzoni Gianluca RaseniDiana QuinteroÎncă nu există evaluări

- Seismic Assessment of RC Building According To ATC 40, FEMA 356 and FEMA 440Document10 paginiSeismic Assessment of RC Building According To ATC 40, FEMA 356 and FEMA 440sobah assidqiÎncă nu există evaluări

- AASHTO - LRFD (Design Example For Steel Girder Superstructure Bridge - 2003)Document698 paginiAASHTO - LRFD (Design Example For Steel Girder Superstructure Bridge - 2003)Ridwan Kris50% (2)

- Pellets Burner 6 00 Manual EnglishDocument22 paginiPellets Burner 6 00 Manual EnglishTasos KachpanisÎncă nu există evaluări

- NS2 Simple Simulation ExampleDocument5 paginiNS2 Simple Simulation ExamplepradeepÎncă nu există evaluări

- Recorder Modifications - Alec Loretto 3Document4 paginiRecorder Modifications - Alec Loretto 3Clown e GregorianoÎncă nu există evaluări

- Sony DCR Sr47Document101 paginiSony DCR Sr47Mitesh ChauhanÎncă nu există evaluări

- Wil El Mil Engineering Limited Gloucester, EnglandDocument4 paginiWil El Mil Engineering Limited Gloucester, EnglandArnold TauroÎncă nu există evaluări

- LCD Interfacing With Microcontroller 8051Document50 paginiLCD Interfacing With Microcontroller 8051Darshan Vala100% (2)

- Chiller: Asian Paints Khandala PlantDocument19 paginiChiller: Asian Paints Khandala PlantAditiÎncă nu există evaluări

- Introduction To Turbomachinery Final Exam 1SY 2016-2017Document1 paginăIntroduction To Turbomachinery Final Exam 1SY 2016-2017Paul RodgersÎncă nu există evaluări

- Justeq07 Product BulletinDocument1 paginăJusteq07 Product BulletinjusteqÎncă nu există evaluări

- Sdhyper: "Make Difference, Make Better."Document2 paginiSdhyper: "Make Difference, Make Better."Juan Torres GamarraÎncă nu există evaluări

- Information: Reading Images - The Grammar of Visual DesignDocument5 paginiInformation: Reading Images - The Grammar of Visual DesignAndang Prasetya Adiwibawa BernardusÎncă nu există evaluări

- History Desktop PublishingDocument16 paginiHistory Desktop PublishingsanchezromanÎncă nu există evaluări

- Otrs Admin BookDocument619 paginiOtrs Admin BookMendoza Carlos100% (1)

- Datasheet - HK f7313 39760Document7 paginiDatasheet - HK f7313 39760niko67Încă nu există evaluări