Documente Academic

Documente Profesional

Documente Cultură

V2i8 Ijertv2is80740

Încărcat de

SuvamTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

V2i8 Ijertv2is80740

Încărcat de

SuvamDrepturi de autor:

Formate disponibile

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 8, August - 2013

Experimental Study of Flexible Pavement by Using Waste Rubber Tyres

1

Sharma Pavan Kumar, 2 Saxena Anil Kumar, 3 Arora T.R.

1

P.G. Student, 2Associate Professor, 3Professor & Head

1, 2,3Lakshmi Narayan College of Technology, Department of Civil, Bhopal

Abstract: Use of Crumb Rubber i.e. the rubber obtained from the waste tires of vehicles in the construction of flexible pavement is gaining

importance. It is also worth mentioning that, the modifier raw-material has been sourced from disposed crumb rubber. This not only allows

us to collect modifier raw material at low cost, but also provides a solution towards ecological menace posed by increased use of rubber. In

the present study, an attempt has been made to use Crumb Rubber, blended using wet process .Marshal method of Bituminous mix

design was carried out for varying percentages of Crumb Rubber to determine the different mix design characteristics. Marshalls mix

design was carried out by changing the modified bitumen content at constant optimum rubber content and subsequent tests have been

performed to determine the different mix design characteristics and for conventional bitumen (VG-30). This has resulted in much improved

characteristics when compared with straight run bitumen and improve the strength of pavement Modified Bitumen is one of the important

construction materials for flexible pavements.

Keywords: Crumb rubber, Wet process, flexible pavements.

1. Introduction Shankar (2009), The crumb rubber modified bitumen (CRMB

As it is estimated that about 60% of waste tyres causes land 55) was blended at specified temperatures. Marshalls mix design

pollution in both urban and rural areas and per capita land is was carried out by changing the modified bitumen content at

decreasing in India due to this hazardous waste, it is either land constant optimum rubber content and subsequent tests have been

filled or incinerated which cause land and air pollution if this performed to determine the different mix design conventional

waste is mixed in to bitumen to improve the quality of road it bitumen (60/70) also. This has resulted in much improved

would prove itself as an eco-friendly characteristics. By using the characteristics and for characteristics when compared with

RT

waste Crumb Rubber as a modifier the properties of bitumen will straight run bitumen and that too at reduced optimum modified

be change and this change in physical properties like softening binder content (5.67%).

point, penetration value, elastic recovery and Marshall stability Siddharth Rokade (2012), The Crumb Rubber was added to

IJE

was checked by different test. In this study we used modifier in 60/70 grade bitumen in varying percentage of 8%, 10% and 12%.

proportion 8%, 10%, 12% and 14% by the weight of VG-30 The mix was prepared with 5 % bitumen and the varying

bitumen. percentages of Crumb Rubber. The bitumen when mixed with

2. Literature Review Crumb Rubber is termed as Crumb Rubber Modified Bitumen

Many researches were carried out by many scholars and (CRMB). The results observed that the Marshal Stability Value

professors of civil engineering in this field, to find the ways and are increased from 8% to 10% Crumb Rubber and then it is

crumb rubber mix in conventional bitumen to improve in decreased 12% of Crumb Rubber of the weight of bitumen is the

engineering properties of bitumen. optimum dose for getting enhanced strength characteristics of

Patel Chirag B (2013),By using the waste plastic and Crumb mix.

Rubber as a modifier the properties of bitumen will be change and Mohd Hizam HARUN & Roziawati RAZAL(2003), Public

this change in physical properties like softening point, penetration Works Department of Malaysia As bitumen additive, various

value, elastic recovery and Marshall stability was checked by forms of rubber which include scrap rubber from motor vehicle

different test. In this study we used modifier in proportion tyres (crumb rubber) have been used . The objectives of the trial

(1%,2%,3% and 4%) by the weight of bitumen. were to compare the performance of bituminous overlay

incorporating crumb rubber modified bitumen in mitigating

R.Vasudevan et.al. (2007), Has studied that the crumb rubber reflective cracking with a similar overlay using conventional

modified bitumen and they construct different stretches and penetration grade 80-100 bitumen. A full-scale road trial was

perform field study with the help of National Transport Planning successfully constructed on Route 2. Section Nos. 340 - 345, in

and Research Centre, Trivandrum. From this field study they Kuantan, in June 2003.

concluded that the entire road having a good skid resistance value Nuha S. Mashaan(2012),In their study presented the application

and from bump instigator study a good surface evenness. of crumb rubber modifier in the asphalt modification of flexible

IJERTV2IS80740 www.ijert.org 1944

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 8, August - 2013

pavement. From the results of previous study, it aspires to 3.4 Penetration properties

consider crumb rubber modifier in hot mix asphalt to improve The penetration is a measure of hardness or softness of bitumen

resistance to rutting and produce pavement with better durability binder which shows an effect by adding crumb rubber to bitumen

by minimizing the distresses caused in hot mix asphalt pavement. binder; it decreases as rubber content is increased. The

Hence, road user would be ensured of safer and smoother roads. penetration shows lower values as rubber content increases at

different mix conditions of Rubberized bitumen binder, indicating

Limitations: The literature which studied I found there was not that the binder becomes stiff and more viscous investigated the

achieved the standard marshal stability that is 1200 kg by mixing properties of rubberized bitumen prepared by physical blending of

different percent of crumb rubber in bitumen .In present study, try bitumen penetration grade with different crumb rubber content

to mix different percent of crumb rubber in bitumen to achieve and various aging phases. The results of penetration values

the marshal stability value 1200kg. decreased over the aging as well as before aging by increasing the

rubber content in the mix. Also, the modified binders have lower

3. Experimental work penetration values than unmodified binders.

3.3 Elastic recovery properties

3.1 General

The elastic recovery or elasticity describes the ability of a

The Bituminous Concrete (BC) mix was prepared using Marshall

bitumen binder to elongate when the tension is applied and to

Method of bituminous mix design. The BC was prepared with

recover its original shape when the tension is released. The degree

conventional VG-30 grade bitumen, varying percentages of

of elastic recovery was used as an indicator of permanent

Crumb Rubber added with VG-30 grade bitumen. The details of

deformation in pavement Materials the elastic recovery property

the experimental programmers shown in Table 1.

is very important in both fatigue and rutting resistance selection

Table 1: Detail of sample constitution and percent constituents.

and evaluation. The elastic recovery is a property that indicates

Sample Sample % Constituent the quality of polymer components in bitumen binders concluded

Constitution Preparation by Weight of from his study, that the elastic recovery of rubberized bitumen

Bitumen binders leads to an increase as the rubber particle size decreases.

Modified bitumen binders showed a significant enhancement on

VG-30 Grade Wet Process the elastic recovery, and, in contrast, the ductility decreased with

RT

bitumen respect to unmodified binders.

3.4 Result of bituminous concrete mix design using crumb

rubber modified bitumen (CRMB).

VG-30 Grade Wet process Crumb Rubber:

IJE

The results show that with 5% bitumen content higher value of

Bitumen + Crumb 8%

Rubber Crumb Rubber: Marshall Stability value and greater density was achieved. All

10% other parameters were also well within the specifications of IRC:

Crumb Rubber: SP: 53-2002 and MORT&H. Hence with 5% bitumen content of

12% VG-30 grade bitumen varying percentages of Crumb Rubber was

Crumb Rubber: added and bituminous concrete mix was prepared. The results of

14% different properties of CRMB & bituminous concrete mix with

varying percentage are shown in Table 2.

3.2Softening point properties Table 2: Different properties of crumb rubber modified bitumen

The viscosity refers to the fluid property of the bitumen, and it is S Crumb Bitumen Softeni Penetr Elastic Marshal

. Rubber % ng ation recove stability

a gauge of flow resistance. the potential of the resulting paving point ry

N % (Kg)

mixes. During compaction or mixing, the low or high viscosity o

has been observed to result in lower stability values. The 55 61 52 883.86

1 8 5

softening point refers to the temperature at which the bitumen

attains a particular degree of softening. The use of crumb rubber 60 54 57 1049.59

in bitumen modification leads to an increase in the softening point 2 10 5

and viscosity as rubber crumb content increases claimed that there

63 48 60 1230.78

is a consistent relationship between viscosity and softening point 3 12 5

at different aging phases of rubberized bitumen binder. Also, it is

reported that the higher crumb rubber content leads to higher 65 45 63 1137.97

4 14 5

viscosity and softening point. The viscosity is a continuously

increasing nonlinear function of rubber content and the relative The corresponding graphs for above results are shown in Fig.1-4

increase is a factor related to the application of temperature.

IJERTV2IS80740 www.ijert.org 1945

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 8, August - 2013

Fig 1: Variation in softening point with different% of crumb rubber Fig 1: Variation in Marshall stability with different% of crumb rubber

4. CONCLUSION

The values of different parameters i.e. Softening point,

Penetration, Elastic recovery and Marshall stability in the cases of

crumb rubber modified bitumen have found out to be within

required specifications. It is observed crumb rubber modified

bitumen reveals that the Marshal Stability value, which is the

strength parameter of bituminous concrete, has shown increasing

trend and the maximum values have increased by about 18 % by

RT

addition of crumb rubber. This experiment will not only

constructively utilize the waste tyres in road construction industry

but also effectively enhance the important parameters which will

IJE

ultimately have better and long living roads. This will provide

more stable and durable mix for the flexible pavements. Thus,

these processes are socially highly relevant, giving better

infrastructure

Fig 1: Variation in Penetration value with different% of crumb rubber REFRENCES:

1. Abdelaziz Mahrez, Mohamed Rehan Karim, (2003),

Rheological Evaluation of Ageing Properties of Rubber

Crumb Modified Bitumen, Journal of the Eastern Asia

Society for Transportation Studies, Vol. 5, pp. 820- 833.

2. Bjorn Birgisson, Reynaldo Roque, Jaeseung Kim, Linh

Vieh Pham, (2004), The Use of Complex Modulus to

Characterize the Performance of Asphalt Mixtures and

Pavements in Florida, Report submitted to the Department

of Transportation, Florida, U.S.A.

3. Carl Thodesen, Feipeng Xiao, Serji Amirkhanian, N.,

(2009), Modeling Viscosity Behaviour of Crumb Rubber

Modified Binders, Construction and Building Materials,

Vol. 23, pp. 3053 3062.

4. Carl Thodesen, Khaldown Shatanawi, Serji Amirkhanian,

(2009), Effect of Crumb Rubber Characteristics on Crumb

Rubber Modified (CRM) Binder Viscosity, Construction

and Building Materials, Vol. 23, pp. 295- 303.

5. Carl Thodesen, Khaldown Shatanawi, Serji Amirkhanian,

William Bridges, (2009), Development of an Empirical

Fig 1: Variation in Elastic recovery with different% of crumb rubber Model for Determining G*/sin in Crumb Rubber

IJERTV2IS80740 www.ijert.org 1946

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 8, August - 2013

Modified Binders, Construction and Building Materials,

Vol. 23, pp. 1922 1927.

6. Didier Lesueur, (2009), The Colloidal Structure of

Bitumen: Consequences on the Rheology and on the

Mechanisms of Bitumen Modification, Advances in

Colloid and Interface Science, Vol. 145, pp. 42 82.

7. IRC: SP: 53-2002. Guidelines on use of polymer and rubber

modified bitumen in road construction , Indian Roads

Congress, New Delhi

8. IS:1202- 1978.Method for testing tar and bitumen materials

determination of specific gravity

9. IS:1203-1978.Method for testing tar and bitumen materials

determination of penetration

10. IS:1205-1978.Method for testing tar and bitumen materials

determination of softening point

11. IS:1208-1978.Method for testing tar and bitumen materials

determination of Ductility

12. Jain, P. K., Kamaraj, C., (2009), Performance Study of

Rubber Modified Bitumen in Structural layers of Flexible

Pavements- A Case Study, Highway Research Journal,

Indian Roads Congress, Vol. 2- 1,pp. 1 9.

13. MS-2 Sixth edition Asphalt institute executive offices and

research centre, research park drive.P.O.. Box

14052lexington,KY 40512-4052 USA.

14. Naha S. Mahaan et. al, An overview of crumb rubber

modified bitumen, International journal of the physical

science, vol.7 (2), 9 january2012, pp.166-170.

15. Prz- Lepe, A., Martinez- Boza, F. J., Galloges, C.,

Gonzlez, O.,Munoz, M. E., Santamaria, A., (2003),

Influence of the Processing Conditions on the

RT

Rheological Behaviour of Polymer- Modified Bitumen,

Fuel, Vol. 82, pp. 1339 1348.

16. Praveen Kumar, Mehndiratta, Lakshman Singh, (2009),

IJE

Effect of Mixing of SBS, EVA and Crumb Rubber as

Properties of Bituminous Binders, Highway Research

Journal, Indian Roads Congress, Vol. 2- 1,pp. 11- 39.

17. S Shankar, Prasad C.S.R.K., Evaluation of Rutting Potential

for Crumb Rubber Modified Bitumen in Asphaltic Mixes,

Emirates Journal for Engineering Research, 14 (2), pp- 91-

95, 2009.

18. Siddharth, R,(2012) use of waste plastic and waste rubber

tyres in flexible highway pavement, international

conference on future environment and energy,2012,vol-28,pp

105-108.

19. Specifications for Road and Bridge Works (MORTH). Indian

Roads Congress, New Delhi

20. Vasudevan, R et.al, Utilization of crumb rubber for flexible

pavement and easy disposal of crumb rubber International

conference on sustainable solid waste management,5-

7september2007,Chennai,india.pp.105-111

IJERTV2IS80740 www.ijert.org 1947

S-ar putea să vă placă și

- Cen 210 Assign 5Document3 paginiCen 210 Assign 5SuvamÎncă nu există evaluări

- Guidelines On The Preparation of A ThesisDocument10 paginiGuidelines On The Preparation of A ThesisSuvamÎncă nu există evaluări

- Lessons From Katrina and Rita What Major DisastersDocument23 paginiLessons From Katrina and Rita What Major DisastersSuvamÎncă nu există evaluări

- Sol 3Document2 paginiSol 3SuvamÎncă nu există evaluări

- Annexure ADocument2 paginiAnnexure ARajesh LingamalluÎncă nu există evaluări

- IIT Roorkee PhD admission instructionsDocument1 paginăIIT Roorkee PhD admission instructionsSuvamÎncă nu există evaluări

- The Theory of Planned Behavior and Competitive Driving in ChinaDocument10 paginiThe Theory of Planned Behavior and Competitive Driving in ChinaSuvamÎncă nu există evaluări

- Feedback As01Document1 paginăFeedback As01SuvamÎncă nu există evaluări

- The Theory of Planned Behavior and Competitive Driving in ChinaDocument10 paginiThe Theory of Planned Behavior and Competitive Driving in ChinaSuvamÎncă nu există evaluări

- IIT Roorkee PhD admission instructionsDocument1 paginăIIT Roorkee PhD admission instructionsSuvamÎncă nu există evaluări

- On Choice ModelingDocument13 paginiOn Choice ModelingSuvamÎncă nu există evaluări

- Safety at Public PlacesDocument74 paginiSafety at Public PlacesSuvamÎncă nu există evaluări

- Evacuation Time Estimates for Nuclear Power PlantsDocument16 paginiEvacuation Time Estimates for Nuclear Power PlantsSuvamÎncă nu există evaluări

- Important InstructionDocument6 paginiImportant InstructionSuvamÎncă nu există evaluări

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document3 paginiIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)SuvamÎncă nu există evaluări

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document3 paginiIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)SuvamÎncă nu există evaluări

- Polytechniq Lecturer Syllabus PDFDocument4 paginiPolytechniq Lecturer Syllabus PDFSuvamÎncă nu există evaluări

- Street Robbery and Public Bus Stops: A Case Study of Activity Nodes and Situational RiskDocument15 paginiStreet Robbery and Public Bus Stops: A Case Study of Activity Nodes and Situational RiskSuvamÎncă nu există evaluări

- Integrating Different Planning Issues Into One On GISDocument19 paginiIntegrating Different Planning Issues Into One On GISSuvamÎncă nu există evaluări

- IIT NotesDocument165 paginiIIT NotesBublu MaharajÎncă nu există evaluări

- Geetam Tiwari-Transport SafetyDocument41 paginiGeetam Tiwari-Transport SafetySuvamÎncă nu există evaluări

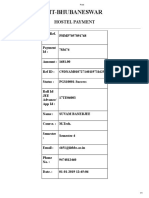

- Iit-Bhubaneswar: Hostel PaymentDocument1 paginăIit-Bhubaneswar: Hostel PaymentSuvamÎncă nu există evaluări

- Polytechniq Lecturer SyllabusDocument6 paginiPolytechniq Lecturer SyllabusSuvamÎncă nu există evaluări

- Route Choice or Trip AssignmentDocument24 paginiRoute Choice or Trip AssignmentSuvamÎncă nu există evaluări

- Assignment 05Document5 paginiAssignment 05SuvamÎncă nu există evaluări

- Route Choice or Trip AssignmentDocument24 paginiRoute Choice or Trip AssignmentSuvamÎncă nu există evaluări

- TAZ Production Attraction TAZ 1 1500 2500 2 1000 1450 3 2600 3700 4 3000 1600 5 1700 500 6 1950 2000 7 1400 2200 8 2800 3000 9 4200 2500 10 2000 2700Document3 paginiTAZ Production Attraction TAZ 1 1500 2500 2 1000 1450 3 2600 3700 4 3000 1600 5 1700 500 6 1950 2000 7 1400 2200 8 2800 3000 9 4200 2500 10 2000 2700SuvamÎncă nu există evaluări

- Transportation ProbDocument28 paginiTransportation ProbSuvamÎncă nu există evaluări

- Regression StatisticsDocument10 paginiRegression StatisticsSuvamÎncă nu există evaluări

- Lec 36Document19 paginiLec 36SuvamÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- PERCENT BY MASS OF HYDROGEN PEROXIDE (H2O2) IN AGUA OXIGENADA (A Post-Laboratory Report)Document10 paginiPERCENT BY MASS OF HYDROGEN PEROXIDE (H2O2) IN AGUA OXIGENADA (A Post-Laboratory Report)Angel Ombid100% (1)

- Determination of Moisture ContentDocument21 paginiDetermination of Moisture ContentasadaltafgillÎncă nu există evaluări

- Johnson Industrial Screens PDFDocument20 paginiJohnson Industrial Screens PDFjaime palenzuela rodriguezÎncă nu există evaluări

- Warna Daun Padi LCCDocument12 paginiWarna Daun Padi LCCM Hisyam NasrullohÎncă nu există evaluări

- RN FDocument52 paginiRN Fhassan SardarÎncă nu există evaluări

- Flexible Packaging Solutions For Liquids: Packaging and Specialty PlasticsDocument12 paginiFlexible Packaging Solutions For Liquids: Packaging and Specialty PlasticsSupermobile 786Încă nu există evaluări

- Onions: Vegetable Crops Production Guide For The Atlantic ProvincesDocument8 paginiOnions: Vegetable Crops Production Guide For The Atlantic ProvincesEglÎncă nu există evaluări

- Analytical Techniques for Evaluating Quality of Herbal DrugsDocument7 paginiAnalytical Techniques for Evaluating Quality of Herbal DrugsZaidÎncă nu există evaluări

- Lubricant Properties CalculatorDocument14 paginiLubricant Properties CalculatorzamijakaÎncă nu există evaluări

- CHM1207 Lab 3 2023 - DRAKES, Tameica (1042436) PDFDocument6 paginiCHM1207 Lab 3 2023 - DRAKES, Tameica (1042436) PDFNikoli MajorÎncă nu există evaluări

- Expwb3ans eDocument67 paginiExpwb3ans eOlivia LinÎncă nu există evaluări

- Solution Manual Chemical Reaction Engineering, 3rd EditionDocument137 paginiSolution Manual Chemical Reaction Engineering, 3rd Editionboni_briantoni75% (8)

- MEM05008C Perform Advanced Manual Thermal Cutting, Gouging and Shaping - Learner GuideDocument8 paginiMEM05008C Perform Advanced Manual Thermal Cutting, Gouging and Shaping - Learner Guidequestionbank.com.au50% (2)

- 1 Auxilliary Equipment - US PricingDocument132 pagini1 Auxilliary Equipment - US PricingOscar EspitiaÎncă nu există evaluări

- ASPHALT METHOD STATEMENTDocument7 paginiASPHALT METHOD STATEMENTBasem Donia100% (1)

- Catalysis Norskov 05 15 02Document36 paginiCatalysis Norskov 05 15 02Rafael Ricardo Celin ManceraÎncă nu există evaluări

- Successful Intraoral RadiographyDocument19 paginiSuccessful Intraoral RadiographyMonica Agustine HartonoÎncă nu există evaluări

- Solutions of ElectrolytesDocument55 paginiSolutions of Electrolytesneha_dand1591100% (1)

- Oil Debate Chromatography PPT 2Document17 paginiOil Debate Chromatography PPT 2Eridha TriwardhaniÎncă nu există evaluări

- Gas LasersDocument53 paginiGas LasersDheeraj100% (1)

- Dotaverine HCLDocument5 paginiDotaverine HCLalbertsmasudoÎncă nu există evaluări

- A Comprehensive Review On The Genus: Mussaenda: Astalakshmi N and Sundara Ganapathy RDocument8 paginiA Comprehensive Review On The Genus: Mussaenda: Astalakshmi N and Sundara Ganapathy RSahabat Baljai100% (1)

- Astm A181-2001 PDFDocument3 paginiAstm A181-2001 PDFMohammed TariqÎncă nu există evaluări

- COC-Dosing Skid - NalcoDocument11 paginiCOC-Dosing Skid - NalcodeyprasenÎncă nu există evaluări

- 2020-Intrinsic and tunable ferromagnetism in Bi0.5Na0.5TiO3 through CaFeO3-δ modification-Scientific Reports (10), 6189 (2020)Document15 pagini2020-Intrinsic and tunable ferromagnetism in Bi0.5Na0.5TiO3 through CaFeO3-δ modification-Scientific Reports (10), 6189 (2020)Lương Hữu Bắc100% (1)

- 20b. Global S CycleDocument15 pagini20b. Global S CyclerossydaÎncă nu există evaluări

- Food Chemistry: Miaomiao Shi, Zhiheng Zhang, Shujuan Yu, Kai Wang, Robert G. Gilbert, Qunyu GaoDocument7 paginiFood Chemistry: Miaomiao Shi, Zhiheng Zhang, Shujuan Yu, Kai Wang, Robert G. Gilbert, Qunyu GaoSÎncă nu există evaluări

- List I (16 5 2011)Document585 paginiList I (16 5 2011)Ayaz Mani50% (2)

- Standard dimensions and data for steel and stainless steel pipe sizesDocument7 paginiStandard dimensions and data for steel and stainless steel pipe sizesRSGatesÎncă nu există evaluări

- Imp of MicronutrientsDocument5 paginiImp of MicronutrientsDanish S MehtaÎncă nu există evaluări