Documente Academic

Documente Profesional

Documente Cultură

Condition Assessment and NDT of Building

Încărcat de

Manish BhatkarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Condition Assessment and NDT of Building

Încărcat de

Manish BhatkarDrepturi de autor:

Formate disponibile

IJSART - Volume 3 Issue 4 APRIL 2017 ISSN [ONLINE]: 2395-1052

Condition Assessment And NDT Of Building

Manish Rameshrao Bhatkar1, Prof. V. K. Gajghate2

Department of Civil Engineering

1,

M.Tech,G.H.Raisoni College of Engineering, Hingana Road, Nagpur

2

Professor,G.H.Raisoni College of Engineering, Hingana Road, Nagpur

Abstract-Concrete is considered as a durable material but it is destructive technique. The main objective of NDT is to

still potentially vulnerable to deterioration, unless certain determine the strength as well as to avoid the damages or the

precautions are taken. Life enhancement of distressed activity of structural components. The NDT gives the brief

concrete structures depend on number of factors such as idea about the condition assessment of the building and

design, detailing, materials used in the original construction, performing the various techniques.

quality control, environment as well as periodic inspection

and regular maintenance. The assessment of concrete Condition assessment of building which gives the

structures consists of not only evaluation of the present brief idea about the damages, shrinkages, etc. of building.

condition but also prediction of the cause of deterioration and Depending upon condition the suitable methods are

its residual life. Hence, it is essential to have accurate conducted, not only one method is applicable to do but also

assessment of physical, chemical and electro-chemical the more over methods are adopted.

properties to enhance the existing life of the structure. If the

cause of deterioration is predicted and a proper assessment of Ultra sonic pulse velocity (UPV) is more usefull non

the structure is made, it may be economically feasible to destructive test, which are so familiar now-a-days and gives

repair the distressed structure and prolong its life.as we know the correlation between RH number and UPV reading and to

that we are facing the problems against the cracking, strength of concrete. Ultrasonic pulse velocity is also most

shrinkages, seepages, etc. to overcome this difficulty there are commonly used method now a days so it very applicable to all

several techniques. NDT, which means Non Destructive user and hence to improve the strength of building is

Testing which helps to improve the structural damages after commonly used. Test procedure is well known described in

proper testing. IS: 13311 Part1 1992.

I. INTRODUCTION Also the Rebound hammer is usefull to detect the

changes in concrete such as cracks, shrinkages, and seepages.

NDT is the test performing on the actual structure or This test is moniterated to the elastic mass depends on the

object without damaging to get strength.NDT allows material principal which on the hardness of surface of rebound. Test

to be examined without changing properties or destroying procedure is described in IS: 13311 Part2 1992.

their usefulness.NDT gives quality assurance when it used

properly. NDT can be easily investigated for New and old II. DESCRIPTION OF STRUCTURE

structure also. Thus, NDT methods are extremely valuable in

condition assessment of building or structure such as bridges Building name : Vasant Mahal Building Santra

highways etc. Market Marwadi Cut Piece Chal Nagpur-440018

NDT is nothing but a non destructive testing which is The building has 70 years long span which shows the

generally been used for gaining the actual strength of building various damages including seepages, spalling, reinforcement

or a material or member of structure.non destructive testing is exposed, major and hair cracks.

gradually using in construction to check the actual report of

strength. Hence this method is used in actual structure to

improve the strength and to recommend that the structure is

capable to resist the further structure.

NDT truly received a great importance in terms of

engineering value and is growing intention during recent

years. Non destructive evalution of concrete are well known

and extensively used. It is very important to use the non

Page | 563 www.ijsart.com

IJSART - Volume 3 Issue 4 APRIL 2017 ISSN [ONLINE]: 2395-1052

III. VISUAL OBSERVATION

1. The building around 70 years old

2. Reinforcement exposed and damaged

3. Concrete portion was fully vanished and only

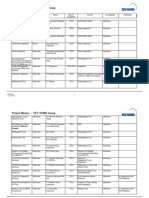

because of it, areas was totally restricted From this test it is observed that the ultrasonic pulse

4. Minor cracks or hair cracks noticed velocity results with direct, indirect and semi direct method

5. Wall plaster was damaged includes that readings are below 3.5 Km/sec, at maximum

6. Spalling observed location.(Refer to IS 13311 ( Part I )1992). Non destructive

7. Vegetation observed in balcony area testing of concrete is medium and doubtful at maximum

8. Balcony and chhajja portion was fully reinforcement location. The readings are taken with indirect method as per IS

exposed from bottom side 13311 (Part I) indirect reading gives less pulse velocity than

direct method generally by 1Km/sec.

IV.NON DESTRUCTIVE TEST

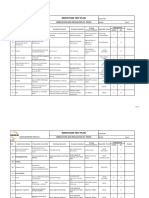

B. REBOUND HAMMER

Keeping in view the visual observations, a

comprehensive test programme was planned for condition Rebound Hammer test is conducted on the column

assessment. faces using an N type Schmidt hammer test for concrete. The

test covered critical column and beam locations in the

A. ULTRASONIC PULSE VELOCITY TEST building. The test is conducted as per the procedure mentioned

in IS 13311: Part II. For each column, six readings are taken

Ultrasonic Pulse Velocity test is conducted on critical ensuring a minimum distance of 20mm between two

column and beam locations in the building. The test is successive points. Finally, average of these readings is taken

conducted as per the procedure mentioned in IS 13311: Part I. as the representative rebound number for the concrete of that

Before measuring the pulse velocity using the transducers, a column. Average rebound number which is obtained is to be

thin layer of grease is applied to testing members so as to act corrected by considering the carbonation effect. The

as acoustic coupling between the transducers and the concrete interpretation of rebound hammer results is carried out based

surface. on the guide lines given in BS 6089: 1881 since IS 13311: Part

II remains silent in this aspect.

Page | 564 www.ijsart.com

IJSART - Volume 3 Issue 4 APRIL 2017 ISSN [ONLINE]: 2395-1052

as per rebound hammer test Ref. IS 13311 (part II) REFERENCES

1992 Non Destructive testing of concrete method of test,

rebound hammer. The maximum reading confirming M10 to [1] IS : 13311 ( Part 2 ) : 1992 Non-destructive Testing of

M15 grade concrete. Concrete Methods of Test, Part 2 Rebound Hammer,

BIS, New Delhi.

V. RECOMMENDATION FOR REPAIR

[2] IS: 13311 ( Part 1 ) : 1992 Non-destructive Testing of

This building causes a major damages as mentioned Concrete Methods of Test , Part 1 Ultrasonic Pulse

above, hence to recover this building and to get strength as Velocity, BIS, New Delhi.

well as to increase the life span of building, mentioned some

remedial measure as below. [3] S. Bhaskar, P. Srinivasan and A. Chellappan (2006)

National Seminar on Non- Destructive Evaluation,

1. All the cover concrete (up to a minimum thickness of proceedings of Indian Society of Non-Destructive

50mm) shall be chipped off exposing the sound Testing.

concrete.

2. Surface shall be cleaned by sand blasting or water [4] Jochen H. Kurz, Christian Boller and Gerd Dobmann

jetting (2013)Condition Assessment of Civil Infrastructure in

3. Wherever core concrete has voids and honeycombs, Europe: RecentDevelopments and What Might Be

it should be strengthened by means of grouting with Ahead, Journal of Engineering Mechanics, Vol. 139, No.

cement 6, ASCE, ISSN 0733-9399

4. All the reinforcement shall be cleaned thoroughly

5. An anticorrosive coating shall be applied on the [5] Jochen H. KURZ, Markus STOPPEL, Alexander TAFFE

surface of the reinforcements and Christian BOLLER (2012) Condition assessment of

6. Micro concrete shall be placed in stages of 1.5m. For reinforced concrete structures using automated multi-

better bonding between old and new concrete, shear sensor systems, 18th World Conference on Non

connectors shall be provided destructive Testing, 16-20 April 2012, Durban, South

7. After demoulding and curing, the entire exposed Africa.

surface of the structure shall be coated with a [6] Waleed F. Tawhed and Sarah L. Gassman (2002)

concrete surface coating which will resist the ingress Damage Assessment of Concrete Bridge Decks using

of carbon dioxide and chloride from the atmosphere. Impact-Echo Method,ACI Materials Journal, V. 99, No.

3, May-June 2002.

VI. SUMMARY AND CONCLUDING REMARK

[7] Dr. Akil Ahmed, Prof. Mehtab Alam, and Dr. Asif Husain

A detailed systematic methodology in conducting the (2013)Investigation of Structural Failure of a RC Hotel

condition assessment of building is presented. This includes under Construction, International Journal of Chemical,

visual observation and documentation, ultrasonic testing on Environmental & Biological Sciences (IJCEBS) Volume

structure such as slab, cantilever, etc for assessing the integrity 1, Issue 3, ISSN 2320-4079.

of concrete, core sampling and testing for estimating the

compressive strength and water absorption. Half-cell potential [8] IS: 456:2000 Indian Standard Plain And Reinforced

measurements were also carried out for assessing the Concrete - Code Of Practice (Fourth Revision).

presenceof corrosion activity. The test results have been

interpreted, and finally assessed the overall concrete quality

and integrity. Based on the test results, it was found that the

distressing of the supporting structure was mainly due to

voids, honeycombing and carbonation of concrete. Necessary

repair measures are suggested to improve the strength and

performance of the structure in a qualitative manner.

Page | 565 www.ijsart.com

S-ar putea să vă placă și

- Review On Condition Assessment and NDT of BuildingDocument2 paginiReview On Condition Assessment and NDT of BuildingManish BhatkarÎncă nu există evaluări

- Non-Destructive Tests On ConcreteDocument34 paginiNon-Destructive Tests On Concretefazil p0% (2)

- Non-Destructive Tests On ConcreteDocument34 paginiNon-Destructive Tests On Concretefazil pÎncă nu există evaluări

- Chapter - 01 (Introduction)Document6 paginiChapter - 01 (Introduction)Amila LiyanaarachchiÎncă nu există evaluări

- DN NAGAR - ReportDocument112 paginiDN NAGAR - ReportPRASHANT MOTWANIÎncă nu există evaluări

- Quotation For Amantran CHS Miraroad PDFDocument5 paginiQuotation For Amantran CHS Miraroad PDFShakuntala GuptaÎncă nu există evaluări

- Ijert Ijert: Feasibility Study of RC Structure For Additional Floor Using NDT Approach-A Case StudyDocument5 paginiIjert Ijert: Feasibility Study of RC Structure For Additional Floor Using NDT Approach-A Case StudyburhanÎncă nu există evaluări

- Non Destructive Testing of ConcreteDocument7 paginiNon Destructive Testing of ConcreteSurya PaudelÎncă nu există evaluări

- 1 SLMN-NDTonconcreteCTTSingapore2002Document16 pagini1 SLMN-NDTonconcreteCTTSingapore2002mohammed abrahimeÎncă nu există evaluări

- NDT - Concrete Investigation SlideDocument26 paginiNDT - Concrete Investigation SlideJohn OLiver100% (1)

- Non Destructive Testing Seminar ReportDocument22 paginiNon Destructive Testing Seminar ReportMonu LodhaÎncă nu există evaluări

- Review of The Rebound Hammer Method-1Document26 paginiReview of The Rebound Hammer Method-1Mr. Jitender KumarÎncă nu există evaluări

- Unit 1Document3 paginiUnit 1Tushar DisodiaÎncă nu există evaluări

- Repair & Rehabilitation of Structures: by Venkatesh MDocument65 paginiRepair & Rehabilitation of Structures: by Venkatesh MVENKATESH MÎncă nu există evaluări

- Shmidt Hammer TestDocument10 paginiShmidt Hammer Testmoloko masemolaÎncă nu există evaluări

- Non Destructive Testing1Document21 paginiNon Destructive Testing1Madhava PadiyarÎncă nu există evaluări

- NDTS Lecture NotesDocument58 paginiNDTS Lecture NotesTushar DisodiaÎncă nu există evaluări

- Non-Destructive Evaluation (NDE) Techniques, AreDocument54 paginiNon-Destructive Evaluation (NDE) Techniques, ArevempadareddyÎncă nu există evaluări

- 2 BrozovskyDocument6 pagini2 BrozovskyvijayÎncă nu există evaluări

- 03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFDocument5 pagini03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFYati R. TankÎncă nu există evaluări

- Design Engineering Sem 6Document89 paginiDesign Engineering Sem 6kunal mahetaÎncă nu există evaluări

- Soundness of Concrete PDFDocument3 paginiSoundness of Concrete PDFIsmail A IsmailÎncă nu există evaluări

- Difference BETWEEN OLD STRUCTURE AND NEW STRUCTURE ON SAME BUILDINGDocument6 paginiDifference BETWEEN OLD STRUCTURE AND NEW STRUCTURE ON SAME BUILDINGSudarshan PatilÎncă nu există evaluări

- Buildings: Ivan Ivanchev and Veselin SlavchevDocument15 paginiBuildings: Ivan Ivanchev and Veselin Slavchevjohn doeÎncă nu există evaluări

- 192459-Article Text-487861-1-10-20200128Document14 pagini192459-Article Text-487861-1-10-20200128Debendra Dev KhanalÎncă nu există evaluări

- Sri Infro Rebound Hammer ReportDocument14 paginiSri Infro Rebound Hammer ReportChandan MondalÎncă nu există evaluări

- Need For Non-Destructive Testing (NDT) of Reinforced Concrete & Various ND Tests Aryan EngineersDocument3 paginiNeed For Non-Destructive Testing (NDT) of Reinforced Concrete & Various ND Tests Aryan EngineersRajwinder Singh BansalÎncă nu există evaluări

- Structural Audit of A Residential Building IJERTV11IS040151Document3 paginiStructural Audit of A Residential Building IJERTV11IS040151TANISHKA VASÎncă nu există evaluări

- Preliminary Report G2Document6 paginiPreliminary Report G2kian hongÎncă nu există evaluări

- ISSC 2016 - Paper 2 PDFDocument9 paginiISSC 2016 - Paper 2 PDFIkhtiar RahmansyahÎncă nu există evaluări

- Necessity of Structural Audit Presentation - WSMDocument16 paginiNecessity of Structural Audit Presentation - WSMwsagarm100% (1)

- Non-Destructive Test: Dr. Priyaranjan PalDocument25 paginiNon-Destructive Test: Dr. Priyaranjan PalRahul KumarÎncă nu există evaluări

- Chapter-1: 1.1 Background of The ProblemDocument63 paginiChapter-1: 1.1 Background of The ProblemAman BansalÎncă nu există evaluări

- Non DestructiveTestingofConcreteAReviewofMethodsDocument10 paginiNon DestructiveTestingofConcreteAReviewofMethodsShreeya SÎncă nu există evaluări

- Comparison of Non-Destructive and Destructive TestDocument7 paginiComparison of Non-Destructive and Destructive TestjoshÎncă nu există evaluări

- M.Tech Seminar ReportDocument33 paginiM.Tech Seminar ReportKalyaniÎncă nu există evaluări

- l4 - Procedure of Civil Structure InspectionDocument30 paginil4 - Procedure of Civil Structure InspectionWajira Sanjaya PereraÎncă nu există evaluări

- Rebound Hammer Test and Non Destructive Testing of ConcreteDe la EverandRebound Hammer Test and Non Destructive Testing of ConcreteÎncă nu există evaluări

- Structural Audit GuideDocument4 paginiStructural Audit GuideDean Arig100% (1)

- Study of Concrete Quality Assessment of Structural Elements Using Rebound Hammer TestDocument7 paginiStudy of Concrete Quality Assessment of Structural Elements Using Rebound Hammer TestTri Jaya EngineeringÎncă nu există evaluări

- Before AfterDocument7 paginiBefore AfterAbuturab SharikmaslatÎncă nu există evaluări

- Methods of Retrofiting For RCC StructureDocument2 paginiMethods of Retrofiting For RCC StructureInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Non Destructive Testing of Structures: From Sri Vasavi Institute of Engineering & TechnologyDocument27 paginiNon Destructive Testing of Structures: From Sri Vasavi Institute of Engineering & TechnologyMohamedSajeerMÎncă nu există evaluări

- Experimental Evaluation of Cracks in Concrete by Ultrasonic Pulse Velocity and J.M Chandra KishenDocument8 paginiExperimental Evaluation of Cracks in Concrete by Ultrasonic Pulse Velocity and J.M Chandra KishenRony YudaÎncă nu există evaluări

- 62 Effect PDFDocument9 pagini62 Effect PDFephÎncă nu există evaluări

- Non Destructive Testing of ConcreteDocument11 paginiNon Destructive Testing of ConcretepraveenÎncă nu există evaluări

- A Presentation On NDTDocument23 paginiA Presentation On NDTBipin ShresthaÎncă nu există evaluări

- Synopsis ReportDocument12 paginiSynopsis ReportviqaarrÎncă nu există evaluări

- A Brief Review On Health Monitoring of StructuresDocument4 paginiA Brief Review On Health Monitoring of StructuresshubhamÎncă nu există evaluări

- Non-Destructive Test of Concrete and Masonry: Khwopa Engineering CollegeDocument11 paginiNon-Destructive Test of Concrete and Masonry: Khwopa Engineering CollegeJeewanÎncă nu există evaluări

- Advanced Structural Audit Scheme - Case Study On Bishop's House Building, PalaiDocument8 paginiAdvanced Structural Audit Scheme - Case Study On Bishop's House Building, PalaiVishvajit PatilÎncă nu există evaluări

- Non Destructive Testing MR NR PatilDocument8 paginiNon Destructive Testing MR NR PatilMaxwell RejilÎncă nu există evaluări

- 135 264 1 SMDocument9 pagini135 264 1 SMmingÎncă nu există evaluări

- M. Tech SynopsisDocument8 paginiM. Tech SynopsisemtiazÎncă nu există evaluări

- Short Summary On The TestsDocument4 paginiShort Summary On The TestsJaguar EngineeringÎncă nu există evaluări

- NDT Report of WIP ColumnsDocument23 paginiNDT Report of WIP ColumnsOM Pandey100% (1)

- 2015.08 POV Gupta SinghDocument10 pagini2015.08 POV Gupta SinghNidDouÎncă nu există evaluări

- A State-of-the-Art Guide for Post-Installed ReinforcementDe la EverandA State-of-the-Art Guide for Post-Installed ReinforcementÎncă nu există evaluări

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceDe la EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceÎncă nu există evaluări

- Reinforced Concrete Buildings: Behavior and DesignDe la EverandReinforced Concrete Buildings: Behavior and DesignEvaluare: 5 din 5 stele5/5 (1)

- UntitledDocument2 paginiUntitledkseshuÎncă nu există evaluări

- Teil A Zur Fachtechnischen Begutachtung Nur Vpi Part A Technical Assessment Only Vpi enDocument14 paginiTeil A Zur Fachtechnischen Begutachtung Nur Vpi Part A Technical Assessment Only Vpi enMarcel BaqueÎncă nu există evaluări

- ISO 3834 - Checklist-2Document6 paginiISO 3834 - Checklist-2Abhishek Anand83% (6)

- L4-UAE-046E (Rev 4) Densitometer Calibration ProcedureDocument4 paginiL4-UAE-046E (Rev 4) Densitometer Calibration ProcedureRahul DubeyÎncă nu există evaluări

- Din 1690 Part 2Document16 paginiDin 1690 Part 2Karthic MannarÎncă nu există evaluări

- Mofazzal CV - 2019 Update PDFDocument3 paginiMofazzal CV - 2019 Update PDFGusti Ryandi AriefÎncă nu există evaluări

- NDT TestDocument109 paginiNDT TestAnonymous uXdS9Y7Încă nu există evaluări

- Iso 04987-2020Document38 paginiIso 04987-2020AshokÎncă nu există evaluări

- TN Experiences Rev.01Document21 paginiTN Experiences Rev.01アユリ ユダÎncă nu există evaluări

- NC 5000Document14 paginiNC 5000AnilÎncă nu există evaluări

- Ut For WeldDocument82 paginiUt For WeldphanthanhhungÎncă nu există evaluări

- Mil STD 248dDocument157 paginiMil STD 248dTom Giles67% (3)

- Inspection Test Plan: Fabrication and Instalation of PipingDocument3 paginiInspection Test Plan: Fabrication and Instalation of PipingRejoy babyÎncă nu există evaluări

- Asme NDT MethodDocument1 paginăAsme NDT Methodkinglordofato100% (1)

- FR 210-11 01 List of NDE Operator (New)Document1 paginăFR 210-11 01 List of NDE Operator (New)aszlizaÎncă nu există evaluări

- En - 10253 4 2008 PDFDocument100 paginiEn - 10253 4 2008 PDFGeorge GhitaÎncă nu există evaluări

- NDT UT Acceptance LevelsDocument22 paginiNDT UT Acceptance LevelsDILIP VELHAL100% (2)

- GEIT-65027US Remote Visual InspectionDocument16 paginiGEIT-65027US Remote Visual InspectionvrapciudorianÎncă nu există evaluări

- Pl-Pipe-3.0.0 (Spec. For Seamless Pipe)Document12 paginiPl-Pipe-3.0.0 (Spec. For Seamless Pipe)Hector MejiaÎncă nu există evaluări

- 7 Tests That You Need On The Steel StructureDocument6 pagini7 Tests That You Need On The Steel StructureBBGÎncă nu există evaluări

- Proposal For Final Year ProjectDocument14 paginiProposal For Final Year ProjectyousefzkrÎncă nu există evaluări

- BS en Iso 18563-2-2017 - (2018-02-08 - 12-55-15 Am)Document18 paginiBS en Iso 18563-2-2017 - (2018-02-08 - 12-55-15 Am)PradeepÎncă nu există evaluări

- IR NDT On Aeronautical Plastics-Flores-BolarinDocument8 paginiIR NDT On Aeronautical Plastics-Flores-BolarinalexanderÎncă nu există evaluări

- STD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureDocument27 paginiSTD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureNikunj KÎncă nu există evaluări

- Module 7 B2Document23 paginiModule 7 B2ali mohmmadiÎncă nu există evaluări

- Emulsification, Penetrant Removal & DeveloperDocument11 paginiEmulsification, Penetrant Removal & DeveloperRajendrasinh PuvarÎncă nu există evaluări

- General Procedure For Radiographic Examination: PAE - RT-001 Rev.0Document13 paginiGeneral Procedure For Radiographic Examination: PAE - RT-001 Rev.0NguyenThanhdung100% (1)

- 32-42-03 4 5 6 7 TR32-2Document106 pagini32-42-03 4 5 6 7 TR32-2kien Duy Phan100% (2)

- Methodology For Fabrication and Erection of Penstock PipeDocument8 paginiMethodology For Fabrication and Erection of Penstock Pipemanju100% (1)

- Saep 1624Document25 paginiSaep 1624Anonymous 4IpmN7OnÎncă nu există evaluări