Documente Academic

Documente Profesional

Documente Cultură

Form Work

Încărcat de

DavidGaliciaGarcia0 evaluări0% au considerat acest document util (0 voturi)

11 vizualizări2 paginiFormwork types

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentFormwork types

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

11 vizualizări2 paginiForm Work

Încărcat de

DavidGaliciaGarciaFormwork types

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Formwork comes in several types:

1. Traditional timber formwork. The formwork is built on site out

of timber and plywood or moisture-resistant particleboard. It is easy to produce but

time-consuming for larger structures, and the plywood facing has a relatively short

lifespan. It is still used extensively where the labour costs are lower than the costs

for procuring reusable formwork. It is also the most flexible type of formwork, so

even where other systems are in use, complicated sections may use it.

2. Engineered Formwork System. This formwork is built out of prefabricated modules

with a metal frame (usually steel or aluminium) and covered on the application

(concrete) side with material having the wanted surface structure (steel, aluminum,

timber, etc.). The two major advantages of formwork systems, compared to

traditional timber formwork, are speed of construction (modular systems pin, clip,

or screw together quickly) and lower life-cycle costs (barring major force, the frame

is almost indestructible, while the covering if made of wood; may have to be

replaced after a few - or a few dozen - uses, but if the covering is made with steel

or aluminium the form can achieve up to two thousand uses depending on care

and the applications).

3. Re-usable plastic formwork. These interlocking and modular systems are used to

build widely variable, but relatively simple, concrete structures. The panels are

lightweight and very robust. They are especially suited for similar structure projects

and low-cost, mass housing schemes.

4. Permanent Insulated Formwork. This formwork is assembled on site, usually out of

insulating concrete forms (ICF). The formwork stays in place after the concrete has

cured, and may provide advantages in terms of speed, strength,

superior thermal and acoustic insulation, space to run utilities within the EPS layer,

and integrated furring strip for cladding finishes.

5. Stay-In-Place structural formwork systems. This formwork is assembled on site,

usually out of prefabricated fiber-reinforced plastic forms. These are in the shape of

hollow tubes, and are usually used for columns and piers. The formwork stays in

place after the concrete has cured and acts as axial and shear reinforcement, as

well as serving to confine the concrete and prevent against environmental effects,

such as corrosion and freeze-thaw cycles.

6. Flexible formwork. In contrast to the rigid moulds described above, flexible

formwork is a system that uses lightweight, high strength sheets of fabric to take

advantage of the fluidity of concrete and create highly optimised, architecturally

interesting, building forms. Using flexible formwork it is possible to cast optimised

structures that use significantly less concrete than an equivalent strength prismatic

section,[1] thereby offering the potential for significant embodied energy savings in

new concrete structures.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- ConcreteDocument2 paginiConcreteDavidGaliciaGarciaÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Coring - Compression TestDocument1 paginăCoring - Compression TestDavidGaliciaGarciaÎncă nu există evaluări

- Steel Is AnDocument2 paginiSteel Is AnDavidGaliciaGarciaÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Modest Petrovich MussorgskyDocument1 paginăModest Petrovich MussorgskyDavidGaliciaGarciaÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- (Pictured), Arguing For The Philosophical Position ofDocument1 pagină(Pictured), Arguing For The Philosophical Position ofDavidGaliciaGarciaÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Joseph Maurice Ravel (: /R Ə Vɛl/ (Ʒozɛf Mɔʁis ʁavɛl)Document1 paginăJoseph Maurice Ravel (: /R Ə Vɛl/ (Ʒozɛf Mɔʁis ʁavɛl)Man Hin Angus ChauÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- 文書1Document1 pagină文書1DavidGaliciaGarciaÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Soil Mechanics Is A Branch ofDocument1 paginăSoil Mechanics Is A Branch ofDavidGaliciaGarciaÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- AsphaltDocument1 paginăAsphaltDavidGaliciaGarciaÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Desk SizeDocument2 paginiDesk SizeDavidGaliciaGarciaÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- ACROW N 2 HL93.pdf: Once You Upload An Approved Document, You Will Be Able To Download The DocumentDocument1 paginăACROW N 2 HL93.pdf: Once You Upload An Approved Document, You Will Be Able To Download The DocumentDavidGaliciaGarciaÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Brain Reporte 7 Enero 2013Document2 paginiBrain Reporte 7 Enero 2013DavidGaliciaGarciaÎncă nu există evaluări

- GraficasDocument1 paginăGraficasDavidGaliciaGarciaÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Desk SizeDocument2 paginiDesk SizeDavidGaliciaGarciaÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Subjects Syllabus Civil EngineeringDocument22 paginiSubjects Syllabus Civil EngineeringDavidGaliciaGarciaÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

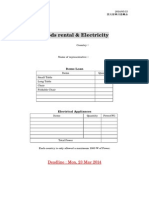

- Application Goods Rental&ElectricityDocument1 paginăApplication Goods Rental&ElectricityDavidGaliciaGarciaÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Chapter 3 EquationsDocument8 paginiChapter 3 EquationsDavidGaliciaGarciaÎncă nu există evaluări

- Kysor Service GuideDocument24 paginiKysor Service GuideAlex Renne ChambiÎncă nu există evaluări

- 8-215 2007 PDFDocument224 pagini8-215 2007 PDFEduardo Torres100% (1)

- Operating Instructions Welding Robot Manipulator PDFDocument84 paginiOperating Instructions Welding Robot Manipulator PDFRodrigo Cariz75% (12)

- PEL Brochure 1 (Word)Document9 paginiPEL Brochure 1 (Word)api-3767913Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Sec 1Document20 paginiSec 1vanthodcÎncă nu există evaluări

- 'Qiana' Fibre AssignmentDocument15 pagini'Qiana' Fibre Assignmentdigvijaynift100% (1)

- 14 Bioepuro Engineering Manual PDFDocument13 pagini14 Bioepuro Engineering Manual PDFanon_59360791100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- CAT Toxorb 2010Document2 paginiCAT Toxorb 2010ecosafe100% (1)

- WTP 3032 Painting WorksDocument9 paginiWTP 3032 Painting WorksWan AnisÎncă nu există evaluări

- t4 Hitech 00-02Document341 paginit4 Hitech 00-02Nicoleta Costea100% (3)

- Onga JS-K-P tds1Document4 paginiOnga JS-K-P tds1EmonÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Quantum Dot Display Technology and Comparison With OLED Display TechnologyDocument6 paginiQuantum Dot Display Technology and Comparison With OLED Display TechnologyGojko RatkovićÎncă nu există evaluări

- Rap 2Document5 paginiRap 2mkhibosÎncă nu există evaluări

- Example2 Two Equal Spans Option1 FinalDocument94 paginiExample2 Two Equal Spans Option1 FinalTakács AttilaÎncă nu există evaluări

- Ewaste 1Document40 paginiEwaste 1aakash87Încă nu există evaluări

- Power DomiLED InGaN DWZB UJG (3J8L) Catalogue-V1Document15 paginiPower DomiLED InGaN DWZB UJG (3J8L) Catalogue-V1Kuba KozerskiÎncă nu există evaluări

- Warning OperationDocument6 paginiWarning OperationMbahdiro KolenxÎncă nu există evaluări

- IV I Results Nov 2015Document91 paginiIV I Results Nov 2015Ann ThomasÎncă nu există evaluări

- Boiler Design For Modern Coal Fired Power PlantsDocument9 paginiBoiler Design For Modern Coal Fired Power PlantsIkhwan MaulanaÎncă nu există evaluări

- Concept of Tubular Design in High Rise Structures (Ingles)Document5 paginiConcept of Tubular Design in High Rise Structures (Ingles)Matheus AlexÎncă nu există evaluări

- #4 Standard 3 Wheel SKD CKD FinalDocument15 pagini#4 Standard 3 Wheel SKD CKD Finalnatan makuÎncă nu există evaluări

- Construction & MaterialityDocument178 paginiConstruction & MaterialityHugh Rolland80% (5)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Fmindds3 InstructionsDocument8 paginiFmindds3 InstructionsAnonymous ttDqU6zÎncă nu există evaluări

- Diode Compressor 1950Document2 paginiDiode Compressor 1950FrançoisPoddevinÎncă nu există evaluări

- Piping QuestionsDocument8 paginiPiping Questionsjijimon85Încă nu există evaluări

- The Big Catalog (Full) PDFDocument1.154 paginiThe Big Catalog (Full) PDFJuan Carlos López ValdiviezoÎncă nu există evaluări

- Precheck Before Light-Up: Drum Metal Temp. DiffDocument12 paginiPrecheck Before Light-Up: Drum Metal Temp. DiffAhemadÎncă nu există evaluări

- Wang Guangbin Et Al - Exploring The High-Efficiency Clash Detection (... ) (2011, Paper)Document7 paginiWang Guangbin Et Al - Exploring The High-Efficiency Clash Detection (... ) (2011, Paper)Roger KriegerÎncă nu există evaluări

- kk731056 enDocument40 paginikk731056 enIulianCiobanuÎncă nu există evaluări

- Site Exploration: Vedprakash C. MarlapalleDocument45 paginiSite Exploration: Vedprakash C. Marlapallevedprakash marlapalle100% (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookDe la EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookÎncă nu există evaluări