Documente Academic

Documente Profesional

Documente Cultură

Automobiles e

Încărcat de

Andi MursalimTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Automobiles e

Încărcat de

Andi MursalimDrepturi de autor:

Formate disponibile

Silicone Materials

for Automobiles

C ONTENTS

Silicone Fluids and Secondary Products for Automotive Applications P2

Silicone Elastomers for Automotive Applications P4

Silicone Elastomers for Automotive Applications Application to Airbags P6

Thermal Interface Materials for Automotive Applications P8

LIMS Materials for Automobiles P10

Silicone Materials for Automobiles

Silicone Fluids and Secondary Products for Automotive Applications

The auto industry has been unremitting in its pursuit of development of automotive technologies to improve safety,

comfort, and fuel efficiency. Silicones have frequently been used as automotive materials, and Shin-Etsu has been using

the latest technologies to develop products to meet evolving needs. In these pages we will present examples of some

typical applications, mainly featuring silicone fluids and their secondary products.

Introduction adding heat-resistance improvers to dimethyl tires wore out quickly and were therefore not

In recent years, automakers have taken silicone fluid. They are used as fan coupling practical. Later, KBE-846 was developed by

efforts to make safer vehicles that are more fluids and in other torque transmission researchers who realized that sulfide silane

comfortable and eco-friendly by adding car applications, and as a heating medium in could be used to improve the wear life of

navigation systems, sensors and other automobiles (Table 1). silica-compounded tires.

features, while making vehicles lighter and

more fuel-efficient. In this article, we will 1-3. Modifier for synthetic leather seat materials 1-6. Plastic & rubber modifiers

discuss some of the places where silicone Double end-capped carbinol-modified fluids Master pellets and acrylic silicone powders

fluids and their secondary products Single end-capped diol-modified fluids Silicone master pellets are plastics compounded

(emulsions, oil blends) are used. We will also Carbinol-modified siloxanes can be used to with highly polymerized siloxanes (30-50% by

discuss auto chemicals and subsidiary improve the slickness and texture of mass). Blended into plastics at roughly 0.1-2%

materials used in the manufacture of auto urethane-based synthetic leather seats. The concentration, they improve mold release

parts. double end-capped carbinol types (KF-6001, properties, which helps boost molding speed. In

KF-6002, KF-6003) improve cold resistance addition, the silicone gradually bleeds out to

1. In-vehicle materials and texture, while the single end-capped provide a sustained lubrication effect. Acrylic

1-1. Sensor fill materials, damper materials diol-modified types (X-22-176 series) silicone powders have good miscibility with PVC

KF-96 improve slickness. resin, EPDM and other synthetic resins. Also, the

For years, dimethyl silicone fluid (KF-96) has silicone component on the powder surface acts

been used as a gloss enhancer for automotive 1-4. Weather strip coating agent to improve tribological properties and provide

waxes, as a fill material in rubber dampers, X-32-1291 anti-blocking properties, anti-wear properties

and a damping medium in instrument meters. X-32-1291 is a solvent-based coating agent and reduce noise created when parts rub

Today, it is used in more wide-ranging for sponge type rubber weather strips. It together (Photos 1 & 2).

applications, as a fill material in sensors and helps prevent wear and reduces squeaks

a damping medium for auto seats. when windows are opened and closed. 2. Automotive chemicals,

other applications

1-2. Power transmission components 1-5. Modifier for tires and rubbers 2-1. Glass water repellents

(fan couplings, etc.) KBE-846 X-24-9418

KF-967, KF-9006 Tires compounded with silica are known to help The fluorosilicone water repellent X-24-9418

These heat-resistant silicone fluids have boost fuel economy and provide better grip on is fluorosilicone in an isopropyl alcohol

enhanced oxidation stability, achieved by wet roads. Unfortunately, silica-compounded solution. Used to treat various substrates, at

Table 1: Silicone fluids for fan couplings Photo 1: Electron micrograph of acrylic silicone powder

Product name KF-967 KF-9006

Parameter

Appearance Tan transparent liquid Tan liquid

Viscosity at 25C mm2 /s 1,000-15,000 6,000-20,000

For closed systems For closed systems

Features

Good viscosity-temperature characteristics Good heat resistance

Base fluid type Dimethyl silicone Methylphenyl silicone

Heat-resistance improver Aromatic amine Aromatic amine

(Not specified values)

Table 2: Glass water repellents

Product name Photo 2: Silicone master pellets

Parameter X-24-9418

Appearance Colorless transparent liquid

Viscosity at 25C mm 2 /s 2.8

Specific gravity at 25C 0.794

Active ingredient % 3

Diluent Isopropyl alcohol

Water contact angle 105

Hexadecane contact angle 55

Water fall angle 15

On glass substrate, after drying for 1 day at room temperature. (Not specified values)

2 Silicone Materials for Automobiles

Table 3: Rubber & plastic molding release agents

Product name KM-862T KM-740T KM-742T KM-722T KM-244F

Parameter

Appearance Creamy white liquid Creamy white liquid Creamy white liquid Creamy white liquid Pale yellow liquid

Active ingredient % 60 38 28 30 100

pH 4.0 6.0 6.0 6.5

Ionicity Nonionic Nonionic Nonionic Nonionic

High viscosity dimethyl Low viscosity dimethyl Low viscosity dimethyl Medium viscosity dimethyl

Features Polyether silicone

silicone emulsion silicone emulsion silicone emulsion silicone emulsion (contains xylene)

(Not specified values)

Table 4: Aluminum die-casting release agents

room temperature it forms a uniform film Product name

Parameter X-22-1877 X-52-8051 Silcast U

with exceptional water repellency, oil

repellency, release properties, and antifouling Appearance Pale yellow transparent liquid Creamy white liquid Creamy white liquid

properties (Table 2). Active ingredient % 100 50 32

Alkyl-aralkyl silicone Alkyl silicone

Features Alkyl-aralkyl silicone

Weakly ionic emulsion Weakly ionic emulsion

2-2. Car waxes and car wash detergents

Dimethyl silicone fluid (KF-96) has long been (Not specified values)

used as a gloss enhancer for car body waxes,

and more recently as a tire gloss enhancer.

For certain applications, it is mixed with when molding tires, radiator hoses, fuel automotive applications have been

fluids containing high-molecular-weight hoses, and other rubber parts (Table 3). Alkyl- developed in cooperation with automakers

silicone resin (KF-9021, KM-9717) or acrylic or alkyl-aralkyl-modified silicone fluids (or and auto parts manufacturers, and

silicone (X-22-8000, -8100 series) to improve their emulsions) are used as release agents Shin-Etsu is simply not at liberty to discuss

film durability. for aluminum die-casting (Table 4). them in this publication.

In car wash machines, the wax component is Without question, specially designed

often an amino silicone emulsion or other Conclusion silicones will continue to be used in places

silicone with amino groups, which improve Automobiles are complex machines with unique requirements. Shin-Etsu is

adsorption onto car body panels. (Polon manufactured using advanced plastics and committed to development of materials that

MF-14EC, X-52-800 series) fabrics, and sophisticated mechanical, meet diverse user needs, and we look forward

electric and electronic components. These to hearing your ideas and requests in this

2-3. Tire & hose mold release agents, parts have to last ten years or more. Most of regard.

aluminum die-casting release agents the materials that are currently under

Silicone emulsions are used as release agents development or that have been used for Information current as of Jan. 2007.

Automotive applications of silicone fluids and their secondary products

Synthetic leather seats

Weather strips

Sensors

Fan couplings

Plastic modifiers

Rubber modifiers

Car waxes, car wash detergents

Dampers Other

Tire & hose molding release agents

Metal part molding release agents

Silicone Materials for Automobiles 3

Silicone Materials for Automobiles

Silicone Elastomers for Automotive Applications

With the quest for higher performance automobiles and the increased use of electronic components, the performance

requirements for silicones and other raw materials are becoming ever more diverse and sophisticated. In this article,

we will present liquid silicone rubbers designed for automotive applications, for the fixing and protection of parts,

thermal interface, and other functions.

Introduction as needs dictate (Table 1). 2. Thermal Interface Materials

As automobiles have become higher The transistors and ICs on circuit boards

performance products, the use of electronic Potting Materials generate considerable heat. Silicones with

components has also increased. In some Like conformal coatings, potting materials high thermal conductivity are used to

models today there are over 70 Electronic protect electronic components arranged on effectively radiate this heat. Because these

Control Units (ECU); silicone elastomers are circuit boards from moisture, condensation silicones are applied directly to electric and

used as sealing materials, adhesives and and dust. Potting also helps reduce electronic components, they have been

potting agents for these ECUs. Silicone mechanical stress on electronic components designed with minimal amounts of

elastomers provide exceptional durability and caused by extreme temperatures and low-molecular-weight siloxane, since this

stable performance over a wide temperature vibration. Regular silicone is called dimethyl substance can cause faulty conduction at

range. In this article, we'll focus on car silicone, and it features methyl groups electrical contacts. Our lineup of thermal

electronics as we present a number of liquid attached to the side chains of the polymer. interface materials includes greases,

silicone rubber products. This type of silicone cannot be used in places adhesives and sheets. The properties of some

where it will be directly exposed to gasoline typical thermal interface adhesives are shown

1. Protecting components or oils, but this weak point can be overcome in Table 4.

In this section, we will discuss products by introducing trifluoropropyl groups into the

designed for the protection of automotive side chains of the base polymer (Table 2). 3. Fastening of parts

components, including conformal coatings, Many adhesives are used for the fastening of

potting materials and sealing materials, plus Case Seal Materials electronic parts and structural bonding.

products designed to prevent sulfurization, Case seal materials are used for waterproofing, Some usage locations stay continually hot,

which are attracting interest throughout the to protect the electronic components inside while others are exposed to gasoline and

industry today. ECUs from damage. These silicones will be other substances. Shin-Etsu has developed a

exposed to the outdoor elements for years, and lineup of adhesives to meet the requirements

Conformal Coatings thus must provide high bonding durability. of diverse applications and manufacturing

Conformal coatings are dielectric materials What's more, by adding substances that processes, so the user can select a product of

applied to electric and electronic capture acidic gases from auto exhausts, the appropriate cure type for their specific

components to protect from moisture, which include NOx and SOx, we have needs (see 4. Curing mechanisms).

condensation and dust. Shin-Etsu has developed silicones that help ensure the

developed eco-friendly solventless products performance of components over years of

and low- and high-viscosity types. Different use (Table 3).

products can be applied in different spots,

Table 1: Conformal coatings Table 2: Potting materials

Product name Product name KE-200

KE-1870 KE-1871 KE-3470 KE-3420 KE-1056 FE-57 KE-1842

Parameter Parameter CX-200

Viscosity mPas 400 800 70 700 Condensation

Cure type Addition Addition Addition

Condensation Condensation (acetone)

Cure type Addition Addition

(acetone) (acetone) Rapid cure,

Cold-resistant, Cold-resistant

Low good deep

23C/50% RH 23C/50% RH Features high transparent section

Cure conditions 150C 0.5 h 150C 0.5 h hardness

7 days 7 days penetration gel curability

Hardness, Durometer A 15 27 35 19 Consistency Liquid Liquid Low viscosity Liquid

Volume resistivity Tm 10 10 20 60 Blue transparent,

Appearance Slightly Light

Relative dielectric constant, 50Hz 3.1 3.1 3 3 Color White pale yellow

hazy brown

Dielectric dissipation factor, 50Hz 1.0 10-3 1.0 10-3 0.1 10-3 3.0 10-3 translucent

(Not specified values) Viscosity mPas 800 2000 4000 2800

Density g/cm3 0.98 1.28 1.00 1.01

Cure conditions 130C 0.5 h 125C 2 h 120C 1 h 23C 72 h

Penetration 90 60

Hardness, Durometer A 13 25

Volume resistivity Tm 8.0 0.02 1 60

Dielectric breakdown voltage kV 14 20 20

Relative dielectric constant, 50Hz 3.0 7.0 3.5 2.9

Dielectric dissipation factor, 50Hz 5 10-4 1 10-2 5 10-3 3 10-3

Electronic components potted with silicone gel (Not specified values)

4 Silicone Materials for Automobiles

Table 3: Case seal materials Table 4: Thermal interface adhesives

Product name Product name

KE-1833 IO-SEAL-300 KE-1875 KE-3466 KE-3467 X-32-2020 KE-1867

Parameter Parameter

Cure type Addition Addition Addition Cure type Condensation (acetone) Addition

High heat- Releases less Reduced low- Reduced low- Flame resistant, Reduced low- Reduced low-

Features molecular-weight molecular- molecular-

resistant acidic gas siloxane Features high thermal molecular-

weight siloxane conductivity weight siloxane weight siloxane

UL certified UL certified

Appearance (after cure) Reddish brown White Black

Consistency Med. viscosity High viscosity High viscosity Med. viscosity

Appearance

Color White White Gray Gray

Viscosity Pas 140 50 50

Viscosity Pas 50 80 100 60

Density g/cm3 1.36 1.23 1.06 Density g/cm3 2.80 2.95 2.83 2.92

Hardness, Durometer A 33 31 26 23C/50% RH 23C/50% RH

Cure conditions 120C 1 h 120C 1 h

Elongation at break % 350 270 380 7 days 7 days

Tensile strength MPa 3.4 2.8 2.5 Hardness, Durometer A 88 90 78 75

Glass 1.8 1.5 1.8 Tensile strength MPa 3.1 3.6 1.8 2.1

Shear

Aluminum 1.8 1.5 1.8 Elongation at break % 30 30 30 60

adhesive MPa

strength PBT 1.8 1.5 1.8 Volume resistivity Tm 2.9 2.5 1.0 1.2

PPS 1.8 1.5 1.8 Dielectric breakdown voltage kV/mm 24 25 23 23

Cure conditions 120C 1 h 100C 1 h 120C 0.5 h Thermal conductivity W/mK 1.9 2.4 1.9 2.2

Shear viscosity 101 (Not specified values) (Not specified values)

4. Curing Mechanisms can interfere with curing. To address this, in as little as one to three days.

There are four types of curing mechanisms Shin-Etsu developed dual-cure products

for silicone elastomers, each with distinctive based on a combination of platinum UV-cure products

characteristics (Table 5). addition/peroxide cure. These products cure rapidly through

irradiation with UV light.

Addition-cure products Condensation-cure products

Generally, the cure temperature is around These products cure by reacting with Conclusion

120C and cure time around one hour. moisture in the air so that, unlike with In the field of automotive components and

Recently, manufacturers are working to addition-cure products, heating devices are materials, there is steadily growing demand

develop products that cure more rapidly and unnecessary. These products are grouped for products that offer greater functionality

at lower temperatures. Virtually no according to the type of gas released in and environmental performance. Shin-Etsu is

byproducts are released during the curing minute quantities during the cure reaction. committed to ongoing development of

reaction. Acetone-cure (i.e. acetone is released) and materials to meet this demand, and we'd like

alcohol-cure types are used for electric and to hear from our customers regarding any

Dual-cure products electronic applications. Generally, curing ideas and requests they may have.

A drawback of addition-cure products is that tin, takes seven days, at 232C and 50% This is an edited version of the original article

nitrogen, phosphorus and sulfur compounds relative humidity, but some products cure released on Apr. 2007.

Table 5: Cure mechanism & characteristics

Application of silicone elastomers in the field of automotive electronics

Cure mechanism Cure temp. Cure time Advantages

1-component 80C or higher about 60 min Rapid cure Passenger protection system ECUs

Addition Heating Sensors: G-force sensors, passenger detectors, acceleration, etc.

Room temp. unnecessary

2-component 1-3 days

or higher (rapid cure) Actuators: airbags (front, side), etc.

150C Resists cure

Dual-cure about 60 min

or higher inhibition

Alcohol

Acetone

1-component 7 days

Conden- Oxime Heating

Room temp.

sation Acetic acid unnecessary

Alcohol

2-component 1-3 days

Acetone

Acrylic Heating

UV-cure Room temp. 20 sec unnecessary

Mercapto (rapid cure) Drive system ECUs

Sensors: vehicle speed, pedal positions,

steering angle, wheel speed, etc.

Actuators: power steering, ABS, suspension, 4WD, 4WS, etc.

Engine control system ECUs

Sensors: temperature, pressure, flow rate, crank position, oxygen, NOx, water temperature, etc.

Actuators: air flow, injectors, valve timing, etc.

Silicone Materials for Automobiles 5

Silicone Materials for Automobiles

Silicone Elastomers for Automotive Applications Application to Airbags

Of all automotive technologies, those designed to help keep drivers and passengers safe in the event of an accident are

among the most critical. The properties of silicone materials have led to their use in numerous locations in modern

vehicles. This article will look at the use of silicones in automobiles, with a particular focus on safety.

wheel, instrument panel, windshield, etc.) 2. 2. Viscosity / strength

In recent years, industry focus has shifted The strength of silicone rubbers can be

to auto airbags made of 6,6-nylon, 6-nylon, enhanced by adding a larger proportion of

polyester and other fabrics coated with silica filler or increasing the polymerization of

silicone rubber. The silicone rubber coating the organopolysiloxane polymer. Normally,

materials are typically dissolved types, silicones are compounded with fumed silica

which are millable or liquid silicones to improve strength, because it is not

dissolved in a solvent, or emulsions. possible to obtain strength sufficient for

However, in the interest of enhancing the industrial products with siloxane polymers

properties required for airbag applications alone 3. See Table 2 for the correlation

and reducing environmental impact, between silica fill content and viscosity/tear

manufacturers are gradually switching to strength.

solventless silicone materials (Table 1). Increasing the silica fill ratio has a

Curtain airbags, which are fitted in spaces mechanical "volume effect", and a

along the roof extending back from the physicochemical "surface effect" (improved

Introduction front pillars, have to maintain inflation for adsorption of the organopolysiloxane

There were over 850,000,000 cars on the a longer period than the airbags installed in molecules to the particle surface, and

world's roads in 2004. With growth in the the driver and front passenger seats. Curtain increased intermolecular force, or chemical

Chinese market, this number is expected to airbags are designed to protect the head and bonding of organopolysiloxane molecules to

reach 1.2 billion by the year 2020 1. In help keep passengers from being ejected silanols on the silica surface), resulting in

automobiles, silicone elastomers have long from the vehicle in the event of an impact or increased tear strength (Fig. 1).

been used to manufacture spark plug boots rollover. The manufacture of curtain airbags Meanwhile, Table 3 illustrates the relationship

and connector seals, and more recently for requires liquid silicone rubber coating between viscosity and tear strength, as affected

such components as intake manifold gaskets agents that have characteristics of low by organopolysiloxane polymerization. With

(fluorosilicone), turbo charger hoses and viscosity, high strength, high adhesiveness, increased polymerization of the polymer, high

silicone wiper blades. moisture resistance, heat resistance, tear strength can be achieved, but it causes

A look at the trends 1 in research and low-temperature flexibility, and stability uneven crosslinking (maldistribution) known as

development of automotive materials reveals over time. "knock tear."

that, in addition to the quest for vehicles that

are lighter and more efficient and for new

sources of power collectively aimed at Table 1: Silicone rubber coating materials

reducing CO2 emissions automakers are Type Millable/

Emulsion Solventless silicone

also working to make vehicles safer. In the Parameter Liquid silicone solution

next section, we will discuss the connection Rubber strength X

between silicone elastomers and car airbags. Environmental properties X

Workability

1. Airbags

X

The first airbags were installed in vehicles in

Table 2: Correlation between silica fill content and viscosity/tear strength

the 1960s. Airbags were developed to reduce

head injuries to passengers wearing seatbelts Sample

Sample 1 Sample 2 Sample 3

Parameter

in the event of a crash, specifically by

Silica content Low Medium High

mitigating secondary impacts (primary

Organopolysiloxane Medium chain Medium chain Medium chain

impact is that of the vehicle hitting another

Viscosity Low High

object, and the secondary impact is that of

Tear strength Low High

the passenger's body hitting the steering

Table 3: Correlation between polymerization of organopolysiloxane and viscosity/tear strength

Sample

Sample 4 Sample 5 Sample 6

Parameter

Silica content Medium Medium Medium

Organopolysiloxane Short chain Medium chain Long chain

Viscosity Low High

Tear strength Low High

6 Silicone Materials for Automobiles

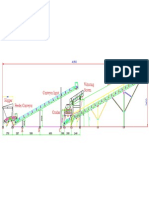

Figure 1: Reinforcing effect of silica particles

Reinforcement factor: 40 times (organopolysiloxane 0.2-0.3 MPag10 MPa after reinforcement)

Mechanical volume effect

Physicochemical surface effect

As Tables 2 and 3 show, with increased Improved adsorption

strength there is an increase in viscosity. of organopolysiloxane

But to enable high-speed application of to the particle surface,

coating materials, researchers must increased

intermolecular force.

develop low-viscosity/high-strength

technologies. Chemical bonding of

organopolysiloxane

Furthermore, when applying coating

molecules to silanols

materials at high speed, the shear viscosity of on the silica surface

the coating material is largely influenced by

the application conditions. Figure 2 shows the

viscosity behavior of Sample 2 and Sample 3

(shown in Table 2) at different shear speeds. It

is essential that the composition of the

coating material be designed such that shear typically like that shown in the following

viscosity meets the requirements of the structural formula 4. Conclusion

coating conditions. "X" represents an organic functional group, In the field of automotive components and

and "Y" a hydrolyzable group. materials, there is steadily growing demand

3. Adhesiveness The organic functional group "X" reacts with for products that offer greater functionality

The next important consideration for an or promotes miscibility with organic and environmental performance. Shin-Etsu

airbag coating is the adhesion of the coating materials. Various types of functional groups is committed to ongoing development of

to the fabric. Silane coupling agents can be are synthesized. materials to meet this demand, and we'd like

used to obtain the desired adhesive Meanwhile, for the hydrolyzable group "Y", to hear from our users regarding any ideas

properties for proper adhesion to the fabric. there are a number of possible functional and requests they may have.

The structure of a silane coupling agent is groups, but the methoxy groups, ethoxy

groups and alkoxy groups are most Information current as of Jul. 2007.

commonly used.

(CH3)n Silane coupling agents, whose molecules References:

contain functional groups, thus act as an 1 Shigeki Suzuki: Journal of the Society Of Rubber Industry,

adhesive auxiliary agent for better adhesion to Japan, Vol. 80 172 (2007)

XRSiY3n fabrics. This is thought to be the effect of 2 http://www.nissan.co.jp/COMPASS/ISF/3rd/PAPER

3 Kunio Ito: Silicone Handbook

hydrogen bonding, or wetting, or miscibilization 4 Hideyoshi Yanagisawa: Silane Coupling Ganryo Kyokai

(Fig. 3). (Pigments Association)

Figure 2: Figure 3:

150

Sample 2

Sample 3 X: organic functional group

Shear viscosity (Pas)

100 Silicone X

rubber

Adhesion

50 promoter

Y

0 Y: hydrolyzable group

1.0E+00 1.0E+01 1.0E+02

Shear speed (1/s)

Fabric

Silicone Materials for Automobiles 7

Silicone Materials for Automobiles

Thermal Interface Materials for Automotive Applications

Car electronics has progressed on a course that should lead to improvements in performance in terms of safety, comfort and the

environment. As electronic devices become smaller in size and higher in performance, thermal interface materials have become a

more and more important theme. Among silicone materials for heat dissipation, this paper discusses those developed for

automotive applications, for which performance requirements are especially strict.

Introduction applications. In light of this background, manifest pump out due to cold or heat shocks

At the same time that the automobile grows silicone thermal interface materials developed or other conditions. Consequently, this type

more and more sophisticated in performance, especially for automotive applications will be of grease has the disadvantage that its

extremely rapid progress is also being made introduced. thermal performance sometimes suddenly

in the electronification of automotive parts. becomes very poor. Nevertheless, given the

And as electronic devices become more 1. Silicone Thermal Interface product characteristics of this grease, it is

compact and more tightly integrated, the Materials extremely difficult to eliminate bleed out or

volumes of heat generated from them have Silicone thermal interface materials start with pump out phenomenon altogether.

risen dramatically. In consequence, materials a base of silicone polymer, which means they Nevertheless, this hurdle is being overcome

that provide outstanding thermal outperform other organic polymers in terms thanks to recent advances in research.

performance have come into strong demand. of heat and cold resistance, weatherability Let us consider an example. Table 2 presents

Automobiles are used in extreme and electrical properties. These special the results of pump out tests performed on

environments ranging from deserts to arctic silicone products excel in long-term reliability the very latest thermal conductive grease

regions, and are exposed to vibrations. It is and are thus used as thermal interface products to be developed and on conventional

imperative, therefore, that thermal interface materials in a wide array of applications. The predecessors. In the conventional products,

materials show durability against heat, cold products are available in sheet form and as as the number of heat cycles advances, pump

and vibrations. As a material that can satisfy paste compositions, and which is used will out and bleed out are slowly produced. In the

these requirements, silicone is ideal, and depend on the intended application (Table 1). very latest products, on the other hand, we

silicone thermal interface materials have see that there is absolutely no change in

proven to be highly reliable in automotive 2. Thermal Interface Grease configuration from the initial state. Newly

Initially, there were many developed grease that exhibits this property

Table 1: Properties and Applications of Silicone Thermal Interface Materials cases in which automakers does not require any additional heat

Property Type Applications used thermal conductive processing after it has been applied as a

Power transistor heat dissipation and insulation grease that can be applied in coating, and it demonstrates highly stabilized

Thermal conductive Power module heat dissipation and insulation mass-production methods performance. Another advantage of the latest

sheet Insulation and thermal conducting media based on automation. grease products is that in comparison to

Sheet-shaped

Recently, however, the conventional sheet-formed thermal materials,

moldings

in temperature sensing components

Low-hardness thermal Semiconductor device heat dissipation performance requirements for they are much softer, so there is no need for

conductive sheet and insulation such thermal conductive concern about damage to electronic devices

Thermal conducting media between grease have been getting much resulting from stress.

Phase change sheet stricter.

heat-emitting elements and cooling materials

Power module heat dissipation In addition to improvements in 3. Thermal Interface Sheets

Thermal conductive the rate of thermal conductivity, Thermal interface sheets are categorized into

compositions

Heat dissipation from heat-generating ICs

grease

demand has arisen for thermal three types: high-hardness rubber thermal

Pasty

Semiconductor device heat dissipation

Thermal conductive For fixing heat dissipation from conductive grease that exhibits interface sheets, low-hardness rubber

gel, adhesive electronic components, for bonding no bleed out or pump out thermal interface sheets, and phase-change

phenomenon. Given that such materials that soften when heated. Here, we

Table 2: Pump out tests grease is a simple mixture of would like to introduce the latest products

Cycle count Newly developed product Conventional product polymer and thermal developed by Shin-Etsu.

conductive filler, depending on The TC-CA Series was developed using

Initial period

how it is used, it can gradually Shin-Etsus proprietary polymer technology

(0 cycle) Figure 1: Structure of TC-SP-1.7 Series

Photo 2: TC-SP-1.7 Series

Adhesive surface:

Thermal conductive silicone rubber of low hardness (gray)

149 cycles Separator film

457 cycles Non-adhesive surface:

Thermal conductive silicone rubber

that contains glass fiber cloth (reddish brown)

8 Silicone Materials for Automobiles

Table 3: General Properties

Product name TC-100CAS-10 TC-100CAB-10 TC-100CAD-10 TC-100CAT-20

Parameter 100 shows 1.0 mm in thickness. 100 shows 1.0 mm in thickness. 100 shows 1.0 mm in thickness. 100 shows 1.0 mm in thickness.

Appearance Dark gray Pink Light reddish purple Gray

Sheet size 300 400 300 400 300 400 300 400

Structure Single layer Single layer Single layer Single layer

Density g/cm3 1.9 2.2 3.0 3.2

Hardness, Asker C 103 103 103 20

Dielectric breakdown voltage, 1mm kV 22 22 15 15

Thermal conductivity1 W/mK 1.8 2.3 3.2 4.5

Thermal resistance2 C/W 0.87 0.64 0.58 0.32

Flammability, UL94 V-0 V-0 V-0 V-0

0.5, 1.0, 1.5, 2.0, 2.5 0.5, 1.0, 1.5, 2.0 0.5, 1.0, 1.5, 2.0 0.5, 1.0, 1.5, 2.0

Thickness mm

3, 4, 5, 6, 7, 8, 9,10 2.5, 3, 4, 5 2.5, 3, 4, 5 2.5, 3, 4, 5

Photo 1: TC-CA Series

Operating temp. range C -40 to 150 -40 to 150 -40 to 180 -40 to 180

1 Based on ISO-22007-2 2 Based on Shin-Etsu method (Thickness: 1 mm) (Not specified values)

and filler compounding technology. These 3 Hardness 30 sheet can be supplied in case of less than 1.5 mm thickness.

low-hardness rubber thermal interface sheets

provide both high thermal conductivity and Table 4: Conventional Products

excellent electrical properties. Their low Conventional products TC-HSV-1.4 TC-THS TC-TXS

hardness also gives them good Thermal conductivity W/mK 1.2 2.1 3.3

compressibility and stress-relieving Based on ISO-22007-2 (Not specified values)

properties, plus excellent processing

characteristics, working properties and gaps of uneven size (Figure 2); 2) They provide components associated with car electronics.

reworkability. Another major feature is their improved resistance to pump-out (i.e. they With demand in the hybrid and electric

advantage in cost performance compared to dont become fluid even at high temperatures) vehicle segments expected to grow in the

conventional low-hardness products (Photo 1, (Photo 3); and 3) They have good transfer coming years, Shin-Etsu will intensify efforts

Table 3, Table 4). properties for greater ease of use. to develop new products and technologies

The TC-SP-1.7 Series is a line of adhesive based on ideas and insight gained from your

sheets which are ultra-soft adhesive sheets, Conclusion feedback as users.

which makes them and are thus highly Silicone thermal interface materials have This is an edited version of the original article

effective as thermal interface materials. The come into widespread use in all types of released on Jul. 2010.

non-adhesive face is reinforced with glass equipment power supplies, as well as in

fiber, so the sheets have outstanding physical computer CPUs and chip sets. In recent Figure 2: Image of Phase-change

strength and dielectric reliability, and excel in years, moreover, progress has been made in

ease of application and processing wide-area mounting of heat-dissipating

characteristics. Products in this series are

Photo3: Pump out in silicone versus olefin materials Heatsink

now being used in the electrical systems of

hybrid vehicles (Photo 2, Figure 1, Table 5). Silicone material Olefin material PCS-LT

Products in the PCS-LT-30 Series are

described as phase-change materials. They

IC IC

consist of an adhesive substance (polymer)

that is solid at room temperature, but

undergoes phase change (softens with heat)

at high temperatures. The polymer is Initial size

compounded with a high proportion of Heatsink

Inserted with clip via glass plate at a tightening force

thermally conductive fillers and manufactured

of 0.9 kg and subjected to thermal application thermal

in sheets (Table 6). These sheets outperform PCS-LT

compression bonding at 70C per hour. Heat cycle was

conventional products in various ways: 1) repeated once every 10 minutes (25 times) from 125 to

IC IC

They can be applied to devices of varying 55C and the spread of phase change sheet was checked.

heights, providing a leveling effect by filling

Table 5: General Properties of TC-SP-1.7 Series Table 6: General Properties of Phase Change Material

Product name Test method TC-100SP-1.7 Product name PCS-LT-30

Parameter Parameter

External appearance, Color tone Gray/Reddish brown Color Gray

Thickness mm 1.0 Initial thickness m 120

Density g/cm3 JIS K 6249 2.32 Bond line thickness2, 3 m 28

Hardness1, Asker C 2 Density at 25C g/cm3 2.4

Thermal conductivity W/mK ASTM E 1530 1.7 Softening point4 C 48

Thermal resistance2 K/W Shin-Etsu measurement method 1.00 Thermal conductivity1 W/mK 3.0

Insulation breakdown voltage kV JIS K 6249 20 Thermal resistance1, 3 cm2K/W 0.11

Flame retardancy UL94 V-0 Sheet size mm 300 400

Standard sheet thickness mm 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 4.0, 5.0 1 Measured by laser flash method. (Not specified values)

1 Measurements taken with 2 overlapping sheets of 6-mm sheet of low hardness. (Not specified values) 2 Measured by Micro gauge.

2 Model heater (TO-3P type, 7 cm2), applied power: 28 W/Load 29.4 kPa (300 gt/ cm2) 3 After 1 hour compression, 200 psi/100C.

4 Measured by Shin-Etsu method.

Silicone Materials for Automobiles 9

Silicone Materials for Automobiles

LIMS Materials for Automobiles

Liquid silicone rubber LIMS materials have attracted wide attention because they can facilitate stepped-up rationalization of formation processes.

Advances are also being made in the use of such materials for automobiles. In particular, products have been developed in which siloxane of low

molecular weight has been removed. This eliminates the need for secondary curing to remove such siloxane. Accordingly, LIMS materials can be

expected to find more widespread applications in automobiles, for which there are very strict requirements for stabilized performance.

Introduction 5. Eco-friendly siloxane are a type of material in which

Silicone elastomers are used in various Eco-friendly molding is made possible because low-molecular-weight siloxane has been

automotive parts because they are there are no curing reaction byproducts and no reduced, without secondary curing, to a

advantageous in terms of heat resistance, need to dispose of molding waste materials. level comparable to that in millable rubber

low-temperature characteristics and after it has been cured at 200C for 4 hours

electrical characteristics. Meanwhile, 2. Materials of Minimal (Fig. 2).

thanks to technological innovations in Low-Molecular-Weight Siloxane Table 1 lists products for which secondary

molding machines, metal molds and The silicone rubber products used around curing is not required (KE-2019 series).

materials, conventional millable or high electrical and electronic equipment can

consistency rubber is being replaced with damage electrical contact points through 3. Applications to Harnesses

liquid-type LIMS (Liquid Injection Molding volatilization of any low-molecular-weight The harnesses used with vehicle-mounted

System) materials, which facilitate siloxane that remains in mold products (Fig. 1). electrical components make up an

rationalization of molding. Normally, therefore, secondary curing is indispensable wiring system that transmits

The physical properties of cured substances performed, using ovens, so as to remove energy and diverse types of information. In

obtained by LIMS molding are in no way low-molecular-weight siloxane before the wake of recent advances toward high

inferior to those of millable rubber, and LIMS application. performance in automobiles, harnesses now

molding facilitates injection molding at low LIMS materials of minimal low-molecular-weight come in a much wider array of types, and

pressure. Moreover, with advances made in

molding machines and metal molds, molding Figure 1:Low-molecular- Mechanism of silica production by low-molecular-weight siloxane

cycles have been shortened. Still another weight siloxane

advantage is that products are flashless and CH3 R

runnerless, so waste produced during Electrical energy H2O+CO2+SiO2

Si O Si O +O2

molding has declined. (arc, spark) (+SiC etc.)

R n

This paper introduces materials recently CH3

developed using LIMS, for which there is no

need for secondary curing.

1. Features of Liquid LIMS materials of minimal low-molecular-weight siloxane

Silicone Rubber LIMS Material Table 1: General purpose, high strength type

1. Outstanding material characteristics Product name KE-2019-40A/B KE-2019-50A/B KE-2019-60A/B

Parameter

These materials offer a number of outstanding Viscosity (0.9S-1) at 23C A/B Pas 320/300 840/710 720/810

characteristics including high strength, heat 130C: MDR T10/T90 s 23/52 27/69 38/65

resistance and electrical insulation. They also Density g/cm3 1.11 1.13 1.14

have excellent transparency, so they can be Hardness, Durometer A 42 52 62

easily colored with pigments, resulting in Tensile strength MPa 9.8 9.3 9.8

vividly colored mold products. Elongation at break % 655 538 470

2. Reduced processing times Tearing strength, Angle shape kN/m 35 44 47

Because liquid silicone rubber can be cured Compression set, 150C 70 h % 12 16 35

by means of addition reaction, the time Low-molecular-weight siloxane D3-D10 ppm 50 80 80

periods required for curing and molding can Curing conditions (Non post cure): 150C 15 min. (Not specified values)

be shortened. Table 2: Oil-bleed type

3. Improved productivity Product name KE-2017-30A/B KE-2017-40A/B KE-2017-50A/B

Parameter

Molding can be executed at low injection

Viscosity (0.9S-1) at 23C A/B Pas 1840/1450 1800/1700 1700/1500

pressure and precision components can be

130C: MDR T10/T90 s 41/77 36/76 32/75

produced. High-quality molds can be realized

Density g/cm3 1.13 1.13 1.13

at good efficiency and with no contaminants.

Hardness, Durometer A 33 42 52

4. Automation of molding Tensile strength MPa 9.9 10.2 9.4

This material facilitates flashless and Elongation at break % 740 650 490

runnerless molding. It also allows molding Tearing strength, Angle shape kN/m 20 33 38

processes to be automated, since products Compression set, 150C 70 h % 16 18 18

can be easily demolded after curing. Low-molecular-weight siloxane D3-D10 ppm 100 80 80

Curing conditions (Non post cure): 150C 15 min. (Not specified values)

10 Silicone Materials for Automobiles

their performances greatly impact upon

reliability (Fig. 3). Figure 2: Comparisons of low-molecular-weight siloxane volumes based on solvent extraction method

Thanks to progress in car electronics,

100000

demand for harnesses has trended upward.

Press cured

Low-molecular-weight siloxane volume (ppm)

At the same time, LIMS, which does not 150C 1 h

require secondary curing, is finding more 10000 200C 4 h

widespread use in harnesses so as to bolster

reliability and production efficiency. Listed in

1000

Table 2 are oil-bleed type products used in

harnesses.

4. Self-adhesive LIMS

100

Materials

Self-adhesive LIMS materials, which do not 10

adhere to metal dies but only to plastic, can be

used with plastic to form integral molds.

1

Additionally, they allow molding at low KE-941-U KE-1950-40 KE-2017-40

pressure, so they can yield moldings in which (General purpose type) (General purpose LIMS material) (LIMS material of

resin deformations are minimized. What is minimal low-molecular-weight siloxane)

more, the level of precision in mold products

can be easily elevated.

5. Prospective Benefits

Figure 3: Points where harnesses are used

Because low-molecular-weight siloxane has

been minimized, metal dies will suffer much

less contamination during molding and they

will have to be cleaned far less frequently.

LIMS materials are eco-friendly, since the

volume of low-molecular-weight siloxane

produced by volatilization during curing is

minimal. What is more, fluctuations in

contraction rates during molding have been

reduced, making it possible to realize Waterproof connectors for harnesses

high-quality mold products.

Table 3: Self-adhesive LIMS materials Conclusion

Product name KE-2096-40A/B KE-2096-50A/B KE-2096-60A/B Eco-friendly products have been attracting

Parameter

more and more attention recently. Against

Viscosity (0.9S-1) at 23C A/B Pas 540/620 610/840 550/800

this backdrop, great expectations have

130 C : MDR T10/T90 s 26/38 32/43 30/45

been put on LIMS materials because they

Density g/cm3 1.12 1.13 1.13

eliminate the need for disposal of waste

Hardness, Durometer A 36 50 61

materials and the need for removal of

Tensile strength MPa 8.2 8.5 8.7

low-molecular-weight siloxane through

Elongation at break % 670 470 430

secondary curing.

Curing conditions (Non post cure): 150C 5 min. (Not specified values)

LIMS materials can be expected to find

applications in a diverse array of fields.

Figure 4: Shearing adhesive strength on various materials (KE-2096-40A/B)

This is an edited version of the original article

released on Jan. 2008.

4

Shearing adhesive strength (MPa)

0

PC PA66 PPA AI SUS

Silicone Materials for Automobiles 11

Silicone Division Shin-Etsu Silicones of America, Inc.

6-1, Ohtemachi 2-chome, Chiyoda-ku, Tokyo, Japan 1150 Damar Drive, Akron, OH 44305, U.S.A.

Phone : +1-330-630-9860 Fax : +1-330-630-9855

Sales and Marketing Department I Shin-Etsu do Brasil Representao de

< Fluids > Produtos Qumicos Ltda.

Phone : +81-(0)3-3246-5132 Fax: +81-(0)3-3246-5361 Parque Cultural Paulista Av. Paulista, 37-4 Andar,

Sales and Marketing Department II CEP 01311-902 Sao Paulo/SP Brazil

< Silanes & Resins > Phone : +55-11-2246-2873 Fax : +55-11-2246-2799

Phone : +81-(0)3-3246-5131 Fax: +81-(0)3-3246-5361 Shin-Etsu Silicones Europe B.V.

Bolderweg 32, 1332 AV, Almere, The Netherlands

Sales and Marketing Department III

< Rubber & LIMS > Phone : +31-(0)36-5493170 Fax : +31-(0)36-5326459

Phone : +81-(0)3-3246-5151 Fax: +81-(0)3-3246-5362 Germany Branch

< Designed Products > Rheingaustrasse 190-196, 65203 Wiesbaden, Germany

Phone : +81-(0)3-3246-5101 Fax: +81-(0)3-3246-5364 Phone : +49-(0)611-962-5366 Fax : +49-(0)611-962-9266

Sales and Marketing Department IV Shin-Etsu Silicone Taiwan Co., Ltd.

< RTV Rubber & Grease Oil compounds > Hung Kuo Bldg. 11F-D, No. 167, Tun Hua N. Rd.,

Taipei, 10549 Taiwan, R.O.C.

Phone : +81-(0)3-3246-5152 Fax: +81-(0)3-3246-5362

< Sealant > Phone : +886-(0)2-2715-0055 Fax : +886-(0)2-2715-0066

Phone : +81-(0)3-3246-5153 Fax: +81-(0)3-3246-5365 Shin-Etsu Silicone Korea Co., Ltd.

GT Tower 15F, 411, Seocho-daero, Seocho-gu,

Seoul 137-856, Korea

Phone : +82-(0)2-590-2500 Fax : +82-(0)2-590-2501

Shin-Etsu Singapore Pte. Ltd.

4 Shenton Way, #10-03/06, SGX Centre II, Singapore 068807

Phone : +65-6743-7277 Fax : +65-6743-7477

India Branch

712, 7th Floor, Ashoka Estate 24, Barakhamba Road,

New Delhi, India, 110001

The data and information presented in this catalog may not be Phone : +91-11-43623081 Fax : +91-11-43623084

relied upon to represent standard values. Shin-Etsu reserves

the right to change such data and information, in whole or in Shin-Etsu Silicones (Thailand) Ltd.

part, in this catalog, including product performance standards 7th Floor, Harindhorn Tower, 54 North Sathorn Road,

and specifications without notice. Bangkok 10500, Thailand

Phone : +66-(0)2-632-2941 Fax : +66-(0)2-632-2945

Users are solely responsible for making preliminary tests to

determine the suitability of products for their intended use. Shin-Etsu Silicone International Trading

Statements concerning possible or suggested uses made (Shanghai) Co., Ltd.

herein may not be relied upon, or be construed, as a guaranty 29F Junyao International Plaza, No.789,

of no patent infringement.

Zhao Jia Bang Road, Shanghai 200032, China

The silicone products described herein have been designed, Phone : +86-(0)21-6443-5550 Fax : +86-(0)21-6443-5868

manufactured and developed solely for general industrial use Guangzhou Branch

only; such silicone products are not designed for, intended for

B-2409, 2410, Shine Plaza, 9 Linhexi Road,

use as, or suitable for, medical, surgical or other particular

Tianhe, Guangzhou, Guangdong 510610, China

purposes. Users have the sole responsibility and obligation to

Phone : +86-(0)20-3831-0212 Fax : +86-(0)20-3831-0207

determine the suitability of the silicone products described

herein for any application, to make preliminary tests, and to

confirm the safety of such products for their use.

Users must never use the silicone products described herein

for the purpose of implantation into the human body and/or

injection into humans.

Users are solely responsible for exporting or importing the The Devel opment an d Manufac ture of

silicone products described herein, and complying with all Sh i n - Et s u Si l i c o n e s a re b a s e d o n t h e

applicable laws, regulations, and rules relating to the use of following registered international quality

such products. Shin-Etsu recommends checking each pertinent and environmental management standards.

country's laws, regulations, and rules in advance, when Gunma Complex ISO 9001 ISO 14001

exporting or importing, and before using the products. (JCQA-0004 JCQA-E-0002)

Naoetsu Plant ISO 9001 ISO 14001

Please contact Shin-Etsu before reproducing any part of this (JCQA-0018 JCQA-E-0064)

catalog. Takefu Plant ISO 9001 ISO 14001

(JQA-0479 JQA-EM0298)

Copyright belongs to Shin-Etsu Chemical Co., Ltd.

Shin-Etsu Silicone is a registered trademark of Shin-Etsu Chemical Co., Ltd. http://www.shinetsusilicone-global.com/

C Shin-Etsu 2011.1/2014.9 2 2.B.P. Printed in Japan.

S-ar putea să vă placă și

- Silicone Mold ProcedureDocument8 paginiSilicone Mold ProcedureMaria_Basta1Încă nu există evaluări

- Shin Etsu RTV Silicone RubberDocument24 paginiShin Etsu RTV Silicone RubberYCYÎncă nu există evaluări

- Dow Corning Glazing MethodDocument32 paginiDow Corning Glazing Methody2kareinÎncă nu există evaluări

- Manual Acrylite Injection Molding BrochureDocument36 paginiManual Acrylite Injection Molding BrochureJuan Miguel Calzada100% (1)

- Water-Based Paint Formulations, Vol. 3De la EverandWater-Based Paint Formulations, Vol. 3Evaluare: 4.5 din 5 stele4.5/5 (6)

- FormulatingDocument123 paginiFormulatingRaju100% (2)

- Compounding Guide: Liquid Natural RubberDocument48 paginiCompounding Guide: Liquid Natural RubberRubber TeamÎncă nu există evaluări

- Product Data Sheet of Resin DM 470-300 PDFDocument4 paginiProduct Data Sheet of Resin DM 470-300 PDFPrashant ShindeÎncă nu există evaluări

- CS1 Epoxy Curing AgentsDocument21 paginiCS1 Epoxy Curing AgentsAlptekin100% (1)

- Auto Care FormulationsDocument42 paginiAuto Care Formulationsmansuraquel80% (15)

- Heat Cured ElastomersDocument40 paginiHeat Cured ElastomerslberrierÎncă nu există evaluări

- Heat Cured ElastomersDocument40 paginiHeat Cured ElastomerslberrierÎncă nu există evaluări

- Combustion in Coal StockpilesDocument12 paginiCombustion in Coal StockpilesMuksin SalehÎncă nu există evaluări

- Type III DMF-Silicon Tubes (Himsan Polymer)Document53 paginiType III DMF-Silicon Tubes (Himsan Polymer)Sreesanth SaruvilÎncă nu există evaluări

- Vehicles and BindersDocument7 paginiVehicles and Bindersberchard100% (1)

- Formulating Silicone Adhesives Rubbers and GelsDocument123 paginiFormulating Silicone Adhesives Rubbers and Gelskreci1100% (1)

- AdhesivesDocument136 paginiAdhesivesDeepak Kumar Gupta50% (2)

- 17rubbercompoundingpptkiran 150318135628 Conversion Gate01Document16 pagini17rubbercompoundingpptkiran 150318135628 Conversion Gate01Madan Saini100% (1)

- Rubber Technology PDFDocument20 paginiRubber Technology PDFVeeresh S Y50% (4)

- 26-1655B-01 Auto Appearance Ebook PDFDocument87 pagini26-1655B-01 Auto Appearance Ebook PDFJorge Manuel Matos100% (1)

- STM Keypad Design GuideDocument35 paginiSTM Keypad Design Guidesav33Încă nu există evaluări

- SiliconeDocument29 paginiSiliconeAkash Yadav100% (2)

- Complete Catalogues - 160613-2 PDFDocument63 paginiComplete Catalogues - 160613-2 PDFGabriel Barriga JaqueÎncă nu există evaluări

- JGI EXeSumDocument2 paginiJGI EXeSumAndi Mursalim100% (1)

- Silicone RubberDocument25 paginiSilicone Rubbern_c_huheey100% (1)

- Alkoxylates: Promoting Superior PerformanceDocument12 paginiAlkoxylates: Promoting Superior PerformanceChanduSaiHemanthÎncă nu există evaluări

- Artificial Accelerated Ageing Test of Silicone Rubber Housing Material For Lightning ArresterDocument6 paginiArtificial Accelerated Ageing Test of Silicone Rubber Housing Material For Lightning ArrestersygabrielaÎncă nu există evaluări

- DC 781 Acetoxy SealantDocument3 paginiDC 781 Acetoxy SealantL.S.Încă nu există evaluări

- CH CH CH - CH CL CL N N: PolymerizationDocument40 paginiCH CH CH - CH CL CL N N: PolymerizationAkash YadavÎncă nu există evaluări

- Section6 Material Selection GuideDocument15 paginiSection6 Material Selection GuidenewmanÎncă nu există evaluări

- Resinas de SiliconaDocument32 paginiResinas de SiliconaWALTER KLISSMAN100% (1)

- 25 799 Resins Intermediates Selection GuideDocument12 pagini25 799 Resins Intermediates Selection GuidejoseÎncă nu există evaluări

- Fluid - e ShinetsuiDocument16 paginiFluid - e ShinetsuiErick FaundezÎncă nu există evaluări

- 25 799 01 Silicone Resins Intermediates Selection GuideDocument12 pagini25 799 01 Silicone Resins Intermediates Selection GuideSơn Toàn PhúÎncă nu există evaluări

- Ghfen IgghhsfffzxDocument5 paginiGhfen Igghhsfffzxk3nnytorr3s18Încă nu există evaluări

- Bonding, Sealing, Potting / Encapsulation and Coating With RTV Silicone Rubber CompoundsDocument38 paginiBonding, Sealing, Potting / Encapsulation and Coating With RTV Silicone Rubber CompoundsrezaÎncă nu există evaluări

- Hybrid Polymer PDFDocument8 paginiHybrid Polymer PDFPranshu JainÎncă nu există evaluări

- SS SF 350 ModDocument1 paginăSS SF 350 ModKarthickÎncă nu există evaluări

- Product Guide 2012Document16 paginiProduct Guide 2012Daniele BoscoÎncă nu există evaluări

- Aufsatz Franssen RFP 03-2012Document6 paginiAufsatz Franssen RFP 03-2012Román M Martín del CÎncă nu există evaluări

- Modified Silica Fume Waste As Filler in RubberDocument11 paginiModified Silica Fume Waste As Filler in RubberDani M RamdhaniÎncă nu există evaluări

- Super-X No.8008Document6 paginiSuper-X No.8008Wang MbaoÎncă nu există evaluări

- Silicone RubberDocument25 paginiSilicone RubberAjinkya SatdiveÎncă nu există evaluări

- Chapter 7Document7 paginiChapter 7Usama AwadÎncă nu există evaluări

- Polyimide Foams For Aerospace VehiclesDocument12 paginiPolyimide Foams For Aerospace VehiclesLanceÎncă nu există evaluări

- Acrylonitrile-Butadiene Rubber - NBRDocument7 paginiAcrylonitrile-Butadiene Rubber - NBRRubik Art100% (1)

- Zeon Productguide 20150717Document16 paginiZeon Productguide 20150717khushboo.mamtani2932Încă nu există evaluări

- 2750 515-131 en Rev 1Document12 pagini2750 515-131 en Rev 1Abohicham AbhÎncă nu există evaluări

- Xiameter PMX-200 Silicone Fluid, 50-1,000 CSDocument11 paginiXiameter PMX-200 Silicone Fluid, 50-1,000 CSluis hernandezÎncă nu există evaluări

- Technical Technical Technical Technical Bulletin Bulletin Bulletin BulletinDocument9 paginiTechnical Technical Technical Technical Bulletin Bulletin Bulletin Bulletinprem prakash mishraÎncă nu există evaluări

- Americas Polyurethane Additives GuideDocument16 paginiAmericas Polyurethane Additives Guidejlvieira1994Încă nu există evaluări

- CW EbookDocument16 paginiCW EbookJoana WoodeÎncă nu există evaluări

- 2750 515-131 en Rev ADocument8 pagini2750 515-131 en Rev Aabdulbaset alselwiÎncă nu există evaluări

- Shell Gas Compressor Oil S1 P: Corena KDocument2 paginiShell Gas Compressor Oil S1 P: Corena Kwill billÎncă nu există evaluări

- BERULUB FR 16 TdsDocument1 paginăBERULUB FR 16 TdsVishal AmleÎncă nu există evaluări

- PolymerDocument7 paginiPolymerShweta UmaleÎncă nu există evaluări

- A Comparison of Hydrocarbon and Silicone Vacuum Greases: White PaperDocument6 paginiA Comparison of Hydrocarbon and Silicone Vacuum Greases: White PaperBhushan MalsheÎncă nu există evaluări

- Textile TreatmentsDocument20 paginiTextile Treatmentsamamess.illustrationsÎncă nu există evaluări

- Nitrile Rubber ApplicationsDocument2 paginiNitrile Rubber ApplicationsWs LimÎncă nu există evaluări

- Characteristic Properties of Silicone Rubber CompoundsDocument16 paginiCharacteristic Properties of Silicone Rubber Compoundslink2u_007Încă nu există evaluări

- Renolin CLP - PIDocument6 paginiRenolin CLP - PIDương LêÎncă nu există evaluări

- Types of Synthetic RubberDocument3 paginiTypes of Synthetic RubberCh. Muhammad UsamaÎncă nu există evaluări

- CH CH CH - CH CL CL N N: PolymerizationDocument34 paginiCH CH CH - CH CL CL N N: PolymerizationBagoes Rebel CrewÎncă nu există evaluări

- T 58Document8 paginiT 58YuvarajÎncă nu există evaluări

- nbr002 1612 PDFDocument32 pagininbr002 1612 PDFRanjith RÎncă nu există evaluări

- Sitasi Mekanik 4 PDFDocument2 paginiSitasi Mekanik 4 PDFMuhammad Hadi HamdaniÎncă nu există evaluări

- Silicon Rubber Laboratory Pre ReportDocument9 paginiSilicon Rubber Laboratory Pre ReportAdrian Adalberto GarayÎncă nu există evaluări

- Modfluid KL 350/ 1000Document1 paginăModfluid KL 350/ 1000Ketan GandhiÎncă nu există evaluări

- Siri Catalog 2020Document8 paginiSiri Catalog 2020Oo OoÎncă nu există evaluări

- XIAMETER™ OFS-6011 Silane: Features & BenefitsDocument4 paginiXIAMETER™ OFS-6011 Silane: Features & BenefitsсветланаÎncă nu există evaluări

- Spirax S2 ATF AX-TDSDocument2 paginiSpirax S2 ATF AX-TDSArthur Sanda LayukÎncă nu există evaluări

- ObesDocument8 paginiObesPutri RamadhantiÎncă nu există evaluări

- Palembang MapDocument1 paginăPalembang MapAndi MursalimÎncă nu există evaluări

- Penawaran FerronickelDocument1 paginăPenawaran FerronickelAndi MursalimÎncă nu există evaluări

- Boarding PassDocument2 paginiBoarding PassAndi MursalimÎncă nu există evaluări

- STP Okt2005Document15 paginiSTP Okt2005Endah Rosita D.Încă nu există evaluări

- Cash Flow Project Timbunan Job Site 14 Segeri - PT - WASE ANUGRAH ILAHIDocument2 paginiCash Flow Project Timbunan Job Site 14 Segeri - PT - WASE ANUGRAH ILAHIAndi MursalimÎncă nu există evaluări

- Hauling RoadDocument1 paginăHauling RoadAndi MursalimÎncă nu există evaluări

- PigmentDocument1 paginăPigmentAndi MursalimÎncă nu există evaluări

- Rendemen Minyak Dari Mikroalga Spirulina Sp. DanDocument10 paginiRendemen Minyak Dari Mikroalga Spirulina Sp. DanAndi MursalimÎncă nu există evaluări

- Laporan Reaksi EsterifikasiDocument8 paginiLaporan Reaksi EsterifikasiAndi MursalimÎncă nu există evaluări

- © Garmin Corporation 1995-2002Document1 pagină© Garmin Corporation 1995-2002Andi MursalimÎncă nu există evaluări

- Haynes Silicone Oil 2014Document5 paginiHaynes Silicone Oil 2014Andi MursalimÎncă nu există evaluări

- ROA Palm Acid OilDocument1 paginăROA Palm Acid OilAndi MursalimÎncă nu există evaluări

- Solvent: Halaman Utama Profile Images Produk KontakDocument2 paginiSolvent: Halaman Utama Profile Images Produk KontakAndi MursalimÎncă nu există evaluări

- Silicone Oil FisherDocument4 paginiSilicone Oil FisherAndi MursalimÎncă nu există evaluări

- PigmentDocument1 paginăPigmentAndi MursalimÎncă nu există evaluări

- Solvent: Halaman Utama Profile Images Produk KontakDocument2 paginiSolvent: Halaman Utama Profile Images Produk KontakAndi MursalimÎncă nu există evaluări

- Solubility of VinnapasDocument1 paginăSolubility of VinnapasAndi MursalimÎncă nu există evaluări

- © Garmin Corporation 1995-2002Document1 pagină© Garmin Corporation 1995-2002Andi MursalimÎncă nu există evaluări

- Cross Section Line 1.Document1 paginăCross Section Line 1.Andi MursalimÎncă nu există evaluări

- Technology Parameters of Equipment 2Document2 paginiTechnology Parameters of Equipment 2Andi MursalimÎncă nu există evaluări

- CCP 400 TPHDocument1 paginăCCP 400 TPHAndi MursalimÎncă nu există evaluări

- Electrolityc Refining CopperDocument7 paginiElectrolityc Refining CopperAndi MursalimÎncă nu există evaluări

- Electrolityc Refining CopperDocument7 paginiElectrolityc Refining CopperAndi MursalimÎncă nu există evaluări

- Electrolityc Refining CopperDocument7 paginiElectrolityc Refining CopperAndi MursalimÎncă nu există evaluări

- Copper Smelting ProcessDocument14 paginiCopper Smelting ProcessAndi MursalimÎncă nu există evaluări

- Electrolityc Refining CopperDocument7 paginiElectrolityc Refining CopperAndi MursalimÎncă nu există evaluări

- Joint SealantsDocument17 paginiJoint Sealantsy2kareinÎncă nu există evaluări

- Sylgard 160Document3 paginiSylgard 160diogocÎncă nu există evaluări

- Chapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018Document40 paginiChapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018aomareltayebÎncă nu există evaluări

- Hydroseal: Organic Extenders For Silicone SealantsDocument2 paginiHydroseal: Organic Extenders For Silicone SealantsPranshu Jain0% (1)

- SiSiB Silicone RubberDocument16 paginiSiSiB Silicone RubberQuality ControlÎncă nu există evaluări

- Technical Details of Bonding ChemicalsDocument18 paginiTechnical Details of Bonding ChemicalsSangeet KarnaÎncă nu există evaluări

- ABB - Composite Hollow Core InsulatorDocument8 paginiABB - Composite Hollow Core InsulatorAnu SunÎncă nu există evaluări

- LSR Users Guide PDFDocument15 paginiLSR Users Guide PDFSreedhar PugalendhiÎncă nu există evaluări

- Impression Evidence PDFDocument20 paginiImpression Evidence PDFhenriquehmÎncă nu există evaluări

- Flexible Heaters Silicone RubberDocument19 paginiFlexible Heaters Silicone RubberEliasÎncă nu există evaluări

- Electrical2013 PDFDocument18 paginiElectrical2013 PDFCorina StanculescuÎncă nu există evaluări

- Akkim CatalogDocument216 paginiAkkim CatalogRiad SaidÎncă nu există evaluări

- QSil CatalogDocument44 paginiQSil CatalogOskar CorderoÎncă nu există evaluări

- CW EbookDocument16 paginiCW EbookJoana WoodeÎncă nu există evaluări

- DC-3522-TD Dow Corning 3522Document2 paginiDC-3522-TD Dow Corning 3522nakul164Încă nu există evaluări

- Chapter 7 - Morphing Skin Foams - 2018 - Morphing Wing TechnologiesDocument24 paginiChapter 7 - Morphing Skin Foams - 2018 - Morphing Wing TechnologiesRichardÎncă nu există evaluări

- Silicones Additives 2017Document36 paginiSilicones Additives 2017Bilson ShuklaÎncă nu există evaluări

- DOWSIL 791 Weatherproofing Sealant Product Data 1799967Document4 paginiDOWSIL 791 Weatherproofing Sealant Product Data 1799967Research DevelopmentÎncă nu există evaluări

- XIAMETER™ RBB-2030-80 Base: Features & Benefits ApplicationsDocument3 paginiXIAMETER™ RBB-2030-80 Base: Features & Benefits ApplicationsDaniela Alejandra Daza LancherosÎncă nu există evaluări

- QP1 Series Data SheetDocument4 paginiQP1 Series Data SheetEthanÎncă nu există evaluări

- ASEAN Rubber Testing Laboratories For Rubber VulcanizatesDocument64 paginiASEAN Rubber Testing Laboratories For Rubber Vulcanizateshery siregarÎncă nu există evaluări