Documente Academic

Documente Profesional

Documente Cultură

MFR

Încărcat de

Alok Kumar100%(1)100% au considerat acest document util (1 vot)

811 vizualizări3 paginiMaster Formula Record Format

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentMaster Formula Record Format

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

811 vizualizări3 paginiMFR

Încărcat de

Alok KumarMaster Formula Record Format

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

MASTER FORMULA RECORD

1.0 Objective: To describe the procedure for preparation of Master Formula

Record.

2.0 Scope: This SOP applies to preparation of Master Formula Record.

3.0 Responsibility:

3.1 Primary Responsibility

F&D and Production Department

3.2 Secondary Responsibility

Quality Assurance Department

4.0 Accountability: Head- Quality Assurance shall be accountable for

implementation of SOP.

5.0 Procedure:

5.1 Production Department in association with F&D, shall prepare Master Formula

Record (MFR).

5.2 Master Formula Record (MFR) shall be prepared as per the format attached

with this SOP.

5.3 Master Formula Record (MFR) shall be divided into two parts as shown in the

attached Format - Manufacturing part and Packaging part.

5.4 The first page of both the sections shall have following details:

5.4.1 Name, Address and Logo of the Company.

5.4.2 Dosage Form:

5.4.3 Brand Name:

5.4.4 Generic Name:

5.4.5 Product Code:

5.4.6 Label claim: This should include all ingredients and text included in product

permission.

5.4.7 Product description:

5.4.8 Batch Size:

5.4.9 Pack size: This should describe the packing style of salable pack and sample

pack. This should be expressed in terms of the number, weight or volume of the

product in final container.

5.4.10 Shelf life:

5.4.11 Storage condition:

5.4.12 Drug schedule: Whether schedule "H" or schedule "G" drug.

5.4.13 Superseded Master Card No. and date:

5.4.14 Present Master Card No. and date:

5.4.15 Present Master Card effective B. No.:

5.4.16 Reference of change control number:

5.5 There shall be authorization on all pages of Master Formula Record (MFR) by

three persons i.e. person who shall prepared the Master Formula Record

(Production Officer), person who shall check the Master Formula Record

(Production Head) and the person who shall finally approve (Quality Assurance

Head) it. All the three persons will sign off all the pages. Their designation and

their name will be printed below their signatures along with the date of signing the

document.

5.6 The second page of manufacturing section shall include - Process steps to be

monitored.

5.7 Subsequent pages shall include the processes to be monitored. The stage wise

movement of the material in a form of flow chart. The flow chart shall cover all

activities beginning from the dispensing of the materials and ending at the transfer

of a batch to finished stores.

5.8 The list of equipments, machines, utensils to be used, shall be described.

5.9 The subsequent page shall include any special precautions to be taken for the

product during manufacturing and packing. The same page should also include

Batch Manufacturing Formula. The batch formula should have following columns :

5.9.1 Serial number

5.9.2 Name of ingredients

5.9.3 Reference of specification of ingredients

5.9.4 Quantity to be added (in mg per ml or per tablet or per capsule or per gram as

the case may be)

5.9.5 Overages to be added (in %)

5.9.6 Quantity to be added per batch or per lot

5.10 Below that give the calculation steps for every active material, ensuring that

the active materials shall be compensated for assay values less than 100 % which

could be due to less potency or higher moisture content.

5.11 In subsequent page, include manufacturing process. Write the process stage

wise and stepwise. At the end of every important stage, include a statement of the

yield with acceptable limits.

5.12 Include in-process quality checks during and at the end of important steps and

stages with their limits.

5.13 The process shall include the process equipments to be used. The methods or

the reference of the methods / procedures to be employed for preparing, cleaning,

assembling, operating the various equipments shall be given.

5.14 Include detailed stepwise processing instructions (e.g. checks on materials,

pretreatments, sequence for adding materials, mixing times, temperatures,

humidity etc.).

5.15 Include the requirements for storage conditions of the products.

5.16 The packing part of Master Formula Record (MFR) should include complete

list of all the packaging materials required for a standard batch size, including

quantities, sizes and types.

5.17 Include line clearance checking during batch coding and batch packing

operations.

5.18 Include reconciliation of printed and unprinted packing materials with

acceptable limits.

5.19 Include destruction of excess or rejected printed packing materials.

5.20 Include description of packaging operation including any significant

subsidiary operations and equipments to be used. Include details of in-process

controls with instructions for sampling and acceptance limits.

5.21 Include reconciliation of the packing yield with acceptable limits.

5.22 Finally include batch release procedure.

6.0 Abbreviations:

6.1 QA: Quality Assurance

6.2 SOP: Standard Operating Procedure

6.3 No.: Number

6.4 e.g.: Example

S-ar putea să vă placă și

- cGMP Current Good Manufacturing Practices for PharmaceuticalsDe la EverandcGMP Current Good Manufacturing Practices for PharmaceuticalsEvaluare: 1 din 5 stele1/5 (2)

- SOP of Instruction of Master Formula RecordDocument2 paginiSOP of Instruction of Master Formula RecordYousif100% (1)

- Master Formula Record (MFR)Document18 paginiMaster Formula Record (MFR)Renaldy NongbetÎncă nu există evaluări

- Masterformularecord 180319024817Document20 paginiMasterformularecord 180319024817Mucharla Praveen KumarÎncă nu există evaluări

- VAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleDocument3 paginiVAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleMarwa Ahmed100% (2)

- What Is BMR (Batch Manufacturing Record)Document2 paginiWhat Is BMR (Batch Manufacturing Record)Prince Moni100% (1)

- Batch Manufacturing RecordDocument3 paginiBatch Manufacturing RecordPrince Moni75% (4)

- Master Formula CardDocument7 paginiMaster Formula CardTrilochan Ayurveda100% (1)

- Prepared by Production: Approved by QA/QC:: NVIDAZOLE® 2500 BolusDocument17 paginiPrepared by Production: Approved by QA/QC:: NVIDAZOLE® 2500 BolusLegese HailuÎncă nu există evaluări

- Sop For Cleaning Capsule Filling Machine C-14 in Capsulation Room 2Document5 paginiSop For Cleaning Capsule Filling Machine C-14 in Capsulation Room 2WANDERA ROBERTÎncă nu există evaluări

- 05-SOP For Raw Material SamplingDocument7 pagini05-SOP For Raw Material Samplinghafiz riasat100% (3)

- Sop 01 Material RequisitionDocument2 paginiSop 01 Material RequisitionM Junaid LatifÎncă nu există evaluări

- Batch Packaging Record (Final) PDFDocument13 paginiBatch Packaging Record (Final) PDFatiq100% (3)

- MFRDocument9 paginiMFRHarshal PawarÎncă nu există evaluări

- FP Spec.Document3 paginiFP Spec.ShagorShagorÎncă nu există evaluări

- MFR Ciprofloxacin Tablets 500 MGDocument10 paginiMFR Ciprofloxacin Tablets 500 MGmaxtar biogenics100% (3)

- Aphrin 500 MG Capsule BPR 2Document16 paginiAphrin 500 MG Capsule BPR 2ShagorShagor100% (2)

- BMR - Elfexo 120 TabletDocument13 paginiBMR - Elfexo 120 TabletShagorShagor100% (1)

- Q Pharma Quality ManualDocument32 paginiQ Pharma Quality Manualsappz354544883% (6)

- Out of SpecificationDocument7 paginiOut of SpecificationMichelle Morgan LongstrethÎncă nu există evaluări

- ASEAN TMHS GMP Training Chapter 5 Annex 5 Sample Batch Manufacturing RecordDocument8 paginiASEAN TMHS GMP Training Chapter 5 Annex 5 Sample Batch Manufacturing RecordSakinah Muhamad50% (2)

- BMR Cephracap 500 Cap Checked 1Document16 paginiBMR Cephracap 500 Cap Checked 1jordan7half7don100% (1)

- 2-E.BMR Liquid InjectionDocument28 pagini2-E.BMR Liquid InjectionMohammed Zubair100% (7)

- Aphrin 500 MG Capsule BPR 1Document12 paginiAphrin 500 MG Capsule BPR 1ShagorShagor100% (1)

- Finished Product - Test ProcedureDocument13 paginiFinished Product - Test ProcedureShagorShagor100% (3)

- SOP For Sampling and Release of Raw Materials - Pharmaceutical GuidelinesDocument2 paginiSOP For Sampling and Release of Raw Materials - Pharmaceutical GuidelinesDwi Annisa AmaliaSari100% (1)

- Prepared by Production: Approved by QA/QC:: TERASOL® 600 BolusDocument19 paginiPrepared by Production: Approved by QA/QC:: TERASOL® 600 BolusLegese HailuÎncă nu există evaluări

- Sop-Qa-038-00-Stability StudiesDocument22 paginiSop-Qa-038-00-Stability Studiesnareshph28Încă nu există evaluări

- Protocol For The Conduct of Stability StudiesDocument4 paginiProtocol For The Conduct of Stability StudiesManish shankarpure100% (1)

- BMR of Vericef 500capsuleDocument17 paginiBMR of Vericef 500capsuleShagorShagor100% (1)

- Master Formula RecordDocument39 paginiMaster Formula RecordAbhijit kanavaje100% (1)

- Process Validation of Ointment Creams 2Document40 paginiProcess Validation of Ointment Creams 2Farhana Shermeen0% (1)

- Batch Manufacturing Record (Capsule) : TitleDocument25 paginiBatch Manufacturing Record (Capsule) : TitleMohammed Zubair100% (3)

- Batch Manufacturing Record: Wellborne Pharmachem & BiologicalsDocument23 paginiBatch Manufacturing Record: Wellborne Pharmachem & BiologicalsMohammed Zubair100% (1)

- Process Validation of Ointment CreamsDocument40 paginiProcess Validation of Ointment CreamsTania Guzman100% (2)

- Annual Product Quality ReviewDocument3 paginiAnnual Product Quality ReviewMITON CHOWDHURY100% (2)

- Example Annual Product Review Report FormatDocument8 paginiExample Annual Product Review Report Format刘朝阳100% (2)

- Destruction SopDocument11 paginiDestruction SopPrince Moni0% (1)

- Process Validation GuidanceDocument11 paginiProcess Validation GuidancedutoitlouwÎncă nu există evaluări

- Co Dabamal Tablet 9m606001Document22 paginiCo Dabamal Tablet 9m606001joerichladÎncă nu există evaluări

- Actpro Al Drysyrup 3b001Document48 paginiActpro Al Drysyrup 3b001joerichladÎncă nu există evaluări

- Vatakulantka Rasa TabletDocument7 paginiVatakulantka Rasa Tabletreflectprakash3610Încă nu există evaluări

- Semi Solid Dosage Forms Manufacturing Tools Critical Process Parameters Strategies Optimization and ValidationDocument9 paginiSemi Solid Dosage Forms Manufacturing Tools Critical Process Parameters Strategies Optimization and ValidationGeotamÎncă nu există evaluări

- RM-Method Validation ProtocolDocument12 paginiRM-Method Validation ProtocolShagorShagorÎncă nu există evaluări

- Process ValidationDocument41 paginiProcess ValidationDANIBATA100% (3)

- Guide To Master Formulae Final 2012Document119 paginiGuide To Master Formulae Final 2012MohamedRefaatMohamedÎncă nu există evaluări

- A Product Which Has Completed All Stages of Manufacture, Including Final PackagingDocument4 paginiA Product Which Has Completed All Stages of Manufacture, Including Final Packagingom shankar JhaÎncă nu există evaluări

- Finished Product SpecDocument1 paginăFinished Product SpecShagorShagor100% (2)

- Standard Operating Procedure Pests and Rodents ControlDocument3 paginiStandard Operating Procedure Pests and Rodents ControlDaniel Yves IV Paez100% (1)

- Ointment Process ValidationDocument25 paginiOintment Process ValidationMuqeet Kazmi75% (12)

- Batch ManufacturingDocument1 paginăBatch ManufacturingAishikpaul50% (2)

- Batch Production RecordDocument83 paginiBatch Production Recordsina yadegari100% (1)

- Sample BMRDocument16 paginiSample BMRspp93% (15)

- 02.SOP of Retention Sample (Raw Material)Document5 pagini02.SOP of Retention Sample (Raw Material)Bejoy Karim100% (2)

- Shri Shankaracharya College of Pharmaceutical Sciences: Master Formula RecordDocument14 paginiShri Shankaracharya College of Pharmaceutical Sciences: Master Formula RecordMegha VermaÎncă nu există evaluări

- What Is BMR (Batch Manufacturing Record) ?Document2 paginiWhat Is BMR (Batch Manufacturing Record) ?YousifÎncă nu există evaluări

- Issuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07Document18 paginiIssuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07ibrahimgomaaÎncă nu există evaluări

- SOP Granulation, CoatingDocument6 paginiSOP Granulation, CoatingDSP PVCÎncă nu există evaluări

- On Site Master FileDocument12 paginiOn Site Master FileMd.Mahbubul AlamÎncă nu există evaluări

- Nutrition and HealthDocument3 paginiNutrition and HealthAlok KumarÎncă nu există evaluări

- UrbanizationDocument10 paginiUrbanizationAlok KumarÎncă nu există evaluări

- Cpcsea Guidelines For Laboratory AnimalsDocument7 paginiCpcsea Guidelines For Laboratory AnimalsAlok KumarÎncă nu există evaluări

- MTP ActDocument14 paginiMTP ActAlok KumarÎncă nu există evaluări

- Pharma LegislationDocument26 paginiPharma LegislationAlok KumarÎncă nu există evaluări

- Concepts of HealthDocument16 paginiConcepts of HealthAlok KumarÎncă nu există evaluări

- Concept of Prevention of DiseaseDocument5 paginiConcept of Prevention of DiseaseAlok KumarÎncă nu există evaluări

- Resume FormatsDocument2 paginiResume FormatsAlok KumarÎncă nu există evaluări

- Curriculum Vitae: Vaani JainDocument2 paginiCurriculum Vitae: Vaani JainAlok KumarÎncă nu există evaluări

- Resume FormatsDocument2 paginiResume FormatsAlok KumarÎncă nu există evaluări

- Riya Pillai: Work Experience Employee Experts: June 2012 To PresentDocument3 paginiRiya Pillai: Work Experience Employee Experts: June 2012 To PresentAlok KumarÎncă nu există evaluări

- Resume FormatsDocument3 paginiResume FormatsAlok KumarÎncă nu există evaluări

- Resume FormatsDocument2 paginiResume FormatsAlok KumarÎncă nu există evaluări

- Riya Pillai: Work Experience Employee Experts: June 2012 To PresentDocument3 paginiRiya Pillai: Work Experience Employee Experts: June 2012 To PresentAlok KumarÎncă nu există evaluări

- Curriculum Vitae: E-Mail: Pramila.S Contact No. 9876543210 ObjectiveDocument2 paginiCurriculum Vitae: E-Mail: Pramila.S Contact No. 9876543210 ObjectiveAlok KumarÎncă nu există evaluări

- Resume FormatsDocument3 paginiResume FormatsAlok KumarÎncă nu există evaluări

- Resume FormatsDocument3 paginiResume FormatsAlok KumarÎncă nu există evaluări

- Neha Jain: 12/1 N S Road, Park Street Phone: 9876543210 Trivandrum Email: PIN: 695001Document3 paginiNeha Jain: 12/1 N S Road, Park Street Phone: 9876543210 Trivandrum Email: PIN: 695001Alok KumarÎncă nu există evaluări

- Resume FormatsDocument3 paginiResume FormatsAlok KumarÎncă nu există evaluări

- Resume FormatsDocument2 paginiResume FormatsvsbrpoÎncă nu există evaluări

- Curriculum Vitae: Contact No: 9876543210 EmailDocument2 paginiCurriculum Vitae: Contact No: 9876543210 EmailAlok KumarÎncă nu există evaluări

- Anarkali Ali: Career ObjectivesDocument3 paginiAnarkali Ali: Career ObjectivesAlok KumarÎncă nu există evaluări

- Resume FormatsDocument5 paginiResume FormatsAlok KumarÎncă nu există evaluări

- Resume FormatsDocument6 paginiResume FormatsAlok KumarÎncă nu există evaluări

- Resume FormatsDocument2 paginiResume FormatsAlok KumarÎncă nu există evaluări

- Seeking Assignments As SAP FIC0 Implementation With An Organisation of ReputeDocument4 paginiSeeking Assignments As SAP FIC0 Implementation With An Organisation of ReputeAlok KumarÎncă nu există evaluări

- CA Anita Singh: ObjectiveDocument3 paginiCA Anita Singh: ObjectiveAlok KumarÎncă nu există evaluări

- Jahanvi Singh: Curriculum VitaeDocument3 paginiJahanvi Singh: Curriculum VitaeAlok KumarÎncă nu există evaluări

- Resume FormatsDocument3 paginiResume FormatsAlok KumarÎncă nu există evaluări

- Double Irish Dutch Sandwich and The Indian Transfer Pricing LawDocument20 paginiDouble Irish Dutch Sandwich and The Indian Transfer Pricing LawRahaMan ShaikÎncă nu există evaluări

- Revised Corporation Code of The PhilippinesDocument22 paginiRevised Corporation Code of The PhilippinesBernadette PanicanÎncă nu există evaluări

- J 1 B T1 Y8 GPSspxdoyDocument16 paginiJ 1 B T1 Y8 GPSspxdoyanandabrh567Încă nu există evaluări

- BGDocument3 paginiBGolimpina olimpinaÎncă nu există evaluări

- Annexure A - Health and Safety Baseline SpecificationDocument40 paginiAnnexure A - Health and Safety Baseline SpecificationVepxvia NadiradzeÎncă nu există evaluări

- Solution Manual For International Financial Management Eun Resnick 6th EditionDocument36 paginiSolution Manual For International Financial Management Eun Resnick 6th Editionoleooilbarouche2uv2y100% (47)

- SMDP - Project LogisticsDocument15 paginiSMDP - Project LogisticsDimas Arie KusumoÎncă nu există evaluări

- Multiple Choice Questions: Introduction To Business ProcessesDocument10 paginiMultiple Choice Questions: Introduction To Business ProcessesTiên Nguyễn ThủyÎncă nu există evaluări

- IntroductionDocument14 paginiIntroductionTendai DzingiraiÎncă nu există evaluări

- Jan 18 ExerciseDocument4 paginiJan 18 ExercisekrisÎncă nu există evaluări

- Dell Technologies PPT PDFDocument13 paginiDell Technologies PPT PDFVETAL SHRUTI VINAYAKÎncă nu există evaluări

- Ai in StocksDocument17 paginiAi in StocksYuvraj SolankiÎncă nu există evaluări

- Soren Chemicals: Presented By: Group 8Document9 paginiSoren Chemicals: Presented By: Group 8Aishwarya SolankiÎncă nu există evaluări

- The Great Eastern Life Insurance Co. vs. Hongkong & Shanghai Banking Corp.Document2 paginiThe Great Eastern Life Insurance Co. vs. Hongkong & Shanghai Banking Corp.Lenie SanchezÎncă nu există evaluări

- 1 Motion in Opposition To Substitute Party PlaintiffDocument5 pagini1 Motion in Opposition To Substitute Party Plaintiff1SantaFeanÎncă nu există evaluări

- Jury Summons Response LetterDocument3 paginiJury Summons Response LetterPaschal James BloiseÎncă nu există evaluări

- Sample of Ppe RecordDocument1 paginăSample of Ppe RecordZulhaidy SalimÎncă nu există evaluări

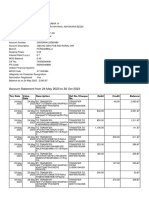

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument3 paginiStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceTanuj KukretiÎncă nu există evaluări

- Economics & Institutions: Starbucks CoffeeDocument21 paginiEconomics & Institutions: Starbucks CoffeeThilina DkÎncă nu există evaluări

- As-02.01.002 - en Alignement GuidesDocument14 paginiAs-02.01.002 - en Alignement Guidessamuel_ventura4100% (1)

- Varsha PandlaDocument2 paginiVarsha Pandlashandhin.malviya07Încă nu există evaluări

- SYAT Bookkeeping TutorialDocument35 paginiSYAT Bookkeeping TutorialJanelle MendozaÎncă nu există evaluări

- CCC2023 028Document7 paginiCCC2023 028majed sawanÎncă nu există evaluări

- Analisis Pendapatan Usaha Kerajinan RotaDocument7 paginiAnalisis Pendapatan Usaha Kerajinan RotaZandry zandryÎncă nu există evaluări

- L1f18bbam0320 Assignment 3Document3 paginiL1f18bbam0320 Assignment 3Abaidullah TanveerÎncă nu există evaluări

- Shipper's Name and Address Air WaybillDocument2 paginiShipper's Name and Address Air Waybilledwinantony303Încă nu există evaluări

- Gsma 2024Document12 paginiGsma 2024Sabrine BelgaiedÎncă nu există evaluări

- Advanced Financial AccountingDocument102 paginiAdvanced Financial AccountingYash WanthÎncă nu există evaluări

- Lampiran 3. Biodata Dosen Pendamping: A. Identitas DiriDocument3 paginiLampiran 3. Biodata Dosen Pendamping: A. Identitas DiriAira PutriÎncă nu există evaluări

- 2 TRANSPORTATION Decision Making in A Integrated SCDocument5 pagini2 TRANSPORTATION Decision Making in A Integrated SCDiego Andres Diaz CuervoÎncă nu există evaluări

- Lower Secondary Science Workbook: Stage 8De la EverandLower Secondary Science Workbook: Stage 8Evaluare: 5 din 5 stele5/5 (1)

- How to Teach Nature Journaling: Curiosity, Wonder, AttentionDe la EverandHow to Teach Nature Journaling: Curiosity, Wonder, AttentionEvaluare: 4.5 din 5 stele4.5/5 (3)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)De la EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Evaluare: 4 din 5 stele4/5 (12)

- How Do Cell Phones Work? Technology Book for Kids | Children's How Things Work BooksDe la EverandHow Do Cell Phones Work? Technology Book for Kids | Children's How Things Work BooksÎncă nu există evaluări

- A-level Biology Revision: Cheeky Revision ShortcutsDe la EverandA-level Biology Revision: Cheeky Revision ShortcutsEvaluare: 5 din 5 stele5/5 (5)

- Quantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityDe la EverandQuantum Physics for Beginners: Simple Illustrated Guide to Discover with Practical Explanations the Paradoxes of the Life and Universe Reconsidering RealityEvaluare: 2 din 5 stele2/5 (1)

- Interactive Science Notebook: The Human Body WorkbookDe la EverandInteractive Science Notebook: The Human Body WorkbookEvaluare: 4 din 5 stele4/5 (2)

- STEM Labs for Physical Science, Grades 6 - 8De la EverandSTEM Labs for Physical Science, Grades 6 - 8Evaluare: 3.5 din 5 stele3.5/5 (6)

- Nature-Based Learning for Young Children: Anytime, Anywhere, on Any BudgetDe la EverandNature-Based Learning for Young Children: Anytime, Anywhere, on Any BudgetEvaluare: 5 din 5 stele5/5 (1)

- AI and the Future of Education: Teaching in the Age of Artificial IntelligenceDe la EverandAI and the Future of Education: Teaching in the Age of Artificial IntelligenceEvaluare: 5 din 5 stele5/5 (1)

- Common Core Science 4 Today, Grade 3: Daily Skill PracticeDe la EverandCommon Core Science 4 Today, Grade 3: Daily Skill PracticeEvaluare: 3.5 din 5 stele3.5/5 (2)

- RASPBERRY PI FOR BEGINNERS: TIPS AND TRICKS TO LEARN RASPBERRY PI PROGRAMMINGDe la EverandRASPBERRY PI FOR BEGINNERS: TIPS AND TRICKS TO LEARN RASPBERRY PI PROGRAMMINGÎncă nu există evaluări