Documente Academic

Documente Profesional

Documente Cultură

Super Lifting

Încărcat de

Mohamed HarbDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Super Lifting

Încărcat de

Mohamed HarbDrepturi de autor:

Formate disponibile

Copyright

SECTION INDEX

STEERING

Section Title Section Number

Removal and Installation of Steering Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5001

Steering Specifications, Pressure Checks, and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5002

Steering Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5005

Center Pivot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5006

Auxiliary Steering Motor and Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5008

Copyright 2007 CNH Italia S.p.A.

CNH Italia S.p.A. All rights reserved.

Viale delle Nazioni, 55

41100 Modena Printed in E.C.

Italia 87551879A Issued January, 2007

Copyright

Copyright

5001

Section

5001

REMOVAL AND INSTALLATION OF STEERING

COMPONENTS

Copyright 2007 CNH Italia S.p.A.

CNH Italia S.p.A. All rights reserved.

Viale delle Nazioni, 55

41100 Modena Printed in E.C.

Italia 87551879A Issued January, 2007

Copyright

5001-2

TABLE OF CONTENTS

STEERING CONTROL VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

AUXILIARY STEERING PRIORITY VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

STEERING PRIORITY VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

AUXILIARY STEERING PUMP AND MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

STEERING CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

STEERING BACK PRESSURE VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-3

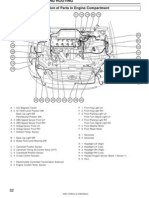

STEERING CONTROL VALVE

Removal STEP 7

STEP 1

Remove the cab skirts from the cab or canopy.

STEP 2

Remove all dirt and grease from steering control

valve.

STEP 3

Remove hydraulic reservoir fill cap, attach a vacuum

pump to the reservoir, start the pump.

BD06G245

STEP 4 Remove the mounting nut and washers from the

Tag hoses connected to steering control valve. steering shaft.

STEP 5 STEP 8

BD06G262 BD06G246

Disconnect hoses from steering control valve, cap or Remove the steering wheel from the shaft.

plug the fittings and hoses, turn off the vacuum

pump.

STEP 9

STEP 6

BD06G247

Remove the six mounting screws from the instrument

BD06G244

cover.

Remove the center cap from the steering wheel.

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-4

STEP 10 STEP 13

BD06G248 BD06G258

Remove the five mounting screws for the left and Remove the two mounting screws from the lower

right hand trim. trim.

STEP 11 STEP 14

BD06G249 BD06G259

Disconnect the ignition switch, remove the right and Pull floor mat away from the column and remove the

left hand trim pieces from the column. lower trim from the column.

STEP 12 STEP 15

BD06G257 BD06G260

Remove the screw from the brace. Remove the two lower mounting screws from the

front vent.

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-5

STEP 16 Installation

STEP 18

BD06G261

Remove the three vents from the front trim, remove

the three mounting bolts inside of the vent holes, BD06G264

remove the vent. Put the rubber bushing on the spacer with the

tapered end towards the steering valve.

STEP 17

STEP 19

Have an assistant push the valve into place while

turning the steering shaft, this will engage the

splines.

STEP 20

BD06G263

Remove the four mounting bolts for the steering

control valve.

IMPORTANT: Have an assistant support and

remove the valve while removing the mounting bolts.

BD06G263

Install and tighten the four mounting bolts for the

steering control valve.

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-6

STEP 21 STEP 24

BD06G261 BD06G257

Install the front trim, install and tighten the three Install the screw into the brace.

mounting bolts inside of the vent holes, install three

vents into the front trim. STEP 25

STEP 22

BD06G249

Connect the ignition switch, install the right and left

BD06G260 hand trim pieces onto the column.

Install the two lower mounting screws that mount the

front vent to the cab. STEP 26

STEP 23

BD06G248

Install and tighten the five mounting screws for the

BD06G258 left and right hand trim.

Install the lower trim onto the column, instal and

tighten the two mounting screws mounting the lower

trim, place the floor mat into position.

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-7

STEP 27 STEP 30

BD06G247 BD06G262

Install and tighten the six mounting screws for the Start the vacuum pump, remove the caps and plugs

instrument cover. the fittings and hoses. Connect hoses to steering

control valve according to the tags installed during

STEP 28 removal, remove and discard the tags.

STEP 31

Remove the vacuum pump from the reservoir, install

and tighten the reservoir fill cap.

STEP 32

Start and run the machine at low idle, turn the wheel

to full left and then to full right, stop the machine and

check for leaks.

STEP 33

BD06G245

Install the skirts onto the cab or canopy.

Install the steering wheel, install and tighten the

mounting nut and washers. STEP 34

Check fluid level in hydraulic reservoir. Add oil as

STEP 29 required. See Section 1002 for specifications.

BD06G244

Install the center cap on the steering wheel.

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-8

AUXILIARY STEERING PRIORITY VALVE

Removal Installation

1. Park loader on level ground and lower bucket to 1. Connect and hand tighten fitting (5) to the elbow

ground. Put transmission in NEUTRAL, apply in the steering priority valve.

parking brake, and shut down engine, 2. Install cap screws, washers and nuts (6).

2. Put master disconnect switch in OFF position. 3. Tighten pressure tube fitting (5).

3. Remove all dirt and grease from auxiliary 4. Tighten the nuts (6).

steering priority valve and adjacent area. See

5. Connect and tighten pressure hose (7).

illustration on page 9.

6. Connect and tighten steering pressure hose (9).

4. Remove hydraulic reservoir fill cap.

7. Connect and tighten steering load sensing hose

5. Connect a vacuum pump to hydraulic reservoir. (1).

6. Start vacuum pump. 8. Connect and tighten load sensing hose (2).

7. Tag and disconnect suction hose from the 9. Connect electrical connector to the pressure

suction port (4) from auxiliary steering pump and switch (3).

motor. Install a cap on the fitting and a plug in the

hose. 10. Connect electrical connector to the steering

solenoid (8).

8. Tag and disconnect tank return tube (10) from

the priority valve. Install a cap on the elbow and 11. Start vacuum pump.

a plug in the tube. 12. Connect and tighten tank return tube (10).

9. Stop the vacuum pump. 13. Connect and tighten hose to auxiliary steering

10. Tag and disconnect the wiring from the steering pump port (4).

solenoid (8). 14. Stop vacuum pump. Disconnect vacuum pump

11. Tag and disconnect the wiring from the pressure from hydraulic reservoir.

switch (3). 15. Install fill cap on hydraulic reservoir.

12. Tag and disconnect load sensing hose (2) from 16. Put battery disconnect switch in ON position.

auxiliary steering priority valve. Install a cap on Start engine and run at low idle for 30 seconds.

the elbow and a plug in the hose. Stop engine and check for leaks.

13. Tag and disconnect load sensing hose (1) from 17. Check to make sure priority valve operates

the priority valve. Install a cap on the elbow and correctly. See Section 5002.

a plug in the hose.

18. Check fluid level in hydraulic reservoir. Add oil as

14. Tag and disconnect steering pressure hose (9) required. See Section 1002 for specifications.

from priority valve. Install a cap on the fitting and

a plug in the hose.

15. Tag and disconnect pressure hose (7) from

priority valve. Install a cap on the fitting and a

plug in the hose.

16. Loosen fitting (5) connected to elbow installed in

steering priority valve.

17. Support auxiliary steering priority valve. Remove

four nuts (6), cap screws, and washers.

18. Remove auxiliary steering priority valve.

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-9

1

2

10

4

9

5

6

8 7

BC05M084

1. STEERING LOAD SENSING HOSE TO PRIORITY VALVE 6. CAP SCREWS AND NUTS

2. STEERING LOAD SENSING HOSE TO STEERING VALVE 7. PRESSURE HOSE

3. PRESSURE SWITCH 8. STEERING SOLENOID

4. SUCTION PORT 9. STEERING PRESSURE HOSE

5. PUMP OUT PRESSURE TUBE FITTING 10. TANK RETURN TUBE

AUXILIARY STEERING PRIORITY VALVE ILLUSTRATION

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-10

STEERING PRIORITY VALVE

Removal Installation

1. Park loader on level ground and lower bucket to 1. Install bolts with washers (8) through priority

ground. Put transmission in NEUTRAL, apply valve. Install new O-ring on top of priority valve

parking brake, and shut down engine, (not shown). Install priority valve (7) onto low

pressure pump, tighten bolts to37 to 48 Nm

2. Put master disconnect switch in OFF position.

(27 to 35.5 pound feet).

3. Remove all dirt and grease from steering priority 2. Install new O-rings (6) onto high pressure pump

valve (7) and adjacent area. See illustration on discharge tube (5).

page 11.

3. Place tube into position and intsall four split

4. Remove hydraulic reservoir fill cap. flanges (3) and eight bolts (4) with washers,

5. Connect a vacuum pump to hydraulic reservoir. tighten bolts.

4. Connect all hoses as tagged to the steering

6. Start vacuum pump.

priority valve (7).

7. Tag and disconnect all hoses connected to the

5. Stop vacuum pump.

steering priority valve (7).

6. Disconnect vacuum pump from hydraulic

8. Loosen and remove eight bolts (4) and four spit

reservoir.

flanges (3).

7. Install fill cap on hydraulic reservoir.

9. Remove the high pressure pump discharge tube

(5), discard O-rings (6). 8. Put battery disconnect switch in ON position.

Start engine and run at low idle for 30 seconds.

10. Support the steering priority valve (7), remove

Stop engine and check for leaks.

mounting bolts (8).

9. Check to make sure steering priority valve

11. Remove steering priority valve (7).

operates correctly. See Section 5002.

10. Check fluid level in hydraulic reservoir. Add oil as

required. See Section 1002 for specifications.

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-11

4

5

3

4 8

BC05M087

1. LOW PRESSURE PUMP (LOADER PUMP) 5. STEERING PUMP OUTPUT LINE

2. HIGH PRESSURE PUMP (STEERING PUMP) 6. O-RINGS

3. SPLIT FLANGE 7. STEERING PRIORITY VALVE

4. BOLT 8. BOLT

STEERING PRIORITY VALVE ILLUSTRATION

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-12

AUXILIARY STEERING PUMP AND MOTOR

Removal 7. Connect ground cable (1) to ground stud of

auxiliary steering pump and motor (7) following

1. Park loader on level ground and lower bucket to tag installed during removal.

ground. Put transmission in NEUTRAL, apply

parking brake, and shut down engine, 8. Connect positive cable (2) to B+ stud of auxiliary

steering pump and motor (7) following tag

2. Put master disconnect switch in OFF position. installed during removal.

3. Tag and disconnect two wiring harness (8) from 9. Connect wiring harness wires (8) to auxiliary

auxiliary steering pump and motor (7) solenoid. steering pump and motor (7) following tags

See illustration on page 13. installed during removal.

4. Tag and disconnect positive cable (2) from B+ 10. Put master disconnect switch in ON position.

stud of auxiliary steering pump and motor (7).

11. Start and run engine at low idle and raise bucket

5. Tag and disconnect ground cable (1) from 500 mm (20 inches) above ground. Check that

ground stud of auxiliary steering pump and motor auxiliary steering light on information center is

(7). OFF.

6. Remove hydraulic reservoir fill cap. IMPORTANT: In following Step, do not run auxiliary

7. Connect a vacuum pump to hydraulic reservoir. steering pump and motor continuously for more than

20 seconds at a time without a two minute cool down.

8. Start vacuum pump.

12. With engine at low idle and machine steering

9. Disconnect suction hose (4) from auxiliary straight ahead, turn key switch to OFF position to

steering pump and motor (7). Install a plug in stop engine and then immediately back to ON

suction hose and cap on fitting. position (not START position). Auxiliary steering

10. Stop vacuum pump. pump and motor should start operating

immediately. Check that auxiliary steering light

11. Loosen fittings on pressure tube (5). on information center is ON and auxiliary

12. Support auxiliary steering pump and motor (7). steering pump and motor is operating.

Remove nuts (3), cap screws, and washers 13. Turn steering wheel all the way to left and right to

securing auxiliary steering pump and motor (7). make sure that auxiliary steering pump and

13. Remove pressure tube (5) and auxiliary steering motor operates correctly.

pump and motor (7). 14. Restart engine. Check that auxiliary steering light

on information center stays ON and auxiliary

steering pump and motor is operating. After

about three seconds motor should stop operating

Installation and auxiliary steering light should go out.

1. Position auxiliary steering pump and motor (7) on 15. Let engine run and allow batteries to recharge for

its mounting plate while connecting and hand a minimum of 10 minutes.

tightening pressure tube (5) to auxiliary steering

priority valve (6). See illustration on page 13.

2. While supporting auxiliary steering pump and

motor (7) have an assistant install cap screws,

washers, and nuts (3) to secure auxiliary steering

pump and motor (7), tighten the nuts.

3. Tighten pressure tube (5) fittings securely.

4. Start vacuum pump.

5. Remove plug from suction hose (4) and cap from

elbow. Connect suction hose to elbow installed in

auxiliary steering pump and motor (7).

6. Stop and disconnect vacuum pump. Install fill

cap in hydraulic reservoir.

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-13

4

5

BC05M085

1. GROUND CABLE 4. SUCTION HOSE 7. AUXILIARY STEERING PUMP AND MOTOR

2. POSITIVE CABLE 5. PRESSURE TUBE 8. WIRING HARNESS

3. NUT (4) 6. AUXILIARY STEERING PRIORITY VALVE

AUXILIARY STEERING PUMP AND MOTOR ILLUSTRATION

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-14

STEERING CYLINDER

Removal Installation

1. Loosen the fill cap for the hydraulic reservoir to 1. Put steering cylinders (11) in position in machine.

release pressure in the reservoir, then tighten the Make sure th at wa shers (4) are installed

fill cap. between steering cylinder (11) and rear frame.

See illustration on page 15.

2. Disconnect grease hoses (1 and 16) from

steering cylinders (11). See illustration on page NOTE: Install a washer (4) on top and bottom of

15. steering cylinders (11) if possible. If only one washer

(4) can be installed, place washer (4) at bottom of

3. Disconnect hydraulic hoses (2, 3, 9, and 10) from

steering cylinders (11).

steering cylinders (11).

2. Make sure washers (14) are installed between

4. Install a plug in each hose (2, 3, 9, and 10) to

steering cylinders (11) and front frame of

prevent entry of foreign matter.

machine.

5. Remove locknut (15).

3. Install the pivot pin (5) to secure rear of steering

6. Remove cap screw (13). cylinders (11) to machine frame. Install spacer

(6), washer (7), and cap screw (8) to secure pivot

7. Remove pin (12).

pin (5).

8. Remove washers (14).

4. Tighten cap screw (8).

9. Remove cap screw (8), washer (7), and spacer

5. Install pin (12) in front of steering cylinders (11).

(6) securing pivot pin (5) at rear of steering

Make sure that washers (14) are installed in

cylinders (11).

correct position.

10. Use a suitable driver and drive pivot pin (5) out of

6. Install cap screw (13) and new locknut (15) in

steering cylinder (11).

steering cylinders (11) rod end and pin (12).

11. Remove washer(s) (4) from between steering Tighten locknut (15).

cylinders (11) and rear frame of machine.

NOTE: Cap screw (13) should turn freely in hole

12. Remove steering cylinders (11). after tightening.

7. Connect hose assemblies (2, 3, 9, and 10) to

steering cylinders (11).

8. Connect grease hoses (1 and 16) to steering

cylinders (11).

9. Tighten hydraulic reservoir fill cap.

10. Start engine.

11. Turn steering wheel all the way to right and then

to the left several times.

12. Stop the engine. Check fluid level in hydraulic

reservoir. Add oil as required. See Section 1002

for specifications.

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-15

9 10

8

6

5

3 11

2

1 1 12

13

14

15

11

16

BS03B141

1. GREASE HOSE 5. PIVOT PIN 9. HOSE ASSEMBLY 13. CAP SCREW

2. HOSE ASSEMBLY 6. SPACER 10. HOSE ASSEMBLY 14. WASHER

3. HOSE ASSEMBLY 7. WASHER 11. STEERING CYLINDER 15. LOCKNUT

4. WASHER 8. CAP SCREW 12. PIN 16. GREASE HOSE

STEERING CYLINDER ILLUSTRATION

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-16

STEERING BACK PRESSURE VALVE

Removal Installation

1. Remove the fill cap for the hydraulic reservoir to 1. Install the valve, bolts, spacers and nuts onto the

release pressure in the reservoir, attach a machine, tighten the bolts.

vacuum pump to the reservoir, start the pump.

2. Install new O-rings onto the fittings of the hoses,

2. Disconnect hoses 2 and 6 from the pressure install and tighten the hoses.

valve.

3. Stop the vacuum pump, install and tighten the

3. Remove the nuts, bolts and spacers from the reservoir filler cap.

pressure vale, remove the valve from the

4. Start and run the machine at low idle, turn the

machine.

steering wheel from full left lock to full right lock

holding the steering over relief.

5. Stop the machine and check for leaks.

6. Check fluid level in hydraulic reservoir. Add oil as

required. See Section 1002 for specifications.

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-17

BS06G529

1. STEERING CONTROL VALVE 5. RELIEF VALVE

2. RETURN HOSE 6. RETURN HOSE TO FILTERS

3. PRESSURE HOSE 7. RETURN MANIFOLD

4. CONNECTOR M27 ORB

STEERING BACK PRESSURE VALVE ILLUSTRATION

87551879A Issued 1-07 Printed in E.C.

Copyright

5001-18

NOTES

87551879A Issued 1-07 Printed in E.C.

Copyright

5002

Section

5002

STEERING SPECIFICATIONS, PRESSURE CHECKS,

AND TROUBLESHOOTING

Copyright 2007 CNH Italia S.p.A.

CNH Italia S.p.A. All rights reserved.

Viale delle Nazioni, 55

41100 Modena Printed in E.C.

Italia 87551879A Issued January, 2007

Copyright

5002-2

TABLE OF CONTENTS

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

TROUBLESHOOTING THE STEERING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

AUXILIARY STEERING SYSTEM PUMP TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

AUXILIARY STEERING SYSTEM MOTOR TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Understanding The Results Of The Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

STEERING PRIORITY VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pressure Setting Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pressure Setting Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

STEERING CYLINDER LEAK TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

STEERING BACK PRESSURE VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pressure Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

87551879A Issued 1-07 Printed in E.C.

Copyright

5002-3

SPECIAL TOOLS

B785789 B009638

OEM-1239 (CAS-10280) FLOWMETER CAS-1804 PRESSURE TEST FITTING KIT

B797157

CAS-1808 FLOWMETER FITTING KIT

TROUBLESHOOTING THE STEERING SYSTEM

NOTE: The steering hydraulic schematic is included 4. Do the main hydraulic pump test. See Section

in the hydraulic schematic. Refer to the rear pocket 8002. If the main pump is bad, repair or replace

of this manual. the main hydraulic pump.

1. Make sure the oil level in the hydraulic reservoir 5. Test the steering cylinders for leakage, refer to

is correct. Visually inspect the steering system instructions on page 8. If a steering cylinder is

for leakage and damage. leaking, repair or replace the steering cylinder.

2. The loader/steering pump differential pressure 6. If the steering system is noisy test the back

must be properly adjusted. Refer to Section 8002 pressure relief valve, refer to instructions on

Testing and Adjusting the Loader/Steering Pump page 9.

differential Pressure.

3. Do the steering limit valve pressure test. Refer to

page 6. If the pressure is above or below

specifications, adjust the steering limit valve.

87551879A Issued 1-07 Printed in E.C.

Copyright

5002-4

AUXILIARY STEERING SYSTEM PUMP TEST

Equipment Required

6. Connect the ammeter clamp (1) to the cable as

1. CAS- 10280 Flowmeter in illustration.

2. CAS-1808 Flowmeter fitting kit

Test Procedure

1. Install articulation lock.

BB830300

1. AMMETER CLAMP

7. Make sure that the parking brake is applied and

1 the bucket is on the floor.

BD03A040

8. Make sure that the oil is at operating

temperature.

1. ARTICULATION LOCK

NOTE: When performing this pressure check, 9. Make sure that the load valve for the flowmeter is

always be sure the articulation lock is in place, open (zero pressure).

especially when working in the articulation joint 10. Start and run the engine.

areas.

11. Stop the engine and turn the key back to the On

2. Loosen and remove the outlet hose to the position.

Auxiliary Steering Pump from the Auxiliary

Steering Priority Valve. 12. Turn the steering wheel, this will activate the

auxiliary steering pump.

3. Install a plug into the Auxiliary Steering Priority

Valve. 13. Turn the load valve on the flowmeter towards

CLOSED until the pressure is 104 bar (1500 psi).

4. Connect the inlet of the flowmeter to the outlet

line of the Auxiliary Steering Pump. 14. Read the flowmeter and ammeter gauges and

record the readings.

5. Install the outlet hose of the flowmeter in the

hydraulic reservoir and hold in place with wire. 15. The flowmeter reading must not be less than

24.6 L/min, (6.5 U.S. gpm). The ammeter

reading must be 315 amps.

16. Turn the key switch to the OFF position. If the

flow was less than the specification, or if the

amperage was more than 315 amperes, remove

the auxiliary steering motor and pump. Test the

auxiliary steering motor. If the motor is good,

make repairs to the pump.

87551879A Issued 1-07 Printed in E.C.

Copyright

5002-5

AUXILIARY STEERING SYSTEM MOTOR TEST

Test Equipment 5. Push the button on the remote starter switch (1)

and look at the voltmeter in the tester.

1. A 24 volt battery that is fully charged.

6. Turn the load control (8) until the voltmeter (7)

NOTE: A 24 volt battery system (two 12 volt indicates 24 volts. Look at the ammeter (6) in the

batteries in a series) is used for this test. A 12 volt tester. Make a record of the ammeter indication.

battery system will cause damage to the auxiliary

steering motor.

2. A remote starter switch. 6 7

3. A tachometer to check the armature speed.

4. A Sun Electric VAT-33 Starting and Charging

System Tester.

8

Test Procedure

1. Remove the connector that is between the

terminals on the magnetic switch and the

auxiliary steering motor.

B795328

2. Remove the auxiliary steering motor from the

auxiliary steering pump. 6. AMMETER

7. VOLTMETER

3. Remove the drive coupling from the auxiliary 8. LOAD CONTROL

steering motor (3).

7. Hold the tachometer against the armature shaft.

4. Connect the auxiliary steering motor (3), remote Look at the tachometer. Make a record of the

starter switch (1) and tester (2) to the 24 volt indication.

battery system (5) as illustrated.

8. Release the button on the remote starter

switch (1).

2

1

Understanding The Results Of The

Test

4 1. If the ammeter indication in step 6 was 30

3 amperes or less and the tachometer indication in

step 7 was 6950 r/min (rpm) or more, the

auxiliary steering motor is good.

2. If the armature speed was less than 6950 r/min

(rpm) and the ammeter indication was higher

5 than 30 amperes, replace the motor.

B790852

1. REMOTE STARTER SWITCH

2. TESTER

3. AUXILIARY STEERING MOTOR

4. AMMETER CLAMP

5. 24 VOLT BATTERY SYSTEM

87551879A Issued 1-07 Printed in E.C.

Copyright

5002-6

STEERING PRIORITY VALVE

NOTE: The loader/steering pump differential pressure must be properly adjusted before doing this test. Refer to

Section 8002 Testing and Adjusting the Loader/Steering Pump Differential Pressure.

Pressure Setting Test 4. Make sure that the temperature of the hydraulic

oil is at least 54 C (129 F).

1. Install articulation lock (1). 5. To measure the temperature of the oil using the

instrument panel:

A. Press the up or down arrow key.

B. Stop at the info screen with the temperatures

that need to be monitored.

6. Apply the parking brake.

7. Start and run the engine at full throttle.

8. Lower the lift arms and hold the control lever in

the FLOAT position.

1 9. Hold the bucket control lever in the rollback

position.

BD03A040 10. Continue holding until the specified temperature

1. ARTICULATION LOCK of the oil is reached.

11. Stop the engine.

IMPORTANT: When performing the following

pressure check and adjustment, the articulation lock 12. Start the engine and operate the machine at full

must be installed. Use caution when working in or throttle.

near the articulation area. 13. With the articulation lock still in place, turn and

2. Remove the dust cap from the test port (1). hold the steering wheel for a hard right turn.

14. Continue holding the steering wheel, and read

the pressure gauge.

15. The pressure gauge must indicate 239 to 243

bar (3465 to 3525 psi). If the pressure is not

correct, adjust the steering relief valve.

BD06F148

1. G1 TEST PORT

2. G2 TEST PORT

3. Connect a 345 bar (5000 psi) pressure gauge to

the test port (2).

NOTE: Make sure when you connect the pressure

gauge that you do so in a manner that you can read

the pressure gauge while sitting in the operators

seat.

87551879A Issued 1-07 Printed in E.C.

Copyright

5002-7

Pressure Setting Adjustment

1. Turn the adjusting screw clockwise to increase

the pressure setting. Turn the adjusting screw

counterclockwise to decrease the pressure

setting.

1

2. Repeat pressure test procedure.

3. If necessary, adjust the limit valve again until

within the specified range.

2

4. Stop the engine before removing the pressure

gauge.

BD06F147

1. STEERING PRIORITY VALVE

2. LIMIT VALVE

87551879A Issued 1-07 Printed in E.C.

Copyright

5002-8

STEERING CYLINDER LEAK TEST

NOTE: Make sure all persons are clear of the area 9. Connect the tube to the rod end of the left-hand

of the center pivot. Make sure the center pivot is free steering cylinder.

of any obstructions.

10. Turn the machine all the way to the left.

1. Park the machine on a level surface.

11. Stop the engine.

2. Turn the machine all the way to the right.

12. Find the tube that is connected to the rod end of

3. Stop the engine and apply the parking brake. the right-hand steering cylinder. Disconnect the

tube from the right-hand steering cylinder.

4. Find the tube that is connected to the rod end of

the left-hand steering cylinder. Disconnect the 13. Install a plug in the tube.

tube from the left-hand cylinder.

14. Start and run the engine at full throttle.

5. Install a plug in the tube.

15. Turn the steering wheel to the left. Hold the

6. Start and run the engine at full throttle. steering wheel for a full left turn. Have another

person check for leakage at the opening of the

7. Turn the steering wheel to the right. Hold the

rod end of the right-hand steering cylinder.

steering wheel for a full right turn. Have another

person check for leakage from the opening of the 16. If there is constant leakage from the rod end, the

rod end of the left-hand steering cylinder. piston packing in the right-hand steering cylinder

is damaged. Repairs must be made. See Section

8. If there is constant leakage from the rod end, the

5005.

piston packing in the left-hand steering cylinder

is damaged. Repairs must be made. See Section 17. Connect the tube to the rod end of the right-hand

5005. steering cylinder.

87551879A Issued 1-07 Printed in E.C.

Copyright

5002-9

STEERING BACK PRESSURE VALVE

BS06G529

1. STEERING CONTROL VALVE 5. RELIEF VALVE

2. RETURN HOSE 6. RETURN HOSE TO FILTERS

3. PRESSURE HOSE 7. RETURN MANIFOLD

4. CONNECTOR M27 ORB

87551879A Issued 1-07 Printed in E.C.

Copyright

5002-10

Pressure Test 4. Turn the steering wheel and observe the

pressure.

1. Disconnect the return hose (2) from the

connector (4). 5. The pressure should be 8 to 10 bar (115 to 145

psi).

2. Install a T fitting and connect a pressure gauge

capable of reading 35 bar (500 psi). 6. If pressure is not as specified, replace the relief

valve.

3. Start and run the machine at high idle.

NOTE: The relief valve is not adjustable.

87551879A Issued 1-07 Printed in E.C.

Copyright

Section

5005

STEERING CYLINDERS

5005

Copyright 2007 CNH Italia S.p.A.

CNH Italia S.p.A. All rights reserved.

Viale delle Nazioni, 55

41100 Modena Printed in E.C.

Italia 87551879A Issued January, 2007

Copyright

5005-2

TABLE OF CONTENTS

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

STEERING CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

87551879A Issued 1-07 Printed in E.C.

Copyright

5005-3

SPECIFICATIONS

Torque for piston cap screw .......................................................................810 to 925 Nm (597.5 to 682 pound feet)

Torque for gland ............................................................................................339 to 475 Nm (250 to 350 pound feet)

STEERING CYLINDER

Disassembly Inspection

1. Fasten tube (18) in a vise. Be careful not to 1. Clean all parts in cleaning solvent.

damage the tube. See illustration on page 4.

2. Check to be sure that piston rod (14) is straight.

2. Remove gland (1) from tube (18). If piston rod is bent, install a new piston rod.

3. Pull piston rod (14) and piston (9) straight out of 3. Inspect inside of tube (18) for deep grooves and

tube (18). other damage. If there is any damage to tube, a

new tube must be used.

4. Fasten piston rod (14) yoke in vise and put a

support below piston rod near piston (9). Put a 4. Remove small scratches on piston rod (14) or

shop cloth between support and piston rod to inside tube (18) with emery cloth of medium grit.

prevent damage to piston rod. Use emery cloth with a rotary motion.

5. Loosen and remove bolt and washer (8) that hold 5. Inspect bushing (17). If bushing requires

piston (9). replacement, remove grease fitting (15) and

retaining rings (16) then press bushing from tube

6. Remove piston (9) from piston rod (14).

end.

7. Remove and discard seal (13), loader ring (12),

wear ring (11), and cast iron ring (10) from piston

(9).

8. Remove gland (1) from piston rod (14).

9. Remove and discard O-ring (7), backup ring (6),

rod wiper (2), rod seal (3), buffer seal (4), and

bearing (5) from gland (1).

87551879A Issued 1-07 Printed in E.C.

Copyright

5005-4

16 15

17

16

18

8

9

19

13

12

11

10

5

4

3

7

6

14

BC05M089

1. GLAND 6. BACKUP RING 11. WEAR RING 15. GREASE FITTING

2. ROD WIPER 7. O-RING 12. RING LOADER 16. RETAINING RING

3. ROD SEAL 8. BOLT AND WASHER 13. SEAL 17. BUSHING

4. BUFFER SEAL 9. PISTON 14. PISTON ROD 18. TUBE

5. BEARING 10. RING CAST IRON

STEERING CYLINDER ILLUSTRATION

87551879A Issued 1-07 Printed in E.C.

Copyright

5005-5

Assembly 17. Install bolt and hardened washer (8) in piston (9).

1. Install bearing (5) in gland (1). 18. Install piston (9) on piston rod (14) and start bolt

(8) into piston rod.

2. Install buffer seal (4) in gland (1) so that lips of

seal are toward small end of gland. 19. Tighten bolt (8) to a torque of 810 to 925 Nm

(597.5 to 682 pound feet).

3. Install rod seal (3) in gland (1). Rod seal must be

installed so that lips of seal are toward small end 20. Fasten tube (18) in vise. Be careful not to

of gland. Seal can be difficult to install. Use tools damage tube.

that will not damage seal. See illustration on 21. Apply petroleum jelly to O-rings (7) and backup

page 4. ring (6) on gland (1) and to sealing surface in

4. Install rod wiper (2) in gland (1) with wiper lips tube (18).

toward large end of gland. 22. Lubricate piston (9) and inside of tube (18) with

5. clean hydraulic oil.

6. Install O-ring (7) on gland (1). 23. Push the piston (9) straight into tube (18). Be

careful not to damage cast iron ring (10), wear

7. Install backup ring (6) on gland (1). The backup ring (11), and seal (13) on piston (9).

ring must be toward large end of gland. If backup

ring is not flat on both sides, the side that is not 24. When piston (9) is in smooth part of tube (18),

flat must be toward O-ring (7). start gland (1) into tube (18).

8. Fasten piston rod (14) yoke in vise. 25. If the original parts are being assembled:

9. Lubricate piston rod (15) and bore in gland (1) A. Tighten gland to a torque of 339 to 475 Nm

with clean hydraulic oil. (250 to 350 pound-feet).

NOTE: If a new gland (1) is being installed, write B. Install and tighten self-tapping screw (19) to a

part number of cylinder on gland. torque of 2.3 Nm (20 inch-pounds).

10. Push gland (1) onto piston rod (14) large end C. If, after tightening gland, the self-tapping

first. If necessary, use a soft hammer to drive the screw (19) holes are not aligned, a new hole

gland onto piston rod. for self-tapping screw must be drilled. See

Step 26.

11. Put a support below and near the end of piston

rod (14). Put a cloth between support and piston 26. If a new gland (1) or a new tube (18) are being

rod to prevent damaging piston rod. assembled:

12. Install new cast iron ring (10) on piston (9). A. Tighten gland (1) to a torque of 339 to 475 Nm

(250 to 350 pound-feet).

13. Install new wear ring (11) on piston (9).

B. Use a No. 27 drill bit and drill a hole half in

14. Install a new loader ring (12) on piston (9). gland (1) and half in tube (18). Drill to a depth

15. Install a new seal (13) over loader ring (12). of 11 mm (7/16 inch). Do not drill within 13 mm

(1/2 inch) of a hole for gland wrench.

16. Clean the threads on the end of piston rod (14)

and threads of bolt (8) using Loctite cleaning C. Install and tighten self-tapping screw (19) to a

solvent. Allow to dry. Apply Loctite 243 to piston torque of 2.3 Nm (20 inch-pounds).

rod threads 6.4 mm (1/4 inch) from open end of 27. If hoses were removed with cylinder, install new

piston rod so that there is 12.7 mm (1/2 inch) of O-rings, if equipped, on hose fittings. Lubricate

Loctite 243 on piston rod threads. DO NOT apply O-rings with clean oil. Install hoses.

Loctite to first 6.4 mm (1/4/inch) of piston rod

threads.

87551879A Issued 1-07 Printed in E.C.

Copyright

5005-6

NOTES

87551879A Issued 1-07 Printed in E.C.

Copyright

Section

5006

CENTER PIVOT

5006

Copyright 2007 CNH Italia S.p.A.

CNH Italia S.p.A. All rights reserved.

Viale delle Nazioni, 55

41100 Modena Printed in E.C.

Italia 87551879A Issued January, 2007

Copyright

5006-2

TABLE OF CONTENTS

SPECIFICATIONs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CENTER PIVOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CONNECTING THE FRONT FRAME TO THE REAR FRAME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

87551879A Issued 1-07 Printed in E.C.

Copyright

5006-3

SPECIFICATIONS

SPECIAL TORQUES

M16 bolt for upper pivot pin.......................................................................220 to 250 Nm (162 to 184 pound-feet)

M12 bolts for bearing retainers and lower pivot pin ..........................................................124 Nm (91 pound-feet)

M12 bolts for lower pin plate .......................................................................128 to 136 Nm (94 to 100 pound-feet)

Ferry head screws for the drive shaft ................................................................61 to 81 Nm (45 to 60 pound-feet)

LUBRICANT

Pivot bearings and seals ............................................................................... Case AKCELA molydisulfide grease

Steering cylinder rod eyes............................................................................. Case AKCELA molydisulfide grease

SPECIAL TOOLS

CAS10219 ....................................................................................................................... Hand pump (hydraulic ram)

CAS10512 ....................................................................................................................................... 10 ton ram (long)

CAS10592 ........................................................................................................... Puller set, includes 24827 leg ends

CAS10600 ................................................................................Bearing cup and seal puller, includes 24850 adapter

CAS10193 ..............................................................................................................................Vacuum pump (12 volt)

CAS2029 .................................................................................. *Top bearing driver, bottom bearing driver and plate

* (Requires screw, two nuts, and two washers from CAS10592)

BC06A174

CAS2029 DRIVER SET

87551879A Issued 1-07 Printed in E.C.

Copyright

5006-4

CENTER PIVOT

Disassembly 19. Disconnect the supply hose.

1. Remove all dirt and grease from the area of the 20. Install a cap on the hose and a plug in the fitting.

center pivot. Park the machine on a level 21. Stop the vacuum pump.

surface.

22. Loosen and remove the self-locking nut and bolt

2. Lower the bucket until the bucket is flat on the that hold the pivot pin for the steering cylinder

floor. rod eye.

3. Stop the engine and apply the parking brake. 23. Remove the pivot pin from the rear frame and the

4. Remove the covers from both sides of the steering cylinder rod eye.

machine. 24. Remove the washer from the rear frame. Move

5. Disconnect the front wiring harness from the cab the steering cylinder out of the way.

floor. 25. Repeat steps 22, 23 and 24 for the other steering

6. Remove any tie straps that fasten the front wiring cylinder.

harness to the chassis near the center pivot. 26. Loosen and remove the Ferry head screws and

7. Loosen and remove the nut and washer that retainers that fasten the drive shaft to the front

fasten the chassis ground wire and cab ground yoke. Move the drive shaft out of the way.

wire to the studs. 27. Place two stands below and in contact with the

8. Loosen and remove the bolt, lock washer, and front frame.

nut that fasten the clamp on the front wiring 28. Install blocks between the rear axle and the rear

harness to the bracket on the rear frame. Move frame on both sides of the machine to prevent

the front wiring harness out of the way. the rear frame from tipping.

9. Loosen and remove the fill cap for the hydraulic 29. Put a jack in contact with both sides of the rear

reservoir. frame near the center pivot area. Use another

10. Connect a vacuum pump to the hydraulic jack at the rear of the machine to prevent the

reservoir. Start the vacuum pump. rear frame from tipping.

11. Disconnect the brake hose from the backside of 30. Loosen and remove the bolt (1), washer (2), and

front brake line bracket. spacer (3) that fasten the upper pivot pin (4) to

the rear chassis (5).

12. Install a plug in the tube and a cap on the fitting.

31. Use a prybar to remove the upper pivot pin (4).

13. Disconnect the hoses for the steering cylinder.

32. Loosen and remove the bolts (1) and washers

14. Install caps on the fittings and plugs in the hoses. (2) that fasten the lower pin plate (15) to the

15. Loosen and remove the bolts, lock washers, and lower pivot pin (10).

self-locking nuts that fasten the mounting bracket 33. Loosen and remove the bolts (1) and washers

for the hoses to the bracket on the front frame. (2) that fasten the lower pin plate (15) to the

16. Loosen and remove the bolts, flat washers, and bottom of the rear chassis (5).

self-locking nuts that fasten the bracket for the 34. Use the ram and hand pump to remove the lower

hoses to the rear frame. pivot pin (10).

17. Disconnect the return hose. 35. Install the puller on the bottom spacer (14), see

18. Install the cap on the hose and a plug in the Special Tools in this section.

fitting.

87551879A Issued 1-07 Printed in E.C.

Copyright

5006-5

1 2

3

4

5

1

6

2

7

5

8

10

6 9

16 12 11

6

8

13

6

2

14

1

8

15 2

2

1

1

BS03B152

1. BOLT 5. REAR CHASSIS 9. UPPER PIVOT BEARING 13. BEARING RETAINER

2. WASHER 6. SEAL 10. LOWER PIVOT PIN 14. BOTTOM SPACER

3. SPACER 7. BEARING RETAINER 11. LOWER BEARING SPACER 15. LOWER PIN PLATE

4. UPPER PIVOT PIN 8. SHIM 12. LOWER PIVOT BEARING 16. FRONT CHASSIS

CENTER PIVOT ASSEMBLY

87551879A Issued 1-07 Printed in E.C.

Copyright

5006-6

36. Remove the bottom spacer (14). Assembly

37. Release the parking brake. 1. Pack the bearing cones with grease. Be careful

38. Use prybars to turn the left rear wheel backwards not to mix the bearing cones.

and the right rear wheel forward to move the 2. Lubricate the bore in the top pivot with grease.

front of the rear frame to the left for access to the

bearings. Install blocks under the wheels to 3. Install a bearing cup (20) in the top pivot (22).

prevent the rear frame from moving. 4. Install the bearing driver (17) and plate (21).

39. Apply the parking brake.

17 18 19

40. Hold the bearing retainer (13) in place and

loosen and remove the bolts (1) and washers (2)

that fasten the bearing retainer (13) and shims

(8) to the bottom of the rear pivot.

41. Remove the bearing retainer (13) and shims (8).

42. Remove the lower bearing spacer (11) from the

top of the lower pivot.

20

43. Loosen and remove the bolts (1) and washers

21 22

(2) that fasten the bearing retainer (7) and shims

(8) to the top of the top pivot. BC06A118

44. Remove the bearing retainer (7) and shims (8). 17. BEARING DRIVER 20. BEARING CUP

18. NUT 21. PLATE

45. Use the puller to remove the seal (6) from the top 19. SREW 22. TOP PIVOT

of the bottom pivot.

5. Tighten a nut (18) on the screw (19) until the

46. Use the puller to remove the seal (6) from the bearing cup (20) is seated in the bore of the top

bottom of the top pivot. pivot (22). Remove the bearing driver (17) and

plate (21) from the top pivot (22).

47. Use an acceptable driver, the hydraulic ram, and

the hand pump to remove the upper pivot 6. Install a bearing cone (25), spacer (24), the other

bearing (9) from the top pivot. See Special Tools bearing cone (23), and the remaining bearing

in this section. cup (26) in the top pivot (22).

NOTE: The spacers are matched to the bearing 7. Install the bearing driver (17) and plate (21).

sets. Do not mix the spacers. Do not use the old

8. Tighten a nut (18) on the screw (19) until the

spacers if new bearing sets are being installed.

bearing cup (26) is seated against the spacer

48. Use an acceptable driver, the hydraulic ram, and (24). Remove the bearing driver (17) and plate

the hand pump to remove the lower pivot bearing (21) from the top pivot (22).

(12) from the bottom pivot. See Special Tools in

this section. 17 18 19

23

NOTE: The spacers are matched to the bearing 26

sets. Do not mix the spacers. Do not use the old 24

spacers if new bearing sets are being installed.

49. Use an acceptable driver to press the seal (6) out

of each bearing retainer (7 and 13).

25

21 22

BC06A119

23. BEARING CONE 25. BEARING CONE

24. SPCAER 26. BEARING CUP

87551879A Issued 1-07 Printed in E.C.

Copyright

5006-7

9. Put the bearing retainer (7) in place on the upper 18. Use an acceptable driver to install the seal (6) in

pivot bearing assembly (9). the bottom of the top pivot.

10. Install the bearing driver (17) and plate (21). 19. The bottom of the seal (6) must be even with the

bottom of the top pivot.

11. Tighten a nut (18) on the screw (19) until the

bearing retainer (7) is tight against the upper

pivot bearing assembly (9).

17 18 19 27

7

BC06A125.

21 22 20. Apply grease to the upper pivot pin (4).

BC06A120 21. Install the upper pivot pin (4) in the top pivot.

12. Measure the gap (27) between the bearing

22. Lubricate the top pivot until grease is forced out

retainer (7) and the top pivot (22). Make a record

of the seal (6).

of the measurement. Subtract 0.0762 to 0.1016

mm (0.003 to 0.004 inch) from the measurement. 23. Rotate the upper pivot pin (4) to check the

Select shims (8) equal to that value. bearing assembly. The upper pivot pin (4) must

rotate smoothly, but not easily. Leave the upper

13. Remove the bearing driver (17), plate (21), and

pivot pin (4) in place to keep dirt out of the upper

bearing retainer (7) from the top pivot.

pivot bearing (9).

14. Install the shims (8) and the bearing retainer (7).

24. Lubricate the bore for the bottom pivot with

15. Install the washers (2) and bolts (1). Tighten the grease. Install a bearing cup in the bottom pivot.

bolts (1) to 124 Nm (91 pound-feet).

25. Install the bearing driver (17) and plate (21).

16. Install the seal (6) in the bearing retainer (7). The

top of the seal (6) must be even with the top of 19

the bearing retainer (7). 21

18

28

29

17

BC06A123

26. Tighten a nut (18) on the screw (19) until the

bearing cup (28) is seated in the bore in the

BC06A121 bottom pivot (29).

17. Fill the other seal (6) for the top pivot with

27. Remove the bearing driver (17) and plate (21)

grease.

from the bottom pivot (29).

28. Install a bearing cone (25), spacer (24), the other

bearing cone (23), and the remaining bearing

cup (26) in the bottom pivot (29).

29. Install the bearing driver (17) and plate (21).

87551879A Issued 1-07 Printed in E.C.

Copyright

5006-8

40. Install the seal (6) in the bearing retainer (13).

21 18 19 The bottom of the seal (6) must be even with the

25 bearing retainer (13).

24

29

23 26

17

BC06A124

30. Tighten a nut (18) on the screw (19) until the

bottom bearing cup (26) is seated against the

spacer (24). BC06A126

41. Install the other seal (6) in the bottom pivot. The

31. Remove the bearing driver (17) and plate (21)

top of the seal (6) must be even with the top of

from the bottom pivot (29).

the bottom pivot.

32. Put the bearing retainer (13) in place on the

lower pivot bearing (12).

33. Install the bearing driver and plate.

21 18 19

29

12 30

BC06A121

13 42. Install the lower bearing spacer (11) and the

17 bottom spacer (14).

BC06A125 43. Apply grease to the lower pivot pin (10).

34. Tighten a nut (18) on the screw (19) until the

44. Install the lower pivot pin (10) in the bottom pivot.

bearing retainer (13) is tight against the lower

pivot bearing assembly (12). 45. Hold the bottom spacer (14) in place and

lubricate the bottom pivot until grease is forced

35. Measure the gap (30) between the bearing

out of the seal (6).

retainer (13) and the bottom pivot (29). Make a

record of the measurement. Subtract 0.0762 to 46. Rotate the lower pivot pin (10) to check the

0.1016 mm (0.003 to 0.004 inch) from the bearing assembly. The lower pivot pin (10) must

measurement. Select shims (8) equal to that rotate smoothly, but not easily.

value.

47. Remove the lower pivot pin (10) and the upper

36. Remove the bearing driver (17), plate (21) and pivot pin (4).

bearing retainer (13) from the bottom pivot.

48. Remove the bottom spacer (14).

37. Install the shims (8), the bearing retainer (13),

washers (2) and bolts (1).

38. Tighten the bolts (1) to 124 Nm (91 pound-feet).

39. Fill the seal (6) for the bearing retainer (13) with

grease.

87551879A Issued 1-07 Printed in E.C.

Copyright

5006-9

CONNECTING THE FRONT FRAME TO THE REAR FRAME

1. Release the parking brake. 26. Align the hole in the pivot pin with the holes in the

2. Move the rear frame into alignment with the front steering cylinder rod eye, and install the pivot

frame. pin.

3. Move the steering cylinders as required to move 27. Install the bolt and self-locking nut that hold the

the rear frame into alignment with the front pivot pin.

frame. 28. Repeat steps 25, 26 and 27 for the other steering

4. Apply the parking brake. cylinder.

5. Apply grease to the upper pivot pin (4). 29. Start the vacuum pump.

6. Install the upper pivot pin (4), spacer (3), washer 30. Connect the return hose.

(2) and bolt (1). Be careful not to damage the 31. Connect the supply hose.

seal (6). 32. Put the bracket for the hoses in position on the

7. Tighten the bolt (1) to 220 to 250 Nm (162 to 184 rear frame. Install the bolts, flat washers, and

pound-feet). self-locking nuts that fasten the bracket to the

8. Apply grease to the lower pivot pin (10). rear frame.

9. Install the lower pivot pin (10) in the frames. Be 33. Put the bracket for the hoses in position on the

careful not to damage the seal (6). front frame.

10. Use the ram and hand pump to install the bottom 34. Install the bolts, flat washers, and self-locking

spacer (14). See Special Tools in this section. nuts that fasten the bracket to the front frame.

11. Install the lower pin plate (15), three inner bolts 35. Connect the hoses for the steering cylinders.

(1), and washers (2) that fasten the lower pin 36. Connect the brake hose for the front brakes at

plate (15) to the lower pivot pin (10). the front bracket.

12. Tighten the bolts (1) to 69 Nm (51 pound-feet). 37. Stop the vacuum pump.

13. Measure the gap between the lower pin plate 38. Connect the front wiring harness to the rear

(15) and the bottom pivot. Make a record of the wiring harness.

measurement. Subtract 0.0762 to 0.1016 mm 39. Put the clamp on the wiring harness in position

(0.003 to 0.004 inch) from the measurement. on the bracket. Install the bolt, lock washer, and

Select shims equal to that value. nut that fasten the clamp on the wiring harness to

14. Loosen the bolts (1) that fasten the lower pin the bracket.

plate (15) to the lower pivot pin (10). 40. Put the ground wire in position on the stud. Install

15. Start the six outer bolts (1) into the lower pin the washer and nut that fasten the ground wire to

plate (15) and the bottom pivot. the stud.

16. Install the shims (8). 41. Install a tie strap to fasten the wiring harness to

17. Tighten the six outer bolts (1) to 128 to 136 Nm the tube.

(94 to 100 pound-feet). 42. Disconnect the vacuum pump from the hydraulic

18. Tighten the three inner bolts (1) to 124 Nm (91 reservoir.

pound-feet). 43. Check the fluid level in the hydraulic reservoir.

19. Remove the jacks from the rear frame. Add oil as required.

20. Remove the blocks from the rear axle. 44. Install the fill cap in the hydraulic reservoir.

21. Remove the stands from the front frame. 45. Bleed air from the front axle bleed screws. Refer

to Section 7002 for complete brake bleeding

22. Put the drive shaft in position on the front yoke. instructions.

23. Install new Ferry head screws that fasten the 46. Lubricate the pivot pins for the steering cylinder

drive shaft to the front yoke. rod eyes.

24. Tighten the Ferry head screws to 61 to 81 Nm 47. Install the covers on both sides of the machine.

(45 to 60 pound-feet).

25. Put the steering cylinder rod eye in position in the

frame. Install the washer between the steering

cylinder rod eye and the rear frame.

87551879A Issued 1-07 Printed in E.C.

Copyright

5006-10

NOTES

87551879A Issued 1-07 Printed in E.C.

Copyright

Section

5008

AUXILIARY STEERING MOTOR AND PUMP

5008

Copyright 2007 CNH Italia S.p.A.

CNH Italia S.p.A. All rights reserved.

Viale delle Nazioni, 55

41100 Modena Printed in E.C.

Italia 87551879A Issued January, 2007

Copyright

5008-2

TABLE OF CONTENTS

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

AUXILIARY STEERING MOTOR AND PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

87551879A Issued 1-07 Printed in E.C.

Copyright

5008-3

SPECIFICATIONS

Auxiliary steering motor

Maximum amperes...............................................................................................................................30 amperes

Minimum armature speed ............................................................................................................ 6950 r/min (rpm)

Motor .......................................................................................................................................................... 24 volts

Auxiliary steering pump

Minimum flow ..............................................................................................24.6 L/min at 104 bar at 315 amperes

(6.5 U.S. gpm at 1500 psi at 315 amperes)

87551879A Issued 1-07 Printed in E.C.

Copyright

5008-4

AUXILIARY STEERING MOTOR AND PUMP

Disassembly Assembly

NOTE: Refer to Section 5001 for removal and 1. Lubricate all parts with clean hydraulic oil before

installation of the auxiliary steering motor and pump. assembly.

NOTE: The pump is the only component that is 2. Lubricate and install a new seal (4) and retaining

disassembled. The switch (8) and motor (1) are ring (3) on the plate (17). Refer to the illustration

replaced as units and are not serviced. Refer to the on page 5.

illustration on page 5.

3. Lubricate and install a new backup ring (5) and a

1. Make an alignment mark on the pump assembly new seal (6) on the plate (17).

and motor (1).

4. Lubricate and install new O-rings (7) on the body

2. Loosen and remove the two screws (15) and lock (18).

washers (14) that hold the pump assembly to the

5. Lubricate and install the pins (22), drive gear

motor (1).

(20), driven gear (19) and wear plates (23) on the

3. Remove and discard the mounting gasket (13), body (18).

retaining ring (3) and seal (4) from the pump

6. Lubricate and install a new backup ring (5) and a

assembly.

new seal (6) on the end plate (21).

4. Loosen and remove the four bolts (2) that hold

7. Align the marks, made during disassembly, on

the pump assembly together.

the end plate (21), body (18) and plate (17) and

5. Remove the end plate (21) from the body (18). install the four bolts (2). Tighten the four bolts (2).

6. Remove and discard the seal (6) and backup 8. Install a new gasket (13) on the pump assembly.

ring (5) from the end plate (21).

9. Align the marks, made during disassembly, on

7. Remove the wear plate (23), drive gear (20) and the pump assembly and the motor (1).

driven gear (19) from the body (18).

10. Install the lock washer (14) and screw (15).

8. Remove the body (18) from the plate (17). Torque the screw (15) to 35 to 39 Nm (312 to

348 pound-inches).

9. Remove and discard the O-rings (7) from the

body (18).

10. Remove the pins (22) and wear plate (23) from

the body (18).

11. Remove and discard the seal (6) and backup

ring (5) from the plate (17).

NOTE: The only serviceable items on the pump

assembly are the seals (6), backup rings (5), O-rings

(7), seal (4), retaining ring (3) and gasket (13). If any

of the other items are damaged, replace the pump

assembly.

Inspection

1. Inspect the wear plates (23) for grooves, scoring

and pitting. If damage is found replace the pump

assembly. Refer to the illustration on page 5.

2. Inspect the drive gear (20) and driven gear (19).

If the shafts are worn or damaged, replace the

pump assembly.

3. Clean all parts in cleaning solvent and air dry.

4. Inspect the plate (17), end plate (21) and body

(18). Replace the pump assembly as necessary.

87551879A Issued 1-07 Printed in E.C.

Copyright

5008-5

10 8

9

11

12 16

13

3 17

4 14

15

5

6

23

19

7

22

18

22

7

20

23

6

5

21

2

BS01C121

1. MOTOR 7. O-RING 13. GASKET 19. DRIVEN GEAR

2. BOLT 8. SWITCH 14. LOCK WASHER 20. DRIVE GEAR

3. RETAINING RING 9. CABLE 15. SCREW 21. END PLATE

4. SEAL 10. SCREW 16. WIRE 22. PINS

5. BACKUP RING 11. LOCK WASHER 17. PLATE 23. WEAR PLATE

6. SEAL 12. WASHER 18. BODY

AUXILIARY STEERING PUMP AND MOTOR ILLUSTRATION

87551879A Issued 1-07 Printed in E.C.

Copyright

5008-6

NOTES

87551879A Issued 1-07 Printed in E.C.

S-ar putea să vă placă și

- Any ThingDocument40 paginiAny ThingMohamed HarbÎncă nu există evaluări

- Nikon d7000 SMDocument198 paginiNikon d7000 SMWorking FotografiasÎncă nu există evaluări

- Master 07 Threshing and Separating PDFDocument274 paginiMaster 07 Threshing and Separating PDFSergey BashtoviyÎncă nu există evaluări

- Smartweight Pro® Series Wheel Balancer: Service InstructionsDocument52 paginiSmartweight Pro® Series Wheel Balancer: Service InstructionsENT ENT100% (1)

- Case Cx290b Crawler Excavator Shop ManualDocument20 paginiCase Cx290b Crawler Excavator Shop Manualjames100% (51)

- MPE060 e 080 SISTEMA ELÉTRICO M524274703-2200YRM1287 - (11-2006) - US-EN-1Document28 paginiMPE060 e 080 SISTEMA ELÉTRICO M524274703-2200YRM1287 - (11-2006) - US-EN-1Eldelson BaggetoÎncă nu există evaluări

- Repair Instructions: Zf-Ecolite 6 S 500 BO Level 3Document104 paginiRepair Instructions: Zf-Ecolite 6 S 500 BO Level 3Cleiton aviÎncă nu există evaluări

- EMCS-ST Operating-Instr 2020-04a 8123668g1Document86 paginiEMCS-ST Operating-Instr 2020-04a 8123668g1Jose ChuyÎncă nu există evaluări

- Service Manual: 721F Tier 4Document305 paginiService Manual: 721F Tier 4Douglas RodriguezÎncă nu există evaluări

- Fsu PDFDocument16 paginiFsu PDFМиша ШаулаÎncă nu există evaluări

- Epiroc Safety and Operating Instructions MBDocument64 paginiEpiroc Safety and Operating Instructions MBLuka BornaÎncă nu există evaluări

- Mitsubishi EVO I-III Installation ManualDocument18 paginiMitsubishi EVO I-III Installation ManualLeiden O'SullivanÎncă nu există evaluări

- Air Conditioning - Heater System 1Document45 paginiAir Conditioning - Heater System 1Bernardo OlivaÎncă nu există evaluări

- RM 6Document39 paginiRM 6Cristian CatalánÎncă nu există evaluări

- 2098-9650 Installation & Operating ManualDocument24 pagini2098-9650 Installation & Operating ManualRickÎncă nu există evaluări

- EVO8XDocument20 paginiEVO8XaubertinadelacruzalzamoraÎncă nu există evaluări

- Operators Instructions Boomer 281-DC10Document89 paginiOperators Instructions Boomer 281-DC10sivaguruk280% (10)

- Installation Manual - ClimateWell SolarChiller - v9 - 33 - 4 - ENDocument31 paginiInstallation Manual - ClimateWell SolarChiller - v9 - 33 - 4 - ENtxaelo100% (1)

- Yale Mpe 060vg - (A292) Lift Truck Service Repair ManualDocument35 paginiYale Mpe 060vg - (A292) Lift Truck Service Repair ManualSul Bases GustavoÎncă nu există evaluări

- ACME DrytypeDistributionTransformers Question&AnswersDocument52 paginiACME DrytypeDistributionTransformers Question&AnswersJÎncă nu există evaluări

- Manual Kato GeneradorDocument48 paginiManual Kato Generadorgilen30Încă nu există evaluări

- Kato Manual 1Document50 paginiKato Manual 1francisco6jav-885612Încă nu există evaluări

- Instruction Manual: Installation Operation Maintenance Motor-Generator SetDocument28 paginiInstruction Manual: Installation Operation Maintenance Motor-Generator SetEslam SadekÎncă nu există evaluări

- 02 VIENTO INSTALLATION-Rev - Eng PRELIM PDFDocument56 pagini02 VIENTO INSTALLATION-Rev - Eng PRELIM PDFwhidow1973100% (1)

- Maxx9 Service Manual PDFDocument901 paginiMaxx9 Service Manual PDFChristopher Anderson75% (8)

- Link G4+ PNP PDFDocument27 paginiLink G4+ PNP PDFSinkar YeeÎncă nu există evaluări

- InstalacionDocument32 paginiInstalacionJuan carlos Isaza gÎncă nu există evaluări

- Axle 112Document163 paginiAxle 112Francisco Javier Lopez Barranco100% (2)

- Landini Mistral America 40-45-50 Tractor Workshop Service Repair Manual 1Document462 paginiLandini Mistral America 40-45-50 Tractor Workshop Service Repair Manual 1Kemal Lisnik Arnautovic60% (10)

- Kato Instruction Manual350 01001 00Document49 paginiKato Instruction Manual350 01001 00corsini999Încă nu există evaluări

- Case Cx700 Tier3 Crawler Excavator Shop ManualDocument20 paginiCase Cx700 Tier3 Crawler Excavator Shop ManualEric100% (49)

- Air Flex - ClutchDocument34 paginiAir Flex - ClutchJuan Gustavo GuillermoÎncă nu există evaluări

- SM 721D - DXT 4 ENDocument214 paginiSM 721D - DXT 4 ENEdmilson RibeiroÎncă nu există evaluări

- Cat 943 EnsambleDocument134 paginiCat 943 Ensamblejose luis juarezÎncă nu există evaluări

- JZX100Document21 paginiJZX100สาโรจน์Încă nu există evaluări

- IPSXM3136 2 Installation ManualDocument20 paginiIPSXM3136 2 Installation ManualdreicouÎncă nu există evaluări

- UseMaintanceManual IvecoGenSets P4D63Z001E July2005 PDFDocument47 paginiUseMaintanceManual IvecoGenSets P4D63Z001E July2005 PDFmanuel segoviaÎncă nu există evaluări

- C110D6Document62 paginiC110D6mario saavedra tarazona100% (1)

- Navistar, Inc.: 2701 Navistar Drive, Lisle, IL 60532 USADocument1.135 paginiNavistar, Inc.: 2701 Navistar Drive, Lisle, IL 60532 USAMinh VũÎncă nu există evaluări

- EVO4 To 8 LINKECUDocument25 paginiEVO4 To 8 LINKECUFred RobertsÎncă nu există evaluări

- Case Cx330 Tier3 Crawler Excavator Shop ManualDocument20 paginiCase Cx330 Tier3 Crawler Excavator Shop Manualmichael100% (34)

- Prostar Service ManualDocument2.963 paginiProstar Service Manualbrucken1987100% (2)

- Service Instructions for VST-SE Actuator Disassembly and ReassemblyDocument1 paginăService Instructions for VST-SE Actuator Disassembly and ReassemblyAhmadÎncă nu există evaluări

- TTL 750 Installation Manual Rev EDocument57 paginiTTL 750 Installation Manual Rev EFso servicio tecnico 2021Încă nu există evaluări

- Art. No. 3206121en: Downloaded From Manuals Search EngineDocument235 paginiArt. No. 3206121en: Downloaded From Manuals Search EnginePhepheronÎncă nu există evaluări

- Installer Manual-0Document80 paginiInstaller Manual-0Syed Hussain DanishÎncă nu există evaluări

- Rev1Document92 paginiRev1RAFAEL RAMÍREZ JURADOÎncă nu există evaluări

- Rockdrill HL650Document74 paginiRockdrill HL650Luis Josue100% (1)

- New Holland E805 Tier 3 Crawler Excavators Service Repair ManualDocument21 paginiNew Holland E805 Tier 3 Crawler Excavators Service Repair ManualggjjjjotonesÎncă nu există evaluări

- 2820 CraneDocument77 pagini2820 CraneGOLAM NADVIRÎncă nu există evaluări

- 9853 1206 01 Overhauling Instructions COP 1238KDocument55 pagini9853 1206 01 Overhauling Instructions COP 1238Kbundajoseph148Încă nu există evaluări

- WSM U17-3Document48 paginiWSM U17-3江宗朋Încă nu există evaluări

- XAP Series Busduct Storage, Installation, and Maintenance: Instruction Booklet IBDocument9 paginiXAP Series Busduct Storage, Installation, and Maintenance: Instruction Booklet IBUmerÎncă nu există evaluări

- Case Crawler Excavator cx75sr cx80 Tier 3 Service Manual PDF FreeDocument630 paginiCase Crawler Excavator cx75sr cx80 Tier 3 Service Manual PDF FreeBoss kevin100% (1)

- YALE A888 ERP12RCF LIFT TRUCK Service Repair Manual PDFDocument8 paginiYALE A888 ERP12RCF LIFT TRUCK Service Repair Manual PDFsekfsekmdddeÎncă nu există evaluări

- Midmark Dental Chair Service and Parts ManualDocument102 paginiMidmark Dental Chair Service and Parts ManualMohammed AhmedÎncă nu există evaluări

- Teardowns: Learn How Electronics Work by Taking Them ApartDe la EverandTeardowns: Learn How Electronics Work by Taking Them ApartÎncă nu există evaluări

- The Crafty Kids Guide to DIY Electronics: 20 Fun Projects for Makers, Crafters, and Everyone in BetweenDe la EverandThe Crafty Kids Guide to DIY Electronics: 20 Fun Projects for Makers, Crafters, and Everyone in BetweenÎncă nu există evaluări

- South Africa’s Renewable Energy IPP Procurement ProgramDe la EverandSouth Africa’s Renewable Energy IPP Procurement ProgramÎncă nu există evaluări

- Section: I BodyDocument6 paginiSection: I BodyMohamed HarbÎncă nu există evaluări

- Main Control Valve Axle Cooling: 980H Wheel Loader Hydraulic SystemDocument2 paginiMain Control Valve Axle Cooling: 980H Wheel Loader Hydraulic SystemMohamed Harb100% (1)

- FSU f16Document16 paginiFSU f16Mohamed HarbÎncă nu există evaluări

- FSU f16Document16 paginiFSU f16Mohamed HarbÎncă nu există evaluări

- Combinational Circuits: Combinational Plds (Programmable Logic Devices) Basic Configuration of Three PldsDocument20 paginiCombinational Circuits: Combinational Plds (Programmable Logic Devices) Basic Configuration of Three PldsMohamed HarbÎncă nu există evaluări

- 66f2 PDFDocument9 pagini66f2 PDFMohamed HarbÎncă nu există evaluări

- MA NissanDocument40 paginiMA NissanMohamed HarbÎncă nu există evaluări

- IP NissanDocument14 paginiIP NissanMohamed HarbÎncă nu există evaluări

- Parking Brake System: SectionDocument4 paginiParking Brake System: SectionTuralÎncă nu există evaluări

- 2 1Document21 pagini2 1المهندسوليدالطويلÎncă nu există evaluări

- Nissan Sentra N16 Body and TrimDocument82 paginiNissan Sentra N16 Body and TrimYong Siang67% (3)

- ECEN 248 - Introduction To Digital Systems Design (Spring 2008) (Sections: 501, 502, 503, 507)Document21 paginiECEN 248 - Introduction To Digital Systems Design (Spring 2008) (Sections: 501, 502, 503, 507)Vipula RawteÎncă nu există evaluări

- LU NissanDocument22 paginiLU NissanMohamed HarbÎncă nu există evaluări

- c7 ACERT PDFDocument2 paginic7 ACERT PDFMohamed Harb100% (1)

- Liebherr 120Document78 paginiLiebherr 120Mohamed Harb100% (1)

- Clutch Section 5c-025Document25 paginiClutch Section 5c-025Mohamed HarbÎncă nu există evaluări

- Caterpillar 938g Loader SchematicDocument10 paginiCaterpillar 938g Loader SchematicMahmoud Elbakry100% (4)

- Electric Circuit PDFDocument2 paginiElectric Circuit PDFMohamed HarbÎncă nu există evaluări

- Electric Circuit PDFDocument2 paginiElectric Circuit PDFMohamed HarbÎncă nu există evaluări

- Reconfigurable Digital Circuits and Memory OrganizationDocument11 paginiReconfigurable Digital Circuits and Memory OrganizationMohamed HarbÎncă nu există evaluări

- Pal Unit PDFDocument11 paginiPal Unit PDFMohamed HarbÎncă nu există evaluări