Documente Academic

Documente Profesional

Documente Cultură

Section A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)

Încărcat de

sebaversaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Section A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)

Încărcat de

sebaversaDrepturi de autor:

Formate disponibile

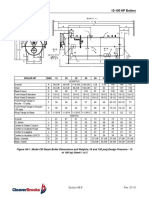

Model CBLE 100-800 HP Boilers

SECTION A1

MODEL CB-LE STEAM BOILER SPECIFICATIONS

(125-800 HP, STEAM 15-300 PSIG)

SAMPLE SPECIFICATIONS (STEAM)

CONTENTS

PART 1 GENERAL ....................................................................................................................................... A1-45

1.1 Boiler Characteristics (Steam) ............................................................................................................ A1-45

1.2 General Boiler Design......................................................................................................................... A1-45

PART 2 PRODUCTS .................................................................................................................................... A1-45

2.1 Boiler Shell (Steam) ............................................................................................................................ A1-45

2.2 Steam Boiler Trim ............................................................................................................................... A1-46

2.3 Burner and Controls............................................................................................................................ A1-47

2.4 Boiler Controls and Control Panel ...................................................................................................... A1-50

2.5 Efficiency Guarantee .......................................................................................................................... A1-53

2.6 Warranty ............................................................................................................................................. A1-53

2.7 Performance Criteria:.......................................................................................................................... A1-54

PART 3 EXECUTION ................................................................................................................................... A1-55

3.1 Shop Tests .......................................................................................................................................... A1-55

3.2 Start-up Service .................................................................................................................................. A1-55

Section A1-44 Rev. 09-09

Model CBLE 100-800 HP Boilers

MODEL CB-LE STEAM BOILER SPECIFICATIONS

(125-800 HP, STEAM 15-300 PSIG)

PART 1 GENERAL

The LE Option specification includes information on the base low emissions package for

60 or 30 ppm NOx (dry volume basis and corrected to 3% O2) when firing natural gas.

For assistance in specifying, or for information on NOx levels below 30 ppm, please

contact your local Cleaver-Brooks authorized representative.

Model CB-LE Steam Boiler (125-800 hp, Steam 15-300 psig)

1.1 Boiler Characteristics (Steam)

A. The Steam Boiler shall be Cleaver-Brooks Model CB, Fuel Series _____ (100, 200,

700), _____ hp designed for _____ psig (15, 150, 200, or other psig steam). The

maximum operating pressure shall be _____ psig.

B. The boiler shall have a maximum output of _____ Btu/hr, or _____ horsepower when

fired with CS 12-48 _____ oil and/or natural gas, _____ Btu/cu-ft. Electrical power

available will be _____ Volt _____ Phase _____ Cycle.

1.2 General Boiler Design

A. The boiler shall be a four pass horizontal firetube updraft boiler with five (5) square

feet (except 750 or 800 hp) of heating surface per rated boiler horsepower. It shall be

mounted on a heavy steel frame with integral forced draft burner and burner controls.

1. The boiler shall be completely preassembled and fire tested at the factory. The

unit shall be ready for immediate mounting on floor or simple foundation and

ready for attachment of water, steam, fuel, electrical, vent and blowdown

connections.

2. The boiler shall be built to comply with the following insurance and codes _____

(Factory Mutual, GE-GAP Insurance, ASME CSD-1).

PART 2 PRODUCTS

Notice

The complete package boiler shall be approved as a unit by Underwriters

Laboratories and shall bear the UL/ULC label, except in the case where 50 Hz has

been selected.

2.1 Boiler Shell (Steam)

A. The boiler shell must be constructed in accordance with ASME Boiler Code and must

receive authorized boiler inspection prior to shipment. A copy of the inspection report

shall be furnished to the purchaser.

B. Two lifting eyes shall be located on top of the boiler.

C. Front and rear doors on the boiler shall be hinged or davited. Doors are to be sealed

with fiberglass tadpole gaskets and fastened tightly using heavy capscrews that

thread into replaceable brass nuts.

Section A1-45 Rev. 09-09

Model CBLE 100-800 HP Boilers

D. Rear refractory and insulation shall be contained in the formed door, which must

swing open for inspection of brick work.

E. The boiler tubes shall not include turbulators, swirlers or other add-on

appurtenances.

F. Front and rear tube sheets and all flues must be fully accessible for inspection and

cleaning when the doors are swung open. The boiler shall be furnished with

adequate handholes to facilitate boiler inspection and cleaning.

G. For boilers 125 horsepower and over, a manhole shall be provided.

H. The exhaust gas vent shall be located near the front of the boiler on the top center

line and shall be capable of supporting:

1. 15-100 hp. 1000 lbs and shall contain a stack thermometer

2. 125-800 hp. 2000 lbs and shall contain a stack thermometer

I. The boiler shell shall contain a chemical feed connection.

J. Observation ports for the inspection of flame conditions shall be provided at each end

of the boiler.

K. The boiler insulation shall consist of a 2 inch blanket under a sectional preformed

sheet metal lagging. This insulation must be readily removable and capable of being

reinstalled, if required.

L. The entire boiler base frame and other components shall be factory painted before

shipment using a hard finish enamel coating.

2.2 Steam Boiler Trim

A. Water Column

A water column shall be located on the right hand side of the boiler complete with

gauge glass set and water column blowdown valves.

1. Feedwater Pump Control

The boiler feedwater pump control shall be included as an integral part of the

water column to automatically actuate a motor driven feed water pump

maintaining the boiler water level within normal limits.

2. WATER COLUMN/LOW WATER CUTOFF AND WATER LEVEL CONTROL

SYSTEM (150-250 psig design):

Shall be a CB LEVEL MASTER Water level control system and shall be

comprised of a microprocessor-based electronic controller, a non-contact, non-

wearing, continuously reading absolute level sensor and pressure chamber. The

control system shall be designed as follows: The electronic controller shall be

mounted in the common control panel (see 2.4 below) and operate in ambient

temperatures from 32 degrees F to 125 degrees F. The pressure chamber shall

be boiler mounted and operate to pressures of 250 PSIG and the level sensor

shall operate to pressures of 250 PSIG and temperatures to 400 degrees F. The

pressure-containing components shall be constructed in accordance with ASME

Code. A shielded, four conductor cable with ground shall be run in metal conduit

between the level sensor and the controller. Supply power shall be 115VAC-1

phase- 60 Hz. All wiring shall be in compliance with the National Electrical Code.

The pressure chamber shall have a sight glass mounted on the side. The level

sensor shall have an accuracy of .01" or greater. The electronic controller shall

have level and error indicating lights, alphanumeric display for messaging, reset/

menu switch and the following features:

a. Continuous Level Indication

Section A1-46 Rev. 09-09

Model CBLE 100-800 HP Boilers

b. Low Water Cutoff & Alarm

c. High Water Alarm

d. Low & High Water Warning

e. Full Modulating Control of Modulating Feedwater Control Valve

f. Continuous Monitoring of Float Operation

g. Column Blowdown Detection and Reminder

h. Auto or Manual Reset

i. Real Time Clock

j. Alarm Annunciation

k. Alarm History Files with Time Stamp

l. Water Column Blowdown Record

m. Auxiliary Low Water Cutoff Check

n. RS 232 Interface

o. Maximum Contacts Rating 15 amps Resistive Load

3. Low Water Cutoff (15 psig design)

The low water cutoff shall be included as an integral part of the boiler feedwater

control wired into the burner control circuit to prevent burner operation if the

boiler water level falls below a safe level.

B. Auxiliary Low Water Cutoff

Auxiliary low water cutoff manual reset shall be included, piped to the vessel, and

wired to the burner control circuit. A manual reset device shall be used on this

control.

C. Steam Pressure Gauge

The steam pressure gauge shall be located at the front of the boiler and include cock

and test connection.

D. Safety Valves

Safety valves of a type and size to comply with ASME Code requirements shall be

shipped loose.

E. Steam Pressure Controls

The steam pressure controls to regulate burner operation shall be mounted near the

water column. Controls shall be a high limit (manual reset), operating limit (auto

reset), and firing rate control (30-800 hp).

2.3 Burner and Controls

A. Mode of Operation

Burner operation shall be full modulation principle. The burner shall always return to

low fire position for ignition.

B. Blower

1. Air for combustion shall be supplied by a forced draft blower mounted in the front

boiler door, above the burner, to eliminate vibration and reduce noise level.

2. Maximum sound level of the boiler/burner package shall not exceed _____ dbA

(when measured in accordance with ABMA Sound Test Standards).

3. The impeller shall be cast aluminum, radial blade, carefully balanced, and directly

connected to the blower motor shaft.

Section A1-47 Rev. 09-09

S-ar putea să vă placă și

- Tech Spec For Plate Heat ExchangersDocument37 paginiTech Spec For Plate Heat ExchangersSHIVAJI CHOUDHURY50% (2)

- Specification ChillerDocument28 paginiSpecification Chillermishtinil100% (1)

- FBC/FBD Fulton Horizontal BoilersDocument58 paginiFBC/FBD Fulton Horizontal BoilersMara Liceo100% (1)

- Exploring Science Edition © Pearson Education Limited 2008Document2 paginiExploring Science Edition © Pearson Education Limited 2008Victor Barber SanchisÎncă nu există evaluări

- Husk Based Power Plant 6T 32 KG FBC With Single Stage Turbine - For Finance, Subsidy & Project Related Support Contact - 9861458008Document28 paginiHusk Based Power Plant 6T 32 KG FBC With Single Stage Turbine - For Finance, Subsidy & Project Related Support Contact - 9861458008Radha Krishna SahooÎncă nu există evaluări

- Steam Boiler Spec.Document17 paginiSteam Boiler Spec.bandithaguru6338100% (1)

- ASB Boiler CatalogueDocument12 paginiASB Boiler CatalogueJivaAliÎncă nu există evaluări

- Husky Hypet 400Document148 paginiHusky Hypet 400Bir Kamaldeep Singh100% (7)

- 02 - Relay Performance TestingDocument46 pagini02 - Relay Performance TestingHassan TahaÎncă nu există evaluări

- Spec Modelcble Steam Mar4Document12 paginiSpec Modelcble Steam Mar4Jason PoloÎncă nu există evaluări

- Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Document12 paginiModel Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Diogenes Rafael TorresÎncă nu există evaluări

- SPEC ModelCBR Steam Mar4Document10 paginiSPEC ModelCBR Steam Mar4Jason PoloÎncă nu există evaluări

- SPEC Model CB Steam Jan11Document12 paginiSPEC Model CB Steam Jan11Stanford BrownÎncă nu există evaluări

- Section A1 Model Cb-Le Hot Water Specifications (125-800 HP, 30 PSIG, 125 PSIG)Document4 paginiSection A1 Model Cb-Le Hot Water Specifications (125-800 HP, 30 PSIG, 125 PSIG)sebaversaÎncă nu există evaluări

- Section A5: Model CBL 900-1800 HP BoilersDocument5 paginiSection A5: Model CBL 900-1800 HP BoilerssebaversaÎncă nu există evaluări

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Document5 paginiModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaÎncă nu există evaluări

- Boiler SpecificationsDocument25 paginiBoiler Specificationspaul kioiÎncă nu există evaluări

- General: Model ICB 100-800 HP BoilersDocument4 paginiGeneral: Model ICB 100-800 HP BoilerssebaversaÎncă nu există evaluări

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 paginiModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaÎncă nu există evaluări

- CB CBLE HW SpecsDocument11 paginiCB CBLE HW SpecsDiogenes Rafael TorresÎncă nu există evaluări

- Model 4WI 100 - 800 HP Boilers: WarrantyDocument4 paginiModel 4WI 100 - 800 HP Boilers: WarrantysebaversaÎncă nu există evaluări

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 paginiModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaÎncă nu există evaluări

- AIA Boiler Specification CM2 v1.2 Master Spec PDFDocument11 paginiAIA Boiler Specification CM2 v1.2 Master Spec PDFbotosionÎncă nu există evaluări

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocument4 paginiModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaÎncă nu există evaluări

- CSI Spec EXN-SGO-07Document5 paginiCSI Spec EXN-SGO-07davidvranaÎncă nu există evaluări

- Bfit Model BFIT Condensing Hot Water Boiler SpecificationDocument8 paginiBfit Model BFIT Condensing Hot Water Boiler SpecificationjoeÎncă nu există evaluări

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 paginiModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaÎncă nu există evaluări

- Turn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsDocument18 paginiTurn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsKarim Galal IsmailÎncă nu există evaluări

- Hurst Boiler & Welding Company, Inc.: SERIES 500 STEAM BOILER (100-1500 HP, STEAM 15-300 Psig) Sample SpecificationsDocument5 paginiHurst Boiler & Welding Company, Inc.: SERIES 500 STEAM BOILER (100-1500 HP, STEAM 15-300 Psig) Sample SpecificationsDaniel GonzalezÎncă nu există evaluări

- SECTION 15550 Hot Water Boilers Part 1 - General 1.1 Related DocumentsDocument13 paginiSECTION 15550 Hot Water Boilers Part 1 - General 1.1 Related DocumentsMunir RasheedÎncă nu există evaluări

- Mohawk Steam Sample SpecificationsDocument7 paginiMohawk Steam Sample SpecificationsXamir Suarez AlejandroÎncă nu există evaluări

- Boiler SpecificationsDocument19 paginiBoiler Specificationspaul kioiÎncă nu există evaluări

- Boiler Manual - EnglishDocument20 paginiBoiler Manual - Englishengrasadullah000Încă nu există evaluări

- Hurst Boiler & Welding Company, Inc.: Sample SpecificationsDocument3 paginiHurst Boiler & Welding Company, Inc.: Sample Specificationskikokiko KarimÎncă nu există evaluări

- Model CB 15-100 HP Boilers: LightsDocument5 paginiModel CB 15-100 HP Boilers: LightssebaversaÎncă nu există evaluări

- Hurst Boiler & Welding Company, IncDocument7 paginiHurst Boiler & Welding Company, IncChristian Veliz CamargoÎncă nu există evaluări

- Series 500 Water SpecDocument5 paginiSeries 500 Water SpecChristhofer Arroyo ChacónÎncă nu există evaluări

- BFS Boiler Book PDFDocument4 paginiBFS Boiler Book PDFfauzi endraÎncă nu există evaluări

- HVAC Guide Specifications Commercial Air-Cooled Condensing UnitsDocument4 paginiHVAC Guide Specifications Commercial Air-Cooled Condensing UnitsHazemÎncă nu există evaluări

- Flash Tank Heat Recovery SpecificationDocument3 paginiFlash Tank Heat Recovery SpecificationMerisaÎncă nu există evaluări

- 8 Series Steam or Hot Water Boiler-Burner Unit Installation & Operating InstructionsDocument24 pagini8 Series Steam or Hot Water Boiler-Burner Unit Installation & Operating Instructionsmanuals1121Încă nu există evaluări

- Espeficiaciones de CalentadorDocument3 paginiEspeficiaciones de CalentadorLeonida del SolÎncă nu există evaluări

- Model CB 15-100 HP BoilersDocument5 paginiModel CB 15-100 HP BoilerssebaversaÎncă nu există evaluări

- Central HeatingDocument6 paginiCentral Heatingsumit11235Încă nu există evaluări

- 88 Series 2 Boiler: Suggested SpecificationsDocument4 pagini88 Series 2 Boiler: Suggested SpecificationsAdam Bin Abu BakarÎncă nu există evaluări

- Model CBLE 100-800 HP BoilersDocument4 paginiModel CBLE 100-800 HP BoilerssebaversaÎncă nu există evaluări

- Model CBL 900-1800 HP BoilersDocument5 paginiModel CBL 900-1800 HP BoilerssebaversaÎncă nu există evaluări

- HVAC Guide Specifications Commercial Air-Cooled Condensing Units 63 To 87 KW (18 To 25 Tons), Nominal 38AH Part 1 GeneralDocument4 paginiHVAC Guide Specifications Commercial Air-Cooled Condensing Units 63 To 87 KW (18 To 25 Tons), Nominal 38AH Part 1 GeneralcarlosorizabaÎncă nu există evaluări

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 paginiModel CBL 900-1800 HP Boilers: Engineering DatasebaversaÎncă nu există evaluări

- Domestic Water Heating SystemDocument7 paginiDomestic Water Heating Systemabdullah sahibÎncă nu există evaluări

- CBEX Elite 100-800 HPDocument4 paginiCBEX Elite 100-800 HPsebaversaÎncă nu există evaluări

- Boiler SpecificationsDocument34 paginiBoiler SpecificationsHenry CoronadoÎncă nu există evaluări

- Easco Suggested SpecDocument7 paginiEasco Suggested SpecMomar Talla DiawÎncă nu există evaluări

- Boiler Spec SheetDocument1 paginăBoiler Spec SheetahmaborashedÎncă nu există evaluări

- Model ICB 100-800 HP BoilersDocument4 paginiModel ICB 100-800 HP BoilerssebaversaÎncă nu există evaluări

- Boiler SpecificationDocument15 paginiBoiler Specificationjrri16Încă nu există evaluări

- Model CBR 125-800 HP BoilersDocument5 paginiModel CBR 125-800 HP BoilerssebaversaÎncă nu există evaluări

- Model 4WG 100 - 800 HP Boilers: Figure A3-9. Boiler Room Length (Typical Layouts) - Model 4WGDocument4 paginiModel 4WG 100 - 800 HP Boilers: Figure A3-9. Boiler Room Length (Typical Layouts) - Model 4WGsebaversaÎncă nu există evaluări

- Articulo Revista Peru ConstruyeDocument1 paginăArticulo Revista Peru ConstruyeJoaquin Contreras AlmidonÎncă nu există evaluări

- An Introduction To High Temperature Water Heating Plants R1Document39 paginiAn Introduction To High Temperature Water Heating Plants R1Kenn WahhÎncă nu există evaluări

- Feed Water UnitDocument2 paginiFeed Water UnitEslam ElsayedÎncă nu există evaluări

- Chiller & FahuDocument12 paginiChiller & FahuHafnazSabeerÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Document5 paginiModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaÎncă nu există evaluări

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 paginiModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaÎncă nu există evaluări

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 paginiModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaÎncă nu există evaluări

- Model CB 15-100 HP Boilers: LightsDocument5 paginiModel CB 15-100 HP Boilers: LightssebaversaÎncă nu există evaluări

- Model CB 15-100 HP BoilersDocument5 paginiModel CB 15-100 HP BoilerssebaversaÎncă nu există evaluări

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 paginiModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaÎncă nu există evaluări

- Model CB 15-100 HP Boilers: Sound LevelDocument5 paginiModel CB 15-100 HP Boilers: Sound LevelsebaversaÎncă nu există evaluări

- Section A5: Model CBL 900-1800 HP BoilersDocument5 paginiSection A5: Model CBL 900-1800 HP BoilerssebaversaÎncă nu există evaluări

- Model CBL 900-1800 HP BoilersDocument5 paginiModel CBL 900-1800 HP BoilerssebaversaÎncă nu există evaluări

- Model CB 15-100 HP BoilersDocument5 paginiModel CB 15-100 HP BoilerssebaversaÎncă nu există evaluări

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 paginiModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaÎncă nu există evaluări

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 paginiModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaÎncă nu există evaluări

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 paginiModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaÎncă nu există evaluări

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 paginiModel CBL 900-1800 HP Boilers: Engineering DatasebaversaÎncă nu există evaluări

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 paginiFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaÎncă nu există evaluări

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 paginiModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaÎncă nu există evaluări

- Model CBR 125-800 HP BoilersDocument5 paginiModel CBR 125-800 HP BoilerssebaversaÎncă nu există evaluări

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 paginiModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaÎncă nu există evaluări

- Model CBL 900-1800 HP BoilersDocument5 paginiModel CBL 900-1800 HP BoilerssebaversaÎncă nu există evaluări

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 paginiModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaÎncă nu există evaluări

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 paginiModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaÎncă nu există evaluări

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocument5 paginiModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaÎncă nu există evaluări

- Model ICB 100-800 HP BoilersDocument4 paginiModel ICB 100-800 HP BoilerssebaversaÎncă nu există evaluări

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocument4 paginiModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaÎncă nu există evaluări

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 paginiModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaÎncă nu există evaluări

- General: Model ICB 100-800 HP BoilersDocument4 paginiGeneral: Model ICB 100-800 HP BoilerssebaversaÎncă nu există evaluări

- Model ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizeDocument4 paginiModel ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizesebaversaÎncă nu există evaluări

- Model ICB 100-800 HP BoilersDocument4 paginiModel ICB 100-800 HP BoilerssebaversaÎncă nu există evaluări

- Model ICB 100-800 HP BoilersDocument4 paginiModel ICB 100-800 HP BoilerssebaversaÎncă nu există evaluări

- Research ArticleDocument9 paginiResearch ArticlesebaversaÎncă nu există evaluări

- Bill of Supply For Electricity: BSES Rajdhani Power LimitedDocument2 paginiBill of Supply For Electricity: BSES Rajdhani Power LimitedVikasÎncă nu există evaluări

- Presentation: Modes of TransportationDocument16 paginiPresentation: Modes of Transportationranjeet1ranaÎncă nu există evaluări

- Custo Screen 300 / 400 - Error Codes: Service ManualDocument3 paginiCusto Screen 300 / 400 - Error Codes: Service ManualHari KarkiÎncă nu există evaluări

- TR ProtectionDocument23 paginiTR Protectionhafiz_hazreenÎncă nu există evaluări

- Magnalock Models M32, M62 and M82B Installation InstructionsDocument1 paginăMagnalock Models M32, M62 and M82B Installation InstructionsMilos StoisavljevicÎncă nu există evaluări

- Brochure Ret 670Document4 paginiBrochure Ret 670Vishwanath TodurkarÎncă nu există evaluări

- Energy Efficient Roadway Lighting Opportunities and BenefitsDocument15 paginiEnergy Efficient Roadway Lighting Opportunities and BenefitsHesham AlzarooniÎncă nu există evaluări

- MSZ-FH09-15NA Operation JG79A806H02 03-14Document44 paginiMSZ-FH09-15NA Operation JG79A806H02 03-14JordanÎncă nu există evaluări

- Water and Energy Efficient Showers: Project ReportDocument54 paginiWater and Energy Efficient Showers: Project ReportMurali Krishna KakaraparthiÎncă nu există evaluări

- Pab 10Document6 paginiPab 10MelvinDapitanonÎncă nu există evaluări

- 3.3 Diesel Engine Manual Gi1ek1Document136 pagini3.3 Diesel Engine Manual Gi1ek1Ljupco RistovskiÎncă nu există evaluări

- Abb Make Hybrid Switchgear PassDocument23 paginiAbb Make Hybrid Switchgear PassAjith AjiÎncă nu există evaluări

- Deputy Engineer ElectricalDocument3 paginiDeputy Engineer ElectricalSargi BeepumohanÎncă nu există evaluări

- OTS60SX2 UG en-medidorRigidezDielectrica PDFDocument14 paginiOTS60SX2 UG en-medidorRigidezDielectrica PDFblancaÎncă nu există evaluări

- Samba™PLC+HMI Installation Guide: General DescriptionDocument12 paginiSamba™PLC+HMI Installation Guide: General DescriptionDragisa DjukicÎncă nu există evaluări

- May Monthly Report GasperDocument14 paginiMay Monthly Report GasperOWTCÎncă nu există evaluări

- Final Report IOCL GuwahatiDocument17 paginiFinal Report IOCL GuwahatiSonu KumarÎncă nu există evaluări

- HS POLYBAG - NEW FACTORY ELECTRICAL SYSTEM 견적서 20190713 (최종)Document11 paginiHS POLYBAG - NEW FACTORY ELECTRICAL SYSTEM 견적서 20190713 (최종)Nhí LêÎncă nu există evaluări

- Chemistry Project: Saturated Solutions: Measuring SolubilityDocument8 paginiChemistry Project: Saturated Solutions: Measuring SolubilityAbhay Kumar NayakÎncă nu există evaluări

- Batch 23 AdvtDocument6 paginiBatch 23 AdvtV. Krishna ThejaÎncă nu există evaluări

- Inorganic Chemistry SummaryDocument8 paginiInorganic Chemistry SummaryClara1212Încă nu există evaluări

- Pm100cva120 - e IGBT PDFDocument6 paginiPm100cva120 - e IGBT PDFDoDuyBacÎncă nu există evaluări

- Kieselmann Butterfly Valves InstruktionDocument23 paginiKieselmann Butterfly Valves InstruktionVLASTAR100% (2)

- 2016 Zapata Hincapie John Alexander ThesisDocument84 pagini2016 Zapata Hincapie John Alexander ThesisbetelgueseÎncă nu există evaluări

- Manual de P'lata Venezolana PDFDocument66 paginiManual de P'lata Venezolana PDFYovanny GuararimaÎncă nu există evaluări

- 2ATech PowerSupply LV (TPS) &LPS Equipment InternalTrainingDocument56 pagini2ATech PowerSupply LV (TPS) &LPS Equipment InternalTrainingzafrikhan875Încă nu există evaluări