Documente Academic

Documente Profesional

Documente Cultură

O&S Instructions - Reducing Valves

Încărcat de

Tifano KhristiyantoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

O&S Instructions - Reducing Valves

Încărcat de

Tifano KhristiyantoDrepturi de autor:

Formate disponibile

Operating and Safety Instructions

Bailey

Pressure Reducing Valves

Birkett

Before installation these instructions must be fully

read and understood

General Installation

• The intent of these instructions is to • Valves are damaged when first placed in service because of failure to clean the connection

acquaint the user with the storage, properly when installed. Before installation flange faces or threaded connections on both valve

installation and operation of this product. and pipeline on which the valve is mounted must be thoroughly cleaned of all dirt and foreign

• Please read these instructions carefully material.

before installation. Because foreign materials that pass into and through reducing valves can damage the valve,

• This Reducing Valve should only be used in the systems on which the valves are tested and finally installed must also be inspected and

accordance with the applicable operating cleaned. New systems in particular are prone to contain foreign objects that will get trapped

instructions and within the application during construction and will destroy the seating surfaces causing leakage, and moving parts

specifications of the purchase order. causing jamming. The system should be thoroughly flushed through before installation of the

• This valve has been tested and adjusted at Reducing Valve.

the factory, if adjustment is required on site. • The gaskets must be dimensionally correct for the specific flanges. The inside diameters must

Check that the spring setting is adequately fully clear the valve inlet and outlet ports so that the gasket does not restrict the flow.

available from the spring fitted in the valve, • For flanged valves, tighten down all connection studs or bolts evenly to avoid possible distortion

by reference to the operating and of the valve body. For threaded valves, apply a wrench to the flats provided on the valve body.

maintenance instructions referenced at the Pressure Reducing Valve installations require accurate design of both inlet and outlet pipe work.

end of this document. Refer to International, National and Industry Standards for guidelines.

• The valve should be installed in horizontal pipe work with its axis vertical. A flow arrow is cast on

the valve body illustrating the direction of flow; always ensure that the arrow is pointing from the

Storage and Handling high-pressure source to the low-pressure source.

• Because cleanliness is essential to the • When installing valves on steam systems, always ensure that the pipe work on the inlet is fitted

satisfactory operation and tightness of a with a pipeline strainer and that the inlet and outlet pipe work is fitted with a ‘dirt leg and

Reducing Valve, precautions should be pocket’ and that adequate steam traps are fitted. This will help to prevent the accumulation of

taken during storage to keep out all foreign foreign objects in the reducing valve, and help prevent the build up of condensate in both pipe

material. Inlet and outlet protectors should work and valve, which will cause the valve to oscillate.

remain in place until the valve is ready to be • Safety Valves should always be fitted into the downstream pipe work of a Pressure Reducing

installed in the system. It is recommended Valve Station; this will ensure that downstream pipe work and equipment is properly protected

that the valve is stored in the original against potential inlet pressure. Safety Valves should be adequately sized to discharge the full

shipping container away from dirt and other system flow rate at the reduced outlet pressure setting.

forms of contamination.

• Reducing Valves must be handled carefully Safety precautions

and never subject to shocks. Rough • Never attempt to remove a Reducing Valve from a system that is pressurized and never attempt

handling may alter the pressure setting, to carry out maintenance on a Reducing Valve when the system is pressurized.

deform valve parts and adversely affect • If the valve is not properly isolated from the system pressure, the valve will be pressurized,

seat tightness and valve performance. which could cause serious injury to personal.

• The valve should be lifted in a safe manner, • The accuracy of regulation of the Reducing Valve is important in the correct operation of the

when it is necessary to use a hoist, the plant. The valve must be maintained according to appropriate instructions and must be

chain or sling should be place around the periodically reconditioned to ensure correct function.

valve body and cover in a manner that will • For further information including adjustment, maintenance, and detail illustrations, obtain the

ensure that the valve is in a vertical position appropriate Operation and Maintenance Manual from the table below. These manuals may be

to facilitate installation. obtained from the factory or are available at www.safetysystemsuk.com

Note WARNING

Service Technicians are available to assist • The improper installation, application or maintenance of the valve or the use of parts or

with your installation or other field problems. components not manufactured by Safety Systems may result in a failure of the Reducing Valve.

Call your nearest Safety Systems • Any installation, maintenance, adjustment, repair or test, performed on the Reducing Valve

representative (details can be found at must be done in accordance with the requirements of all applicable Safety Systems

www.safetysystemsuk.com) or our factory at procedures and instructions as applicable National and International Codes and Standards.

the address shown below. • The information, specifications and technical data (the “Specifications”) contained in this

document are subject to change without notice. Safety Systems does not warrant that the

Bailey Birkett specifications are current and assumes no responsibility for the use or misuse thereof. The

c/o Safety Systems UK Ltd. purchaser should verify that there have been no changes to the specifications prior to use.

Sharp Street, Worsley

Manchester, M28 3NA Documentation

United Kingdom

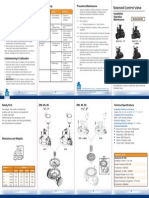

Valve models Document

Tel: +44 (0)161 790 7741

G4 ES/G4/0/006 Commissioning

Fax: +44 (0)161 703 8451

G4 ES/G4/0/007 Maintenance

Web: www.safetysystemsuk.com

G4 ES/G4/0/008 Spares

Class T ES/T/0/002

470 ES/470/0/003

Class F ES/F/0/002

We reserve the right to change the contents without notice BBVDR-0003-EN-0202

S-ar putea să vă placă și

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedDocument47 paginiInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasÎncă nu există evaluări

- O&S Instructions - Pilot OperatedDocument2 paginiO&S Instructions - Pilot OperatedTifano KhristiyantoÎncă nu există evaluări

- PED - Operating Safety Instructions for Direct Spring Safety ValvesDocument2 paginiPED - Operating Safety Instructions for Direct Spring Safety ValvesndngnngdngngÎncă nu există evaluări

- Apollo Ball Valve Installation & Maintenance ManualDocument9 paginiApollo Ball Valve Installation & Maintenance ManualErcan YilmazÎncă nu există evaluări

- Rotary Valve Operating InstructionsDocument11 paginiRotary Valve Operating InstructionsAdem AltanÎncă nu există evaluări

- IOM-P14-R0 Quarter Turn BVDocument9 paginiIOM-P14-R0 Quarter Turn BVDonovan BonnerÎncă nu există evaluări

- AG Tank Blanketing RegulatorDocument3 paginiAG Tank Blanketing Regulatormicroco4Încă nu există evaluări

- Butterfly Valve User ManualDocument10 paginiButterfly Valve User ManualEduardoAscencioÎncă nu există evaluări

- Hattersley+A5+IOM+Fig.370+&+Fig.371+Colour 0119 WEBDocument4 paginiHattersley+A5+IOM+Fig.370+&+Fig.371+Colour 0119 WEBFareethAbdullahÎncă nu există evaluări

- CVS EZ Instruction ManualDocument28 paginiCVS EZ Instruction ManualJohn Harry RamirezÎncă nu există evaluări

- V800 - Ball - Installation & Maintenance ManualDocument15 paginiV800 - Ball - Installation & Maintenance ManualHayderr HassÎncă nu există evaluări

- Vciom 06208 enDocument18 paginiVciom 06208 enElver AmesquitaÎncă nu există evaluări

- AGCO 800-900 IS-V3117 AGCSB-0072-ENDocument5 paginiAGCO 800-900 IS-V3117 AGCSB-0072-ENChirasak PaksasornÎncă nu există evaluări

- Hopkinson Valves IOM Manual PDFDocument7 paginiHopkinson Valves IOM Manual PDFGiorgiana RosuÎncă nu există evaluări

- Sanyo Inverter Sap KRV 186-246 Eh Tech Data Om & ServiceDocument117 paginiSanyo Inverter Sap KRV 186-246 Eh Tech Data Om & ServiceambraÎncă nu există evaluări

- Install, operate and maintain Hopkinsons swing check valveDocument7 paginiInstall, operate and maintain Hopkinsons swing check valveGiorgiana RosuÎncă nu există evaluări

- Wolter Roof Fans Manual 20100319Document13 paginiWolter Roof Fans Manual 20100319ashishÎncă nu există evaluări

- Flowvalves KSB Va Pn16Document11 paginiFlowvalves KSB Va Pn16JavierÎncă nu există evaluări

- 755Document19 pagini755JOHNÎncă nu există evaluări

- 1100 Globe Single SeatedDocument24 pagini1100 Globe Single SeatedAde Husni ChaniagoÎncă nu există evaluări

- Avk Gate Valves PDFDocument9 paginiAvk Gate Valves PDFDanielÎncă nu există evaluări

- ACT-Plug Valve Manual (FMC)Document11 paginiACT-Plug Valve Manual (FMC)PHILIPUAE100% (1)

- Vaas Automation C47 cryogenic valve manualDocument8 paginiVaas Automation C47 cryogenic valve manualKannan KrisÎncă nu există evaluări

- BR33 Rotary Valve ManualDocument20 paginiBR33 Rotary Valve ManualHimozaesÎncă nu există evaluări

- Install and Maintain Pressure RegulatorDocument8 paginiInstall and Maintain Pressure RegulatorAcep WahyudinÎncă nu există evaluări

- installation_operating_manual_forged_valveDocument39 paginiinstallation_operating_manual_forged_valveBenny 37Încă nu există evaluări

- 727 PosrvDocument7 pagini727 Posrvtxlucky80Încă nu există evaluări

- 05-9040-070 Angmc-6028-UsDocument2 pagini05-9040-070 Angmc-6028-Ustxlucky80Încă nu există evaluări

- Enviro Seal System Rotary ValavesDocument16 paginiEnviro Seal System Rotary ValavesJhne OkÎncă nu există evaluări

- Valve Installation InstructionsDocument8 paginiValve Installation InstructionsilkinÎncă nu există evaluări

- 2000 Iom SeriesDocument6 pagini2000 Iom SeriesLakshmi NarayananÎncă nu există evaluări

- Virgo Virgo: Installation Installation Operation & Operation & Maintenance Maintenance Manual ManualDocument17 paginiVirgo Virgo: Installation Installation Operation & Operation & Maintenance Maintenance Manual ManualRio WitcandraÎncă nu există evaluări

- Install and maintain check valvesDocument6 paginiInstall and maintain check valvesHimanshu PatilÎncă nu există evaluări

- Water-Cooled Chiller Technical ManualDocument41 paginiWater-Cooled Chiller Technical ManualJulian ArizaÎncă nu există evaluări

- Worcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeDocument16 paginiWorcester Controls 10, 15, 20 ACCESS I and 10-40 ACCESS M 39 Actuators Intrinsically SafeMijin28Încă nu există evaluări

- Instalación y Mantenimiento de Válvulas RotativasDocument4 paginiInstalación y Mantenimiento de Válvulas RotativasGustavo León CarreraÎncă nu există evaluări

- I & M Mark V-100 Series: NtroductionDocument16 paginiI & M Mark V-100 Series: Ntroductionwagner machado de moraesÎncă nu există evaluări

- Floating Ball Valve Installation, Operation and Maintenance ManualDocument29 paginiFloating Ball Valve Installation, Operation and Maintenance ManualRio WitcandraÎncă nu există evaluări

- MNV20052 1210 (SS)Document16 paginiMNV20052 1210 (SS)wikijeg975Încă nu există evaluări

- Fisher EZ Control Valve-Instruction ManualDocument36 paginiFisher EZ Control Valve-Instruction ManualPark SataveeÎncă nu există evaluări

- Manual de Dren AutomaticoDocument42 paginiManual de Dren AutomaticoDarvin chi tecÎncă nu există evaluări

- Rotary Flow Meter - Instruction Manual - MNV10151-1907Document18 paginiRotary Flow Meter - Instruction Manual - MNV10151-1907dharanÎncă nu există evaluări

- Thermo scuba valve maintenance guideDocument24 paginiThermo scuba valve maintenance guideCarlos Arturo Martinez SalcedoÎncă nu există evaluări

- Sluice ValveDocument14 paginiSluice ValverajkumarÎncă nu există evaluări

- Installation and Operating Instructions: Straight Through Control Valves STEVI 448/449Document18 paginiInstallation and Operating Instructions: Straight Through Control Valves STEVI 448/449widuri nirmalaÎncă nu există evaluări

- Series 39 Inline Check Valve: Installation, Operation, and Maintenance ManualDocument4 paginiSeries 39 Inline Check Valve: Installation, Operation, and Maintenance ManualLalo SepulvedaÎncă nu există evaluări

- Operating InstructionDocument2 paginiOperating InstructionÖmer KarahanÎncă nu există evaluări

- Installation, Operation & Maintenance Manual EX Knife Gate ValveDocument15 paginiInstallation, Operation & Maintenance Manual EX Knife Gate ValveMD. Ejajul HaqueÎncă nu există evaluări

- Fisher Design ETR ValveDocument24 paginiFisher Design ETR ValveTanuTiganuÎncă nu există evaluări

- Control ValveDocument64 paginiControl Valvearvind14dec100% (2)

- MANUAL - PUZeN e - EN - 170202Document56 paginiMANUAL - PUZeN e - EN - 170202Mark Louie GuintoÎncă nu există evaluări

- ECo FLOW Steppari T80113 (ID 29889)Document2 paginiECo FLOW Steppari T80113 (ID 29889)snaipperiÎncă nu există evaluări

- Overspeed GovernorDocument13 paginiOverspeed GovernorAli DiabÎncă nu există evaluări

- Sempell: Before Installation These Instructions Must Be Fully Read and UnderstoodDocument1 paginăSempell: Before Installation These Instructions Must Be Fully Read and UnderstoodDGWÎncă nu există evaluări

- Erection and Installation Procedure: GEA Mechanical EquipmentDocument13 paginiErection and Installation Procedure: GEA Mechanical EquipmentGUSTAVOÎncă nu există evaluări

- RP Is 009 009 FS+2214Document8 paginiRP Is 009 009 FS+2214Prabath KÎncă nu există evaluări

- Ball Valve For PipelineDocument12 paginiBall Valve For Pipelinemahesh chandÎncă nu există evaluări

- Dot 3-Way Control Valve: Installation, Operating and Maintenance Instructions SupplementDocument10 paginiDot 3-Way Control Valve: Installation, Operating and Maintenance Instructions Supplementابزار دقیقÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDe la Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsEvaluare: 4 din 5 stele4/5 (1)

- Crude Oil Tank - OrchartDocument1 paginăCrude Oil Tank - OrchartTifano KhristiyantoÎncă nu există evaluări

- 3516LDDocument6 pagini3516LDnavas1972Încă nu există evaluări

- Steam, Vapor, Density, Latent, Sensible Heat Vaporization, Specific, Volume, Pressure, Dynamic Viscosity, EnthalpyDocument1 paginăSteam, Vapor, Density, Latent, Sensible Heat Vaporization, Specific, Volume, Pressure, Dynamic Viscosity, EnthalpyTifano KhristiyantoÎncă nu există evaluări

- Summary Mto (Kendari) : Item DIA Class / SCH Material Description QTY Unit Remarks NODocument1 paginăSummary Mto (Kendari) : Item DIA Class / SCH Material Description QTY Unit Remarks NOTifano KhristiyantoÎncă nu există evaluări

- ReadmeDocument8 paginiReadmeTifano KhristiyantoÎncă nu există evaluări

- Chemical List 2014-10-15Document25 paginiChemical List 2014-10-15Tifano Khristiyanto100% (1)

- ReceiptDocument1 paginăReceiptTifano KhristiyantoÎncă nu există evaluări

- Table TableDocument8 paginiTable TableTifano KhristiyantoÎncă nu există evaluări

- Driven by Our Energy Comart Reference List: Stefano Schiavo Ravenna, 24 February 2016Document18 paginiDriven by Our Energy Comart Reference List: Stefano Schiavo Ravenna, 24 February 2016Tifano KhristiyantoÎncă nu există evaluări

- Sharing Session - Block-A (Process)Document18 paginiSharing Session - Block-A (Process)Tifano KhristiyantoÎncă nu există evaluări

- Modelling of Claus Sulfur Recovery UnitDocument5 paginiModelling of Claus Sulfur Recovery UnitTifano KhristiyantoÎncă nu există evaluări

- ReadmeDocument8 paginiReadmeTifano KhristiyantoÎncă nu există evaluări

- Arch Ivo 117Document26 paginiArch Ivo 117Prasert ThongsongÎncă nu există evaluări

- Chemical System Study Provides Overview of Production and Non-Production ChemicalsDocument45 paginiChemical System Study Provides Overview of Production and Non-Production ChemicalsTifano Khristiyanto100% (2)

- 50 kVA Perkins Diesel Generator Set - Non EPA - 50Hz TP-P50-T1-50 PDFDocument5 pagini50 kVA Perkins Diesel Generator Set - Non EPA - 50Hz TP-P50-T1-50 PDFTifano KhristiyantoÎncă nu există evaluări

- MITSUBISHI MGS2700HV DIESEL GENERATORDocument4 paginiMITSUBISHI MGS2700HV DIESEL GENERATORTifano KhristiyantoÎncă nu există evaluări

- Gas Development ProjectDocument8 paginiGas Development ProjectTifano KhristiyantoÎncă nu există evaluări

- IDBC-TS-MTTDS-FGR623304 Rev 50 Production Flowline Pig ReceiverDocument18 paginiIDBC-TS-MTTDS-FGR623304 Rev 50 Production Flowline Pig ReceiverTifano KhristiyantoÎncă nu există evaluări

- AAV ThermaxDocument2 paginiAAV Thermax123habib123fikriÎncă nu există evaluări

- TBA - Vessel InternalsDocument5 paginiTBA - Vessel InternalsTifano KhristiyantoÎncă nu există evaluări

- Centaour 50 Solar TurbineDocument2 paginiCentaour 50 Solar TurbineTifano KhristiyantoÎncă nu există evaluări

- PFD DPCU & GuidelineDocument2 paginiPFD DPCU & GuidelineTifano Khristiyanto100% (1)

- Petron-Limay-Pep-Crude Oil Tank Construction by YokDocument49 paginiPetron-Limay-Pep-Crude Oil Tank Construction by YokTifano KhristiyantoÎncă nu există evaluări

- Over-engineered piping: How grooved joints improve efficiencyDocument36 paginiOver-engineered piping: How grooved joints improve efficiencyTifano KhristiyantoÎncă nu există evaluări

- Transfer BCA Mama - 1Document1 paginăTransfer BCA Mama - 1Tifano KhristiyantoÎncă nu există evaluări

- O&S Instructions - ATEX SRV PDFDocument1 paginăO&S Instructions - ATEX SRV PDFTifano KhristiyantoÎncă nu există evaluări

- O&S Instructions - ATEX SRV PDFDocument1 paginăO&S Instructions - ATEX SRV PDFTifano KhristiyantoÎncă nu există evaluări

- Horizontal Separator Adequacy CheckDocument4 paginiHorizontal Separator Adequacy CheckTifano KhristiyantoÎncă nu există evaluări

- L .. Eee - .: Distribution Voltage RegulatorsDocument11 paginiL .. Eee - .: Distribution Voltage RegulatorsSirajulÎncă nu există evaluări

- Manufacturing Technology (ME461) Lecture1Document39 paginiManufacturing Technology (ME461) Lecture1Rishabh JainÎncă nu există evaluări

- Abstract Substructure Conc - Frame Westgate RealDocument4 paginiAbstract Substructure Conc - Frame Westgate RealTashamiswa MajachaniÎncă nu există evaluări

- Slabs Are Plate Elements Forming Floors andDocument5 paginiSlabs Are Plate Elements Forming Floors andyasas89Încă nu există evaluări

- IQ3-95SP-BC dimensional data sheetDocument2 paginiIQ3-95SP-BC dimensional data sheetren kaiÎncă nu există evaluări

- Solids Flow Feeder Equipment for Precise Measurement & ControlDocument7 paginiSolids Flow Feeder Equipment for Precise Measurement & ControlAbhishek DuttaÎncă nu există evaluări

- Occupant Manikin Introduction: 95th Percentile Male Driver ModelDocument9 paginiOccupant Manikin Introduction: 95th Percentile Male Driver ModelarstjunkÎncă nu există evaluări

- RecruitmentDocument73 paginiRecruitmentArif Ryhan100% (1)

- Shallow Foundation Assignment 1 (Finals)Document2 paginiShallow Foundation Assignment 1 (Finals)Lensearfwyn NamocatcatÎncă nu există evaluări

- D16021.1200.RE.10-003 REV.1 Datasheet (1200-P-3003AB)Document3 paginiD16021.1200.RE.10-003 REV.1 Datasheet (1200-P-3003AB)anwar sadatÎncă nu există evaluări

- How To Enable Nationality Field in IrecruitmentDocument2 paginiHow To Enable Nationality Field in IrecruitmentnhawiÎncă nu există evaluări

- Green Finance For Green GrowthDocument24 paginiGreen Finance For Green GrowthSreejith BhattathiriÎncă nu există evaluări

- Temporary Revision 12 053: Aircraft Maintenance ManualDocument26 paginiTemporary Revision 12 053: Aircraft Maintenance ManualKentÎncă nu există evaluări

- PDF Ebook Pickle Things by Marc Brown Download BookDocument5 paginiPDF Ebook Pickle Things by Marc Brown Download BookCorissÎncă nu există evaluări

- Date Company Code Bank RefDocument16 paginiDate Company Code Bank RefSrinivas YÎncă nu există evaluări

- Huffman & ShannonDocument30 paginiHuffman & ShannonDhamodharan SrinivasanÎncă nu există evaluări

- Unethical Business Pratices in Corporates: March 2016Document13 paginiUnethical Business Pratices in Corporates: March 2016Manju Nadh ChakravadhanulaÎncă nu există evaluări

- Accenture Inside Corporate MandADocument28 paginiAccenture Inside Corporate MandAshshanksÎncă nu există evaluări

- I2C Bus ManualDocument51 paginiI2C Bus Manualapi-26349602100% (6)

- Mindmup Group-2Document10 paginiMindmup Group-2api-271772521Încă nu există evaluări

- Dsi Suspa Systems Eta 07 0186 Suspa Wire Ex enDocument48 paginiDsi Suspa Systems Eta 07 0186 Suspa Wire Ex enAnonymous TxhyGfÎncă nu există evaluări

- MELHORES SITES DE INFOPRODUTOS PLR E SUAS RANKS NO ALEXADocument8 paginiMELHORES SITES DE INFOPRODUTOS PLR E SUAS RANKS NO ALEXAAlexandre Silva100% (2)

- FinePrint pdfFactory Pro Trial Version PDF CreationDocument40 paginiFinePrint pdfFactory Pro Trial Version PDF CreationTUAN NGUYEN VANÎncă nu există evaluări

- Range and Angle Tracking Techniques for Moving Target EstimationDocument34 paginiRange and Angle Tracking Techniques for Moving Target Estimationmykingboody2156Încă nu există evaluări

- OTC13998Document15 paginiOTC13998Raifel MoralesÎncă nu există evaluări

- Greddy E-Manage Installation ManualDocument6 paginiGreddy E-Manage Installation ManualTHMotorsports.net100% (2)

- HGS HSM SL 20 007 - Adjustment of Valve ClearanceDocument66 paginiHGS HSM SL 20 007 - Adjustment of Valve Clearanceajshsu5682Încă nu există evaluări

- Tech Tip 3 Viscosity and Thixotropic IndexDocument2 paginiTech Tip 3 Viscosity and Thixotropic IndexnationÎncă nu există evaluări

- ExMED Debrief 2019Document16 paginiExMED Debrief 2019Hamilton WintersÎncă nu există evaluări

- Modern Soil Stabilization TechniquesDocument25 paginiModern Soil Stabilization TechniquesSagar Jha100% (3)