Documente Academic

Documente Profesional

Documente Cultură

SWMS Info Kit PDF

Încărcat de

Beste Ardıç ArslanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SWMS Info Kit PDF

Încărcat de

Beste Ardıç ArslanDrepturi de autor:

Formate disponibile

Safe Work Method Statement

a basic explanation

What is a Safe Work Method Statement (SWMS)?

A SWMS is an explanation of all steps that need to be completed on a job, all steps. From arriving

on-site, unloading the vehicle, checking the workplace, carrying out the job, clearing the workplace,

loading the vehicle and leaving site. Its purpose is to show that the people who are carrying out

the work have thought through the whole process, assessed any risks involved and taken suitable

measures to minimise the risk to themselves, other people and properties.

SWMS is also known as a Safe Operating Procedure or Job Safety Analysis.

Who must complete a SWMS?

Anybody who:

- Build or constructs anything on-site

- Uses plant or machinery (forklift, boomlift, scissor lift, crane, tilt tray etc.)

- Manually handles weights over 25kg

- Requires welding, grinding or other ‘hot work’

- Uses equipment that makes excessive noise (jackhammers, compressors etc.)

- Carries out work in a confined space

- Any job that requires dangerous substances or chemicals, in which case a MSDS

(materials safety data sheet) must also be supplied.

Who writes the SWMS?

Usually the work supervisor or contractor. However, it is important that this is done in consultation

with those who actually carry out the job. This will give a more complete insight into the various

steps involved in the job and the hazards that may be encountered while performing the job. This

will also encourage ownership and commitment to the safe working methods by those doing the

job.

A valid SWMS must be on the organisation’s letterhead, showing the name and registered office

address of the organisation. In addition, each SWMS must carry the signature of a senior

management representative of the organisation and the date it was signed.

At the very least SWMS must include:

q a description of the work to be undertaken,

q foreseeable hazards associated with the work

q the step by step sequence in doing the work

q the safety controls that will be used to minimise these hazards,

q all precautions to be taken to protect health and safety,

q identification of all health and safety law, standards or codes applicable to the work,

For major works, the following details need to be added:

q the names and qualifications of those who will supervise the work and inspect and approve

work area, work methods, protective measures, plant, equipment and power tools, a

description of what training is given to people doing the work,

q identification of plant and equipment needed on site to do the job eg ladders, scaffolds,

electrical leads, welding machines etc.,

q details of the inspection and maintenance checks that will be, or have been, carried out on

the equipment listed.

The WorkCover Authority’s Guidelines for writing work method statements in plain English (1998)

also sets out a SWMS form which is acceptable under current legislation. Major contractors should

refer to this WorkCover guide for assistance in the production of SWMS.

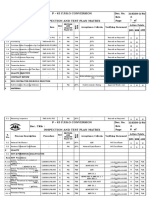

Safe Work Method Statement

Company name & details: Statement prepared by:

Position:

Date:

Description of job: Signature:

Work site: Commencement date:

Critical steps in this job Potential Hazards Safety controls

Use as many pages as required to describe the complete job

Contractor staff / personnel details – All staff to sign after reading the statement

Name Position Signature

OH&S Officer use only

Date received Event Name

Approved by Event date

Signature MSDS required /

supplied

Safe Work Method Statement

Company name & details: Statement prepared by:

Position:

Date:

Description of job: Signature:

Work site: Commencement date:

E

Critical steps in this job Potential Hazards Safety controls

Loading & unloading of staging Equipment may fall on persons if Experienced truck driver is to

equipment. load is not correctly secured using ensure that all loads are securely

straps and/or rope. tied down.

Loading. Potential for back injury if Apply safe lifting techniques

incorrect lifting techniques are (keep back straight and bend

LY L

Loading with forklift.

used.

Equipment may fall and cause

injury to persons working near

by.

knees). Use forklifts where

practicable.

Only experienced and ticketed

drivers are to operate forklifts.

N P

Pushing trolleys or case from Incorrect manual handling causes Apply correct manual handling

loading dock to where needed back problems techniques when pushing or

Unable to control trolley or case if pulling trolleys or cases

too heavy Ensure sufficient people to control

Trolley rolls over feet the trolley or case

Keep feet clear from wheels

O M

Wear steel cap boots if suitable

Assemble equipment on-site Incorrect assembly may cause the Follow manufacturer instructions

equipment to collapse or and carry out checks.

malfunction

SA

Use as many pages as required to describe the complete job

Contractor staff / personnel details – All staff to sign after reading the statement

Name Position Signature

OH&S Officer use only

Date received Event Name

Approved by Event date

Signature MSDS required /

supplied

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Srs DocumentDocument11 paginiSrs DocumentMohit DubeyÎncă nu există evaluări

- Shell Australia Lubricants Product Data Guide 2013Document196 paginiShell Australia Lubricants Product Data Guide 2013letranquanghaÎncă nu există evaluări

- Hydrochloric Acid HandbookDocument51 paginiHydrochloric Acid HandbookCarlos DiazÎncă nu există evaluări

- FMEA Template and RankingsDocument43 paginiFMEA Template and RankingsBeste Ardıç ArslanÎncă nu există evaluări

- Itil and Iso 20000Document56 paginiItil and Iso 20000Anshuman Tiwari100% (2)

- ITP For Piping WorksDocument44 paginiITP For Piping WorksSyafril Akbar100% (3)

- Horizon Horizontal Lifeline Instruction Manual - enDocument68 paginiHorizon Horizontal Lifeline Instruction Manual - enrm_037Încă nu există evaluări

- PD 25111-2010Document36 paginiPD 25111-2010Beste Ardıç ArslanÎncă nu există evaluări

- KC FLT 8809008 enDocument24 paginiKC FLT 8809008 enAnonymous l05hkK4yUV50% (4)

- Hill and Jones Chapter 4 Strategy at Functional LevelDocument31 paginiHill and Jones Chapter 4 Strategy at Functional LevelRommel de VeraÎncă nu există evaluări

- Fmea For HseDocument62 paginiFmea For HseBartosz Kurecki100% (2)

- Catalogo Overview PERI UPDocument36 paginiCatalogo Overview PERI UPBeste Ardıç ArslanÎncă nu există evaluări

- Sl10496 Nas Cli HolDocument45 paginiSl10496 Nas Cli HolemcviltÎncă nu există evaluări

- Yapı işleri-CPWR-YTÜ-G.SÖNMEZ-2020Document70 paginiYapı işleri-CPWR-YTÜ-G.SÖNMEZ-2020Beste Ardıç ArslanÎncă nu există evaluări

- API PandemicGuide PDFDocument38 paginiAPI PandemicGuide PDFCanaviri C. Nexus KaramatzoÎncă nu există evaluări

- 1B - Amy Timmerman - ISO 45001 PDFDocument43 pagini1B - Amy Timmerman - ISO 45001 PDFArdago LenggaÎncă nu există evaluări

- WAH ToolkitDocument74 paginiWAH ToolkitKhuda BukshÎncă nu există evaluări

- Curiosity April Cal Jazz FinalDocument2 paginiCuriosity April Cal Jazz FinalBeste Ardıç ArslanÎncă nu există evaluări

- Lift Plan Test PaperDocument1 paginăLift Plan Test PaperBeste Ardıç ArslanÎncă nu există evaluări

- Top 10 Reasons Risk Assessments Don't WorkDocument56 paginiTop 10 Reasons Risk Assessments Don't WorkBeste Ardıç ArslanÎncă nu există evaluări

- Scottish Water Safety Bulletin PDFDocument3 paginiScottish Water Safety Bulletin PDFBeste Ardıç ArslanÎncă nu există evaluări

- Tutorial 7 KeyDocument5 paginiTutorial 7 KeyBeste Ardıç ArslanÎncă nu există evaluări

- OSHA3895Document3 paginiOSHA3895Beste Ardıç ArslanÎncă nu există evaluări

- 6496 - Nano Risk FrameworkDocument104 pagini6496 - Nano Risk FrameworkRohitÎncă nu există evaluări

- CCPS Combined GlossaryDocument164 paginiCCPS Combined GlossaryshabbigÎncă nu există evaluări

- Ex 4Document1 paginăEx 4Beste Ardıç ArslanÎncă nu există evaluări

- MJIRI v30n1p280 enDocument9 paginiMJIRI v30n1p280 enBeste Ardıç ArslanÎncă nu există evaluări

- Use of Failure Mode and Effects Analysis in Improving Safety: A Case Study in An Oil CompanyDocument8 paginiUse of Failure Mode and Effects Analysis in Improving Safety: A Case Study in An Oil CompanyBeste Ardıç ArslanÎncă nu există evaluări

- Failure Modes and Effects Analysis FMEADocument17 paginiFailure Modes and Effects Analysis FMEABeste Ardıç ArslanÎncă nu există evaluări

- Sws 10 Lecture 8Document33 paginiSws 10 Lecture 8mahendranÎncă nu există evaluări

- Siemens PLM Polarion How To Conduct A Failure Modes and Effects Analysis FMEA WP 60071 A3Document8 paginiSiemens PLM Polarion How To Conduct A Failure Modes and Effects Analysis FMEA WP 60071 A3Rajesh MurugesanÎncă nu există evaluări

- JHSC Investigations Facilitator PDF enDocument46 paginiJHSC Investigations Facilitator PDF enBeste Ardıç ArslanÎncă nu există evaluări

- Session 3 Essentials of Contractor Safety MGMT SeiderDocument12 paginiSession 3 Essentials of Contractor Safety MGMT SeiderBeste Ardıç ArslanÎncă nu există evaluări

- Hazard MappingDocument26 paginiHazard MappingDavid SmithÎncă nu există evaluări

- Instructor Teaching Guide For Additional ScenariosDocument23 paginiInstructor Teaching Guide For Additional ScenariosBeste Ardıç ArslanÎncă nu există evaluări

- Incident Investigation Process and ExerciseDocument10 paginiIncident Investigation Process and ExerciseSarawut SaseesaoÎncă nu există evaluări

- Contractor Safety Framework V1.2 Final PDFDocument8 paginiContractor Safety Framework V1.2 Final PDFBeste Ardıç ArslanÎncă nu există evaluări

- STANDARD Isolated Power Systems Installation, Operation and Maintenace ManualDocument20 paginiSTANDARD Isolated Power Systems Installation, Operation and Maintenace Manualرضا میرزانیاÎncă nu există evaluări

- Host EuropeDocument5 paginiHost EuropeAnonymous Q86F7P0Încă nu există evaluări

- Msi MS-7366 - Rev 1.0Document32 paginiMsi MS-7366 - Rev 1.0zack9mm2003Încă nu există evaluări

- JMT Machine Tools (Press Brakes, Fiber Laser, Plasma Machines, Iron Worker, Shears, Angle Rolls,)Document78 paginiJMT Machine Tools (Press Brakes, Fiber Laser, Plasma Machines, Iron Worker, Shears, Angle Rolls,)Ermal HamzajÎncă nu există evaluări

- Computer Networking Lab Manual ET&T-6Document10 paginiComputer Networking Lab Manual ET&T-6shriram1082883Încă nu există evaluări

- Configuring A Zone-Based Policy Firewall (ZPF)Document13 paginiConfiguring A Zone-Based Policy Firewall (ZPF)JahazielCruzMonzon100% (1)

- A 318Document213 paginiA 318Paul Dan PribacÎncă nu există evaluări

- Installation Manual: Paralleling and Protection Unit Type PPUDocument26 paginiInstallation Manual: Paralleling and Protection Unit Type PPUKukuh WidodoÎncă nu există evaluări

- Mk7C Factsheet EnglishDocument2 paginiMk7C Factsheet EnglishMikeÎncă nu există evaluări

- PCS-902 - X - Instruction Manual - EN - Overseas General - X - R1.05 - (EN - XLBH5102.0086.0016) PDFDocument470 paginiPCS-902 - X - Instruction Manual - EN - Overseas General - X - R1.05 - (EN - XLBH5102.0086.0016) PDFKAREEM OLAWALE100% (1)

- Gmail - Ticket Booking On SMSDocument4 paginiGmail - Ticket Booking On SMSMark WarnarÎncă nu există evaluări

- The Governance ContinuumDocument3 paginiThe Governance Continuumnathan_lawler4416Încă nu există evaluări

- DS13200C 23200C PDFDocument2 paginiDS13200C 23200C PDFSEONCITEFAÎncă nu există evaluări

- Evermotion Archmodels Vol 01 PDFDocument2 paginiEvermotion Archmodels Vol 01 PDFAndreaÎncă nu există evaluări

- Task-Based Standard Operating Procedure Approach To Implement Business Process Management in RetailDocument19 paginiTask-Based Standard Operating Procedure Approach To Implement Business Process Management in RetailKanti ModhavadiyaÎncă nu există evaluări

- Spider III Standard and Premium Line Switches - English - Original - 96284Document8 paginiSpider III Standard and Premium Line Switches - English - Original - 96284Luis RobertoÎncă nu există evaluări

- CG1 02Document2 paginiCG1 02vomoriÎncă nu există evaluări

- Sound Power Determination With or Without IS09614-1: by Erik Cletus Petersen, Bruei&Kjser, DenmarkDocument2 paginiSound Power Determination With or Without IS09614-1: by Erik Cletus Petersen, Bruei&Kjser, Denmarkeng13Încă nu există evaluări

- NW & NT Brochure-2012Document8 paginiNW & NT Brochure-2012nooruddinkhan1Încă nu există evaluări

- Eclipse RCPDocument56 paginiEclipse RCPbeamman82100% (1)

- Ashly Protea 4,24GDocument20 paginiAshly Protea 4,24GChristian DuboisÎncă nu există evaluări

- Class II, Type B2 (Total Exhaust) Biological Safety CabinetsDocument12 paginiClass II, Type B2 (Total Exhaust) Biological Safety CabinetsDexa Arfindo PratamaÎncă nu există evaluări