Documente Academic

Documente Profesional

Documente Cultură

AU234 Vehicle Systems Lab 0-0-3-1 2016 Prerequisite: Nil: Course Code Course Name L-T-P - Credits Year of

Încărcat de

vaisakmctDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

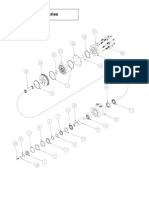

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

AU234 Vehicle Systems Lab 0-0-3-1 2016 Prerequisite: Nil: Course Code Course Name L-T-P - Credits Year of

Încărcat de

vaisakmctDrepturi de autor:

Formate disponibile

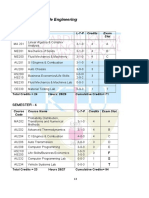

Course code Course Name L-T-P - Credits Year of

Introduction

AU234 VEHICLE SYSTEMS LAB 0-0-3-1 2016

Prerequisite : Nil

Course Objectives

To study about hand tools, special purpose tools, and their uses.

To familiarize with various systems and components of an automobile.

To know about writing technical specifications and description of all types of chassis and

transmission components of automobiles, including body and interiors

List of Exercises/Experiments (Minimum 12 exercises/experiments are mandatory)

1. Servicing of clutch assembly, checking the spring tension of coil springs in spring tester.

2. Dismantling of gear box, inspecting components, servicing, checking the gear ratios.

3. Dismantling of differential assembly, servicing, backlash adjustments, check for drive

axis ratio.

4. Servicing of A. C. mechanical fuel pump and testing the pump.

5. Servicing of Carburetor, Study Various Circuits on it, tuning of carburetor.

6. Servicing master and wheel cylinders in hydraulic brake system & bleeding of brakes.

7. Valve timing setting including valve clearance adjustment.

8. Servicing of steering gear box, checking for end play in shafts.

9. Overhauling of a complete strut type suspension system.

10. Dismantle and assemble C.V joint. Also examine a slip joint, U.J cross in propeller shaft.

11. Compression test of petrol and diesel engine.

12. Disassembling cylinder head, decarbonizing, Valve Seat Grinding

13. Disassembling of engine: inspection of engine components, servicing of components,

measurement of dimensions of different components of engine, compare with standard

specifications, piston ring setting, assembling using special tools.

14. Rectifying the troubles in ignition system, adjusting spark plug and C. B. Point gap,

checking ignition timing.

15. Cylinder reconditioning: Checking the cylinder bore, setting the tool, re-boring operation

using vertical or portable cylinder reboring machine.

16. Tyre removing, inspection, check for cuts, bulges and excessive tread wear, resetting

using pneumatic tyre changer & Wheel balancing: Balancing of wheels by computerized

wheel balancing machine.

17. Wheel alignment: Checking the camber, caster, king pin inclination, toe in and toe out

with computerized wheel alignment machine.

18. F. I. P Calibration and phasing: Setting the angle of fuel delivery, calibration of fuel

quantity by FIP calibrating machine.

19. Brake drum re-conditioning: Brake drum skimming after leveling machine, ovality

measurement and setting the tool.

20. Testing of Two wheeled vehicles on chassis dynamometer

Expected outcome.

After this course the student will be able to

i. handle any maintenance issue in a vehicle

ii. identify the troubles of the vehicles from the symptoms shown.

Text Book:

1. Boyce Dwiggins – Automobile Repair guide, Theodor Audel and Co., Indiana – 1978.

2. A. W. Judge – Maintenance of high speed diesel engine, Chapmann Hall Ltd.

3. A. W. Judge – Motor vehicle engine servicing 3rd edition, Pitman paper mark, London,

1969.

4. Vehicle service manuals and reputed manufacturers.

S-ar putea să vă placă și

- g1 Test GuideDocument12 paginig1 Test GuideOctavio Maciel100% (1)

- Service Manual: Wabco Air CompressorsDocument24 paginiService Manual: Wabco Air CompressorsMuriel RembertoÎncă nu există evaluări

- Competency Based Learning Material: Servicing BrakesDocument33 paginiCompetency Based Learning Material: Servicing BrakesMelvy de la Torre100% (2)

- Vehicle Service History RecordsDocument53 paginiVehicle Service History Recordsbetelhem ermiasÎncă nu există evaluări

- Major Process Equipment Maintenance and RepairDe la EverandMajor Process Equipment Maintenance and RepairEvaluare: 4 din 5 stele4/5 (4)

- Workshop ManualDocument787 paginiWorkshop ManualGoran Apostolov92% (38)

- 140M Elect Diagram PDFDocument27 pagini140M Elect Diagram PDFcriman45Încă nu există evaluări

- 317 Training Manual 0704Document219 pagini317 Training Manual 0704mliugong100% (4)

- All Formulas HvacDocument11 paginiAll Formulas HvacrockÎncă nu există evaluări

- Automobile EngineeringDocument5 paginiAutomobile Engineeringshriram_sciÎncă nu există evaluări

- XCT100 SpecifDocument37 paginiXCT100 SpecifErika Justiniano VargasÎncă nu există evaluări

- D11RDocument24 paginiD11RRicardo Contreras B100% (1)

- Experiment 7-Pump Performance - Single PumpDocument12 paginiExperiment 7-Pump Performance - Single PumpVasanthan Rao0% (1)

- ICF Coach MaintenanceDocument18 paginiICF Coach MaintenanceLuv KushÎncă nu există evaluări

- AU305 Vehicle MaintenanceDocument2 paginiAU305 Vehicle MaintenancevaisakmctÎncă nu există evaluări

- Aut 116-05 8wk Revised 1-11 FinalDocument13 paginiAut 116-05 8wk Revised 1-11 FinalJsy LangÎncă nu există evaluări

- Syllabus AutomobileDocument16 paginiSyllabus AutomobileBharani 27Încă nu există evaluări

- 15me655 AeDocument2 pagini15me655 Aeyoussef ibrahimÎncă nu există evaluări

- Ae Mod1 5@azdocuments - inDocument188 paginiAe Mod1 5@azdocuments - inBhargav AngadiÎncă nu există evaluări

- AU201 SI Engines and CombustionDocument3 paginiAU201 SI Engines and CombustionvaisakmctÎncă nu există evaluări

- AU206 Auto TransmissionDocument2 paginiAU206 Auto TransmissionVivek Venugopal0% (1)

- Untitled NotesDocument149 paginiUntitled NotesShashank BiligiÎncă nu există evaluări

- List of Open Electives Offered by Automobile Engg BoardDocument15 paginiList of Open Electives Offered by Automobile Engg BoardpurnaÎncă nu există evaluări

- ENGINEERING TITLEDocument37 paginiENGINEERING TITLEferiha khanÎncă nu există evaluări

- Automobile - Full Notes - 6TH PDFDocument179 paginiAutomobile - Full Notes - 6TH PDFShailesh RajuÎncă nu există evaluări

- Gujarat Technological University: % WeightageDocument4 paginiGujarat Technological University: % WeightageEr Samkit ShahÎncă nu există evaluări

- Automotive Shs-DipDocument4 paginiAutomotive Shs-DipAl M. GamzÎncă nu există evaluări

- Least of Lab EquipmentsDocument1 paginăLeast of Lab EquipmentsGirish ShetÎncă nu există evaluări

- Thermal and Automobile EngineeringDocument7 paginiThermal and Automobile Engineeringpriya dharshini100% (1)

- MSBTE - Final Copy DTDocument6 paginiMSBTE - Final Copy DTnavneetkpatil8409Încă nu există evaluări

- Summer - 15 PaperDocument20 paginiSummer - 15 PaperAnonymous NWEepcYwÎncă nu există evaluări

- Engine and Transmission SystemsDocument3 paginiEngine and Transmission SystemstigerbooksÎncă nu există evaluări

- Automobile Engineering I: 1. Introductory TopicsDocument2 paginiAutomobile Engineering I: 1. Introductory TopicsjigarÎncă nu există evaluări

- Cos Modul 7 Clutch RepairDocument12 paginiCos Modul 7 Clutch Repaireizz88Încă nu există evaluări

- Automobile Engineering Scheme and Credits Credits Semester-VIIIDocument2 paginiAutomobile Engineering Scheme and Credits Credits Semester-VIIIVikash KumarÎncă nu există evaluări

- Automobile Maintenance and Pollution Control Laboratory ManualDocument12 paginiAutomobile Maintenance and Pollution Control Laboratory ManualLohia Mohmed RafikÎncă nu există evaluări

- Auto Engine Course Document SummaryDocument13 paginiAuto Engine Course Document SummaryDineshNewalkarÎncă nu există evaluări

- Uts English - Muhammad Syafri Fadhila - Tro 1.2 - 2206034Document10 paginiUts English - Muhammad Syafri Fadhila - Tro 1.2 - 2206034syafri fadhillaÎncă nu există evaluări

- Syllabus - Driver Cum Auto MechanicDocument13 paginiSyllabus - Driver Cum Auto MechanicMichael Alba100% (1)

- Fourth 1 PDFDocument23 paginiFourth 1 PDFMathews P RejiÎncă nu există evaluări

- CalDocument2 paginiCalThangamKumarÎncă nu există evaluări

- VT Lab Manual FinalDocument50 paginiVT Lab Manual FinalKannan MuthuÎncă nu există evaluări

- 3046 Heavy Equipment Maintenance RepairDocument12 pagini3046 Heavy Equipment Maintenance Repairام احمدÎncă nu există evaluări

- Automobile Engineering SyllabusDocument2 paginiAutomobile Engineering SyllabusAnbarasu AthimoolamÎncă nu există evaluări

- AU212 Automobile Power PlantDocument3 paginiAU212 Automobile Power PlantvaisakmctÎncă nu există evaluări

- AU301 Auto TransmissionDocument2 paginiAU301 Auto TransmissionvaisakmctÎncă nu există evaluări

- Practical - QP - R - 2017 - AT8411 - OK - AT8411 - 4.1Document3 paginiPractical - QP - R - 2017 - AT8411 - OK - AT8411 - 4.1Palani VelÎncă nu există evaluări

- Automobile Service Tests SpecificationsDocument23 paginiAutomobile Service Tests SpecificationsAbdo JondiÎncă nu există evaluări

- AU 8th SEM - AU 21-22071021124446Document4 paginiAU 8th SEM - AU 21-22071021124446Sumit VermaÎncă nu există evaluări

- AE8005 Aero Engine Maintenance and Repair LTPC 3 0 0 3 ObjectivesDocument1 paginăAE8005 Aero Engine Maintenance and Repair LTPC 3 0 0 3 ObjectivesAERO JPRÎncă nu există evaluări

- IC ENGINES LABDocument3 paginiIC ENGINES LABPiyuesh GoyalÎncă nu există evaluări

- TM-104 Main SCH-TRTDocument19 paginiTM-104 Main SCH-TRTsanjayisdonÎncă nu există evaluări

- Course Title: Vehicle Testing Lab Course Code: 6058 Course Category: A Periods/Week: 6 Periods/Semester: 90 Credits: 3Document2 paginiCourse Title: Vehicle Testing Lab Course Code: 6058 Course Category: A Periods/Week: 6 Periods/Semester: 90 Credits: 3VaisakVenugopalÎncă nu există evaluări

- Course Title: Automobile Servicing & Maintenance Course Code: 6052 Course Category: A Periods/Week: 6 Periods/Semester: 75 Credits: 6Document5 paginiCourse Title: Automobile Servicing & Maintenance Course Code: 6052 Course Category: A Periods/Week: 6 Periods/Semester: 75 Credits: 6VaisakVenugopalÎncă nu există evaluări

- 5 1Document13 pagini5 1gabrieltinÎncă nu există evaluări

- Advanced Automotive SystemsDocument14 paginiAdvanced Automotive SystemsVikram Athreya VÎncă nu există evaluări

- Diagnosis and Testing - I (Auto Engines)Document2 paginiDiagnosis and Testing - I (Auto Engines)raumil1237590100% (1)

- Final Cits TractorDocument22 paginiFinal Cits Tractorparveenrathee123Încă nu există evaluări

- CBLM RAV As Service Clutch SystemDocument261 paginiCBLM RAV As Service Clutch SystemjovenalÎncă nu există evaluări

- Automobile TechnologyDocument7 paginiAutomobile Technologypurusottam2765Încă nu există evaluări

- Primera Entrega TR1 Ingles TecnicoDocument8 paginiPrimera Entrega TR1 Ingles TecnicoYolvi YsagaÎncă nu există evaluări

- Rajasthan State Road Transport CorporationDocument5 paginiRajasthan State Road Transport Corporationchandra1985Încă nu există evaluări

- Automobile Engineering SyllabusDocument3 paginiAutomobile Engineering SyllabusRajesh MurkurÎncă nu există evaluări

- Automobile EngineeringDocument4 paginiAutomobile EngineeringRita KalaniÎncă nu există evaluări

- Engine Tune-Up Guide: Checkups, Procedures & DiagnosticsDocument37 paginiEngine Tune-Up Guide: Checkups, Procedures & DiagnosticsEmran MuftiÎncă nu există evaluări

- CI Engines & Combustion CourseDocument3 paginiCI Engines & Combustion CourseVivek Venugopal0% (1)

- Course Title: Health & Physical Education Course Code: 1009 Course Category: C Periods/Week: 3 (1 Theory +2 Practical) Periods/Semester: 45 Credits: 2Document4 paginiCourse Title: Health & Physical Education Course Code: 1009 Course Category: C Periods/Week: 3 (1 Theory +2 Practical) Periods/Semester: 45 Credits: 2vaisakmctÎncă nu există evaluări

- 1002Document8 pagini1002vaisakmctÎncă nu există evaluări

- Course Title: Engineering Graphics Course Code: 2005 Course Category: F Periods/ Week: 5 Periods/ Semester: 75 Credit: 0Document5 paginiCourse Title: Engineering Graphics Course Code: 2005 Course Category: F Periods/ Week: 5 Periods/ Semester: 75 Credit: 0vaisakmctÎncă nu există evaluări

- Course Title: Electrical & Electrononics Engineering Course Code: 3021 Course Category: B Periods/Week: 5 Periods/Semester: 75 Credits: 5Document4 paginiCourse Title: Electrical & Electrononics Engineering Course Code: 3021 Course Category: B Periods/Week: 5 Periods/Semester: 75 Credits: 5vaisakmctÎncă nu există evaluări

- Course Title: Project Work and Seminar Course Code: 6009a Course Category: A Periods/Week: 6 Periods/Semester: 90 Credits: 10 Time Schedule Topic Periods I II III IV TotalDocument1 paginăCourse Title: Project Work and Seminar Course Code: 6009a Course Category: A Periods/Week: 6 Periods/Semester: 90 Credits: 10 Time Schedule Topic Periods I II III IV TotalvaisakmctÎncă nu există evaluări

- Course Title: English For Communication I Course Code: 1001 Course Category: F Periods/Week: 4 Periods/Semester: 60 Credits: 3Document2 paginiCourse Title: English For Communication I Course Code: 1001 Course Category: F Periods/Week: 4 Periods/Semester: 60 Credits: 3vaisakmctÎncă nu există evaluări

- Advanced Automobile Engineering Dte KeralaDocument3 paginiAdvanced Automobile Engineering Dte KeralavaisakmctÎncă nu există evaluări

- 3001 2 PDFDocument6 pagini3001 2 PDFvaisakmctÎncă nu există evaluări

- Course Title: Fuels & Combustion Course Code: 5053 Course Category: E Periods/Week: 4 Periods/Semester: 60 Credits: 4Document3 paginiCourse Title: Fuels & Combustion Course Code: 5053 Course Category: E Periods/Week: 4 Periods/Semester: 60 Credits: 4vaisakmctÎncă nu există evaluări

- 3001 2 PDFDocument6 pagini3001 2 PDFvaisakmctÎncă nu există evaluări

- AU208 Computer ProgrammingDocument2 paginiAU208 Computer ProgrammingVivek VenugopalÎncă nu există evaluări

- AU212 Automobile Power PlantDocument3 paginiAU212 Automobile Power PlantvaisakmctÎncă nu există evaluări

- Academic Calendar DiplomaDocument2 paginiAcademic Calendar DiplomaVaisakVenugopal0% (1)

- AU203 Auto Chassis 3-0-0-3 2016 Prerequisite: Nil: Course Code Course Name L-T-P - Credits Year ofDocument2 paginiAU203 Auto Chassis 3-0-0-3 2016 Prerequisite: Nil: Course Code Course Name L-T-P - Credits Year ofvaisakmctÎncă nu există evaluări

- ME 206 Fluid Machinery PDFDocument3 paginiME 206 Fluid Machinery PDFnandan144Încă nu există evaluări

- AU301 Auto TransmissionDocument2 paginiAU301 Auto TransmissionvaisakmctÎncă nu există evaluări

- ADVANCED THERMODYNAMICS COURSEDocument2 paginiADVANCED THERMODYNAMICS COURSEVivek VenugopalÎncă nu există evaluări

- Academic Calendar 2017-18Document5 paginiAcademic Calendar 2017-18Srikanth KodothÎncă nu există evaluări

- ME201 Mechanics of Solids Course SyllabusDocument3 paginiME201 Mechanics of Solids Course SyllabusSudeesh SudevanÎncă nu există evaluări

- Ktu Manufacturing Technology PDFDocument5 paginiKtu Manufacturing Technology PDFseminarprojectÎncă nu există evaluări

- At SyllabusDocument2 paginiAt SyllabusvaisakmctÎncă nu există evaluări

- Automobile Engineering: Semester - 3Document5 paginiAutomobile Engineering: Semester - 3vaisakmctÎncă nu există evaluări

- AU201 SI Engines and CombustionDocument3 paginiAU201 SI Engines and CombustionvaisakmctÎncă nu există evaluări

- Tecumseh Fast Moving Parts Guide PDFDocument50 paginiTecumseh Fast Moving Parts Guide PDFWilliam WebbÎncă nu există evaluări

- Road Tanker Fas CatDocument2 paginiRoad Tanker Fas CatmohsenÎncă nu există evaluări

- Consumption of Toyota HZJ78 SparesDocument22 paginiConsumption of Toyota HZJ78 SparesIgga GeorgeÎncă nu există evaluări

- ZF 8000 SeriesDocument4 paginiZF 8000 SeriesBattiÎncă nu există evaluări

- 2012-03-09 Die Mercedes-Benz Dieselmotoren Powertrains Für Die Neue A - Und B-Klasse - ENDocument20 pagini2012-03-09 Die Mercedes-Benz Dieselmotoren Powertrains Für Die Neue A - Und B-Klasse - ENFayez AlnamarnehÎncă nu există evaluări

- Art Cool Inverter Product Data BookDocument31 paginiArt Cool Inverter Product Data Bookacer_5101Încă nu există evaluări

- Question Bank 3150910 Emi IDocument3 paginiQuestion Bank 3150910 Emi IHardik NakraniÎncă nu există evaluări

- FU (H4SO) Fuel InjectionDocument61 paginiFU (H4SO) Fuel InjectionHMs SamuelÎncă nu există evaluări

- Inadvertent Energization Generator Protection IEEEDocument1 paginăInadvertent Energization Generator Protection IEEEFirmanJohannesMaruliTuaSimanullangÎncă nu există evaluări

- Ashrae 90 1 2010 (237-270)Document34 paginiAshrae 90 1 2010 (237-270)alvaro moraÎncă nu există evaluări

- HUSABERG FE 450 2013: Spare Parts Manual: EngineDocument28 paginiHUSABERG FE 450 2013: Spare Parts Manual: EngineDaniel Eduardo Frias CasalÎncă nu există evaluări

- 500 - Parts Motor de HormigoneraDocument2 pagini500 - Parts Motor de HormigoneraluismdmjÎncă nu există evaluări

- NL PrdescrDocument256 paginiNL PrdescrJimmy BobbyÎncă nu există evaluări

- 150 Ton Link Belt LS 238HSpecsDocument6 pagini150 Ton Link Belt LS 238HSpecsYosses Sang Nahkoda0% (1)

- Auxiliary Units of CompressorDocument4 paginiAuxiliary Units of CompressorBalasubramanian CÎncă nu există evaluări

- Eni Oil Brochure Oct 2012Document5 paginiEni Oil Brochure Oct 2012Oscar Christian Espinal GuerreroÎncă nu există evaluări

- Valve Culata G3412 EspecificacionDocument3 paginiValve Culata G3412 Especificacioncarlos angelÎncă nu există evaluări

- SH-E Pump Motor - Final - 2014Document213 paginiSH-E Pump Motor - Final - 2014Md. Nobin KhanÎncă nu există evaluări

- HOK Work BookDocument42 paginiHOK Work BooksathishÎncă nu există evaluări

- Problem Set-Turbines and PumpsDocument3 paginiProblem Set-Turbines and PumpsBob MarleyÎncă nu există evaluări

- Data Kamag 2400 SDocument4 paginiData Kamag 2400 Skoko sri handokoÎncă nu există evaluări

- Four Stroke EngineDocument9 paginiFour Stroke Enginepawarsikander100% (3)