Documente Academic

Documente Profesional

Documente Cultură

Toriconical Head 87 Psi

Încărcat de

Fabio Augusto Hincapie HenaoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Toriconical Head 87 Psi

Încărcat de

Fabio Augusto Hincapie HenaoDrepturi de autor:

Formate disponibile

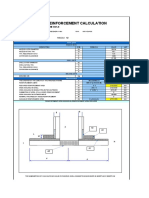

ASME CODE CALCULATIONS SECTION VIII DIVISION 1 2004 EDITION

2006 ADDENDA

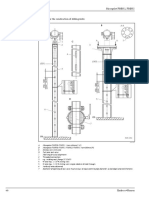

TORICONICAL HEAD CALCULATIONS JOB No. 101241

1.0 Design Data

Design Pressure P= 87,00 psi UG-22

Design Temperature T= T= 300,00 °F UG-20

Inside Diameter ID= 23,722 inch

Corrosion Allowance C= 0 inch UG-25

Head Material SA 36

Allowable Stress at Design Temp. S= 16600 psi Sect IID,1A

Allowable Stress at Ambient Temp. S= 16600 psi Sect IID,1A

Head Efficiency E= E= 0,65 UW-12

Corroded Diameter D= 23,722 inch

Half Apex Angle a= 35,00 °

Knuckle Radius r= 9,840 inch

Minor Diameter Dm= 4,250 inch

2.1 Conical Section Thickness Calculations

Di=D-2(r+C)cos a Di= 20,1626 inch

t=PDi/[2cos a(SE-0.6P)] t= 0,0997 inch

treq=t + C treq= 0,0997 inch

2.2 Spherical Section Thickness Calculations

L=Di/(2cos a) L= 12,307 inch

M=1/4[3+Sqrt[L/(r+C)] M= 1,030

t=PLM/(2SE-0.2P) t= 0,051 inch

treq=t + C treq= 0,0511 inch

2.3 Head Thickness Calculations

treq=Greater of the above treq= 0,0997 inch

tactual= 0,1000 inch

tnom= 0,1000 inch

rmin=3tnom rmin= 0,3000 inch

3.1 MAWP Hot and Corroded Calculations

P=2SEtcos a/(Di+1.2tcos a) P= 87,25 psi

P=2SEt/(LM+0.2t) P= 170,04 psi

P= Lower of the above P= 87,25 psi

MAWP = P-H MAWP= 87,25 psi

3.2 MAWP Cold and New Calculations

P=2SEtcos a/(Di+1.2tcos a) P= 87,25 psi

P=2SEt/(LM+0.2t) P= 222,01 psi

P= Lower of the above P= 87,25 psi

14/12/2017 03:53 p.m. BY:Fabio A Hincapie PAGE 1 OF 2

ASME CODE CALCULATIONS SECTION VIII DIVISION 1 2004 EDITION

2006 ADDENDA

TORICONICAL HEAD CALCULATIONS JOB No. 101241

MAWP = P-H MAWP= 87,25 psi

4.0 Small End Calculations

Small End Shell Material SA 105 & SA 36

Allowable Stress at Design Temp. Ss= 16600 psi

Small End Radius R= 2,125 inch

Shell Longitudinal Joint Efficiency E1= 0,55

Cone Longitudinal Joint Efficiency E2= 0,65

Cone Thickness at Small End tc= 0,199 inch

Small end Shell Thickness ts= 0,15 inch

Axial Load in the Small End f2= 500,000 lb/in.

P/SsE1= 0,010

D= 8,717 °

The Small End Junction requires Reinforcement Calculations

k= 1,0000

Qs=P(R+C)/2+f2 Qs= 592,4375 lb/in

Ars=[kQs(R+C)/(SsE1)](1-DELTA/ALFA)tanALFA Ars= 0,072503 Sq.In.

t=P(R+C)/(SsE1-0.6P) t= 0,020366 inch

tr=P(Dm+2C)/[2cosALFA(SE2-0.6P)] tr= 0,042037 inch

Aes=[0.78Sqrt[(R+C)(ts-C)][(ts-t-C)+(tc-tr-C)/CosALFA] Aes= 0,076 inch2

Aes 0.78 ( R C ) (ts C ) (ts t C ) (tc tr C ) / Cos

M=1/4[3+Sqrt[L/(r+C)]

t=PLM/(2SE-0.2P) t= 0,000 inch

treq=t + C treq= 0,0000 inch

2.3 Head Thickness Calculations

treq=Greater of the above treq= 0,0000 inch

tactual= 0,0000 inch

tnom= 0,0000 inch

rmin=3tnom rmin= 0,0000 inch

3.1 MAWP Hot and Corroded Calculations

P=2SEtcos a/(Di+1.2tcos a) P= 2,64 psi

P=2SEt/(LM+0.2t) P= 1,89 psi

P= Lower of the above P= 0,00 psi

MAWP = P-H MAWP= 0,00 psi

P=2SEtcos a/(Di+1.2tcos a) P= 0,00 psi

P=2SEt/(LM+0.2t) P= 0,00 psi

P= Lower of the above P= 0,00 psi

14/12/2017 03:53 p.m. BY:Fabio A Hincapie PAGE 2 OF 2

S-ar putea să vă placă și

- Stillwell Pipe ArrangementDocument1 paginăStillwell Pipe ArrangementVishalDhimanÎncă nu există evaluări

- Toriconical Head Ver 1.1Document4 paginiToriconical Head Ver 1.1Iqbal AhmadsÎncă nu există evaluări

- CEPE02100A1 CAG Updated Jan23 14Document60 paginiCEPE02100A1 CAG Updated Jan23 14rudi setiawanÎncă nu există evaluări

- Astm F436.04 PDFDocument6 paginiAstm F436.04 PDFWelington Volpatto MoraisÎncă nu există evaluări

- Oil Gas Construction Factory L.L.CDocument2 paginiOil Gas Construction Factory L.L.CRenny DevassyÎncă nu există evaluări

- Flange calculation as per ASME Section VIIIDocument9 paginiFlange calculation as per ASME Section VIIIDarshan PanchalÎncă nu există evaluări

- Tank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeDocument1 paginăTank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeABIDEEN BAMNEÎncă nu există evaluări

- Eqn Reference ASME BPVC r1sDocument5 paginiEqn Reference ASME BPVC r1sagarcia654127Încă nu există evaluări

- Asme B31.8 Nozzles CalcDocument16 paginiAsme B31.8 Nozzles CalcSAMER OSMANÎncă nu există evaluări

- Sa 420Document10 paginiSa 420Widya widyaÎncă nu există evaluări

- S275JR PDFDocument1 paginăS275JR PDFEmrahCayboylu100% (1)

- Shell Thickness CalculationsDocument2 paginiShell Thickness CalculationsskocogluÎncă nu există evaluări

- PV Elite Vessel Analysis Program HorizontalDocument55 paginiPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriÎncă nu există evaluări

- S-Stamp Calculation Nozzle ShellDocument4 paginiS-Stamp Calculation Nozzle ShellmukeshÎncă nu există evaluări

- ASME VIII Division 1 & 2 Pressure Vessel SeriesDocument6 paginiASME VIII Division 1 & 2 Pressure Vessel SeriesThanh Phuc NguyenÎncă nu există evaluări

- Design Procedure For Aes He PDFDocument30 paginiDesign Procedure For Aes He PDFRyan Goh Chuang HongÎncă nu există evaluări

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocument2 pagini2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebÎncă nu există evaluări

- F&D Head Design Tool: Pressure Vessel Engineering LTDDocument1 paginăF&D Head Design Tool: Pressure Vessel Engineering LTDMauricio KookcÎncă nu există evaluări

- Comparison ASME KTADocument7 paginiComparison ASME KTAAndres_Pastor1987Încă nu există evaluări

- Flat Ends With A Relief GrooveDocument11 paginiFlat Ends With A Relief GrooveEng-CalculationsÎncă nu există evaluări

- Compress CalculationDocument106 paginiCompress CalculationKrupal Patel100% (1)

- 299 - Elliptical Head Design Tool Ver E4.01Document1 pagină299 - Elliptical Head Design Tool Ver E4.01Pankaj SinglaÎncă nu există evaluări

- Cylindrical ShellsDocument3 paginiCylindrical ShellsEng-CalculationsÎncă nu există evaluări

- BPVC Viii-1 Udr-2Document2 paginiBPVC Viii-1 Udr-2asniff08Încă nu există evaluări

- E4.5.1 6 PTB 4 2015 PDFDocument50 paginiE4.5.1 6 PTB 4 2015 PDFKingston RivingtonÎncă nu există evaluări

- Small Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFDocument6 paginiSmall Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFhussamammarÎncă nu există evaluări

- COMPARISON OF MATERIAL STANDARDS FOR TUBESDocument1 paginăCOMPARISON OF MATERIAL STANDARDS FOR TUBESRaja HoneÎncă nu există evaluări

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 paginiCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareÎncă nu există evaluări

- ASME CODE Section VIII Div 1 Vs Div 2 Design FactorDocument7 paginiASME CODE Section VIII Div 1 Vs Div 2 Design FactorsarvannnÎncă nu există evaluări

- Calculo Brida Ejemplo PV - EliteDocument8 paginiCalculo Brida Ejemplo PV - ElitePedro Montes MarinÎncă nu există evaluări

- What Is An ASME Appendix 2 Flange Design PDFDocument1 paginăWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleÎncă nu există evaluări

- Static Equipment Generator 2019 BrochureDocument4 paginiStatic Equipment Generator 2019 BrochureDennis RaymondÎncă nu există evaluări

- Material P NumberDocument11 paginiMaterial P NumberChaitanya Sai TÎncă nu există evaluări

- BREVIA DE CALCUL PENTRU SEPARATORUL ORIZONTAL TRIFAZIC 80MCDocument223 paginiBREVIA DE CALCUL PENTRU SEPARATORUL ORIZONTAL TRIFAZIC 80MCakın ersözÎncă nu există evaluări

- Deaera DesignDocument13 paginiDeaera DesignBhanu K PrakashÎncă nu există evaluări

- Internal Pipe Distributor Design ProcedureDocument5 paginiInternal Pipe Distributor Design Proceduresenthil kumarÎncă nu există evaluări

- Section VIII CalDocument22 paginiSection VIII CalthodathersÎncă nu există evaluări

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 paginiCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDocument4 paginiLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhaleÎncă nu există evaluări

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Document9 paginiPipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo GuerraÎncă nu există evaluări

- Pressure Vessel RT TestDocument3 paginiPressure Vessel RT TestAriq FauzanÎncă nu există evaluări

- B Jack Nos For Cs Ss MaterialDocument12 paginiB Jack Nos For Cs Ss MaterialfahadfiazÎncă nu există evaluări

- Ejma7r2 Bellows Worksheet-1Document11 paginiEjma7r2 Bellows Worksheet-1odormicchiÎncă nu există evaluări

- Flat End With A Full-Face Gasket For Single Isolated OpeningDocument3 paginiFlat End With A Full-Face Gasket For Single Isolated OpeningEng-CalculationsÎncă nu există evaluări

- Atm Sto Tanks Venting Req API2000 2009 Rev1 - TESTDocument18 paginiAtm Sto Tanks Venting Req API2000 2009 Rev1 - TESTRanjit PaulÎncă nu există evaluări

- Torispherical Head TolvaDocument1 paginăTorispherical Head TolvaFabio Augusto Hincapie HenaoÎncă nu există evaluări

- THICKNESS CALCULATIONS AND NOZZLE REINFORCEMENTDocument10 paginiTHICKNESS CALCULATIONS AND NOZZLE REINFORCEMENTelleÎncă nu există evaluări

- Determine Shell ThicknessDocument53 paginiDetermine Shell ThicknessRajul MuraliÎncă nu există evaluări

- Shell CalculationsDocument3 paginiShell CalculationsBaher Elsheikh100% (7)

- Heat load and log mean temperature difference calculationDocument3 paginiHeat load and log mean temperature difference calculationElzubair EljaaliÎncă nu există evaluări

- Inner Vessel Check Shell Thickness For Internal PressureDocument6 paginiInner Vessel Check Shell Thickness For Internal PressureSAMER OSMANÎncă nu există evaluări

- Shell (S) : ASME Code VIII Div I 2010 Edition 2012 AddendaDocument1 paginăShell (S) : ASME Code VIII Div I 2010 Edition 2012 AddendaPhát NguyễnÎncă nu există evaluări

- Modulus of Elasticity at DT 'E' (Ksi)Document8 paginiModulus of Elasticity at DT 'E' (Ksi)Debabrata MajiÎncă nu există evaluări

- Heat Exchanger DesignDocument7 paginiHeat Exchanger Designsiva sankarÎncă nu există evaluări

- Calculo EjemploDocument52 paginiCalculo EjemplodmagnetoÎncă nu există evaluări

- StairDocument1 paginăStairAek JanÎncă nu există evaluări

- Design of Shell & Tube HXDocument62 paginiDesign of Shell & Tube HXUmirahRashidahÎncă nu există evaluări

- Dish End Calculations As Per ASME Section VII Div 1Document2 paginiDish End Calculations As Per ASME Section VII Div 1sksiddique83% (6)

- Asme Viii CalcsDocument20 paginiAsme Viii CalcsSriram VjÎncă nu există evaluări

- Metallurgical Microscope Lab KitDocument1 paginăMetallurgical Microscope Lab KitFabio Augusto Hincapie HenaoÎncă nu există evaluări

- FjugandofisicaDocument5 paginiFjugandofisicaFernanda VillalpandoÎncă nu există evaluări

- Control de Nivel Mcdonnell Miller 259Document12 paginiControl de Nivel Mcdonnell Miller 259Appleuk SudarÎncă nu există evaluări

- Tolva Sand Blasting Shell1Document1 paginăTolva Sand Blasting Shell1Fabio Augusto Hincapie HenaoÎncă nu există evaluări

- Tolva Sand Blasting Shell1Document1 paginăTolva Sand Blasting Shell1Fabio Augusto Hincapie HenaoÎncă nu există evaluări

- Condensate Return Systems 10.11.12 PDFDocument53 paginiCondensate Return Systems 10.11.12 PDFarunyoga100% (2)

- Pfi Es-24Document10 paginiPfi Es-24kingstonÎncă nu există evaluări

- Control de Nivel Mcdonnell Miller 259Document12 paginiControl de Nivel Mcdonnell Miller 259Appleuk SudarÎncă nu există evaluări

- Toriconical Head 87 PsiDocument2 paginiToriconical Head 87 PsiFabio Augusto Hincapie HenaoÎncă nu există evaluări

- Torispherical Head TolvaDocument1 paginăTorispherical Head TolvaFabio Augusto Hincapie HenaoÎncă nu există evaluări

- Tolva Sand Blasting Shell1Document1 paginăTolva Sand Blasting Shell1Fabio Augusto Hincapie HenaoÎncă nu există evaluări

- Tolva Sand Blasting Shell1Document1 paginăTolva Sand Blasting Shell1Fabio Augusto Hincapie HenaoÎncă nu există evaluări

- Astm A319.370238-1Document2 paginiAstm A319.370238-1Fabio Augusto Hincapie Henao100% (1)

- ASME B16 20 Metallic Gaskets For Pipe Flanges PDFDocument2 paginiASME B16 20 Metallic Gaskets For Pipe Flanges PDFFabio Augusto Hincapie HenaoÎncă nu există evaluări

- Tolva Sand Blasting Shell1Document1 paginăTolva Sand Blasting Shell1Fabio Augusto Hincapie HenaoÎncă nu există evaluări

- Miller TIG HandbookDocument20 paginiMiller TIG Handbookquiron2010Încă nu există evaluări

- How to Cut and Strip a VGA Cable for DIY ProjectsDocument7 paginiHow to Cut and Strip a VGA Cable for DIY ProjectsDlanor AvadecÎncă nu există evaluări

- 3 Way Ball ValvesDocument17 pagini3 Way Ball ValvesSagar Bhosale100% (1)

- Flexible Pavement DesignDocument15 paginiFlexible Pavement Designপ্রিয়দীপ প্রিয়ম100% (1)

- Construction of District Court Complex Electrical WorksDocument76 paginiConstruction of District Court Complex Electrical WorkssunilrauloÎncă nu există evaluări

- Matlab Code ABBD MatrixDocument4 paginiMatlab Code ABBD MatrixmehdiÎncă nu există evaluări

- Section A-A: Karnaphuli Water Supply Project - Phase 2 (Kwsp2) Drainage Plan & DetailsDocument1 paginăSection A-A: Karnaphuli Water Supply Project - Phase 2 (Kwsp2) Drainage Plan & DetailsgawtomÎncă nu există evaluări

- Experimental and Numerical Investigations On Seismic Responses of Reinforced Concrete Structures Considering Strain Rate EffectDocument15 paginiExperimental and Numerical Investigations On Seismic Responses of Reinforced Concrete Structures Considering Strain Rate EffectIon SococolÎncă nu există evaluări

- clark-public-utilities-ICEA S-94-649-AEIC CS8Document21 paginiclark-public-utilities-ICEA S-94-649-AEIC CS8chrisÎncă nu există evaluări

- Strength Development of Binary Cement Concrete UsiDocument18 paginiStrength Development of Binary Cement Concrete UsiAvinash LalÎncă nu există evaluări

- Proceedings of The 9th International Conference On Civil EngineeringDocument627 paginiProceedings of The 9th International Conference On Civil Engineeringtsaniya.mardhiyahÎncă nu există evaluări

- Technical Specification SG-45Document7 paginiTechnical Specification SG-45KrunoslavÎncă nu există evaluări

- New COADocument15 paginiNew COAAhadNurParagÎncă nu există evaluări

- ROTARY SCREW AIR COMPRESSOR SAFETY MANUALDocument86 paginiROTARY SCREW AIR COMPRESSOR SAFETY MANUALpabloÎncă nu există evaluări

- Steel Cross-Section ClassificationDocument2 paginiSteel Cross-Section ClassificationMohan BhalmeÎncă nu există evaluări

- 1 s2.0 S223878542300652X MainDocument14 pagini1 s2.0 S223878542300652X MainFahra Aqilla AzzurahÎncă nu există evaluări

- Sika Solutions For Watertight Tunnel StructuresDocument36 paginiSika Solutions For Watertight Tunnel StructuresAdrian FrantescuÎncă nu există evaluări

- Activity Report 2010Document56 paginiActivity Report 2010Javier_FIQÎncă nu există evaluări

- MORTH BT, CC, Causeway, BridgeDocument247 paginiMORTH BT, CC, Causeway, BridgesrinivasparasaÎncă nu există evaluări

- Repairing and Waterproofing Concrete Balcony WalkwaysDocument2 paginiRepairing and Waterproofing Concrete Balcony WalkwayskoliÎncă nu există evaluări

- Catalogue Pipe Hangers SupportsDocument111 paginiCatalogue Pipe Hangers SupportsIlija Runjajic100% (1)

- Turner's IOR Key to Risk ManagementDocument9 paginiTurner's IOR Key to Risk Managementremya_392830015Încă nu există evaluări

- Construction Concrete Pre Pour Checklist Gdq5ygDocument1 paginăConstruction Concrete Pre Pour Checklist Gdq5ygJay Mark ArbuesÎncă nu există evaluări

- Development of design codes for concrete structuresDocument1 paginăDevelopment of design codes for concrete structuresGregory SimmonÎncă nu există evaluări

- VGC50 VGC Product Data: Vinylester Glass Capsule Anchoring AdhesiveDocument5 paginiVGC50 VGC Product Data: Vinylester Glass Capsule Anchoring AdhesiveJonathan DouglasÎncă nu există evaluări

- Hafsa - Bensghir French PrimeveraDocument3 paginiHafsa - Bensghir French Primeverahz135874Încă nu există evaluări

- Rev2 - MDCC MDC Park Central North Tower 32-35F Architectural Fitout Works - High Level PDFDocument4 paginiRev2 - MDCC MDC Park Central North Tower 32-35F Architectural Fitout Works - High Level PDFChristelle Marie Aquino BeroñaÎncă nu există evaluări

- Case Histories of Failure of Deep Excavation. Examination of Where Things Went Wrong: Nicoll Highway Collapse, SingaporeDocument8 paginiCase Histories of Failure of Deep Excavation. Examination of Where Things Went Wrong: Nicoll Highway Collapse, SingaporeThaungMyintÎncă nu există evaluări

- Terex Rh200 Maintenance Training: Hydraulic Cooling SystemDocument14 paginiTerex Rh200 Maintenance Training: Hydraulic Cooling Systemchurypizarro2367Încă nu există evaluări

- Structural Engg NotesDocument139 paginiStructural Engg NotesVicky MateÎncă nu există evaluări

- Triptico InglesDocument3 paginiTriptico InglesMARIANGEL .A SALDIVIIAÎncă nu există evaluări