Documente Academic

Documente Profesional

Documente Cultură

DI Pipe Support On The Concrete

Încărcat de

Немања КараклајићTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DI Pipe Support On The Concrete

Încărcat de

Немања КараклајићDrepturi de autor:

Formate disponibile

Princess Noura Bint Abdulrahman University for Women Project Joint venture

Riyadh, Kingdom of Saudi Arabia El Seif/CCC

part / package: package 3 - Utillity area references: time: date:

department: ENGINEERING 1:58 PM 1/16/2018

calcs by: Aleksandar Jankovic sr.str.eng

Valve chambers EF-BT-2-WVC-01 Φ=… 150 mm

1 .1 Input data:

Span between supports ……..……………………………………… 1.3 m

Steel grade of the pipe as per ASTM A36………………………… 245 N/mm2

The thickness of the steel pipe…………………………………….. 6.3 mm

The pipe diameter……………………………………...…………….. 157.4 mm

The thickness of the insulation………..…………………………… 0 mm

The thickness of the HDPE jacket………..…………………………… 0 mm

The self density of PU insulation…………………………………….. 180 kg/m3

The self density of HDPE jacket…………………………………….. 960 kg/m3

The weight of valve…………….. 87 No 4 …. 348 kg

The weight of fitings/accessories…………………………………. 50 kg

The density of the fluid………………………………………………. 1000 kg/m3

The design criteria as per…….. AISC ASD , safety factor.. 2

The self weight of the steel………………………………………. 7860 kg/m3

The thickness of the concrete wall………………………………… 350 mm

The concrete brand (strength)……………………………………… 35 MPa

The weights of pipe branches:

D= 80 mm,with length of 3 w= 28.09164 g= 84.27492 kg

D= 0 mm,with length of 0 w= 0 g= 0 kg

D= 0 mm,with length of 0 w= 0 g= 0 kg

total= 84.27492 kg

The weights of the fluid from branches:

D= 80 mm,with length of 3 ………………….g= 15.072 kg

D= 0 mm,with length of 0 ………………….g= 0 kg

D= 0 mm,with length of 0 ………………….g= 0 kg

total= 15.072 kg

The weights of the valves from branches:

D= 80 mm,with weight of.. 50 No 4 g= 200 kg

D= 0 mm,with weight of.. 0 No 0 g= 0 kg

D= 0 mm,with weight of.. 0 No 0 g= 0 kg

total= 200

1 .2 Section properties of the pipe:

d= 157.4 mm-inside diameter of pipe

d1= 170 mm-outside diameter of pipe Wx=Wy= 99445.054 mm3

d2= 170 mm-outside diameter of insulation Aa= 3238.3134 mm2

d3= 170 mm-outside diameter of HDPE Wo= 198890.11 mm3

1 . 3 The loads:

Concentrate force…G=Gvalve+Gfitings=……………………………… 398 kg

Uniform load……g=ginsulation+gpipe+ghdpe+gfluid+gbranches=… 275.16819 kg/m

Max. Shear=…. 3.7785932 kN

Max. Moment= 1.8747928 kNm

Building / area: Valve chambers rev: VALVE CHAMBERS Sheet:

issued for: APPROVAL 0 pipe supports 0 3 2

Princess Noura Bint Abdulrahman University for Women Project Joint venture

Riyadh, Kingdom of Saudi Arabia El Seif/CCC

part / package: package 3 - Utillity area references: time: date:

department: ENGINEERING 1:58 PM 1/16/2018

calcs by: Aleksandar Jankovic sr.str.eng

Shear capacity of the pipe:

Pscap=0.6*Aa*Py/Ω=…………. 238.01603 > 3.778593 kN-maximum shear…………… safe

Moment capacity of the pipe

Mbcap=Wxx*Py/Ω=…………… 12.182019 > 1.874793 kNm-maximum moment……… safe

total stress ratio:

R=((Mb/Mbcap)^2+(Ps/Psacp)^2)=……………. 0.154715 < 1 safe

1 .4 Bearing capacity of the pipe sleeve embedded in the concrete wall:

La=r*3.14*120/360=…………………………………………………… 82.372667 mm

Sleeve area for bearing load, Aasl=La*Twall=………..………….. 28830.433 mm2

Bearing stress Pbs=Psmax/Aasl=………………………………. 0.1310627 N/mm2

Pbs=…………………………….. 0.1310627 < 35 ,fc(N/mm2)…………………….. safe

stress distribution in the sleeve

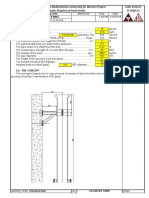

1 .5 The stress check of the steel beam support beneath the pipe

adopted beam: C 100x50x10 with following properties:

height……..H= 100 mm

width………B= 50 mm

flange thk…Tf= 8 mm

web thk…..Tw= 5 mm

Total force acting on the upper beam flange …………………..F= 3.7785932 kN

The steel clamp as per approved drawings, B= 50 L2= 320 mm

Assuming 45 degree stress dissapation, the lengts are: L1= 345 mm

L3= 345 mm

L4= 345 mm

the stres check in the point 1-upper beam flange:

bending moment Mb=F*B/4=… 0.0944648 kNm,shear force Ps= 3.7785932 kN

section property at point 1: Aa=Tf*L1=…………. 2760 mm2

Wx= (L1*Tf^2)/6=…. 3680 mm3

Shear capacity of the pipe:

Pscap=0.6*Aa*Py/Ω=…………. 202.86 > 3.778593 kN………….maximum shear safe

Moment capacity of the pipe

Mbcap=Wxx*Py/Ω=…………… 0.4508 > 0.094465 kNm………..bending moment safe

total stress ratio:

R=((Mb/Mbcap)^2+(Ps/Psacp)^2)=……………. 0.210376 < 1 safe

Building / area: Valve chambers rev: VALVE CHAMBERS Sheet:

issued for: APPROVAL 0 pipe supports 0 3 3

Princess Noura Bint Abdulrahman University for Women Project Joint venture

Riyadh, Kingdom of Saudi Arabia El Seif/CCC

part / package: package 3 - Utillity area references: time: date:

department: ENGINEERING 1:58 PM 1/16/2018

calcs by: Aleksandar Jankovic sr.str.eng

the stres check in the points 2,3,4-beam web:

bending moment Mb=F*B/4=… 0.0944648 kNm,comp force Ps= 3.7785932 kN

section property at point 1: Aa=Tw*L2=…………. 1725 mm2

Wx= (L1*Tw^2)/6=…. 1437.5 mm3

Shear capacity of the pipe:

Pscap=0.6*Aa*Py/Ω=…………. 126.7875 > 3.778593 kN………….maximum shear safe

Moment capacity of the pipe

Mbcap=Wxx*Py/Ω=…………… 0.1760938 > 0.094465 kNm………..bending moment safe

total stress ratio:

R=((Mb/Mbcap)^2+(Ps/Psacp)^2)=……………. 0.537273 < 1 safe

Adopted beam section as shown on following figure:

stiffener plate 5 mm thk

stiffener weld adopted of 5 mm all around

adopted beam length of ……………………………………………. 395 mm

Structural comment:

In case that designed beam is not available, the C channel with the same height,

width, web thk and flange thk can be used since the stress distribution is the same.

1 .6 The check of compressive strength of the concrete bellow the beam

compressive area beneath the beam...……………………...Aac= 19750 mm2

compression stress on concrete Pscc=F/Aac= 0.191321 < 35 N/mm2 safe

1 .7 The check of compressive strength of the infill material (grout) bellow the beam

compressive area beneath the beam...……………………...Aac= 19750 mm2

compression stress on grout….. Pscc=F/Aac= 0.191321 < 98 N/mm2 safe

1 .8 The check of connection bolts between steel clamp/beam

Since there is no pull out and shear force (the dead load only) there is no need for bolt

calculations and the bolts are adopted as 2 bolts M12 GR 4.8

1 .8 The check of anchor bolts between steel clamp/beam

Since there is no pull out and shear force (the dead load only) there is no need for anchor

bolts calculations and the bolts are dopted as hooked anchor bolts M 14 steel grade ASTM

A 36 with minimum embedded length of 100 mm.

1 .8 The dimensions of the concrete plinth

width B=Bbeam+2*50=………. 150 mm

length L=Lbeam+2*50=………. 495 mm

height H= to be confirmed as per MEP requirements (piping lay out).

The concrete pedestals to be checked by concrete engineer prior to loads and dimensions

mentioned in this transmittal.The plinths details (rebars) will follow this transmittal.

Building / area: Valve chambers rev: VALVE CHAMBERS Sheet:

issued for: APPROVAL 0 pipe supports 0 3 4

S-ar putea să vă placă și

- Elbow SupportDocument3 paginiElbow SupportНемања КараклајићÎncă nu există evaluări

- Vertical Bracket With U BoltDocument2 paginiVertical Bracket With U BoltНемања Караклајић100% (1)

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocument4 paginiSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRÎncă nu există evaluări

- Design of lifting lug on spreader beamDocument2 paginiDesign of lifting lug on spreader beamSabrang LorÎncă nu există evaluări

- SEISMIC ANALYSIS KazzincDocument14 paginiSEISMIC ANALYSIS KazzincArees KhambattaÎncă nu există evaluări

- Anchor Steel Supports-LoadsDocument3 paginiAnchor Steel Supports-LoadsНемања КараклајићÎncă nu există evaluări

- Shutter ConnectionDocument2 paginiShutter ConnectionНемања КараклајићÎncă nu există evaluări

- Copiar de Vessel - Weld - EfficiencyDocument4 paginiCopiar de Vessel - Weld - EfficiencylavascudoÎncă nu există evaluări

- CO2 Condenser 02-03-2023-15 PMDocument37 paginiCO2 Condenser 02-03-2023-15 PMahmad santosoÎncă nu există evaluări

- New Storage Tanks Design GuidelinesDocument6 paginiNew Storage Tanks Design GuidelineschrisevabÎncă nu există evaluări

- Torispherical Head TolvaDocument1 paginăTorispherical Head TolvaFabio Augusto Hincapie HenaoÎncă nu există evaluări

- Trunnion 6 TonDocument3 paginiTrunnion 6 TonEngr Khurram Jaan RamayÎncă nu există evaluări

- Calculation of Lifting ForcesDocument9 paginiCalculation of Lifting ForcesprantikduarahÎncă nu există evaluări

- Synechron: Customer Name Date Created byDocument1 paginăSynechron: Customer Name Date Created byneelÎncă nu există evaluări

- Compress EvaluateDocument23 paginiCompress EvaluateVishalDhiman100% (1)

- Tailing Lifting Lug Design 57 V 202 r2Document10 paginiTailing Lifting Lug Design 57 V 202 r2Dinesh KhaparkarÎncă nu există evaluări

- Platform - Bracing SupportDocument12 paginiPlatform - Bracing Supportpandiangv100% (1)

- Stress at Junction of Shell & HeadDocument13 paginiStress at Junction of Shell & HeadRey Fiedacan100% (1)

- NDT Calculation: Test Package No: PA-SS08-03 Project: Mead Johnson Nutritional CE370-12Document7 paginiNDT Calculation: Test Package No: PA-SS08-03 Project: Mead Johnson Nutritional CE370-12ravivarmadatla2011Încă nu există evaluări

- API 650 Tank Design 1Document5 paginiAPI 650 Tank Design 1Jose Ortiz100% (1)

- Side Wall of Screen Chamber & Grit Chamber DataDocument5 paginiSide Wall of Screen Chamber & Grit Chamber DataShankarappa NÎncă nu există evaluări

- Design of Lifting Lug: InputsDocument4 paginiDesign of Lifting Lug: InputsBahtiar Anak LaNangÎncă nu există evaluări

- Slot Expansion CalculationDocument1 paginăSlot Expansion CalculationSarfaraz KhanÎncă nu există evaluări

- Time To Empty Out Vessel No Dished EndsDocument2 paginiTime To Empty Out Vessel No Dished EndsHeiner PalaciosÎncă nu există evaluări

- Point Load CalculationsDocument3 paginiPoint Load Calculationskedar kavathekarÎncă nu există evaluări

- Design-Calculation Acid Wash TankDocument5 paginiDesign-Calculation Acid Wash TankWiz DomÎncă nu există evaluări

- Thermal Insulation Thickness Calculation (By James)Document1 paginăThermal Insulation Thickness Calculation (By James)Ah BengÎncă nu există evaluări

- Pipe Davit & Guide & Support Calculation 1/3) : (For Pressure Vessel Design Manual Procedure 6-1 (Type-B) )Document4 paginiPipe Davit & Guide & Support Calculation 1/3) : (For Pressure Vessel Design Manual Procedure 6-1 (Type-B) )vamsiÎncă nu există evaluări

- Calculation Trunion (By Maniacs)Document5 paginiCalculation Trunion (By Maniacs)SyahkullahÎncă nu există evaluări

- Weld Neck Flange Design Raised Face Bolt CalculationsDocument2 paginiWeld Neck Flange Design Raised Face Bolt CalculationsKashif KaziÎncă nu există evaluări

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Document35 paginiDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainÎncă nu există evaluări

- PV Elite ResultDocument239 paginiPV Elite ResultChaitanya Sai TÎncă nu există evaluări

- PDF2 L Hydraulic CylinderDocument56 paginiPDF2 L Hydraulic CylinderShyam Srinivasan100% (1)

- Etank Full ReportDocument108 paginiEtank Full ReportFaizal SattuÎncă nu există evaluări

- Find Eq - Length (M) :: Manual Pressure Drop CalculationDocument7 paginiFind Eq - Length (M) :: Manual Pressure Drop Calculationcryptic postÎncă nu există evaluări

- API 650 Baseplate DesignDocument3 paginiAPI 650 Baseplate DesignmjlazoÎncă nu există evaluări

- Skid Frame Calculation Sheet: LPG MeteringDocument11 paginiSkid Frame Calculation Sheet: LPG MeteringidilfitriÎncă nu există evaluări

- Horizontal Cylindrical Tank Volume and Level CalculatorDocument5 paginiHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraÎncă nu există evaluări

- LPG Amine Cooler-SummaryDocument15 paginiLPG Amine Cooler-SummaryJEEVITHAÎncă nu există evaluări

- Sendai: Eversendai Consulting Engineers (P) LTDDocument6 paginiSendai: Eversendai Consulting Engineers (P) LTDfsijestÎncă nu există evaluări

- Lifting - Lug (Modification)Document11 paginiLifting - Lug (Modification)Sam LowÎncă nu există evaluări

- Heat ExchangersDocument30 paginiHeat ExchangersvpjagannaathÎncă nu există evaluări

- Wind Calculation SheetDocument32 paginiWind Calculation SheetaauppalÎncă nu există evaluări

- Member Requirement: Classification of Section For DuctilityDocument4 paginiMember Requirement: Classification of Section For DuctilityWilly SetiawanÎncă nu există evaluări

- Lifting Lug CalculationDocument2 paginiLifting Lug Calculationmih1Încă nu există evaluări

- Design Pressure and Temperature for Flanges and GasketsDocument4 paginiDesign Pressure and Temperature for Flanges and GasketsSergio SmithÎncă nu există evaluări

- Welded PipeDocument2 paginiWelded PipeНемања КараклајићÎncă nu există evaluări

- DrinkingDocument6 paginiDrinkingНемања Караклајић100% (1)

- Storm Water Pump StationDocument6 paginiStorm Water Pump StationНемања КараклајићÎncă nu există evaluări

- Dead Load Only From The PipeDocument5 paginiDead Load Only From The PipeНемања Караклајић100% (1)

- Elevated Tank 150Document6 paginiElevated Tank 150Немања КараклајићÎncă nu există evaluări

- Irrigation-Hanging BracketDocument5 paginiIrrigation-Hanging BracketНемања КараклајићÎncă nu există evaluări

- Pedestrian BridgesDocument7 paginiPedestrian BridgesНемања Караклајић100% (1)

- Beechcraft 1900D Specs and Performance HighlightsDocument2 paginiBeechcraft 1900D Specs and Performance HighlightsArif PramudanaÎncă nu există evaluări

- Structural support design for spray nozzle systemDocument66 paginiStructural support design for spray nozzle systemajitÎncă nu există evaluări

- Technical DataDocument32 paginiTechnical Datarpagarwal2Încă nu există evaluări

- Full Text 01Document102 paginiFull Text 01hohoÎncă nu există evaluări

- G650 Unimog UL1750 RAAF Data Summary 0Document4 paginiG650 Unimog UL1750 RAAF Data Summary 0Jimmy50% (2)

- Done By: 1. Giyon Bezabh 0572/10 2. Mikiyas Adefa 0837/10Document50 paginiDone By: 1. Giyon Bezabh 0572/10 2. Mikiyas Adefa 0837/10Mikey CouthinhoÎncă nu există evaluări

- Andreev Rodion 201508 MSC PDFDocument157 paginiAndreev Rodion 201508 MSC PDFcdkueaÎncă nu există evaluări

- As Tutorial MetricDocument168 paginiAs Tutorial Metrichonestman1Încă nu există evaluări

- Welded Connection With I BeamDocument8 paginiWelded Connection With I BeamНемања КараклајићÎncă nu există evaluări

- Tunnel Section 0-250-Rev 01Document51 paginiTunnel Section 0-250-Rev 01Немања Караклајић100% (2)

- Washer PlateDocument2 paginiWasher PlateНемања Караклајић100% (2)

- Welded C ChannelDocument3 paginiWelded C ChannelНемања Караклајић100% (1)

- Tunnel Section 0-250-Rev 01Document51 paginiTunnel Section 0-250-Rev 01Немања Караклајић100% (2)

- Welded PipeDocument2 paginiWelded PipeНемања КараклајићÎncă nu există evaluări

- Air SeparatorsDocument2 paginiAir SeparatorsНемања КараклајићÎncă nu există evaluări

- Steel Dropers-Tunnel 0+200Document95 paginiSteel Dropers-Tunnel 0+200Немања Караклајић100% (1)

- Tunnel Added Beam On SupportDocument9 paginiTunnel Added Beam On SupportНемања Караклајић100% (1)

- Air SeparatorsDocument2 paginiAir SeparatorsНемања КараклајићÎncă nu există evaluări

- The Clamp BoltsDocument2 paginiThe Clamp BoltsНемања Караклајић100% (1)

- Vertical Movement Connection-TopDocument2 paginiVertical Movement Connection-TopНемања Караклајић100% (1)

- Typical TemplateDocument4 paginiTypical TemplateНемања КараклајићÎncă nu există evaluări

- Shutter Beam Check and Plate StresDocument2 paginiShutter Beam Check and Plate StresНемања КараклајићÎncă nu există evaluări

- Steel DropersDocument94 paginiSteel DropersНемања КараклајићÎncă nu există evaluări

- Support RadiatorsDocument5 paginiSupport RadiatorsНемања КараклајићÎncă nu există evaluări

- Shear Steel ConnectionDocument3 paginiShear Steel ConnectionНемања Караклајић100% (1)

- Air SeparatorsDocument2 paginiAir SeparatorsНемања КараклајићÎncă nu există evaluări

- Steel DropersDocument94 paginiSteel DropersНемања КараклајићÎncă nu există evaluări

- Pump Station-CoverDocument1 paginăPump Station-CoverНемања КараклајићÎncă nu există evaluări

- Air SeparatorsDocument2 paginiAir SeparatorsНемања КараклајићÎncă nu există evaluări

- Storm Water Pump StationDocument6 paginiStorm Water Pump StationНемања КараклајићÎncă nu există evaluări

- Shutter ConnectionDocument2 paginiShutter ConnectionНемања КараклајићÎncă nu există evaluări

- Elevated Tank 150Document6 paginiElevated Tank 150Немања КараклајићÎncă nu există evaluări

- Section CapacityDocument8 paginiSection CapacityНемања КараклајићÎncă nu există evaluări

- Potable-Cover-Rev 1Document2 paginiPotable-Cover-Rev 1Немања КараклајићÎncă nu există evaluări

- Irrigation-Hanging BracketDocument5 paginiIrrigation-Hanging BracketНемања КараклајићÎncă nu există evaluări

- ReportDocument5 paginiReportНемања КараклајићÎncă nu există evaluări

- ICE PPT v1Document16 paginiICE PPT v1Alessio ScarabelliÎncă nu există evaluări

- Slickline Pressure Control Equipment StringDocument2 paginiSlickline Pressure Control Equipment StringalanparraÎncă nu există evaluări

- Manual P250AF, P265F Gas Powered Burners EnglishDocument46 paginiManual P250AF, P265F Gas Powered Burners EnglishCARLOS RAMOSÎncă nu există evaluări

- BE Brochure HydronicChilledWaterFancoilCeilingCassette PDFDocument2 paginiBE Brochure HydronicChilledWaterFancoilCeilingCassette PDFAdriel CerrudÎncă nu există evaluări

- Cement Grouted Rock Bolts PDFDocument28 paginiCement Grouted Rock Bolts PDFSushmit SharmaÎncă nu există evaluări

- 2x16 AWG TC 600V Shielded Control CableDocument2 pagini2x16 AWG TC 600V Shielded Control CableRicardo GómezÎncă nu există evaluări

- Gate 1533Document7 paginiGate 1533Darshit D RajÎncă nu există evaluări

- Company AddDocument37 paginiCompany Addapi-3745493100% (3)

- DyeDocument12 paginiDyeVeby LamanepaÎncă nu există evaluări

- Motor Starters: Explosionproof, Dust-Ignitionproof, WatertightDocument37 paginiMotor Starters: Explosionproof, Dust-Ignitionproof, WatertightWaseem ArshadÎncă nu există evaluări

- 5Document17 pagini5PpanÎncă nu există evaluări

- Cost Savings Through Intelligent Robotization For The 21 CenturyDocument8 paginiCost Savings Through Intelligent Robotization For The 21 CenturySanta Kim100% (1)

- AmietDocument3 paginiAmietVignesh RamakrishnanÎncă nu există evaluări

- Best PPT On VALVESDocument155 paginiBest PPT On VALVESPanda BoyÎncă nu există evaluări

- Materials HandlingDocument27 paginiMaterials HandlingPatricia de LeonÎncă nu există evaluări

- HAGER ENCLOSURES - Cat HK02 EnclosuresDocument24 paginiHAGER ENCLOSURES - Cat HK02 Enclosurestinduong100% (1)

- 7.1. Concrete MixDocument17 pagini7.1. Concrete MixKrishna SankarÎncă nu există evaluări

- 0000 VMC 4525Document32 pagini0000 VMC 4525Silvia_282008roÎncă nu există evaluări

- Ginaf Systeemboek Hpvs EvsDocument157 paginiGinaf Systeemboek Hpvs Evsfish11173100% (3)

- Lift Slab ConstructionDocument123 paginiLift Slab Constructionarunavails100% (2)

- InternshipDocument14 paginiInternshipMohammed Shaheeruddin0% (1)

- Forces & Moments Measurement in Wind TunnelsDocument13 paginiForces & Moments Measurement in Wind Tunnelsanon_287164994Încă nu există evaluări

- Caterpillar Cat GC45K SWB Forklift Lift Trucks Service Repair Manual SN AT87A-00001 and Up PDFDocument35 paginiCaterpillar Cat GC45K SWB Forklift Lift Trucks Service Repair Manual SN AT87A-00001 and Up PDFfjkskekmdmmeÎncă nu există evaluări

- GCM01 Mu GB 12.2Document33 paginiGCM01 Mu GB 12.2Kaiser IqbalÎncă nu există evaluări

- CMC356 Eh297j PDFDocument9 paginiCMC356 Eh297j PDFDaniel Gabriel MARAVI CAMARAÎncă nu există evaluări

- Or TutorialDocument29 paginiOr TutorialhehehuhuÎncă nu există evaluări

- Chapter ViiDocument33 paginiChapter ViiChris AlcausinÎncă nu există evaluări

- Hydraulic Fan Bypass Valve: 12M, 120M, 140M, and 160M Hydraulic System Series 2 Motor GraderDocument4 paginiHydraulic Fan Bypass Valve: 12M, 120M, 140M, and 160M Hydraulic System Series 2 Motor GraderRembertoÎncă nu există evaluări

- Use & Care Manual: DishwasherDocument16 paginiUse & Care Manual: DishwashermacaronmaniacÎncă nu există evaluări

- TCC82 Pilecap DesignDocument99 paginiTCC82 Pilecap DesignFatima Marah100% (2)