Documente Academic

Documente Profesional

Documente Cultură

5 1 Mine Dump Truck Wheel Spindle REMAN

Încărcat de

SACHIDHANANDHAM ADrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

5 1 Mine Dump Truck Wheel Spindle REMAN

Încărcat de

SACHIDHANANDHAM ADrepturi de autor:

Formate disponibile

Case Study: 5.

Rear wheel spindle and drive train maintenance underway on a 400t payload dump truck (supported by Hedweld’s Trilift XC30).

New LaserBond® Deposition method offers superior REMAN parts made in Australia.

Large dump trucks are used extensively in the Australian mining environment. The CAT 777 is a common mid-sized off

highway dump truck and a characteristic off highway vehicle used in mining. Wheel spindles are a high wear high cost

component that can readily be remanufactured but not within Australia until now. With the downturn in mining there is a

growing number of dump trucks ‘parked-up’ awaiting maintenance overhauls. By using our laser cladding to reclaim these

- and other high cost components - significant time and money can be saved on waiting for new or replacement parts.

The Problem:

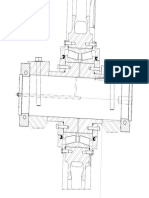

Fretting of the bearing surfaces, damage to the drive

splines and contamination can all lead to drive spindle

failures. When a truck is not in active service (‘down time’)

this represents lost capacity within the fleet of trucks, and

decreasing efficiencies. The process of remanufacturing

these complex, load bearing, safety critical components

needs to be carefully controlled. Quality is an extremely

important consideration for this type of work. Sometimes

unsuitable repair processes like welding or thermal spraying

are used which can compound the problem further.

((left) Wheel spindle bearing journal fretting and spline damage before LaserBond repair.

(right) Delamination of previous spray repair.

LaserBond Limited | www.laserbond.com.au

Sydney | Adelaide | Freecall 1300 LASERBOND

International +61 2 4631 4500 | Fax +61 2 4631 4555

Email info@laserbond.com.au Quality 9001, Environment 14001,

Health & Safety 4801

Case Study: 5.1

After benefits and feedback

The Solution

LaserBond uses the same laser cladding

process used by OEM’s like CAT to rebuild

worn or damaged surfaces. The metallurgical

bond allows applied layers to be used in

high impact, heavily loaded situations

with no risk of spalling or separation of

the overlay. The infinite controllability of

the laser energy allows minimisation of

undesirable thermal decomposition of

hard phases such as carbides, resulting in

decomposition, dilution of substrate and

distortion effects associated with other

repair methods.

CAT 777F wheel spindle after Laserbond deposition of the bearing journal surfaces.

Key Benefits

• Faster component turn around means less service time for fleet

equipment – overall increase in operating efficiency

• maintenance

Machine availability improved with increased OEE and less

• Cost savings over OEM replacement parts

• footprint

Better outcome for environment - less waste, lower carbon

The CAT 777F dump truck spindle ready for shipping back to customer.

Feedback

The customer commented: “Now we don’t have to pay and wait for new parts or overseas REMAN. LaserBond offers a better than new replacement

part at a fraction of the cost.”

About LaserBond

LaserBond Limited is an Australian engineering company specialising in surface reclamation and engineering, precision machining and

fabrication. LaserBond manufactures, repairs, reclaims and enhances the performance of high wear, critical metal components in a range of capital

intensive industries including mining, minerals processing, energy, agricultural, transport, steel, aluminium, marine and manufacturing sectors.

LaserBond Limited | www.laserbond.com.au

Sydney | Adelaide | Freecall 1300 LASERBOND

International +61 2 4631 4500 | Fax +61 2 4631 4555

Email info@laserbond.com.au

14598

S-ar putea să vă placă și

- Acacia ReactorDocument11 paginiAcacia ReactorPedrin Cha OlivosÎncă nu există evaluări

- Trolley Assist To Optimise Hauling Cycles With Electric Trucks PDFDocument16 paginiTrolley Assist To Optimise Hauling Cycles With Electric Trucks PDFSACHIDHANANDHAM A100% (1)

- Testing Methods of Chemical Resistance For Plastic Parts: Nissan Engineering StandardDocument13 paginiTesting Methods of Chemical Resistance For Plastic Parts: Nissan Engineering StandardDiego Camargo100% (1)

- Reusable Gear Guide HTT - GG1 - 0711Document18 paginiReusable Gear Guide HTT - GG1 - 0711sphiri600100% (1)

- 3 Electric Motors and HybridsDocument110 pagini3 Electric Motors and HybridsSung Ryoung LimÎncă nu există evaluări

- Evaluation of Park Lock Mechanism in A DCT TransmissionDocument42 paginiEvaluation of Park Lock Mechanism in A DCT TransmissionMandeep Singh ChawlaÎncă nu există evaluări

- As 3819.1-1998 Heavy Duty Towing Components 70 MM and 110 MM Diameter Towballs For Heavy Duty CouplingsDocument6 paginiAs 3819.1-1998 Heavy Duty Towing Components 70 MM and 110 MM Diameter Towballs For Heavy Duty CouplingsSAI Global - APACÎncă nu există evaluări

- 2 Types of TrucksDocument24 pagini2 Types of TrucksTeguh HardiÎncă nu există evaluări

- Fine-Tuning 300-Ton Haulers: HyperWorks at Hitachi Truck ManufacturingDocument4 paginiFine-Tuning 300-Ton Haulers: HyperWorks at Hitachi Truck ManufacturingAltairKoreaÎncă nu există evaluări

- KG 650,000 LB 172 T 190 U.S. Ton 1491 KW 2,000 HP: Maximum GVW Payload Gross HorsepowerDocument4 paginiKG 650,000 LB 172 T 190 U.S. Ton 1491 KW 2,000 HP: Maximum GVW Payload Gross HorsepowerJavierPariÎncă nu există evaluări

- HD605-7RDocument6 paginiHD605-7RGustavo Mora SaavedraÎncă nu există evaluări

- EH750-3 Vs EH750-2 Differences - Technical Version-0607Document59 paginiEH750-3 Vs EH750-2 Differences - Technical Version-0607TABUENCA MAQUINARIAÎncă nu există evaluări

- DG743 PDFDocument977 paginiDG743 PDFtechnical trainer 011cÎncă nu există evaluări

- Welding Simulation Suite: From Fast Distortion Engineering & Fabrication Planning To Weld Repair & Root Cause AnalysisDocument4 paginiWelding Simulation Suite: From Fast Distortion Engineering & Fabrication Planning To Weld Repair & Root Cause Analysisamd mhmÎncă nu există evaluări

- Modificacion Arnes Sensor Temp Motores Eh4000ac2Document12 paginiModificacion Arnes Sensor Temp Motores Eh4000ac2willy torresÎncă nu există evaluări

- Analysis of The State and Development of Vehicles Working in The QuarryDocument4 paginiAnalysis of The State and Development of Vehicles Working in The QuarryResearch ParkÎncă nu există evaluări

- Customised Dump Truck Bodies Brochure LRDocument13 paginiCustomised Dump Truck Bodies Brochure LRKureiÎncă nu există evaluări

- AA02083G Approved GE LubesDocument4 paginiAA02083G Approved GE LubesSebastiao Duarte100% (1)

- HTTP WWW - Etftrucks.eu Downloads Etf BrochureDocument20 paginiHTTP WWW - Etftrucks.eu Downloads Etf Brochuregamarus7771372Încă nu există evaluări

- CNC Honing: Special Optional Software Packages AllowDocument102 paginiCNC Honing: Special Optional Software Packages AllowSaqib KhanÎncă nu există evaluări

- NTB T236 enGB-USDocument28 paginiNTB T236 enGB-USJohn CollinsÎncă nu există evaluări

- Todos Los Tipos de Suspension HDocument8 paginiTodos Los Tipos de Suspension HJorge MarquezÎncă nu există evaluări

- Lubrication SystemDocument4 paginiLubrication SystemArun BoseÎncă nu există evaluări

- H E Parts Brochure Wheel GroupsDocument7 paginiH E Parts Brochure Wheel GroupsSebastiao DuarteÎncă nu există evaluări

- Reducing Fuel Consumption of Haul Trucks in Surface Mines Using ADocument14 paginiReducing Fuel Consumption of Haul Trucks in Surface Mines Using AAhmed IdiÎncă nu există evaluări

- 777 BrochureDocument36 pagini777 BrochureAlexandra Ioana IoanaÎncă nu există evaluări

- Splined ShaftDocument2 paginiSplined Shaftjmpateiro1985Încă nu există evaluări

- 360jet Sales SheetDocument1 pagină360jet Sales Sheetباسل ديوبÎncă nu există evaluări

- Catalina Punta Pluma 7495 HRDocument1 paginăCatalina Punta Pluma 7495 HRmilenko CortesÎncă nu există evaluări

- September 2016Document96 paginiSeptember 2016Pumper MagazineÎncă nu există evaluări

- LUBRICACIONDocument6 paginiLUBRICACIONOrlando LaraÎncă nu există evaluări

- Kumba Iron Ore SishenDocument24 paginiKumba Iron Ore SishenBenÎncă nu există evaluări

- Car Mechanics 03 2024Document100 paginiCar Mechanics 03 2024Eddy ChanÎncă nu există evaluări

- What Is A RetarderDocument10 paginiWhat Is A RetarderAsheÎncă nu există evaluări

- Design of Machine Elements 2019 BeemerDocument145 paginiDesign of Machine Elements 2019 BeemerSandeep MandaÎncă nu există evaluări

- 530M-1/4 Parts and Service News - Kac Product: PT United Tractors TBK Service DivisionDocument24 pagini530M-1/4 Parts and Service News - Kac Product: PT United Tractors TBK Service DivisionLodyÎncă nu există evaluări

- AA03163 Chrome STRG BallsDocument1 paginăAA03163 Chrome STRG BallsSebastiao DuarteÎncă nu există evaluări

- PC8000-6 A4 InternetDocument8 paginiPC8000-6 A4 InternetSACHIDHANANDHAM A100% (1)

- Camion Lieber NTB T236 EnGB-USDocument24 paginiCamion Lieber NTB T236 EnGB-USBillie Joe ArmstrongÎncă nu există evaluări

- Driving Heavy Duty Engine Oil Towards API CI-4Document18 paginiDriving Heavy Duty Engine Oil Towards API CI-4robertoalfaro492023100% (1)

- 930e-2 PresentasionDocument62 pagini930e-2 PresentasionRohman100% (1)

- Liebherr t262Document8 paginiLiebherr t262ForomaquinasÎncă nu există evaluări

- Ge Mining Cas Smart Group 17 Oct 2013Document81 paginiGe Mining Cas Smart Group 17 Oct 2013Eleazar DavidÎncă nu există evaluări

- Mining Truck Body - SSABDocument2 paginiMining Truck Body - SSABJose CamposÎncă nu există evaluări

- Reliability Analysis and Critical Part LDocument7 paginiReliability Analysis and Critical Part LShinta Nur HasanahÎncă nu există evaluări

- Heavy Equipment - Spek RH120EDocument12 paginiHeavy Equipment - Spek RH120EDavid HalomoanÎncă nu există evaluări

- Off-Highway Application Guide BookDocument12 paginiOff-Highway Application Guide BookAndreea Boacara100% (1)

- Vehicle Specifications - LADA Vesta Sedan - LADA PDFDocument1 paginăVehicle Specifications - LADA Vesta Sedan - LADA PDFCarlos Iran Benitez MedinaÎncă nu există evaluări

- Komatsu Haul Trucks Rev2 InstallationDocument30 paginiKomatsu Haul Trucks Rev2 InstallationHugo Victor Huayanca ValverdeÎncă nu există evaluări

- MFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T) (2) SD313 2 Full Circuit DiagramsDocument1 paginăMFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T) (2) SD313 2 Full Circuit DiagramsHuy Trần Quốc0% (1)

- Chaseling CompanyDocument6 paginiChaseling CompanyLuis MoyaÎncă nu există evaluări

- A Guide To Your Dampers Chapter From FSAE Book by Jim KasprzakDocument2 paginiA Guide To Your Dampers Chapter From FSAE Book by Jim KasprzakMilan StojnicÎncă nu există evaluări

- Welding InstructionsDocument12 paginiWelding Instructionsrahman asadiÎncă nu există evaluări

- ETF Truck Presentation April 2011 PDFDocument43 paginiETF Truck Presentation April 2011 PDFwilledworkerÎncă nu există evaluări

- Export BrochureDocument30 paginiExport Brochureagustinmisaza100% (1)

- Caterpillar 775G Case Study: Dump Truck Sound AttenuationDocument3 paginiCaterpillar 775G Case Study: Dump Truck Sound AttenuationMINETEKÎncă nu există evaluări

- Gestión Del Mantenimiento: Deje A La Aplicación Guiar Su Estrategia de MantenimientoDocument52 paginiGestión Del Mantenimiento: Deje A La Aplicación Guiar Su Estrategia de Mantenimientowilson_sanchez6183100% (1)

- BELAZDocument7 paginiBELAZphucdc095041Încă nu există evaluări

- Pressed PDFDocument337 paginiPressed PDFJuvenal SantibañezÎncă nu există evaluări

- Equipment & Dimensions: EH4500: Standard Equipment Optional Equipment Eh4500 Ac Wheel MotorDocument2 paginiEquipment & Dimensions: EH4500: Standard Equipment Optional Equipment Eh4500 Ac Wheel MotorAndi Wardiman AnwarÎncă nu există evaluări

- Top Gear Episode List - WikipediaDocument16 paginiTop Gear Episode List - WikipediaanwharÎncă nu există evaluări

- Field Assembly Manual: Dump TruckDocument199 paginiField Assembly Manual: Dump TruckFútbol y más100% (1)

- Mobilfluid 424 Mobilfluid 424 Mobilfluid 424 Mobilfluid 424Document4 paginiMobilfluid 424 Mobilfluid 424 Mobilfluid 424 Mobilfluid 424Sounak SasmalÎncă nu există evaluări

- Propane: Propane at A Glance, 2015Document4 paginiPropane: Propane at A Glance, 2015SACHIDHANANDHAM AÎncă nu există evaluări

- Liebherr R9800Document4 paginiLiebherr R9800SACHIDHANANDHAM AÎncă nu există evaluări

- Universal Wheel Nut Tool: Features and BenefitsDocument1 paginăUniversal Wheel Nut Tool: Features and BenefitsSACHIDHANANDHAM AÎncă nu există evaluări

- Fuelling Savings in Tough Times: Fuel EconomyDocument7 paginiFuelling Savings in Tough Times: Fuel EconomySACHIDHANANDHAM AÎncă nu există evaluări

- IDM 70 Series: Atlas Copco Blasthole DrillsDocument4 paginiIDM 70 Series: Atlas Copco Blasthole DrillsSACHIDHANANDHAM A100% (1)

- Complete Trolley Assist SolutionDocument2 paginiComplete Trolley Assist SolutionSACHIDHANANDHAM A100% (1)

- TS-7 Paper 03 SK MukhopadhyayDocument6 paginiTS-7 Paper 03 SK MukhopadhyaySACHIDHANANDHAM AÎncă nu există evaluări

- Atlas Copco Blasthole Drills Dm30 Ii-SeriesDocument4 paginiAtlas Copco Blasthole Drills Dm30 Ii-SeriesSACHIDHANANDHAM A0% (1)

- Sun HillsDocument16 paginiSun HillsSACHIDHANANDHAM AÎncă nu există evaluări

- Engine Test DataDocument5 paginiEngine Test DataSACHIDHANANDHAM A100% (1)

- ShanxiJiacheng Introduction PDFDocument51 paginiShanxiJiacheng Introduction PDFSACHIDHANANDHAM AÎncă nu există evaluări

- Optimus BrochureDocument8 paginiOptimus BrochureSACHIDHANANDHAM AÎncă nu există evaluări

- PC8000-6 A4 InternetDocument8 paginiPC8000-6 A4 InternetSACHIDHANANDHAM A100% (1)

- Cloudbreak Mine Overburden Conveyor System InstallationDocument1 paginăCloudbreak Mine Overburden Conveyor System InstallationSACHIDHANANDHAM AÎncă nu există evaluări

- Luan Tires Techncial DetailsDocument1 paginăLuan Tires Techncial DetailsSACHIDHANANDHAM AÎncă nu există evaluări

- Triveni DumpersTrial FormatsDocument1 paginăTriveni DumpersTrial FormatsSACHIDHANANDHAM AÎncă nu există evaluări

- Risk AssesmentDocument7 paginiRisk AssesmentSACHIDHANANDHAM AÎncă nu există evaluări

- Moore 2012 PDocument7 paginiMoore 2012 PSACHIDHANANDHAM AÎncă nu există evaluări

- Sleipner E550 20170620Document4 paginiSleipner E550 20170620SACHIDHANANDHAM A100% (1)

- Asset Optimization Systems: 5 Lessons From 10 Years in MiningDocument12 paginiAsset Optimization Systems: 5 Lessons From 10 Years in MiningSACHIDHANANDHAM AÎncă nu există evaluări

- Spin Atomic Model: Role of Electron Spin in Forming Atoms and MoleculesDocument8 paginiSpin Atomic Model: Role of Electron Spin in Forming Atoms and MoleculesGhanshyam JadhavÎncă nu există evaluări

- Full Download General Organic and Biological Chemistry 2nd Edition Janice Gorzynski Smith Test Bank PDF Full ChapterDocument36 paginiFull Download General Organic and Biological Chemistry 2nd Edition Janice Gorzynski Smith Test Bank PDF Full Chapternuggetessayistypcu100% (18)

- (William Jones, C. N. R. Rao) Supramolecular OrganDocument456 pagini(William Jones, C. N. R. Rao) Supramolecular OrganJennifer Carolina Rosales NoriegaÎncă nu există evaluări

- Environmental Chemistry and Microbiology - Unit 3 - Week 1Document6 paginiEnvironmental Chemistry and Microbiology - Unit 3 - Week 1Abhijit NathÎncă nu există evaluări

- Petromole F GradesDocument4 paginiPetromole F GradesmehrsaÎncă nu există evaluări

- PowerPoint PresentationSNLDocument6 paginiPowerPoint PresentationSNLAfifah N AhmedÎncă nu există evaluări

- How To Eliminatdadde Outgassing, The Powder Coating Faux PasDocument2 paginiHow To Eliminatdadde Outgassing, The Powder Coating Faux PasSandra ArianaÎncă nu există evaluări

- Cryogenic TurboexpandersDocument9 paginiCryogenic TurboexpandersDwinaRahmayaniÎncă nu există evaluări

- Chapter 4 Light Emitting DiodeDocument33 paginiChapter 4 Light Emitting DiodeRufiat KhanÎncă nu există evaluări

- Alphabetic List of Iran Refinery Plant PDFDocument108 paginiAlphabetic List of Iran Refinery Plant PDFBambang Kardito100% (1)

- D 2295 - 96 R02 - RdiyotuDocument3 paginiD 2295 - 96 R02 - RdiyotuJorgeÎncă nu există evaluări

- Neet Test Series 2022 Test Code: NT - 02: Biology Physics ChemistryDocument16 paginiNeet Test Series 2022 Test Code: NT - 02: Biology Physics Chemistry6 months AgoÎncă nu există evaluări

- Heating and Cooling CurveDocument4 paginiHeating and Cooling CurveADogThat GoesBarkÎncă nu există evaluări

- Centricut Catalogue 2019 - Laser - MazakDocument42 paginiCentricut Catalogue 2019 - Laser - MazakIvan YordanovÎncă nu există evaluări

- Factors Influencing ToxicityDocument7 paginiFactors Influencing ToxicityderrickÎncă nu există evaluări

- Safety of Baby Diapers - ANSES 2019Document240 paginiSafety of Baby Diapers - ANSES 2019IvyÎncă nu există evaluări

- Benzene: Training On The Hazards of Benzene in The WorkplaceDocument26 paginiBenzene: Training On The Hazards of Benzene in The WorkplaceAgung RahmadaniÎncă nu există evaluări

- Compounding PracticeDocument19 paginiCompounding PracticeBrix GallardoÎncă nu există evaluări

- 11th CRP - PT-3 - JEE (ADV) - PAPER-2 - 09-04-2023 - AnswerDocument1 pagină11th CRP - PT-3 - JEE (ADV) - PAPER-2 - 09-04-2023 - AnswerGully GamingÎncă nu există evaluări

- 02 Torque and Socket OptimizeDocument26 pagini02 Torque and Socket OptimizeANDI SETIAWANÎncă nu există evaluări

- ASTM B505-B505M-12 Standard Specification For Cooper Alloy Continuous CastingsDocument10 paginiASTM B505-B505M-12 Standard Specification For Cooper Alloy Continuous CastingsAarón Escorza MistránÎncă nu există evaluări

- PS1Document4 paginiPS1cptudorÎncă nu există evaluări

- STUDY GUIDE - Lipid and Carbohydrate CombinedDocument5 paginiSTUDY GUIDE - Lipid and Carbohydrate CombinedMaya Abou MradÎncă nu există evaluări

- Numerical List SABSDocument1.143 paginiNumerical List SABSJason GlassÎncă nu există evaluări

- Some Applications of State-Of-The-Art Capillary Gas Chromatography in The Pharmaceutical IndustryDocument10 paginiSome Applications of State-Of-The-Art Capillary Gas Chromatography in The Pharmaceutical IndustryAamir TufailÎncă nu există evaluări

- NAAMM EMMA 557-20 Standards For Expanded MetalDocument18 paginiNAAMM EMMA 557-20 Standards For Expanded MetalScott NorrisÎncă nu există evaluări

- Unit 6 Practice Test (Periodic Table)Document5 paginiUnit 6 Practice Test (Periodic Table)Xazerco LaxÎncă nu există evaluări

- Whole Transcriptome Analysis Highlights Nutrient Limitation of Nitrogen Cycle Bacteria in Simulated MicrogravityDocument19 paginiWhole Transcriptome Analysis Highlights Nutrient Limitation of Nitrogen Cycle Bacteria in Simulated MicrogravityclameriqueÎncă nu există evaluări