Documente Academic

Documente Profesional

Documente Cultură

IEC Pub 245-2 Rubber Insulated Cables

Încărcat de

we2020 evaluări0% au considerat acest document util (0 voturi)

116 vizualizări22 paginiIEC Pub 245-2 Rubber Insulated Cables

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentIEC Pub 245-2 Rubber Insulated Cables

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

116 vizualizări22 paginiIEC Pub 245-2 Rubber Insulated Cables

Încărcat de

we202IEC Pub 245-2 Rubber Insulated Cables

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF sau citiți online pe Scribd

Sunteți pe pagina 1din 22

BOO WO. GOTT

MMC OIL & GAS LIBRARY

Publication 245-2

15 JUL 1992

COMMISSION ELECTROTECHNIQUE INTERNATIONALE

NORME DE LA CEL

INTERNATIONAL ELECTROTECHNICAL COMMISSION

TEC STANDARD

Publication 245-2

Premiére eon ~ First edition

1980

Conducteurs et cables isolés au caoutchouc,

de tension nominale au plus égale 4 450/750 V

Deuxiéme partie: Méthodes d'essais

Rubber insulated cables

of rated voltages up to and including 450/750 V

Part 2: Test methods

SUWGAPORE. (SSTITOTE

AND UOUSTRAL

LIBRA!

24 JUL1981

GAAS ND

| RECEIVED ay

LAS eIV EO

Droits de reproduction seres ~ Copyright - all ights reseed

Bureau Central de la Commission Electrotechnique Internationale

» ruedeerembe

Gendve Suisse

4

|

Révision de la présente publication

‘Le contenu technique des publications dc la CEI est constam-

ment revu par la Commission afin dassurer qu'il reflete bien

état actuel de a technique

Les renseignements relatifs ce travail de révision, a Pétabis-

sement des ditions révisées et aux mises & jour peuvent tre

‘obvenus auprés des Comités nationaux de la CEI et en consul-

tant les documents ci-dessous:

© Bulletinde la CEL

Publié annuellement

© Catalogue des publications dela CEL

Publig annuellement

‘Terminologie

En co qui concere [a terminologie générale, le lecteur se

reportera & la Publication $0 de la CEI: Vocabulaire Electro-

technique International (VE), qui est tablie sous forme de

cchapitees séparés traitam chacun d'un sujet defini, Pindex.

pénéral é1ant publié séparément Des détails complets sur le

VEL peuvent étre obtenussurdemande

Les termes et défintions figurant dans la présente publi

sion ont é& soit cepris du VE. soit spécifiquement approuvés

aux fins de cette publication

‘Symboles graphiques et littéraux

Pour les spmboles graphiques, symbols litéraux et signes

usage général approuvés par la CE, le lecteur eonsultera:

la Publication 27 de la CEI: Symboles littéraux & utiliser

endlectrotechnique;

la Publication 117 de la CEI: Symboles graphiques recom-

andes

Les symboles et signes contenus dans la présente publication

‘ont été sot repris des Publications 27 ou 117 dela CEI, soit spe

cifiquement epprouvés aux fins de cete publication

Autres publications de la CEI établies par le méme

Comité d’Etudes

[Lawtention du lecteur est attiée sur la page 3 de la couver:

ture, qui énumére les autres publications de la CEI préparées

par le Comité d'Etudes quia élabli la présente publication.

Revision of this publication

pt unde

“The technical content of LEC publications it KEP MT cis

stant review by the IEC, thus ensuring that th 6

current technology

Information on the work of revision, the sue

sions and amendment sheets may be obseinel £60

‘National Commies and fom the following IEC 5

TEC Bulletin

Report on TEC Activities

Published yearly

© Catalogue of IEC Publications

Published yearly

Terminology )

c public

wo (EI

For general terminology, eadersare refer'ed 81 E Sy eV.),

ere pblished 35 ©

verpupplied oF

tion 50: International Electrotechnical

which is isued in the form of separate chapt

with a specific field, the General Index being P

separate booklet. Full details of the LEV. will

request s

‘The terms and definitions contained in

tion have either been taken from the LEV. oF

‘ally approved forthe purpose ofthis pubticat

sent publics

ye pre ite

‘rove been speci

Graphical and letter symbols

approved

For graphical symbols, ad letter sym

by the IEC for general use. readers are refer -

— LEC Publication 27: Leuer symbols to Be USE

technology: ;

= 1E€ Publication 117: Recommended graphic

cal

a electri

symbols

gent publicatio!

‘The symbols and signs contained in the PFESE™ FOr 117. ©

have either been taken from IEC PublicatiOM® F145 ouplic:

have been specifically approved forthe purPOS™

tion

ame

Other IEC publications prepared BY #HE =

‘Technical Committee

side of he

y ene T

icatic

in

esued P!

‘nt publi

‘The attention of readers is drawn 10 URE

cover, which lists other IEC publications #5"

tical Committee which has prepared the PF ©

€.0.U./U.D.C.; 621.315.211.2.027 475 001.4

COMMISSION ELECTROTECHNIQUE INTERNATIONALE

NORME DE LACE!

INTERNATIONAL ELECTROTECHNICAL COMMISSION

1EC STANDARD

Publication 245-2

Preméreédivon ~ Fistedtion

1980

Conducteurs et cables isolés au caoutchouc,

de tension nominale au plus égale 4 450/750 V

Deuxiéme partie: Méthodes d'essais

Rubber insulated cables

of rated voltages up to and including 450/750 V

Part 2: Test methods

Koy words: eabloe with solid insulation

par = JEOV er testing

Droits de cepreduction céservés ~ Copynght- all nghts vesened

acne pre de ie Sulcan eget re posite tte suk Na pal of ha pathaion nay BE vaabeted oF oans 8 ay

cute oie ave esata pu nun pete. decvoncen sy naca foi by sty mete esvent we methane mung Prose

‘ut vconprslephoccneetisoncn sas latet sens tet 9 mm met aemtaon morgan EDDIE

Bureau Central de la Commission Electeotechnique Intetnationale

1 vege Varembé

Geneve Suisse

Prix

Price

Frs 33.-

CONTENTS

FOREWORD

PREFACE .

Clause

1. General

Ll General requirements : ‘|

1.2 Applicable tests

13. Classification of tests according tothe frequency with which they are carried out -

14 Samplin

15 Preconditioning. cee ce .

1.6 Test temperature ‘ : : : Peete

17 Test voltage RESHEee sel feeSeeee

1.8 Checking of the indelibiity of colours and markings. : oo

1.9 Measurement of thickness of insulation : See ereee eeeceeced

1.10 Measurement of thickness of sheath eee

LIL Measurement of overall dimensions and ovality

2. Electrical tests, . cee ety

2.1 Electrical resistance of conductors. : an

22 Voltage test carried out on completed cables... a :

23° Voltageteston cores . ce

3. Tests of mechanical strength of completed flexiblecables .

31 Flexingtest . . - i 7

3.2. Static flexibility test i

33 Wearresistancetest . 7

34

Tensile strength ofthe central heart of lift cables

4. Tests for the mechanical properties of insulation consisting of rubber compound type 1 1

4.1 General a : EEE Cece recta

42. Sampling : aed :

43 Stateas delivered

44

45

46

Ageingin the airovenforten days... 7

Ageing in the oxygen bomb for four days :

Ageing in the oxygen bomb for seven days. - : paaee

5. Flame retardance test for lift cables

2

2

2

24

23

25

29

INTERNATIONAL ELECTROTECHNICAL COMMISSION

RUBBER INSULATED CABLES

OF RATED VOLTAGES UP TO AND INCLUDING 450/750 V

Part 2: Test methods

FOREWORD

1) The formal decisions or agreements of the 1EC on echnical matters, prepared by Technical Committees on whichall the

National Committees having a special interest therein are represented, expres, as neatly as possible, am international

consensus of opinion on the subjects dealt with

They have the form of recommendations for international use and they are cepted by the National Committeesin that

3

{m order to promote international unification, the TEC expresses the wish tha all National Committees should adopt the

{ext of the LEC recommendation for their national rules in so far as national conditions will permit Any divergence

between the LEC recommendation ard the corresponding ational rules should, 35 far as posible be clearly incieed in

the later

4

‘The TEC has not laid down sny procedure concerning marking as an indication of approval and has no responsibility

when an item of equipment is declared to.comply with one of is recommendations

PREFACE

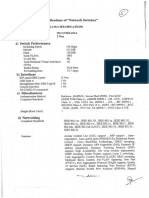

«a Thissondard hasbeen prepared by Sub-Commitee 208:Low-vohiage Cables. of IEC Techeical Committe No 2: Eee

‘This publication forms Part 2:Test Methods, of IEC Publication 245: Rubber Insulated Cables of Rated Voltages up to

nd Including 450/750 V The other pars of the complete standard are:

~ Pari I: Generat Requirements, jsued as !EC Publication 24

~ Part 3: Heat Resistant Silicone Insulated Cables, issued as (EC Publication 245-3;

~ Part 4: Cords and Flexible Cables, issued as {EC Publication 245-4;

~ Part 3: Lift Cables, issued as IEC Publication 245-5,

~ Part 6: Are Welding Electrode Cables, issued as [EC Publication 245-6

Parts 3.4, etc are for particular types of eable and should each be read in conjunetion with Parts land 2

Further parts may be added in the future as other types are standardized.

The complete standard, com pisingall the parts replaces he previous [EC Publication 245 and itsamendments

The complete standard contains considerable additions in comparison withthe previous IEC Publication 243, ie partic

cular in Part3 which is completely new and in Part which ow alta specifies ordinary polyehloroprene or aher equivalent

Syntheticelastomer sheathed cords

AA drat was discussed atthe mestng held in Oslo in 1976 Asa result ofthis meeting. draft, which contained the fists

pars of this standaré, was sutomitiedas Document 20R(Central Ofie\7l tothe National Commies or approval under

the Six Months Rule in December 1977

The Nasional Committes of the following countries voted explicitly in favour of publication:

Austria Israel South Africa (Republic of)

Betgium aly Spain

Canada Japan Sweden

Czechoslovakia Netherlands Turkey

Egypt Norway Union of Soviet

Finland Poland Socialist Republics

Germany Romania

Other 18 C publications quoteet in this standard

Publications Nos 173: Coloursof the Cores of Flexibles Cables and Cords

228: Conductors of insulated Cables.

332-1: Test on Electric Cables Under Fire conditions, Part 1:Test ona Single Vertical Insulated Wire

or Cable

540: Tost Methods for Insulations and Sheaths of Electric Cables and Cords (Elastomericand Ther-

‘moplastic Compounds)

RUBBER INSULATED CABLES

OF RATED VOLTAGES UP TO AND INCLUDING 450/750 V

Part 2: Test methods

General

11 General requirements

‘The methods of carrying out the tests specified in all parts of IEC Publication 245 are given

in this part and in the following IEC publications:

TEC Publication 332-1: Tests on Electric Cables under Fire Conditions, Part 1: Test 0° ®

Single Vertical Insulated Wire or Cable.

TEC Publication 540: Test Methods for Insulations and Sheaths of Electric Cable:

Cords (Elastomeric and Thermoplastic Compounds).

1s and

1.2. Applicable tests

: are c

‘The tests applicable to the types of cables are given in the particular specifications ge

Publications 245-3, 245-4, etc.).

1.3 Classification of tests according to the frequency with which they are carried out

in

The tests specified are type tests (symbol T) and/or sample tests (symbol S) as éefined

Sub-clause 2.2 of IEC Publication 245-1

‘The symbols T and S are used in the relevant tables of the particular spec

Publications 245-3, 245-4, etc.)

14 Sampling

ken

Ifa marking is in relief in insulation or sheath the samples used for the tests shall be ta

so as to include such marking.

three

For multicore cables, except for the test specified in Sub-clause 1.9, not more than

cores (of different colours, if applicable) shall be tested unless otherwise specified.

1.5 Pre-conditioning

a ing oF

Al the tests shal be carried out not less than 16 hafter the vuleanization of the ims swlat#8S

sheathing compounds.

L6 Test temperature

Unless otherwise specified, tests shall be made at ambient temperature.

17 Test voltage

Unless otherwise specified, the test voltages shall be a.c. 49 Hz to 61 Hz of appre 7%.

sinewave form, the ratio peak value/r.m.s. value being equal to ¥2 with a tolerance ©!

‘The values quoted are r.ms. values.

~9-

1.8 Checking of the indelibility of colours and markings

Compliance with this requirement shall be checked by trying to remove the marking of the

manufacturer's name or trade mark and the colours of cores or numerals by rubbing lightly

ten times with a piece of cotton wool or cloth soaked in water.

1.9 Measurement of thickness of insulation

LOL Procedure

The thickness of insulation shall be measured in accordance with Sub-clause 4.1 of LEC

Publication 540.

One sample of cable shall be taken from each of three places, separated by at least | r.

Compliance shall be checked on each core of cables having up to five cores, and on any five

cores of cables with more than five cores,

If withdrawal of the conductor is difficult, it shall be stretched in a tensile machine or the

Piece of core shall be immersed in mercury until the insulation becomes loose.

19.2 Evaluation of results

The mean of the 18 values (expressed in millimetres) obtained from the three pieces of insu-

lation from each core shall be calculated to two decimal places and rounded off as given

below, and this shall be taken as the mean value of the thickness of insulation.

in the catcutation the second decimal figure is 5 or more, the first decimal figure stall be

raised to the next number, thus, for example, 1.74 shall be rounded off to 1.7 and 1.75 to 1.8.

The lowest of all values obtained shall be taken as the minimum thickness of insutation at

any place.

This test may be combined with any other measurements of thickness, for instance those of |

Sub-clause 5 2.4 of [EC Publication 245-1

1.10 Measurement of thickness of sheath

L101 Procedure

The thickness of sheath shall be measured in accordance with Sub-clause 4.2 of TEC Publi-

cation $40.

‘One sample of cable shall be taken from each of three places, separated by at least | m

1.102 Evaluation of results

The mean of alll the values (expressed in millimetres) obtained from the three pieces of

sheath shall be calculated to two decimal places and rounded off.as given below, and this shall

be taken as the mean value of the thickness of sheath.

If in the calculation the second decimal figure is 5 or more, the first decimal figure shall be

raised to the next number, thus, for example, 1.74 shall be rounded off to 1.7 and [.75to 1.8.

The lowest of all values obtained shall be taken as the mii

imum thickness of sheath at any

place.

This test may be combined with any other measurements of thickness, for instance those of

Sub-clause 5.5.4 of [EC Publication 245-1.

The three samples taken in accordance with Sub-clause 1.9 or 1.10 shall be used.

The measurement of the overall diameter of any circular cable and of the overall cime*”

sions of flat cables with a major dimension not exceeding 15 mm shall be carried out "

accordance with Sub-clause 4.3 of IEC Publication 540.

For the measurement of flat cables with a dimension exceeding 15 mm, a micrometer, *

profile projector or similar appliance shall be used.

‘The mean of the values obtained shall be taken as the mean overall dimension.

Fi le

For checking the cable ovality of circular sheathed cables, two measurements shall be a6

at the same cross-section of the cable.

2. Electrical tests

2. Electrical resistance of conductors

In order to check the electrical resistance of conductors, the resistance of each condUCteE

shall be measured of a sample of cable of at least 1 m in length, and the length of &

sample shall be measured.

If necessary, a correction to 20°C and to a length of 1 km shall be obtained by the formula:

2545, 1000

Ry = R, sats « 1000

wR Ba540 7

temperature ofthe sample at the moment of measurement, in degrees Celsius

resistance at 20°C. in obms/kilometre

R= resistance of L metresofeable at 1°C, in ohms

L__ = length of the sample of cable, in metres (length of the complete sample and not of the individ tal

wires)

1 cores oF

2.2 Voltage test carried out on completed cables

the

‘A sample of cable as delivered shall be immersed in water. The length of the sample,

. eee bli

temperature of the water and the duration of immersion are given in Table IIT of I EC Pui

cation 245-1.

on

A voltage shall be applied in turn between each conductor and all the others Lope ST ors

nected to the water and the metal central heart, if any; and then between all CO™

together and the water connected to the metal central heart, if any.

IEC

“The voltage and the duration of its application are given for each case in Table 1X1 Of gE

Publication 245-1.

23 Voltage test on cores

‘The test applies to sheathed or braided cables.

all braid

‘The test shall be made on a sample of cable of $ m length. The sheath or the ow ©*"

and any other covering or filling shall be removed without damaging the cores

-13-

The cores shall be immersed in water as specified in Table IIT of IEC Publication 245-1,

‘and a voltage shall be applied between the conductors and the water.

The voltage and the duration of its application are given for each case in Table IIT of TEC

Publication 245-1,

3. Tests of mechanical strength of completed flexible cables

3.1 Flexing test

The requirements are given in Sub-clause 5.6 3.1 of [EC Publication 245-1.

Flexible cables having conductors with a nominal cross-se

nal area exceeding 4mm?

and all single-core cables are not subjected to this test.

‘The test shall be carried out by means of the apparatus shown in Figure 1, page 15. This

apparatus has a carrier C supporting two pulleys A and B arranged so that the cable is hori-

zontal between the pulleys. The carrier makes a backward and forward movement over a dis-

tance of | m, at an approximately constant speed of 0.33 m/s.

__ A sample of flexible cable about 5 m in length shall be stretched over the pulleys as shown

in Figure |, each end being loaded with a weight. The mass of this weight and the diameter of

the pulleys A and B are as shown in the following table:

Masso | Diemeer

‘Type of cable weight | of pulleys

(te) (mami

Braided cord 10 wo |

Ordinary tough rubber sheathed cord and ordinary polychloroprene or other |

‘equivalent synthetic elasiomer sheathed cord with a nominal cross-sectional

area of conductors:

= not exceeding | mm? 10 80

= 1Smmtand2 5mm? Is wo |

Heavy polychloroprene or other equivalent synthetic elastomer sheathed cable |

with a nominal cross-sectional area of conductors: |

= notexceeding2 mm? 1s 120

> 4mm? 20 20 |

The pulleys have a semi-circular shaped groove for circular cables and a flat groove fer flat

cables. The restrairaing clamps D shall be fixed so that the pull is always applied by the weight

from which the carrier is moving away. The carrier makes backward and forward movements.

Each conductor of the sample shall be loaded with the current specified in the follcwing

table:

‘Nominal cross-sectional area

‘of conductors Cureent

(um) “

075 9

1 u

15 4

25 20

4 25

-15-

For two-core cables, the voltage between the conductors shall be about 220 Vac For all

other cables having three or more cores, a three-phase ac. voltage of about 380 V shall be

applied to the three conductors, any additional conductors being connected to the neutral.

After this test the sheath, if any, of cables with three or more cores shall be removed. The

cable or cores shall then withstand the voltage test carried out in accordance with Sub-clause

2.2 of 2.3 of this standard as appropriate, but with a test voltage not exceeding the value

specified in Sub-clause 5.6.3.1 of [EC Publication 245-1

Fig. 1. - Flexing apparatus

3.2 Static flexibility test

The requirements are given in Sub-clause 5.6.3.2 of IEC Publication 245-1.

A sample with a length of 3 0.05 m shall be tested in an apparatus similar to that show™.

in Figure 2, page 18. Two clamps, A and B, shall be located at a height of at least 1.5 m above

ground level,

Clamp A shall be fixed and clamp B shall move horizontally at the level of clamp A-

‘The ends of the sample shall be clamped vertically (and remain vertical during the test), ONC

end in clamp A, the other in the movable clamp B which shall be at a distance | = 0.20 m from

clamp A. The cable takes roughly the shape indicated in Figure 2 by the dotted lines.

The movable clamp B shall then be moved away from the fixed clamp A until the ior

formed by the cable takes the shape, indicated in Figure 2 by the heavy outline, of the

enclosed wholly between two plumb lines through the clamps and set up tangentially to {©

external generatrix of the cable. This test shall be done twice, the cable being turned i the

clamp, after the first test, through 180°

The mean of the two values of I’ shall be measured between the two plumb lines.

Lf the results of the test are unfavourable, the sample shall be pre-conditioned by winding 1

four times on and off a reel with a diameter approximately 20 times the outer diameter Of ES

cable; in this case, the sample shall be turned each time through 90°. After this pre-CO™ Z a

tioning, the sample shall be subjected to the test described above and shall meet the specifie

requirements.

-I7-

33° Wear resistance test*

The requirements are given in Sub-clause 5.6.3.3 of IEC Publication 245-1

This test shall be made on three pairs of samples of flexible cable, each sample having a

length of about | m

In each pair one sample shall be wound so as to give nearly two turns on a fixed reel having

8 diameter of 40 mm at the bottom of the groove as shown in Figure 3, page 19, the distance

between the flanges of the reel being such that the turns are in close contact with each other.

The sample shall then be fixed to prevent any movement relative to the reel

The other sample shall be placed in the groove formed by the turns and a weight having a

mass of 500 g shall be attached to one end

The other end shall be moved up and down over a distance of 0.10 m, at a rate of about 40

single strokes per minute.

* Arevision of thistest is under consideration.

-18-

aun quia

Seo uy qunie

Fic. 2. ~ Essai statique de souplesse.

Static flexibility test.

-19-

a

the turns of the fixed sample

Echantition xa

Fixed sample

sm |

2 40 mm,

L

Poulie fixe

Fixed veal

Poids __

‘woight |

FIG. 3, - Disposition pour l’essai de résistance a l'usure,

Arrangement for wear-resistance test.

=

24 Tensile strength of the central heart of lift cables

A sample of the completed cable, 1 m long, shall be weighed.

After removal of all covering and cores over a distance of about 0.20 m at both ends of the

sample, the central heart including the strain-bearing centre shall be subjected t

force, corresponding to the mass of 300 m of cable.

9 a tensile

i t

“The force shall be applied for | min. The central heart or the strain-beating centre shall 8

rupture during this period.

A freely hanging weight or suitable mechanical strength testing machine capable of apply

ing a constant force may be used

4. Tests for the mechanical properties of insulation consisting of rubber compound type LE 1

4.1 General

“The tests are cartied outin accordance with Clauses 5 and 6 of IEC Publication $40 i CO”

junction with the modifications and additions given hereafter:

jescribed

[Note ~tn the case of compound type 1E 1, the procedure andthe limit values forthe test are speifie€ 35 O° mine

below to take aecountol the fact thatthe insulation may be made of natural rubber, synthetic rabP=T

{re ofthe two. A synopsis of tests and requirement is given in Figure 4 page 27

4.2 Sampling

The number of small pieces of core taken from each of the three places shall be a

6 (8) small pieces, whatever the cross-sectional area.

‘Note ~The number in brackets only applies where additional ageing in oxygen proves necessary

n of cross-sectional area of im!

After preparation of the test pieces and determi

the test pieces bearing the numbers:

1. and 3 shall be subjected to the conditioning and to the tensile test, in the state as deli

2and 4 shall be subjected to the ageing in the air oven for 10 days and thereafter ©

tioning and to the tensile test;

Oand 5 shall be subjected to the ageing in the oxygen bomb for four days or sever da

successively to the operations indicated above;

6 and 7, if necessary, shall be subjected to the ageing in the oxygen bomb for sever™

then to the operations indicated above.

43 State as delivered

For the test pieces numbered | and 3, compliance shall be checked with the vax

in Table I of IEC Publication 245-1.

4.4 Ageing in the air oven for ten days

For the test pieces numbered 2 and 4 a treatment involving accelerated ageine

oven shall be carried out in accordance with Sub-clause 6.1 of IEC Publica t®

under the conditions of duration and temperature specified in Table 1 of 1E <>

245-1

5 follows:

ulation,

vered:

0 the condi-

ys, and

days, and

ues specified

in the air

con 540 and

‘Publication

4s

-23-

‘Compliance shail be checked with the values specified in Table I of [EC Publication 245-1

Furthermore the following requirements also apply:

~ if the median value of the tensile strength after this ageing test is equal to or higher than

5.0 N/mm: (e, in Figure 4, page 27), the median values of the tensile strength and elonga-

tion-at-break shall not differ from the median values obtained without ageing, by more

than 40% of the median values without ageing, and the accelerated ageing test in the oxygen

bomb for four days shall be carried out (see Sub-clause 4 5 of this standard);

~ if the median value of tensile strength after the ageing test in the air oven for 10 days is

lower than 5.0 N/mm?, but not less than 4.2 N/mm? (e, in Figure 4), the accelerated ageing

test in the oxygen bomb for seven days shall be carried out (see Sub-clause 4.6 of this,

standard);

~ if the tensile tests are not cartied out at an ambient temperature of 20 + 5 °C and if the

variation of 40% specified above is exceeded, the tensile test on test pieces taken from the

insulation of the cable as delivered shall be repeated at exactly the same temperatureas that

at which the tensile test after the ageing treatment was carried out. In this case, the values

after ageing shall be compared with the values obtained from the re-test procedure,

Ageing in the oxygen bomb for four days

The test pieces numbered 0 and 5, under the circumstances specified above, shall be sub-

jected to accelerated ageing in the oxygen bomb for four days in accordance with Sub-clause

6.3 of IEC Publication 540 and under the conditions of duration and temperature specfied in

Table | of IEC Publication 245-1

Compliance of’ the mechanical properties shall be checked with the values specified in

Table I of IEC Publication 245-1.

Furthermore the following requirements also apply:

~ if the median value of the tensile strength after this ageing test is equal to or higher than

5.0 N/mm? and if the change in tensile strength or elongation-at-break after the ageing test

in the air overy does not exceed 25% (f, in Figure 4), the median value after ageing in the

oxygen bomb shall not differ from that obtained without ageing by more than:

40% of the mectian value without ageing, for the tensile strength, and

30% of the mectian value without ageing, for the elongation-at-break:

~ if the median value of the tensile strength after the ageing test in the oxygen bomb for four

days is equal to or higher than 5.0 N/mm® and if the change in tensile strength or elonga-

tion-at-break after the ageing test in the air oven exceeds 25% (f, in Figure 4), the median

value after age ing in the oxygen bomb shall not differ from that obtained without ageing,

by more than:

25% of the mectian value without ageing, for the tensile strength, and

35% of the meciian value without ageing, for the elongation-at-break;

~ if the median v-alue of the tensile strength after the ageing test in the oxygen bomb for four

days is less than 5.0 N/mm®, but not less than 4.2 N/mm? (f, in Figure 4), the accelerated

ageing test in thae oxygen bomb for seven days shall then be carried out;

46

-25-

= if the tensile tests are not carried out at an ambient temperature of 20 + 5°C ard if #0

variation as specified above is exceeded, the tensile test on test pisces taken from the inst

tion of the cable as delivered shall be repeated at exactly the same temperature as thal

which the tensile test after the ageing treatment was carried out. In this case the va ues 14°F

ageing shall be compared with the values obtained from the re-test procedure.

Ageing in the oxygen bomb for seven days

Ifthe median value of the tensile strength after the accelerated ageing test cither in the 2

oven (Sub-clause 4.4) or in the oxygen bomb for four days (Sub-clause 45) is less tat

5.0 N/mm, but not less than 4.2 N/mm, and provided that the median value of the elOREt,

tion-at-break is at least 250%, the test pieces numbered 6 and 7 or the test pieces numnber®

and 5, as appropriate, shall be subjected to the accelerated ageing test in the oxygen’ bomb for

seven days, in accordance with Sub-clause 6.3 of IEC Publication 540 and under the condi-

tions of duration and temperature specified in Table I of IEC Publication 245-1.

Compliance of the mechanical properties shall be checked with the values specified in

Table I of IEC Publication 245-1

If the tensile tests are not carried out at an ambient temperature of 20+ 5°C and if any Va"

ation as specified in Table I of IEC Publication 540 is exceeded, the tensile test on test PIC®

taken from the insulation of the cable as delivered shall be repeated at exactly the same eer

perature as that at which the tensile test after the ageing treatment was carried out. In this case,

the values after ageing shall be compared with the values obtained from the retest procedure”

MMC OIL & GAS LIBRARY

~27-

Synopsis of tests and requirements

Testinstateas delivered

(Sub-clause4 3)

‘Test pieces |and3

Requiced: TSS S0N/mm™

EBS 250%

—

]

‘Racing tein ar oven Tor Todays

at 70°C

(Sub-clause 4 4)

‘Test pieces Zand

Required: TS S42 N/m

EBS 50%

Wea S0Nmm WTS < SON/mm?

hen

Required:

maximum difference TS and EB: 40%

[Aeeingtestin oxygen bom forfour days

a 70°C

(Sub-clause 4 5)

Test pieces Oands

Required: TSS 42.Nimm™

t EB 250%

If, fe 4

MTS 50 N/mm? and if,

after ageing test in air over

(ub-clause 4.4) difference

If TSS 5.0 N/mm? and if,

17S < SON/mm?

after ageing test in air oven

(Sub-clause 44) difference

TSor £8 225% TSor EB >25%

then then 7 rer

Required Shor geing es in oxygen bomb ferseven

ani oauc daysat 70°C

Aifferences difference Subclause 46)

TS aoe a ‘estpieces Gand For Vand 5

EB 30% 5B 35%

‘Required:

Hrs = 42.N/mm

EBS 250%

differences

15 25%

TS = tensilestreng th EB 35%

EB» elongation-at break

compotund type TE |

FIG.4~ Synopsis of tests for the mechanical properties of insulation consisting of rubber

-29-

5. Flame retardance test for lif

‘cables

‘The test shall be carried out in accordance with IEC Publication 332-1

The cable shall comply with the requirements in the above-mentioned publication and in

addition to this, no short circuit between the cores shall occur during the test.

Before the test, alternate conductors of the cable shall be connected in series.

‘A voltage of about 220 Vin series with a lamp of about 100 W/220 V shall be applied to the

two circuits so formed.

[At the other end of the two circuits, an indicator lamp of about 10 W/220 V shall be con

nected.

Note ~ For cables with more than one lyer of cores, the connection instis of alternate conductors stall be made

throughout ezeh layer in turn, so that adjacent cotes in each layer are so far as possible, notin the same

During the test, the indicator lamp shall remain alight.

Atypical electri

| circuit diagram is shown in Figure 5.

=10w

2

“Three sided metal screen

=—-

| ‘Cable sample

a4

iE ; ee

= 10

Ph

=m0Vv

N 269/80

Fic. 5, - Electric wiring for the flame retardance test.

‘Autres publications de la CEI préparées

par le Comité d’Etudes N°20

$5: Cables isolés au papier imprégné sous gaine métallique pour

‘des tensions assignées inféricures ou égoles &

18/30 kV (avec ames conductrices en cuivre ou ale

‘minium et exclusion des cibles& pression de gaz

et dhuile Muide)

551(1978) _Premigre partie: Esais,

{t:~ Essais de edbles & hulle Nuide,& pression de gaz et de leurs

dispostits accessoires

|41-1(1976) Premiére partie: Cables au papier a hulle Muide et &

fine métallique et accessoires pour des tensions

alternatives inférieures ou égales 4400 kV.

$41-2(1963) Deusigme partie: Cables 4 pression de gaz interne

ft accessoires pour des tensions alternatives inlé-

rieures ouéyates 8275 kV

Modification n° | (1967).

141-3(1963) Troisitme pantie: Cables a pression de gaz externe

(& compression de gaz) et accessoires pour des ten-

sions alternatives inférieures ou égales 275 KV.

Modification n0 111967)

'41-4(1980) Quatriéme partie: Cables & hulle fluide en tuyau &

isolation de papier imprégné sous forte pression

S huile et accessoires pour des tensions alternatives

inférieures ou ges 4 400 kV

17311964) Couleurs pour les conducteurs descibles souples

183(1965) Guide au choix des cables a haute tension

227: Conducieurs et ciblesisolés au polychlorure de vinyle, de

tension nominate au plus égale& 450/750 V

227-1 1979) Premigre partie: Prescriptions générales

227-2(1979)Deuxieme partie: Methodes d essais,

(1978) Trosieme pans: Conducteus pour installations

2274(1979) Quasieme pare: Cables sus gine pour instal

51979) Cinquiéme parte: Cabies souples

2281978) Amesdes ciblesisolés

29(1966) _Essais de revétements de protection contte a corro:

sion des gsines métalliques de cdbles

Modification n° 1 (1970)

2301966) Essals de choc des cables et de leurs accessoires

245:-Conducteurs et cdbles isolés au ceoutchoue, de tension

‘nominale au plus gale & 450/750 V.

245-1 1980) Premigre partie: Prescriptions générales

245-3(1980) Troisiéme partie: Conducteurs isolés au silicone,

sistant ala chaleur.

245-4(1980) Quatritme partie: Cables souples

245-5 (1980) Cinquitme pantie: Cables pour ascenseurs

245-6(1980) Sixiéme partie: Cables souples pour électrodes de

soudagedl are

Caleul du courant admissible dans les edbles en

égime permanent ((acteur de charge 100%)

Premiere édition (1969) comprenant les Modifica-

tions n° 1 (1971) et n2-2 (1974)

Modification 293(1977)

Modification n* (1978)

28TA(1978) Premier complément: Annexe C:Caleul numérique

des quantitésindiquées sous forme de graphiques

Caractéristiqus des cable tietriques sistant au

3321 Essais des cables slectriques soumis au feu

332-1 (1979) Premiére parte: Essai effectué sur un céble vertical

287(1969)

3311970)

(Suiteau verso)

Piblenion248.2

Other LEC publications prepared

by Technical Committee No. 20

55: Paperinsulated metal-sheathed cables for rated voltages up

{0 18/30 kV (with copper or aluminium conductors

and excluding ges-pressure and oil-filled cables)

S5-1(1978) Part 1: Tess

141: Tests on oil-filled and gas-pressure cables and their acces:

141-1 (1976) Part 1: Oifilled, paper-insulated, metal-sheathed

‘ables and accessories for alternating voltages up

toand including 400 kV.

141-2(1963) Part Internal gas-pressure cables and accessories,

foralternating voltages up 10 275 Y

Amendment No 1 (1967)

141-3(1963) Part & External gas-pressure (gas compression)

cables and accessories for alternating voltages up

10275 kV

Amendment No 1 (1967)

141-4(1980) Part 4: Oil impregnated paper-insulated high pres-

sure oil-filled pipe-type cables anc accessories for

alternating voltages up (o and including 400 KY

173(1964) Colours of the cores of flexible cabs and cords

183(1965) Guide the selection of high-voltage cables

227:- Polyvinyl chloride insulated cables of rated voltages up to

‘and including 450/750 V

207-1 (1979) Part I:General requirements

7-2(1979) Part: Test methods

7-3(1919)_ Part 3: Non-sheathed cables forfixed wiring,

227-4(1979) Parka: Sheathed cables for fixed wiring

327:5(1979) Part: Flexible cables (cords)

22811978) Conductors of insulated cables

229(1966) Tests on anti-corrosion protective coverings of

metalic cable sheaths

‘Amendment No | (1970),

23011966) Impulse esis on cables and their aczessories

245; Rubber insulated cables of rated voltages up to and in.

cluding 450/750 V

245-1 (1980) Part I: General eequirements

248-3 (1980) Part 3: Heat resistant silicone insulcted cables

245-4(1980) Part 4: Cords and flexible cables

245.5 (1980) Part $: Lift cables

245.6(1980) Part 6: Atc welding electrode cables

Cateulation of the continuous cxrrent rating of

cables (100%eload factor)

First edition (1969) incorporating Amendments

No 1(1971)and No 2(1974)

Amendment No 3(1977)

‘Amendment No. (1978)

287A(1978) First supplement: Appendix C: Digital calculation

fof quantities given graphically

Fire-esisting characteristics of electric cables

287 (1969),

3311970)

332:- Tests on electric cables under fire conditions

332-1(1979) Part: Test on a single vertical insulated wire or

cable

(Continued overteat)

‘Autres publications dea CEI préparées

parle Comité d'Etudes N°20

(Suite)

3021978)

540(1976)

S40A.979)

541 (1976)

Cables de transport dénergie isolés par diélecti-

{ques massifs exirudés pour des tensions assignées

de 1k 30KV.

Méthodes dessais pour les enveloppes isolantes et

les gaines des cables élecriques rigides et souples

(mélanges sastoméres et thermoplastiques)

Modification n® 1 (1978)

Premier complément

Comparaison des cdbles souples de la CEI et des

‘bles souples de’ Amérique du Nord

Other IEC pul

rations prepared

by Technical Committee No, 20

(Continued)

5021978)

540(1976)

‘540 (1979)

'341,(1976)

lesfor

Extreded solid dielectric insulated power

rated voltages from 1 kV up to 30V

eats of electro

fest methods for insulations and 4

“Test methods for insu sot

cables and cords (elastomeric ard tf

compounds).

‘Amendment No. (1979)

First supplement.

Comparative information on 16¢ and Nos

PRINTED IN SWITZERLAND

‘Computer typesetting and printing by Basler Zeitung, Basle

COMMISSION ELECTROTECHNIQUE INTERNATIONALE

NORME DE LA CEI

INTERNATIONAL ELECTROTECHNICAL COMMISSION

1EC STANDARD

Modification n° 1 Amendment No. 1

dates 1988 July 1985

Publication 245-2

1980

Conducteurs et cables isolés au caoutchouc,

de tension nominale au plus égale 4 450/750 V

Deuxiéme partie : Méthodes d'essais

Rubber insulated cables

of rated voltages up to and including 450/750 V

Part 2 : Test methods

© CEL 1985,

Droits de reproduction résorvis — Copyright — all igh reserved

Bureau Central de la Commission Electrotechnique Internationale

3, rue de Vorembé

Genéve, Suisse

Pre Ha

fie 8 Te

245-2 Amend, 1 © IEC 1985 -3-

PREFACE

This amendment has been prepared by Sub-Committee 20B : Low-voltage Cables, of TEC Technical

Committee No. 20: Electric Cables.

‘The text of this amendment is based upon the following documents:

Six Months’ Rule Report on Voting

208(CO)87 208(C0)94

Further information can be found in the Report on Voting indicated in the table above.

Page 3

‘CONTENTS

1.8 Checking of the indelibility of colours and markings ©... . oe

Replace the title of this sub-clause by the following:

1.8 Checking of the durability of colours and markings 6. es ss >

Page 9

18 Checking of the indelibility of colours and markings

Replace the title of this sub-clause by the following

1.8 Checking of the durability of colours and markings

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- SAP HCM Case StudyDocument17 paginiSAP HCM Case StudyRafidaFatimatuzzahraÎncă nu există evaluări

- Iroquois Clothes and WampumDocument3 paginiIroquois Clothes and Wampumapi-254323856Încă nu există evaluări

- Pipeline Operations and Maintenance ManualDocument72 paginiPipeline Operations and Maintenance Manualwe202Încă nu există evaluări

- ASTM A36 - Standard Specification For Carbon Structural SteelDocument3 paginiASTM A36 - Standard Specification For Carbon Structural SteelLeo Kapmas SinambelaÎncă nu există evaluări

- Epc1 - Floating Production UnitDocument15 paginiEpc1 - Floating Production Unitwe202Încă nu există evaluări

- AnsiDocument10 paginiAnsiwe202Încă nu există evaluări

- 15.6 Color Coding RequirementDocument4 pagini15.6 Color Coding Requirementwe202Încă nu există evaluări

- Astm A139 2000Document6 paginiAstm A139 2000Rolando CastilloÎncă nu există evaluări

- NPT Thread PDFDocument1 paginăNPT Thread PDFAli BelhaylaÎncă nu există evaluări

- Gex Sis Switchboard WireDocument2 paginiGex Sis Switchboard Wirewe202Încă nu există evaluări

- Prepare For A New ERA: InternationalDocument4 paginiPrepare For A New ERA: Internationalwe202Încă nu există evaluări

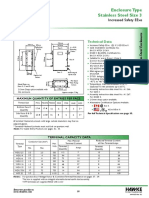

- Type ICG 653-UniversalDocument1 paginăType ICG 653-Universalwe202Încă nu există evaluări

- Stainless Steel Size 3 Enclosure Type: Increased Safety EexeDocument1 paginăStainless Steel Size 3 Enclosure Type: Increased Safety Eexewe202Încă nu există evaluări

- Type 501-453-Universal PDFDocument1 paginăType 501-453-Universal PDFwe202Încă nu există evaluări

- Stainless Steel Size 1 Enclosure Type: Increased Safety EexeDocument1 paginăStainless Steel Size 1 Enclosure Type: Increased Safety Eexewe202Încă nu există evaluări

- 701 Cable Gland Type: Industrial General PurposeDocument1 pagină701 Cable Gland Type: Industrial General Purposewe202Încă nu există evaluări

- DFJ-AE3 Heat DetectorDocument1 paginăDFJ-AE3 Heat Detectorwe202Încă nu există evaluări

- 753 Cable Gland Type: Explosion ProofDocument1 pagină753 Cable Gland Type: Explosion Proofwe202Încă nu există evaluări

- Industrial General Purpose: Cable Gland Selection TableDocument1 paginăIndustrial General Purpose: Cable Gland Selection Tablewe202Încă nu există evaluări

- 121 Cable Gland Type: Industrial General PurposeDocument1 pagină121 Cable Gland Type: Industrial General Purposewe202Încă nu există evaluări

- Avery Hardoll DM Series BulkmeterDocument4 paginiAvery Hardoll DM Series Bulkmeterwe202Încă nu există evaluări

- 501/421 Cable Gland Type: Flameproof and Increased SafetyDocument1 pagină501/421 Cable Gland Type: Flameproof and Increased Safetywe202Încă nu există evaluări

- Cross Link Process ComparisonDocument1 paginăCross Link Process Comparisonwe202Încă nu există evaluări

- Brochure Paga 1700 810121Document4 paginiBrochure Paga 1700 810121we202Încă nu există evaluări

- Cable Solutions: Harsh EnvironmentDocument1 paginăCable Solutions: Harsh Environmentwe202Încă nu există evaluări

- Mpa 1600 Paga VB 186677Document4 paginiMpa 1600 Paga VB 186677we202Încă nu există evaluări

- 1756 Control Logix ControllerDocument44 pagini1756 Control Logix Controllerwe202Încă nu există evaluări

- Critch LeyDocument17 paginiCritch LeyhendrabudimanÎncă nu există evaluări

- FM-200 (GX-20)Document4 paginiFM-200 (GX-20)Cipon MariponÎncă nu există evaluări

- Vesda Sped PDFDocument11 paginiVesda Sped PDFwe202Încă nu există evaluări

- DRAKA - XLPE Cable PDFDocument2 paginiDRAKA - XLPE Cable PDFwe202Încă nu există evaluări

- Ns SpecsDocument7 paginiNs Specswe202Încă nu există evaluări

- Early Christian ArchitectureDocument38 paginiEarly Christian ArchitectureInspirations & ArchitectureÎncă nu există evaluări

- Turnbull CV OnlineDocument7 paginiTurnbull CV Onlineapi-294951257Încă nu există evaluări

- Family Factors: Its Effect On The Academic Performance of The Grade 6 Pupils of East Bayugan Central Elementary SchoolDocument11 paginiFamily Factors: Its Effect On The Academic Performance of The Grade 6 Pupils of East Bayugan Central Elementary SchoolGrace Joy AsorÎncă nu există evaluări

- PMDG 737NGX Tutorial 2 PDFDocument148 paginiPMDG 737NGX Tutorial 2 PDFMatt HenryÎncă nu există evaluări

- ProjectDocument22 paginiProjectSayan MondalÎncă nu există evaluări

- EvolutionCombatMedic 2022Document17 paginiEvolutionCombatMedic 2022smith.kevin1420344100% (1)

- PP Checklist (From IB)Document2 paginiPP Checklist (From IB)Pete GoodmanÎncă nu există evaluări

- Agency Procurement Request: Ipil Heights Elementary SchoolDocument1 paginăAgency Procurement Request: Ipil Heights Elementary SchoolShar Nur JeanÎncă nu există evaluări

- Aqa Ms Ss1a W QP Jun13Document20 paginiAqa Ms Ss1a W QP Jun13prsara1975Încă nu există evaluări

- Model No. TH-65JX850M/MF Chassis. 9K56T: LED TelevisionDocument53 paginiModel No. TH-65JX850M/MF Chassis. 9K56T: LED TelevisionRavi ChandranÎncă nu există evaluări

- CP3 - June2019 2Document5 paginiCP3 - June2019 2Sifei ZhangÎncă nu există evaluări

- The Impact of Personnel Behaviour in Clean RoomDocument59 paginiThe Impact of Personnel Behaviour in Clean Roomisrael afolayan mayomiÎncă nu există evaluări

- Net Pert: Cable QualifierDocument4 paginiNet Pert: Cable QualifierAndrés Felipe Fandiño MÎncă nu există evaluări

- NHL DB Rulebook ENGLISHDocument6 paginiNHL DB Rulebook ENGLISHAdhika WidyaparagaÎncă nu există evaluări

- Dash8 200 300 Electrical PDFDocument35 paginiDash8 200 300 Electrical PDFCarina Ramo LakaÎncă nu există evaluări

- Report On Monitoring and Evaluation-Ilagan CityDocument5 paginiReport On Monitoring and Evaluation-Ilagan CityRonnie Francisco TejanoÎncă nu există evaluări

- Black Hole Safety Brochure Trifold FinalDocument2 paginiBlack Hole Safety Brochure Trifold Finalvixy1830Încă nu există evaluări

- Model 900 Automated Viscometer: Drilling Fluids EquipmentDocument2 paginiModel 900 Automated Viscometer: Drilling Fluids EquipmentJazminÎncă nu există evaluări

- Chapter 10 OutlineDocument3 paginiChapter 10 OutlineFerrari75% (4)

- Internship Report PDFDocument71 paginiInternship Report PDFNafiz FahimÎncă nu există evaluări

- Lesson 23 Career PathwaysDocument34 paginiLesson 23 Career PathwaysAlfredo ModestoÎncă nu există evaluări

- M.Sc. Steel Structures LEC. #7 Plastic Analysis and Design: Dr. Qasim Shaukat KhanDocument43 paginiM.Sc. Steel Structures LEC. #7 Plastic Analysis and Design: Dr. Qasim Shaukat KhanSSÎncă nu există evaluări

- Frequently Asked Questions: Lecture 7 To 9 Hydraulic PumpsDocument5 paginiFrequently Asked Questions: Lecture 7 To 9 Hydraulic PumpsJatadhara GSÎncă nu există evaluări

- CO 101 Introductory Computing CO 102 Computing LabDocument17 paginiCO 101 Introductory Computing CO 102 Computing Labadityabaid4Încă nu există evaluări

- Motion To Dismiss Guidry Trademark Infringement ClaimDocument23 paginiMotion To Dismiss Guidry Trademark Infringement ClaimDaniel BallardÎncă nu există evaluări

- PixiiDocument3 paginiPixiiFoxÎncă nu există evaluări

- GladioDocument28 paginiGladioPedro Navarro SeguraÎncă nu există evaluări

- 2 Calculation ProblemsDocument4 pagini2 Calculation ProblemsFathia IbrahimÎncă nu există evaluări