Documente Academic

Documente Profesional

Documente Cultură

Basement Column Supporting Lateral Resisting Frame Based On ACI 318-08 Input Data & Design Summary

Încărcat de

Anonymous fLgaidVBhzTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Basement Column Supporting Lateral Resisting Frame Based On ACI 318-08 Input Data & Design Summary

Încărcat de

Anonymous fLgaidVBhzDrepturi de autor:

Formate disponibile

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

Basement Column Supporting Lateral Resisting Frame Based on ACI 318-08

INPUT DATA & DESIGN SUMMARY

CONCRETE STRENGTH fc' = 4.5 ksi

REBAR YIELD STRESS fy = 60 ksi

COLUMN CLEAR HEIGHT h = 14 ft

COLUMN SIZE c1 = 24 in

c2 = 24 in

AMPLIFICATION FACTOR (ASCE 7 Tab 12.2-1) W0 = 2.2

DESIGN LEVEL BASEMENT DISPLACEMENT DS = 0 in

LOADS, ASD (ft-kips, kips)

P V M Pground

DL 225 157.5

LL 270 90

E / 1.4 -333.3 131 0.1

( - P for uplift)

LONGITUDINAL REINFORCING

SECTION TOP BOTTOM

LEFT 5 # 10 5 # 10

(d = 21.37 in ) (d = 21.37 in )

( 1 Layer) ( 1 Layer)

RIGHT 5 # 10 5 # 10

( d = 21.37 in ) ( d = 21.37 in )

( 1 Layer) ( 1 Layer) THE COLUMN DESIGN IS ADEQUATE.

TRANSVERSE REINFORCEMENT FOR CONFINEMENT

4 Legs # 4 @ 5 in, o.c., full height (ACI 318-08 4.4.5)

ANALYSIS

DESIGN CRITERIA

1. Since the column supported reaction from lateral resisting frame, ASCE 7-05 12.3.3.3 apply.

2. Since the column is not part of the lateral force resisting system, ACI 318-08 21.13 apply.

3. Since the transverse reinforcement required 12" at least into footing per ACI 318-08 21.6.4.6

a condition of pinned top & fixed bottom should be used.

DESIGN LOADS AT TOP OF COLUMN

U1 = (1.2±0.2SDS) D + f1 L +1.0 W0 Eh , (ACI 318-05 21.13) U2 = (0.9±0.2SDS) D ± 1.0 W0 Eh

Pu = -527.9 kips Mu = 0.3 ft-kips Pu = -777.6 kips Mu = 0.3 ft-kips

Vu = 403.5 kips f1 = 0.5 Vu = 403.5 kips

SDS = 1.246

U3 = 1.2 D + 1.6 L , (ACI 318-05 9.2.1)

Pu = 891.0 kips Mu = 0.0 ft-kips

Vu = 0.0 kips

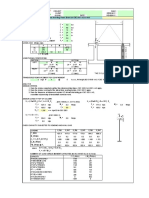

CHECK CAPACITY SUBJECTED TO BENDING AND AXIAL LOAD

LOADING U1,top U1,bot U2,top U2,bot U3,top U3,bot

Pu (kips) -527.9 -517.8 -777.6 -770.1 891.0 902.8

Mu (ft-kips) 0.3 0.2 0.3 0.2 0.0 0.0

dns = Cm/[1-Pu/(0.75Pc)] 1.000 1.000 1.000 1.000 1.148 1.150

dnsMu (ft-kips) 0.3 0.2 0.3 0.2 0.0 0.0

fMn (ft-kips) @ Pu 426.7 822.4 822.4 822.4 822.3 822.3

where EI = 0.4EcIg / (1+bd) = 0.25 EcIg

Pc = p2EI / (kLu)2

SUMMARY OF LOAD VERSUS MOMENT CAPACITIES (for ACI 318-08 10.2 & 10.3 only)

CAPACITY f Pn (kips) f Mn (ft-kips)

AT AXIAL LOAD ONLY 1739 0

AT MAXIMUM LOAD 1739 281

AT 0 % TENSION 1384 487

AT 25 % TENSION 1148 580

AT 50 % TENSION 941 648

AT e t = 0.002 605 743

AT BALANCED CONDITION 585 751

AT e t = 0.005 258 943

AT FLEXURE ONLY 0 822

AT TENSION ONLY -1097 0

f Pn (kips) (cont'd)

2000.0

1500.0

1000.0

500.0

0.0 f Mn (ft-kips)

0.0 100.0 200.0 300.0 400.0 500.0 600.0 700.0 800.0 900.0 1000.0

-500.0

-1000.0

-1500.0

All load points to be within capacity diagram. [Satisfactory]

DETERMINE INDUCED MOMENT IN THE COLUMN

3 E c I cd u

MD PD 168.0906 ft-kips

h2

where Ec = 57000 (fc')0.5 = 3824 ksi, ACI 318-08 8.5.1

Ig = c1 c23 / 12 = 27648 in4

Ic = 0.7 Ig = 19354 in4 , ACI 318-08 9.5.2.3 & 10.11.1

Cd = 5.0 dxe = 0.1 in

du = Cd dxe / I = 0.50 I= 1.0

D = 0.5 du = 0.25 in, ACI 318-08 21.13.3

P = 0.9 PDL = 202.5 kips, ACI 318-08 21.13.3

CHECK REQUIREMENTS OF NOT PART OF THE LATERAL RESISTING SYSTEM

Mu = 1.2 MDL + 1.0 MLL + MD = 168.0906 ft-kips

< f Mn =

822.3 kips [Satisfactory]

Pu, max = 902.8 kips > 0.1Agfc' = 259.2 kips [Satisfactory]

Per ACI 318-08 21.13.4.3, the column shall satisfy ACI 318-08 21.6.3, 21.6.4, 21.6.5, and 21.7.3.1.

CHECK SECTION REQUIREMENTS (ACI 318-08 21.6.1)

cmin =MIN(c1, c2) = 24 in > 12 in [Satisfactory]

cmin / cmax = 1.00 > 0.4 [Satisfactory]

CHECK TRANSVERSE REINFORCING AT BOTTOM OF COLUMN (ACI 318-08 21.6.4)

Ash = 0.80 in2 > MAX[ 0.09shcfc' / fyh , 0.3shc(Ag/Ach-1)fc' / fyh ] = 0.71 in2

[Satisfactory] where s = MAX[MIN(c1/4, 6db, 4+(14-hx)/3, 6), 4] = 5 in

hc = c1 - 2Cover - dt = 20.5 in

Ach = (c1-3)(c2-3) = 441.0 in2

CHECK FLEXURAL REINFORCING (ACI 318-08 21.6.1.1)

rtotal = 0.040 > rmin = 0.010 [Satisfactory]

< rmax = 0.060 [Satisfactory]

CHECK SHEAR STRENGTH (ACI 318-08 21.6.4.6)

Ve = MAX[ (Mpr, left, top + Mpr, right,bot) / h , Vu,max] = 73.4 kips

< 8f(fc')0.5c2d = 206.4 kips [Satisfactory]

< f[2(fc')0.5c2d + Avfyd / s] = 205.4 kips [Satisfactory]

where rtop,left = 0.012 > rmin=MIN[3(fc')0.5/fy, 200/fy ]= 0.003 [Satisfactory]

rbot,left = 0.012 > rmin = 0.003 [Satisfactory]

Mpr, left, top = 0 ft-kips f = 0.75

Mpr, right, bot = 1.25Mn,col,max = 1028 ft-kips Av = 0.8 in2

Vu, max = 0.033 ft-kips

DETERMINE SEISMIC TENSION DEVELOPMENT, Ld, INTO THE FOOTING PER ACI 318-08 21.6.4.6

db f

L dh MAX

y

, 8d b , 6 in 14 db = 17 in, (ACI 318-08 21.7.5.1)

65 f '

c

L d MAX 3.5L dhb , 12 in 48 db = 61 in, (ACI 318-08 21.7.5.2)

where db = 1.27 in

b = 1.0 , (1.2 for epoxy-coated, ACI 318-08 21.7.5.4 & 12.2.4)

Daniel PROJECT : PAGE :

CLIENT : DESIGN BY :

Tian Li JOB NO. : DATE : REVIEW BY :

Concrete Column Design Based on ACI 318-02

INPUT DATA & DESIGN SUMMARY

CONCRETE STRENGTH fc' = 4.5 ksi

REBAR YIELD STRESS fy = 60 ksi e

COLUMN DIMENSUINS cx = 24 in

cy = 24 in

FACTORED AXIAL LOAD Pu = -527.88 k

FACTORED MOMENT LOAD Mu,x = 0.308 ft-k

Mu,y = 0.0001 ft-k

q

e

FACTORED SHEAR LOAD Vu,x = 0 k

Vu,y = 0 k

COLUMN VERT. REINF. 5 # 10 at x dir.

(Total 16 # 10)

5 # 10 at y dir.

SHEAR REINF. 4 legs,# 4 @ 4 in o.c., x dir. THE COLUMN DESIGN IS ADEQUATE.

2 legs,# 4 @ 4 in o.c., y dir.

ANALYSIS

2 0.85 f

'

C '

eo , E c 57 f C , E s 29000ksi

2000 Ec

e e 2

c c ,

0.85 f C 2

'

for 0 e c e o

1500 fC e o e o

'

0.85 f C , for e c e o

e s E s , for e s e y

1000

f Pn (k) fS

f , for e s e y

y

500 f Pn (kips) f Mn (ft-kips)

AT AXIAL LOAD ONLY 1739 0

0 AT MAXIMUM LOAD 1739 281

0 100 200 300 400 500 600 700 800 900 1000 AT 0 % TENSION 1384 487

AT 25 % TENSION 1148 580

-500

AT 50 % TENSION 941 648

AT e t = 0.002 605 743

-1000

AT BALANCED CONDITION 585 751

f Mn (ft-k) AT e t = 0.005 258 943

AT FLEXURE ONLY 0 822

CHECK FLEXURAL & AXIAL CAPACITY

Mu = ( Mu,x2 + Mu,y2 )0.5 = 0.30801 ft-k, (combined bending load.) q = 0.02 o

, (the direction of combined load.)

f Pmax =0.80 f [ 0.85 fc' (Ag - Ast) + fy Ast] = 1739.2 kips., (at max axial load, ACI 318-02, Sec. 10.3.6.2)

where f = 0.65 (ACI 318-02, Sec.9.3.2.2) > Pu [Satisfactory]

Ag = 576 in2. Ast = 20.32 in2.

a = Cbb1 = 10 in (at balanced strain condition, ACI 10.3.2)

f = 0.48 + 83 et = 0.652 (ACI 318-02, Fig. R9.3.2)

where Cb = d ec / (ec + es) = 13 in et = 0.002069 ec = 0.003

d = 21.3726 in, (ACI 7.7.1) b1 = 0.825 ( ACI 318-02, Sec. 10.2.7.3 )

f Mn = 0.9 Mn = 822 ft-kips @ Pn = 0, (ACI 318-02, Sec. 9.3.2)

f Mn = 427 ft-kips @ Pu = -528 kips > Mu [Satisfactory]

rmax = 0.08 (ACI 318-02, Section 10.9) rprovd = 0.035

rmin = 0.01 (ACI 318-02, Section 10.9) [Satisfactory]

CHECK SHEAR CAPACITY (ACI 318-02 Sec. 11.1.1, 11.3.1, & 11.5.6.2)

f Vn = f (Vs + Vc) (ACI 318-02 Sec. 11.1.1)

> Vu [Satisfactory]

where f = 0.75 (ACI 318-02 Sec. 9.3.2.3) fy = 60 ksi

d A0 Av Vc = 2 (fc') A0

0.5

Vs = MIN (d fy Av / s , 4Vc) f Vn

x 21.37 512.8 0.80 68.8 256.4 244

y 21.37 512.8 0.40 68.8 128.2 148

smax = 12 (ACI 318-02, Section 10.16.8.5) sprovd = 4 in

smin = 1 (ACI 318-02, Section 7.10.4.3) [Satisfactory]

S-ar putea să vă placă și

- Footing 2 Storey Design 1Document4 paginiFooting 2 Storey Design 1Arvin Torres GuintoÎncă nu există evaluări

- PDS STAAD Foundation Advanced LTR EN LR PDFDocument2 paginiPDS STAAD Foundation Advanced LTR EN LR PDFAndres Felipe Forero GacharnáÎncă nu există evaluări

- GRDSLABDocument22 paginiGRDSLABCesar Rosas100% (1)

- Design of Retaining StructuresDocument14 paginiDesign of Retaining Structuressu1705100% (1)

- Water Tank Slab 1. Ground Floor Slab: 2 - WAY SLAB Design To BS 8110 (With Corner Restraints) ProjectDocument2 paginiWater Tank Slab 1. Ground Floor Slab: 2 - WAY SLAB Design To BS 8110 (With Corner Restraints) ProjectAh Leng LauÎncă nu există evaluări

- Setha's CV & Cover LetterDocument10 paginiSetha's CV & Cover LetterMen Keo RathaÎncă nu există evaluări

- 1 Way SlabDocument12 pagini1 Way SlabSemahegn GebiruÎncă nu există evaluări

- Wind UBCDocument6 paginiWind UBCLivian TeddyÎncă nu există evaluări

- Load Calculations for Steel Frame StructureDocument1 paginăLoad Calculations for Steel Frame Structurefrog15Încă nu există evaluări

- "Grdslab" - Concrete Slab On Grade Analysis: Program DescriptionDocument11 pagini"Grdslab" - Concrete Slab On Grade Analysis: Program Descriptioncjcute91100% (1)

- Shallow Foundation Design 2: SettlementDocument32 paginiShallow Foundation Design 2: SettlementPhanna MongÎncă nu există evaluări

- Dimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingDocument1 paginăDimension Is 350mm X 350mm of Columns With 8pcs - Ø16mm: Proposed Two Storey Commercial BuildingMark Christian EsguerraÎncă nu există evaluări

- Wind LoadDocument10 paginiWind LoadGrace Talaroc SuperalesÎncă nu există evaluări

- 5-Design of Raft FoundationDocument2 pagini5-Design of Raft FoundationheshamÎncă nu există evaluări

- RC Slab Crack Width CalculationDocument6 paginiRC Slab Crack Width CalculationDonny. B TampubolonÎncă nu există evaluări

- Study Material - 2011 PE Civil SQS ErrataDocument1 paginăStudy Material - 2011 PE Civil SQS ErrataAlbert PizarroÎncă nu există evaluări

- Structural DesignDocument7 paginiStructural DesignDENCOÎncă nu există evaluări

- Design of Floor (Slab 4) : La LBDocument10 paginiDesign of Floor (Slab 4) : La LBAyreesh Mey SpntÎncă nu există evaluări

- Steel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiDocument6 paginiSteel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Windload AnalysisDocument6 paginiWindload AnalysisJerico Enriquez CacaoÎncă nu există evaluări

- Design of roof slab, beam and column for houseDocument18 paginiDesign of roof slab, beam and column for housekkhan_451062Încă nu există evaluări

- Isolated Footing Design For Pipe Supports/Sliding Supports (SS) Serial NoDocument11 paginiIsolated Footing Design For Pipe Supports/Sliding Supports (SS) Serial NoNazeer NÎncă nu există evaluări

- Seismic design parameters for Manila Water emergency reservoirDocument2 paginiSeismic design parameters for Manila Water emergency reservoirmark ignacioÎncă nu există evaluări

- Sample Column DesignDocument1 paginăSample Column DesignjologscresenciaÎncă nu există evaluări

- Initial P-Delta Analysis ETABSDocument1 paginăInitial P-Delta Analysis ETABSkatherineqj100% (1)

- Ultimate Strength Design (Doubly)Document17 paginiUltimate Strength Design (Doubly)C.j. CaparasÎncă nu există evaluări

- Shear Lug Verification Example 2Document1 paginăShear Lug Verification Example 2Nasrul AdliÎncă nu există evaluări

- Check Punching Shear of PILE and COLUMN REactionsDocument4 paginiCheck Punching Shear of PILE and COLUMN REactionsMa'rruf AmarÎncă nu există evaluări

- Rectangular Spread Footing DesignDocument42 paginiRectangular Spread Footing DesignJedidiah MelakuÎncă nu există evaluări

- Retaining Wall Analysis & Design (BS8002)Document10 paginiRetaining Wall Analysis & Design (BS8002)Thoong Yew ChanÎncă nu există evaluări

- Combined Footing DesignDocument48 paginiCombined Footing DesignWanda BeasleyÎncă nu există evaluări

- Designing Steel Structures For Deflection - TRNC03044Document36 paginiDesigning Steel Structures For Deflection - TRNC03044AKSÎncă nu există evaluări

- PAEC2017 - Slab On Grade InvestigationDocument2 paginiPAEC2017 - Slab On Grade InvestigationSayavi Nicole Sayavi NickÎncă nu există evaluări

- Column Base Design:: Input DataDocument3 paginiColumn Base Design:: Input DataEng HatemÎncă nu există evaluări

- Axial load capacity for deep foundationsDocument8 paginiAxial load capacity for deep foundationsacidrisamuel2656Încă nu există evaluări

- Truss Design - Faculty Wing - EN1993Document13 paginiTruss Design - Faculty Wing - EN1993JonathanÎncă nu există evaluări

- Three-end continuous two-way slab designDocument21 paginiThree-end continuous two-way slab designJanine Leah Candelaria BiendimaÎncă nu există evaluări

- Slender Column - Sway Frame - ACI 318-08 Reinforced Concrete Design Example HassounDocument8 paginiSlender Column - Sway Frame - ACI 318-08 Reinforced Concrete Design Example HassounMike2322100% (1)

- Corbel Design CalculationsDocument2 paginiCorbel Design CalculationsMisqal A IqbalÎncă nu există evaluări

- Terzaghi Si Hansen 24343261-Bearing-Capasity-OfsoilDocument46 paginiTerzaghi Si Hansen 24343261-Bearing-Capasity-OfsoilOana MateiÎncă nu există evaluări

- RC Two Way Slab Design ACI318 05 PDFDocument6 paginiRC Two Way Slab Design ACI318 05 PDFSafi Zabihullah SafiÎncă nu există evaluări

- Design of Reinforced Concrete Shear WallDocument8 paginiDesign of Reinforced Concrete Shear WallklynchelleÎncă nu există evaluări

- 2 Storey Event CenterDocument5 pagini2 Storey Event CenterjohnÎncă nu există evaluări

- Cellular BeamDocument14 paginiCellular BeamAlphaÎncă nu există evaluări

- Geotecnical FormulasDocument13 paginiGeotecnical FormulasArnel Tan100% (1)

- ProtaStructure Suite 2016 Whats NewDocument41 paginiProtaStructure Suite 2016 Whats NewPlacid FabiloÎncă nu există evaluări

- Compined FootingDocument12 paginiCompined Footinghuyxpkiss100% (1)

- Wind Load and Roof Load CalculationDocument20 paginiWind Load and Roof Load CalculationleodegarioporralÎncă nu există evaluări

- Tengs DistributionDocument2 paginiTengs DistributionRajdeep ChakrabortyÎncă nu există evaluări

- Lecture 11-1 Bases by H.J. MtyanaDocument29 paginiLecture 11-1 Bases by H.J. MtyanaHarold Jackson Mtyana100% (1)

- Staad BasicsDocument17 paginiStaad BasicsCindy SisonÎncă nu există evaluări

- Basement Column Design Analysis and Capacity CheckDocument3 paginiBasement Column Design Analysis and Capacity CheckPhanithÎncă nu există evaluări

- Basement Column Supporting Lateral Resisting Frame Based On CBC 2001/ ACI 318-05 Input Data & Design SummaryDocument28 paginiBasement Column Supporting Lateral Resisting Frame Based On CBC 2001/ ACI 318-05 Input Data & Design SummaryFranklyn GenoveÎncă nu există evaluări

- Columna de SotanoDocument40 paginiColumna de SotanoMed SbitiÎncă nu există evaluări

- Column Supporting DiscontinuousDocument40 paginiColumn Supporting DiscontinuousRohan JaiswalÎncă nu există evaluări

- Basement Column Design AnalysisDocument4 paginiBasement Column Design AnalysisErielle AngelaÎncă nu există evaluări

- Bolted Moment ConnectionDocument9 paginiBolted Moment ConnectionAmey Gudigar100% (1)

- Drilled Pile: & L Comply With The Tension Development. Otherwise Pinned at Top., M, & VDocument8 paginiDrilled Pile: & L Comply With The Tension Development. Otherwise Pinned at Top., M, & VHayman AhmedÎncă nu există evaluări

- 8-Bolted Moment Connection DesignDocument18 pagini8-Bolted Moment Connection DesignAlpha50% (2)

- Vigas Columnas y Nudos DPPDocument6 paginiVigas Columnas y Nudos DPPJhonatan PlasenciaÎncă nu există evaluări

- Cross Section1Document1 paginăCross Section1Anonymous fLgaidVBhzÎncă nu există evaluări

- Cross Section2Document1 paginăCross Section2Anonymous fLgaidVBhzÎncă nu există evaluări

- Cross SectionDocument1 paginăCross SectionAnonymous fLgaidVBhzÎncă nu există evaluări

- Electricity Consumption Bill For LT Consumers Only: 29-05-2014 2000699423 Transaction Successful 3735.00Document1 paginăElectricity Consumption Bill For LT Consumers Only: 29-05-2014 2000699423 Transaction Successful 3735.00Rashid AyubiÎncă nu există evaluări

- Electricity Consumption Bill For LT Consumers Only: 29-05-2014 2000699423 Transaction Successful 3735.00Document1 paginăElectricity Consumption Bill For LT Consumers Only: 29-05-2014 2000699423 Transaction Successful 3735.00Rashid AyubiÎncă nu există evaluări

- Cross Section3Document1 paginăCross Section3Anonymous fLgaidVBhzÎncă nu există evaluări

- The History of AutomobilesDocument50 paginiThe History of AutomobilesPradeshwaran BalajiÎncă nu există evaluări

- Electricity Consumption Bill For LT Consumers Only: 29-05-2014 2000699423 Transaction Successful 3735.00Document1 paginăElectricity Consumption Bill For LT Consumers Only: 29-05-2014 2000699423 Transaction Successful 3735.00Rashid AyubiÎncă nu există evaluări

- Transaction Successful Acknowledgement Slip: Thank You For Your Concern Towards The Environment by Paying OnlineDocument1 paginăTransaction Successful Acknowledgement Slip: Thank You For Your Concern Towards The Environment by Paying OnlinevimalÎncă nu există evaluări

- CESC OCT 19 Bill PMNTDocument1 paginăCESC OCT 19 Bill PMNTAmit PaulÎncă nu există evaluări

- Paid 30.09.19-SepDocument1 paginăPaid 30.09.19-SepAnonymous fLgaidVBhzÎncă nu există evaluări

- Electricity Consumption Bill For LT Consumers Only: 29-05-2014 2000699423 Transaction Successful 3735.00Document1 paginăElectricity Consumption Bill For LT Consumers Only: 29-05-2014 2000699423 Transaction Successful 3735.00Rashid AyubiÎncă nu există evaluări

- The Design and Construction of Concrete-Filled Steel Tube Column FramesDocument12 paginiThe Design and Construction of Concrete-Filled Steel Tube Column FramesrohitÎncă nu există evaluări

- Engineering Drawing ManualDocument128 paginiEngineering Drawing Manualadnan100% (6)

- Electricity Consumption Bill For LT Consumers Only: 29-05-2014 2000699423 Transaction Successful 3735.00Document1 paginăElectricity Consumption Bill For LT Consumers Only: 29-05-2014 2000699423 Transaction Successful 3735.00Rashid AyubiÎncă nu există evaluări

- Detailed Route Survey For Kakinada-Srikakulam Pipeline ProjectDocument5 paginiDetailed Route Survey For Kakinada-Srikakulam Pipeline ProjectAnonymous fLgaidVBhzÎncă nu există evaluări

- Evaluating Liquefaction Triggering Potential Using Seismic Input Parameters That Are Consistent With ASCE 7-16Document10 paginiEvaluating Liquefaction Triggering Potential Using Seismic Input Parameters That Are Consistent With ASCE 7-16Anonymous fLgaidVBhzÎncă nu există evaluări

- Asme Y14Document4 paginiAsme Y14nagrav0% (2)

- Route Survey SORDocument67 paginiRoute Survey SORAnonymous fLgaidVBhzÎncă nu există evaluări

- 06-GB Moment ConnectionsDocument16 pagini06-GB Moment ConnectionscblerÎncă nu există evaluări

- Bridge Foundation Design GuidanceDocument30 paginiBridge Foundation Design GuidanceAnonymous fLgaidVBhzÎncă nu există evaluări

- ANSI Y14.1-1980v Drawing Sheet Size And: American National StandardsDocument23 paginiANSI Y14.1-1980v Drawing Sheet Size And: American National Standardsavr8784Încă nu există evaluări

- Concrete Filled Steel Tube Columns Under Earthquake LoadsDocument10 paginiConcrete Filled Steel Tube Columns Under Earthquake LoadsAnonymous fLgaidVBhzÎncă nu există evaluări

- Survey - All SamplesDocument168 paginiSurvey - All SamplesAnonymous fLgaidVBhzÎncă nu există evaluări

- 2.ANNEXUREDocument89 pagini2.ANNEXUREAnonymous fLgaidVBhzÎncă nu există evaluări

- Pipe Support3of 5Document1 paginăPipe Support3of 5Anonymous fLgaidVBhzÎncă nu există evaluări

- 1.Dfr ReportDocument132 pagini1.Dfr ReportAnonymous fLgaidVBhzÎncă nu există evaluări

- Pipe Support2of 5Document1 paginăPipe Support2of 5Anonymous fLgaidVBhz100% (1)

- Pipe Support4of 5Document1 paginăPipe Support4of 5Anonymous fLgaidVBhzÎncă nu există evaluări

- Pipe Support 1of 5Document1 paginăPipe Support 1of 5Anonymous fLgaidVBhzÎncă nu există evaluări

- Welder CardDocument1 paginăWelder CardRaju KumarÎncă nu există evaluări

- DesignDocument23 paginiDesignscribddisantoÎncă nu există evaluări

- ArcelorMittal SWOT AnalysisDocument2 paginiArcelorMittal SWOT AnalysisUmer RazzaqÎncă nu există evaluări

- A Comparative Evaluation of Welding Consumables For Dissimilar Welds Between 316LN Austenitic Stainless Steel and Alloy 800Document12 paginiA Comparative Evaluation of Welding Consumables For Dissimilar Welds Between 316LN Austenitic Stainless Steel and Alloy 800Élida AlvesÎncă nu există evaluări

- Astm A254 (1997)Document4 paginiAstm A254 (1997)Yalavarthi ChandrasekharÎncă nu există evaluări

- 2nd Sem Question PDFDocument36 pagini2nd Sem Question PDFjankimchandraÎncă nu există evaluări

- Brayco Micronic 864 Ht/200: S S G S S SDocument4 paginiBrayco Micronic 864 Ht/200: S S G S S SDavid ArauzÎncă nu există evaluări

- Iso 3506 1 2020Document46 paginiIso 3506 1 2020Anna BubblegumÎncă nu există evaluări

- Spot WeldDocument8 paginiSpot Weld0502raviÎncă nu există evaluări

- Mini a-LOK BookletDocument162 paginiMini a-LOK BookletjcastelohÎncă nu există evaluări

- A-A-59326a (1) AcoplamentoDocument15 paginiA-A-59326a (1) AcoplamentogilsonÎncă nu există evaluări

- Mega Parts Book - Vol 2Document102 paginiMega Parts Book - Vol 2Mohamed Cheikh100% (1)

- 1 Way Continous SlabDocument5 pagini1 Way Continous SlabZayyan RomjonÎncă nu există evaluări

- A Historical Examination of Concrete PDFDocument324 paginiA Historical Examination of Concrete PDFMa Ria Fe100% (1)

- Question With Answer Mechanic Trade May-13Document51 paginiQuestion With Answer Mechanic Trade May-13Pawan Porwal71% (42)

- 59a. IS - 2041 - 2009Document9 pagini59a. IS - 2041 - 2009hhr2412Încă nu există evaluări

- Features: 40 - 600mm ASME Class 150Document5 paginiFeatures: 40 - 600mm ASME Class 150Capacitacion TodocatÎncă nu există evaluări

- Kitchen Equipment SpecificationsDocument17 paginiKitchen Equipment SpecificationsJinu ChackoÎncă nu există evaluări

- Hot Rod - Technical Paper Rod Mill Processes - NDT - 1099 - E PDFDocument11 paginiHot Rod - Technical Paper Rod Mill Processes - NDT - 1099 - E PDFradinasrÎncă nu există evaluări

- GIS E6 2006-Gas Industry StandardDocument15 paginiGIS E6 2006-Gas Industry StandardQualidadeTFÎncă nu există evaluări

- Steel Beam Connections Used in StructuresDocument5 paginiSteel Beam Connections Used in StructuresJammiÎncă nu există evaluări

- Daphne Magplus AM 30: Lubricant Product InformationDocument2 paginiDaphne Magplus AM 30: Lubricant Product InformationDewi Lanjarsari Purnama SastriÎncă nu există evaluări

- Cast-iron welding guide covers standardsDocument10 paginiCast-iron welding guide covers standardsclnÎncă nu există evaluări

- Resistance Welding: Introduction and Recent Developments: S. Tripathy & Ajitav SahooDocument6 paginiResistance Welding: Introduction and Recent Developments: S. Tripathy & Ajitav SahooTJPRC PublicationsÎncă nu există evaluări

- NDT ReportDocument4 paginiNDT ReportTHI SEN NGUYENÎncă nu există evaluări

- Welding Standards PDFDocument30 paginiWelding Standards PDFAnant AjithkumarÎncă nu există evaluări

- Welding MCQ Module for Mechanical EngineeringDocument14 paginiWelding MCQ Module for Mechanical Engineeringanil100% (1)

- GMAW Butt Joint Project ReportDocument43 paginiGMAW Butt Joint Project ReportahmedÎncă nu există evaluări

- Dodge Et Al., 2014Document7 paginiDodge Et Al., 2014Luan CaetanoÎncă nu există evaluări

- Plain Carbon SteelsDocument47 paginiPlain Carbon SteelsRicci Marcelo ÜÎncă nu există evaluări