Documente Academic

Documente Profesional

Documente Cultură

ChE 134 Attrition Mill - Guanlao

Încărcat de

Jelor Gallego100%(1)100% au considerat acest document util (1 vot)

501 vizualizări1 paginăAn attrition mill is a device that reduces the size of solid particles by intense agitation of a slurry of material being milled and coarse milling media. It originated from hand flour mills and was developed further in the 1960s. It consists of a feed hopper, grinding discs that crush materials through attrition, and a discharge vessel to collect the output. It is generally used to pulverize soft solids and produces a very fine powder.

Descriere originală:

Attrition Mill

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentAn attrition mill is a device that reduces the size of solid particles by intense agitation of a slurry of material being milled and coarse milling media. It originated from hand flour mills and was developed further in the 1960s. It consists of a feed hopper, grinding discs that crush materials through attrition, and a discharge vessel to collect the output. It is generally used to pulverize soft solids and produces a very fine powder.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

501 vizualizări1 paginăChE 134 Attrition Mill - Guanlao

Încărcat de

Jelor GallegoAn attrition mill is a device that reduces the size of solid particles by intense agitation of a slurry of material being milled and coarse milling media. It originated from hand flour mills and was developed further in the 1960s. It consists of a feed hopper, grinding discs that crush materials through attrition, and a discharge vessel to collect the output. It is generally used to pulverize soft solids and produces a very fine powder.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

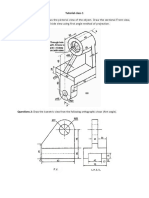

ATTRITION MILL

they are ine enough to exit from the

Attrition Mill - Device for mechanically reducing gap at the edges of the disc

solid particle size ● Discharge Vessel - Where the crushed

● Reduce particle size by intense and ground material is collected after

agitation of a slurry of material being it exits the grinding zone

milled and the coarse milling media Types

● Pulverize materials such as grains, 1. Single Disc Attrition Mill

spices, sand, plastics, waxes, polymers 2. Double Disc Attrition Mill

and other ibrous materials by sliding, 3. Vibrating Disc Mill

scrubbing or rolling with a surface or General Features

with each other ● Generally used for soft solids

History ● Usually oriented in the horizontal axis,

● Originated from the hand lour mill sometimes vertical

● Similar to ancient Buhrstone mill: one of ● Product is very ine: powder

the oldest types of mill, with either ● Air is drawn to get the product

horizontal or vertical stones, used to ● Cooling is essential while operation

grind grains and hard materials Advantages and Disadvantages

● Developed by the US Bureau of Mines ● Advantages: high level of strength is

(early 1960s): effective for producing required for hard materials (like stone,

paper-coating clay from coarse kaolins etc.), have a relatively larger capacity,

(clay mineral) relatively quiet than other kinds of mills

Basic Parts ● Disadvantages: relatively expensive to

● Feed Hopper – where material is fed run and maintain, consume much more

○ storage container used to power than other shredding machines

dispense granular materials Applications

through the use of a chute to ● Agricultural Applications

restrict low, sometimes ● Food and Chemical Processing

assisted by mechanical ● Mining Operations

agitation ● Recycling Plants

● Grinding discs - crush materials by

attrition force at great speeds until

S-ar putea să vă placă și

- List of TablesDocument13 paginiList of Tablesahmad100% (1)

- Final Report Disk MillDocument10 paginiFinal Report Disk MillMuhammad Irfan MalikÎncă nu există evaluări

- Size ReductionDocument33 paginiSize ReductionMakhdoom Ibad HashmiÎncă nu există evaluări

- Size Reduction EquipmentDocument3 paginiSize Reduction Equipmentermittler75% (4)

- Pset 1Document6 paginiPset 1DIANE JOY PANGANIBANÎncă nu există evaluări

- MO Assignment 2 NumericalDocument1 paginăMO Assignment 2 NumericalBHAVINÎncă nu există evaluări

- Lecture 3 - Size ReductionDocument54 paginiLecture 3 - Size ReductionMuhammad Ahmad100% (1)

- Cane Unloading and Transport (Preparation)Document49 paginiCane Unloading and Transport (Preparation)valerie annÎncă nu există evaluări

- Catalogo Tecnico ENGDocument52 paginiCatalogo Tecnico ENGAdvokat HadziTonicÎncă nu există evaluări

- Industrial Training ReportDocument14 paginiIndustrial Training ReportSobri Salamun AhmadunÎncă nu există evaluări

- ICHEMDocument4 paginiICHEMAnthon ToledanoÎncă nu există evaluări

- SIze Reduction EquipmentDocument2 paginiSIze Reduction EquipmentGaurav Sharma100% (1)

- PDFDocument3 paginiPDFINAP 0Încă nu există evaluări

- Rate of Reaction Sample ProblemsDocument1 paginăRate of Reaction Sample ProblemsKatrina JewelÎncă nu există evaluări

- Crystallization Competency Exam (TIP)Document2 paginiCrystallization Competency Exam (TIP)Kuo SarongÎncă nu există evaluări

- WRRRWWDocument86 paginiWRRRWWalaialiÎncă nu există evaluări

- Stone CrushersDocument21 paginiStone Crushersashish chavan100% (2)

- Particle ReductionDocument27 paginiParticle ReductionYagnesh ChainyÎncă nu există evaluări

- Size Redcution of SolidsDocument25 paginiSize Redcution of SolidsTammineni Dushyanth kumarÎncă nu există evaluări

- GrindingDocument25 paginiGrindingZeel PatelÎncă nu există evaluări

- Unit 2: Aggregates and Testing of AggregatesDocument54 paginiUnit 2: Aggregates and Testing of AggregatesAparna SwaminathanÎncă nu există evaluări

- Lecture 5Document16 paginiLecture 5Green JeskÎncă nu există evaluări

- PPMF MidtermDocument55 paginiPPMF MidtermDEBBRA LIZZIE E NACPILÎncă nu există evaluări

- Laboratory Disk Mill: Rapid Fine Grinding 100 M For Brittle To Very Hard MaterialsDocument4 paginiLaboratory Disk Mill: Rapid Fine Grinding 100 M For Brittle To Very Hard MaterialsEloquent EloquentÎncă nu există evaluări

- 2.3 Crushing and BlendingDocument10 pagini2.3 Crushing and BlendingYhaneÎncă nu există evaluări

- Size Reduction Equipment ComparisonDocument1 paginăSize Reduction Equipment ComparisonWadih Al-amriyÎncă nu există evaluări

- Met124: Mineral Processing: CrushingDocument27 paginiMet124: Mineral Processing: CrushingShane NakhuiÎncă nu există evaluări

- GrindingDocument59 paginiGrindingKosgi LavanyaÎncă nu există evaluări

- Grinding MachinesDocument25 paginiGrinding MachinesZain - ul -hassnÎncă nu există evaluări

- Particle Technology: Department of Chemical Engineering, COMSATS University Islamabad, Lahore-PakistanDocument26 paginiParticle Technology: Department of Chemical Engineering, COMSATS University Islamabad, Lahore-PakistanFurqan AhmedÎncă nu există evaluări

- 19PWCHE1431Document6 pagini19PWCHE1431Khan AaghaÎncă nu există evaluări

- Crusher GuideDocument19 paginiCrusher GuideWidodo PutraÎncă nu există evaluări

- Allgaier Apt Tro Dryingtechnologiesformineralrawmaterials enDocument12 paginiAllgaier Apt Tro Dryingtechnologiesformineralrawmaterials enesteÎncă nu există evaluări

- EME Grinding MachineDocument23 paginiEME Grinding Machinejonelle27Încă nu există evaluări

- Chapter 6Document19 paginiChapter 6Haftamu HilufÎncă nu există evaluări

- Quiz 2 Reviewer ImeDocument7 paginiQuiz 2 Reviewer ImeAllaine VictoriaÎncă nu există evaluări

- Definition: Industrial Applications:: DiagramDocument1 paginăDefinition: Industrial Applications:: DiagramAffan MaqsoodÎncă nu există evaluări

- RMH & GrindingDocument132 paginiRMH & Grindingmkpq100% (1)

- Laboratory EquipmentsDocument11 paginiLaboratory EquipmentsPrince OwusuÎncă nu există evaluări

- Raw Material Handling and GrindingDocument78 paginiRaw Material Handling and GrindingmkpqÎncă nu există evaluări

- 2 Stone Crushing Eqp 2Document22 pagini2 Stone Crushing Eqp 2Ankit DalviÎncă nu există evaluări

- Hard To Reduce ParticlesDocument5 paginiHard To Reduce ParticlesRAZNAVAÎncă nu există evaluări

- PharmaceuticalsDocument42 paginiPharmaceuticalsAninaÎncă nu există evaluări

- Trituración-Molienda (1) - Convertido (Recuperado)Document81 paginiTrituración-Molienda (1) - Convertido (Recuperado)Brigitte PorezÎncă nu există evaluări

- Size Reduction EquipmentsDocument15 paginiSize Reduction EquipmentsDebashish MohantyÎncă nu există evaluări

- BWE and CSMDocument43 paginiBWE and CSMAnshul yadavÎncă nu există evaluări

- Size Reduction - Mechanical OperationsDocument30 paginiSize Reduction - Mechanical Operationssaidasa100% (1)

- Crushers 1.1Document45 paginiCrushers 1.1Chandan KumarÎncă nu există evaluări

- Particle Tech ReportDocument5 paginiParticle Tech ReportBea UyÎncă nu există evaluări

- Ball MillDocument4 paginiBall Millmohan804Încă nu există evaluări

- Mp8 GrindingDocument107 paginiMp8 GrindingAditya BhardwajÎncă nu există evaluări

- TraaanssDocument4 paginiTraaanssNyasha J ChidziyahÎncă nu există evaluări

- Black Line Breaker ToolsDocument16 paginiBlack Line Breaker ToolsDeno Manuel LudzanÎncă nu există evaluări

- NBC Cement BrochureDocument23 paginiNBC Cement BrochureAnkit SharmaÎncă nu există evaluări

- Rotary ScrubberDocument2 paginiRotary ScrubberTamal Tanu RoyÎncă nu există evaluări

- Comminution (Automaticky Uloženo) PDFDocument21 paginiComminution (Automaticky Uloženo) PDFAntonioJavierOstosMachadoÎncă nu există evaluări

- 01.introduction For GranulatorDocument7 pagini01.introduction For GranulatorPAUL LLAQUE DE LA PIEDRAÎncă nu există evaluări

- Methods, Processes, and Equipment in Size Reduction of Solids - 5ME2Document35 paginiMethods, Processes, and Equipment in Size Reduction of Solids - 5ME2Ana Marie Baysa100% (3)

- Ball MillDocument58 paginiBall MillFelipe CidÎncă nu există evaluări

- Che 131 Ps-Heat1Document1 paginăChe 131 Ps-Heat1Jelor GallegoÎncă nu există evaluări

- 131.11c Unsteady-State Heat TransferDocument25 pagini131.11c Unsteady-State Heat TransferJelor GallegoÎncă nu există evaluări

- Che 131 Ps-Heat2Document1 paginăChe 131 Ps-Heat2Jelor GallegoÎncă nu există evaluări

- ChE 131 PS-MassDocument1 paginăChE 131 PS-MassJelor GallegoÎncă nu există evaluări

- 131.10a Shell Energy BalanceDocument28 pagini131.10a Shell Energy BalanceJelor GallegoÎncă nu există evaluări

- Lecture 3 - Independent and Dependent ReactionsDocument19 paginiLecture 3 - Independent and Dependent ReactionsJelor GallegoÎncă nu există evaluări

- 131.11b Heat Equations of Change Part 2Document20 pagini131.11b Heat Equations of Change Part 2Jelor GallegoÎncă nu există evaluări

- 131.8 Introduction To Heat TransferDocument41 pagini131.8 Introduction To Heat TransferJelor GallegoÎncă nu există evaluări

- 131.15 Equations of ContinuityDocument25 pagini131.15 Equations of ContinuityJelor GallegoÎncă nu există evaluări

- Homework: Advanced Chemical Reaction Engineering IIDocument1 paginăHomework: Advanced Chemical Reaction Engineering IIJelor GallegoÎncă nu există evaluări

- Che 125: Chemical Reaction Engineering IDocument2 paginiChe 125: Chemical Reaction Engineering IJelor GallegoÎncă nu există evaluări

- Greening The Roadmap of The Philippine Pulp and Paper IndustryDocument14 paginiGreening The Roadmap of The Philippine Pulp and Paper IndustryJelor Gallego100% (1)

- World Voyager Fund - March 2016Document41 paginiWorld Voyager Fund - March 2016Jelor GallegoÎncă nu există evaluări

- ChE 140 1.01 IntroductionDocument30 paginiChE 140 1.01 IntroductionJelor GallegoÎncă nu există evaluări

- 1 s2.0 S0263876299718186 Main PDFDocument7 pagini1 s2.0 S0263876299718186 Main PDFLeydi PatiñoÎncă nu există evaluări

- Compliance Monitoring ReportDocument6 paginiCompliance Monitoring ReportJelor Gallego100% (1)

- BPI US Equity Feeder Fund Latest DisclosureDocument3 paginiBPI US Equity Feeder Fund Latest DisclosureJelor GallegoÎncă nu există evaluări

- Eq Uitf Bpi Gefof Nov 2017Document4 paginiEq Uitf Bpi Gefof Nov 2017Jelor GallegoÎncă nu există evaluări

- Mibk MSDS PDFDocument5 paginiMibk MSDS PDFJelor GallegoÎncă nu există evaluări

- Che 197 SWX Lecture 14 - Mmda - MSWDocument19 paginiChe 197 SWX Lecture 14 - Mmda - MSWJelor GallegoÎncă nu există evaluări

- Anies. Cleofe. Estacio. NogalesDocument44 paginiAnies. Cleofe. Estacio. NogalesJelor GallegoÎncă nu există evaluări

- 08 Double Integrals in Polar Coordinates - HandoutDocument12 pagini08 Double Integrals in Polar Coordinates - HandoutJelor GallegoÎncă nu există evaluări

- Mickley MethodDocument1 paginăMickley MethodJelor GallegoÎncă nu există evaluări

- Epson Eb-W22 ProjectorDocument2 paginiEpson Eb-W22 Projectorandresboy123Încă nu există evaluări

- Process Control in SpinningDocument31 paginiProcess Control in Spinningapi-2649455553% (15)

- Chip DielDocument45 paginiChip DielJUANCANEXTÎncă nu există evaluări

- Review of C++ Programming: Sheng-Fang HuangDocument49 paginiReview of C++ Programming: Sheng-Fang HuangIfat NixÎncă nu există evaluări

- MMD 74 XX DR PS 0020 - C03Document1 paginăMMD 74 XX DR PS 0020 - C03bramexÎncă nu există evaluări

- JLG 600A 660AJ From Serial 0300177361 Service Manual (1) (1) Gabriel DSDDocument4 paginiJLG 600A 660AJ From Serial 0300177361 Service Manual (1) (1) Gabriel DSDCASAQUI LVAÎncă nu există evaluări

- Encore 7.1 BoxDocument10 paginiEncore 7.1 BoxNicolas HarambilletÎncă nu există evaluări

- Data Flow Diagrams PDFDocument9 paginiData Flow Diagrams PDFYasmine2410Încă nu există evaluări

- SunstarDocument189 paginiSunstarSarvesh Chandra SaxenaÎncă nu există evaluări

- Green Line TransformerDocument4 paginiGreen Line TransformerwakasÎncă nu există evaluări

- Item Rate For GMCTH Jajpur Rate Acceptance For Sub Structure - Concrete, Shuttering, Reinforcement Work & Pile Chipping WorkDocument3 paginiItem Rate For GMCTH Jajpur Rate Acceptance For Sub Structure - Concrete, Shuttering, Reinforcement Work & Pile Chipping WorkBittudubey officialÎncă nu există evaluări

- Desmophen 1200 - en - 00134597 17947398 20766463Document3 paginiDesmophen 1200 - en - 00134597 17947398 20766463Sabri AeroChemÎncă nu există evaluări

- Winter Internship Report (23/09/2016 - 31/01/2017)Document56 paginiWinter Internship Report (23/09/2016 - 31/01/2017)AyushÎncă nu există evaluări

- Alloc 150 DMDocument301 paginiAlloc 150 DMSheik Mohamed ImranÎncă nu există evaluări

- Suzuki B-King Indicator Mod CompleteDocument9 paginiSuzuki B-King Indicator Mod Completehookuspookus1Încă nu există evaluări

- Reverse Logistics: Overview and Challenges For Supply Chain ManagementDocument7 paginiReverse Logistics: Overview and Challenges For Supply Chain ManagementSri WulandariÎncă nu există evaluări

- PT 0817 Cebu Room Assignment PDFDocument16 paginiPT 0817 Cebu Room Assignment PDFPhilBoardResultsÎncă nu există evaluări

- Wireshark Protocol Help Product PreviewDocument6 paginiWireshark Protocol Help Product Previewsunil1978Încă nu există evaluări

- Interfacing Seven Segment Display With LPC1769Document18 paginiInterfacing Seven Segment Display With LPC1769Gurudatta Palankar0% (1)

- GYANDOOT SamitiDocument16 paginiGYANDOOT SamitivinaykoolsÎncă nu există evaluări

- PDK Repair Aftersales TrainingDocument22 paginiPDK Repair Aftersales TrainingEderson BJJÎncă nu există evaluări

- Tutorial Class 1 Questions 1Document2 paginiTutorial Class 1 Questions 1Bố Quỳnh ChiÎncă nu există evaluări

- Copy Move Forgery Based On DWT-DCTDocument4 paginiCopy Move Forgery Based On DWT-DCTShiva KeeÎncă nu există evaluări

- Lab Manual 11 Infrared SpectrosDocument5 paginiLab Manual 11 Infrared SpectrosLuca Selva CampobassoÎncă nu există evaluări

- 400017A C65 Users Manual V5XXDocument61 pagini400017A C65 Users Manual V5XXwhusada100% (1)

- CE 411 Lecture 03 - Moment AreaDocument27 paginiCE 411 Lecture 03 - Moment AreaNophiÎncă nu există evaluări

- Bomba FlightDocument2 paginiBomba FlightGustavo HRÎncă nu există evaluări

- Viewnet Diy PricelistDocument2 paginiViewnet Diy PricelistKhay SaadÎncă nu există evaluări

- Reading Material CH 14 Other Artificial Lift MethodsDocument18 paginiReading Material CH 14 Other Artificial Lift MethodsSagar DadhichÎncă nu există evaluări

- While We Sleep - A Story of Government Without Law by Alan R. AdaschikDocument165 paginiWhile We Sleep - A Story of Government Without Law by Alan R. Adaschikwbradleyjr18739100% (2)